* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download 1. Mechanical Joining Processes

Survey

Document related concepts

Power engineering wikipedia , lookup

Electrical substation wikipedia , lookup

Opto-isolator wikipedia , lookup

Electrical ballast wikipedia , lookup

Ground (electricity) wikipedia , lookup

Spark-gap transmitter wikipedia , lookup

Current source wikipedia , lookup

Electrification wikipedia , lookup

Portable appliance testing wikipedia , lookup

Buck converter wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Voltage optimisation wikipedia , lookup

Stray voltage wikipedia , lookup

History of electric power transmission wikipedia , lookup

Alternating current wikipedia , lookup

Transcript

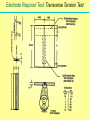

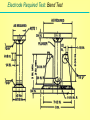

“In The Name of God” Welding Course 1 Arc Welding Processes By: M. Seidi Oct. 2007 Introduction Joining Processes Metallurgical Welding Brazing Chemical Mineral & Organic Glue Mechanical Screw & Rivet Nail & Peen Introduction: 1. Mechanical Joining Processes Mechanical Fastening Threaded Fasters Bolts Screws Nuts Other Fastening Methods Stapling Crimping Snap-in Fasteners Shrink and press fits Introduction: 1. Mechanical Joining Processes Rivets a) Solid b) Tubular c) Split (bifurcated) d) compression Introduction: 1. Mechanical Joining Processes Design guidelines for riveting (a) Exposed shank is too long; the result is buckling instead of upsetting (b) Rivets should be placed sufficiently far from edges to avoid stress concentrations Introduction: 1. Mechanical Joining Processes Design guidelines for riveting (c)Joined sections should allow ample clearance for riveting tools (d) section curvature should not interfere with the riveting process Introduction: 2. Chemical Joining Processes Adhesive Bonding Products are joined and assembled by the use of Adhesives Adhesives properties to be considered Strength Toughness Resistance to various fluids Ability to wet the surface to be bonded Introduction: 2. Chemical Joining Processes Types of adhesives Property Introduction: 2. Chemical Joining Processes Adhesive Peeling Test Peeling Force (a) (b) Characteristic behavior of adhesive in a peeling test : (a) brittle adhesive (b) tough adhesive Introduction: 2. Chemical Joining Processes Joint Design in Adhesive Bonding a. Poor Adhesive b. Good c. Very Good d. Combination Joints Adhesive Rivet Adhesive Spot Weld Introduction: 2. Chemical Joining Processes Configurations for adhesive bonds (a) Single lap (b) Double lap Introduction: 2. Chemical Joining Processes Configurations for adhesive bonds (c) Scarf (d) Strap Introduction: 3. Metallurgical Joining Processes Joining Solid state welding Resistance welding Cold welding Friction welding Diffusion welding Flash welding Ultrasonic welding Explosion welding Consumable electrode Gas metal arc welding Shielded metal arc welding Submerged arc welding Flux cored arc welding Electrogas welding Electroslag welding Fusion welding Soldering and brazing Soldering Brazing Arc energy Chemical energy Oxyacetylene welding Oxyfuel gas welding Non consumable electrode Gas tungsten arc welding Atomic hydrogen welding Plasma arc welding Other processes Laser beam welding Thermit welding Electron beam welding … Introduction: Arc Welding Processes Electric arc welding refers to a group of fusion welding processes that use an electric arc to produce the heat required for melting the metal. Advantages: Inexpensive power source Relatively inexpensive equipment Welders use standard domestic current. Portable equipment is available Process is fast and reliable Short learning curve Equipment can be used for multiple functions Electric arc heat is about 5,000 oC Introduction: Arc Welding Processes All fusion welding process have thee requirements: Heat Shielding Filler metal The method used to meet these three requirements is the difference between arc welding processes. In this class you will have the opportunity to use four arc welding processes: SMAW GMAW GTAW SAW Additional Electric Arc Welding Processes 1. FCAW (Flux Core Arc Welding) 2. ESW (Electroslag Welding) 3. EGW (Electrogas Welding) 4. PAW (Plasma Arc Welding) 5. ASW (Arc Stud Welding) Safe Practices Protection from : Arc’s rays Welding fumes Sparks Contact with hot metal Arc Welding Power Supplies The current for arc welder can be supplied by line current or an alternator/generator. The type of and polarity of the welding current is one of the differences between the different arc welding processes. Line current must be transformed: High voltage--Low amperage High amperage--low voltage SMAW GMAW GTAW Constant current (CC), AC, DC+ or DCConstant voltage (CV) DC+ or DCConstant Current (CC) ), AC, DC+ or DC- Welding current differences can include: Amperage Voltage Polarity High frequency current Wave form Considerations When Selecting an Arc Welding Power Supply 1. Maximum Amperage 7. Size and portability 2. Duty cycle 8. Future needs for a 3. Amperage range 4. Amperage adjustment mechanism power