* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Wind Energy Systems for Electric Power - Van

Utility frequency wikipedia , lookup

Wireless power transfer wikipedia , lookup

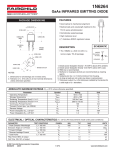

Opto-isolator wikipedia , lookup

Stray voltage wikipedia , lookup

Electrical substation wikipedia , lookup

Grid energy storage wikipedia , lookup

Solar micro-inverter wikipedia , lookup

Three-phase electric power wikipedia , lookup

Power inverter wikipedia , lookup

Electric power system wikipedia , lookup

Induction motor wikipedia , lookup

Electrification wikipedia , lookup

Wind turbine wikipedia , lookup

History of electric power transmission wikipedia , lookup

Electrical grid wikipedia , lookup

Amtrak's 25 Hz traction power system wikipedia , lookup

Voltage optimisation wikipedia , lookup

Buck converter wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Life-cycle greenhouse-gas emissions of energy sources wikipedia , lookup

Power electronics wikipedia , lookup

Intermittent energy source wikipedia , lookup

Mains electricity wikipedia , lookup

Power engineering wikipedia , lookup