* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download biotreated bran - MSU College of Engineering

Survey

Document related concepts

Point mutation wikipedia , lookup

Nucleic acid analogue wikipedia , lookup

Genetic code wikipedia , lookup

Proteolysis wikipedia , lookup

Butyric acid wikipedia , lookup

Phosphorylation wikipedia , lookup

Glyceroneogenesis wikipedia , lookup

Specialized pro-resolving mediators wikipedia , lookup

Amino acid synthesis wikipedia , lookup

Citric acid cycle wikipedia , lookup

Biosynthesis wikipedia , lookup

Fatty acid synthesis wikipedia , lookup

Transcript

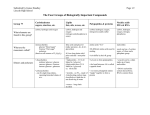

S-1007 Multistate Research Committee The Science and Engineering for a Biobased Industry and Economy E N V I R O N M E N T Raw Materials, Byproducts, Agricultural “wastes” Bioprocessing, Bioconversion, Bioreactor design and E D U C A T I O N control, “Biorefineries” Bulk Chemicals, Biofuels Specialty Biomaterials Biochemicals E C O N O M I C S Biochemicals Subgroup Donal Day, Shulin Chen, Mark Eiteman, Arun Bhunia, Mike Tumbleson, Caye Drapcho, Danielle Carrier, Cady Engler, Jin-Woo Kim, Ruihong Zhang, Lorraine Day, Mike Zhang, Lonnie Ingram, Terry Walker, John Benemann, Any others? [email protected] [email protected] [email protected] [email protected] [email protected] [email protected] [email protected] [email protected] [email protected] [email protected] [email protected] [email protected] [email protected] [email protected] [email protected] Please sign up Local power grid •Electricity •Electricity •Steam •Steam •Electricity •Steam System Boundary Inputs •Fertilizers •Fuel •Agrochemicals Cropping systems Animal Animal waste treatment •Nutrient operation Energy Inputs Surplus •Electricity Inputs •Steam •Chemicals, Enzyme Biorefinery Biorefinery Pre -Processing Intermediates •Sugars •Lipids •Lignin •Ash •Protein Final product •Food •Food •Other •Otherproducts products Final Processing Final product •Ethanol •Ethanol •Biopolymers •Biopolymers •Chemicals •Chemicals •Hydrogen •Hydrogen Cogeneration •Ash Biopharmaceutical Mechanisms • Macro – Whole animal system – Whole plant system (glycosylation limitation) – Whole insect system ( “ ) • Micro – – – – Mammalian Cell Culture Plant cell culture Insect cell culture (baculovirus mechanism) Bacterial and fungal culture (E. coli, S.cerevisiae, Pichiae) • Molecular – Genomics, Proteomics, Metabolomics, Systems Biology – Chaperone mechanisms Byprodu ct Primar y Primar y enzyme Product Byproduct Bioconversions to Products of Increasing Value Substrate /Microbi al strain Animal waste Wood fibers Potato/ S weet potato Dairy waste Oily waste Rice brokens Rice straw Switchgrass Complex Xylan Glucose Sugarcane bagasse Corn stover Xylose Pyruvate Acrylonitril e D-xylulose Corn starch Glucose Molasses (sugarcane) Sucrose Lactose Lipids Glucose Xylose Xylose Glucose Glucose Glucose Glucose Glucose Glucose Specific Media Glucose Glucose Glucose Glucose Serum Serum Serum (M. flagellate) Clostridium sp. SAIV1 Alcohol dehydrogenase (K. marxianus) -galactosidase Lipase (esterases) (C. acetobutylicum) Citrate synthase Lactose dehydrogenase (L. delbrueckii) Pyruvate decarboxylase (Acetobacter sp.) Nitrile hydratase Methane Ethanol Ethanol (thermophilic pathway) Glucose and Galactose Fatty acids Acetone/butanol (30/60) Citric acid Lactic acid (30 million kg/yr) Acetic acid Xylose reductase (C. tropicalis)2 Glucose isomerase Xylitol Fumarase (B. ammoniagenes) AcetylCoA carboxylase (C. glutamicum)-biotin Aspartic amino transferase (E. coli) Aspartase (E. coli) L-aminocaprolactam hydrolase (C. laurentii) (P. fluorescens) Penicillin amidase (P. chrysogenum) (B. lichenformis) (B. amyloliquefaciens) (Rhizopus, Aspergillus) Anthrobacter simplex Hybridomas Human fibroblasts Monkey kidney cells 1 Murty and Chandra (1997) 2 Hortis u et al. (1992) Acrylamide (15,000 tons/yr) High fructose corn syrup (8 million tons/yr) L-malic acid L-glutamic acid (340,000 tons/yr) MS G L-phenylalanine (Aspartame synthesis) L-aspartic acid L-lysine (70,000 tons/yr) ($2/lb) L-histidine 6-aminopenicilloic acid (7500 tons/yr) Proteases ($236 mil/yr) Amylases ($70 mil/yr) Other enzymes ($92 mil/yr) Prednisolone Monoclonal antibodies Interferon Polio vaccine Increasing Product Value Examples of Research University Collaborations Research at Clemson University • Fungal production of essential fatty acids and SFE fractionation – Walker, Hui, Kuan, Heaton, Cantrell • Algal production of polar lipids and proposed hydrogen co-production – Drapcho, Brune, Walker • “Microalgae Platform” – Brune, Benemann Bioconversion and SFE Process SFE i. Raw Material(s) ii. Organism Selection iii. Metabolic Engineering Microfiltration Monitor -Control Station Bioreactor Partially-Refined Product Purified Product LC and Analysis (HPLC or GC) Figure 1. Typical bioprocess for bioconversion of raw materials to nutraceutical and specialty biochemicals. Primary separation procedures include ultrafiltration (UF), supercritical fluid extraction (SFE) and liquid chromatography (LC). Analytical techniques include gas chromatography (GC) and high pressure liquid chromatography (HPLC). Samples of oil extracted by different extraction methods compared to commercial sample of refined rice bran oil Soxhlet extracted sample (biotreated bran) Soxhlet extracted sample (raw bran) SFE extracted sample (biotreated bran) Commercial refined rice ban oil Figure 1. Conceptual Process Flow Diagram for Hydrogen Production from Biomass Enzyme Hydrolysis & H2 Production AFEX Pretreatment Biomass H2 + CO2 Novel Membrane Separation Novel CO2-fixing Microbial Strains Co-products (Organic acids) Methane-forming Microbial Cultures CO2 Absorption Steam Reforming Methane Production CH4 + CO2 CH4 CO2 Absorption Pure H2 Energy Research at Washington State University • Manure conversion to sugars: – Analysis of manure components: cellulose, hemicellulose, lignin, sugar, protein, amino acids, and metal element, – Extensive studies were conducted on pretreatment • • • • single stage acid hydrolysis, two-stage acid hydrolysis, dilute acid hydrolysis, concentrated acid hydrolysis, enzyme hydrolysis combined acid and enzyme hydrolysis. • Cull Potato conversion to lactic acid – Fungal and bacterial fermentation • Whey/whey permeate conversion to nisin Research at Virginia Tech • Protein separation from feedstocks – Aqueous two-phase extractions – Zhang • Xylitol Bioproduction Research at LSU and University of Arkansas • Low-cost pretreatment of bagasse – Delignification using singlet oxygen – Donal Day (LSU Audubon Sugar Institute) • Characterization and extraction of antioxidants in blackstrap molasses – Julie Carrier (UARK), D. Day ?s