* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Click to view Product Presentation- Electronics

Immunity-aware programming wikipedia , lookup

Electrification wikipedia , lookup

Electrical ballast wikipedia , lookup

Mercury-arc valve wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Electric battery wikipedia , lookup

Power inverter wikipedia , lookup

Power engineering wikipedia , lookup

Transformer wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Current source wikipedia , lookup

Electrical substation wikipedia , lookup

Schmitt trigger wikipedia , lookup

Stray voltage wikipedia , lookup

Three-phase electric power wikipedia , lookup

Rechargeable battery wikipedia , lookup

Surge protector wikipedia , lookup

Power electronics wikipedia , lookup

History of electric power transmission wikipedia , lookup

Voltage regulator wikipedia , lookup

Transformer types wikipedia , lookup

Opto-isolator wikipedia , lookup

Buck converter wikipedia , lookup

Voltage optimisation wikipedia , lookup

Alternating current wikipedia , lookup

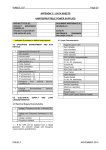

Battery Charger up to 1500AH Power Saver Panel up to 200kVA DC Power Pack up to 220VDC Dry Type Transformers up to 1 MVA Description: We are Manufacturing Battery Charger up to 150A The thyristor controlled rectifier is fully a solid state equipment for providing constant Voltage and Constant current for the battery charging process. Voltage Ranges : 12V, 24V, 48V, 72V, 110V, 220V ( options are float, boost, trickle) & (Auto , Manual) Types: Float Cum Boost Charger Float Charger & Boost Charger Dual Float Cum Boost Charger Float Charger &Float Cum Boost Charger Automatic voltage regulation Smoothening filter circuit Short circuit and overload Protection Over voltage cut-off keep load and battery bank secure Automatic float/boost change over based on the current drawn by the battery Conventional Design and High quality standards Low maintenance, Remote operation, user friendly Battery charger can be used in following industries Power Plants Sub station Cement Plants Oil and Refinery Plants Solar Projects Type Test certificate for 220V, 100A Battery charger Type Test certificate for 110V, 50A Battery charger Power saving is above 20% in lighting No load currents is very low below 1% of the rated output current On/off control can be achieved by time, dusk –dawn control, PLC& manual mode When used in manual mode all the control circuit is been bypassed directly, used in case of emergency Compact in size, box can be custom designed as per the requirement of the customer Programmable logic controller can be used for sequential, on/off for lights Easy to install with existing control unit and cabling Payback period is 8 to 12 months based on site conditions and usage Low maintenance, No moving parts, easy to service When there is 5% drop (when 95% contactor is on): Line voltage Input voltage 5% Input current Total watts /ph 237 224 R-N 8 1792 235 222 Y-N 10 2220 229 216 B-N 14.7 3175 Total Avg (W)/Ph 2395 Line voltage Input voltage 10% Input current Total watts /ph 237 215 7.9 1698 235 213 9.7 2066 229 208 14.6 3036 Total Avg (W)/Ph 2266 Difference between Input and Drop 5%, 10%: Difference between input & 5% drop 111 watts Difference between 5% & 10% drop 129 watts Difference between input drop & 10% drop 240 watts Used in Outdoor Lighting Garden Lights High Mast Residential Layout Automatic On/off for lights The Power Pack is used as a power source for VCB panel in substation where station battery supply is not available. Power pack gets charged from line connected PT. It can supply DC connected load for operation close/trip coils and other essential loads such as auxiliary supply to protection relay etc. I/P Voltage Ranges : 110VAC or 230VAC O/P Voltage Ranges : 12VDC /24VDC / 48VDC / 110VDC /220VDC Input Burden without Load: 10mA to 25mA Continuous Load : 90% Impulse load : 110% Battery : 7AH & 14AH 12/24V Protection : Over voltage & Short Circuit Indication : Charger ON ,Output ON, Battery Operation, Output over load, . . … Battery low, Battery Reverse HT Panels for Auxiliary supply LT Panels HT & LT Vacuum Pressure Impregnation Transformer up to 1MVA Isolation Transformer Industrial Transformer Rectifier Transformer Ferro Resonant Constant voltage Transformer Scott-T Transformer Auto Transformer Potential Transformer Type : Vacuum Pressure Impregnated/ Cast Resin Capacity : Up to 1MVA Insulation Level : Up to Class H Insulation Load Regulation: < 5% IR Value: 100Mega Ohms Breakdown Strength : 2.5KV Frequency : 47 to 63 Hz Efficiency : > 96% IS standard : IS 2026 & IS 11171 NTPC TNEB ICF – Chennai Southern Railway Southern Railway – Construction Steel Authority of India Limited, Burnpur Odisha Mega Lift Projects Neyveli Lignite Corporation Defense Research and Development Organisation