supply 9. Available skills 10. Safety 5. Input power requirements 11. Manufacturer's support 6. Initial cost and operating cost 12. Open circuit voltage Arc Welding Requirements Process Heat Shielding Filler Material MMAW Electric Arc Flux Stick Electrode Electric Arc Inert Gas (Cylinder) Spool Wire GTAW Electric Arc Inert Gas (Cylinder) Straight Rod SAW Electric Arc Flux Coil Wire GMAW Amperage Output & Duty cycle Optimum output amperage is determined by: thickness of the metal, type of joint, welding position type of electrode. The amount of continuous welding time a power supply can be used is determined by the duty cycle of the power supply. – Duty cycle is based on a 10 minute interval. – Many power supplies have a sloping duty cycle. Five Common Output Currents 1. AC (Alternating Current) 2. DC (Direct Current) 3. ACHF (Alternating Current-High Frequency) 4. PC (Pulsed Current) 5. Square wave Addition Features Available on Some Electric Arc Power Supplies: 1. Remote control 2. High frequency 3. Wave balancing 4. Voltage control Electric Arc Welding Electrical Terms Electrical Circuit Constant potential Direct current (DC) Constant current Alternating current (AC) Voltage drop Ampere Open circuit voltage Volt Arc voltage Resistance Polarity Ohms Law Dual Control Electrical Circuit An electrical circuit is a complete path for electricity. When the arc is established, an electrical circuit is also completed. Alternating Current The type of current where the flow of electrons reverses direction (polarity) at regular intervals. Recommended current for general purpose electrodes and flat position. Direct Current • The type of current where the flow of electrons (polarity) is in one direction. • Controlling the polarity allows the welder to influence the location of the heat. • When the electrode is positive (+) DCRP or DCEP it will be slightly hotter than the base metal. • When the base metal is positive (+), DCSP or DCEN, the base metal will be slightly hotter than the electrode. • DC current is required for some electrodes and recommended for out of position welding. Ampere • Amperes: the unit of measure for current flow. • One ampere is equal to 6.24150948×1018 electrons passing by a point per second. • Electricity passing through a resistance causes heat. • An air gap is a high resistance • The greater the amperage flowing through the resistance (air gap)--the greater the heat. • The electrode also has resistance. • Excessive amperage for the diameter of the electrode over heats the electrode. • Insufficient amperage for the diameter of electrode makes electrode hard to start. Volt The volt is the measure of electromotive force. It is defined as the potential difference across a conductor when a current of one ampere dissipates one watt of power. The voltage at the electrode determines the harshness of the arc. Voltage is only adjustable in dual control machines. Resistance That characteristic of a material that impedes the flow of an electrical current. Measured in units of Ohm’s ( ) When ever an electrical current passes through a resistance heat is produced. Air is a high resistance Electrical current passing through air produces a lot of heat. Ohm’s Law Ohm's law states that, in an electrical circuit, the current passing through a material is directly proportional to the potential difference applied across them. Commonly expressed as: Can also be used to teach electrical safety. E=I.R Amperage is the harmful portion of electrical current. Rearranging Ohm’s Law for amperage shows that amperage (current flow) is determined by the voltage divided by the resistance: I=E/R The higher the resistance, the less current that will flow for a given voltage. Power Supply There are 2 different types of power supplies: Constant current Constant potential • In a constant current power supply, the current (amperage) stays relatively constant when the voltage is changed. • In a constant potential power supply, the voltage stays relatively constant when the amperage is changed. Constant Current Power Supply Characteristics of constant current power supply: • The machine provides a high voltage for striking the arc. • Open circuit voltage (OCV) • OCV is not adjustable for most machines • When the arc is struck the voltage drops to the welding voltage. • Arc voltage • Arc voltage varies with the arc length. • As the welding proceeds the current will not vary much as the arc length changes. Constant Current Power Supply-Cont. Increasing the voltage from 20 to 25 volts (25%) only decreases the amperage from 113 to 120 Amp (5.8%). Constant Potential Power Supply The constant potential power supply is modified to produce a relatively constant voltage as the amperage changes. 80 70 60 Volts 50 40 30 20 10 0 0 50 100 150 200 Anperes Characteristic of GMAW power supplies. 250 Voltage Drop Voltage drop is the reduction in voltage in an electrical circuit between the source and the load. Primary cause is resistance. When an excessive voltage drop exists, the electrical circuit will not perform as designed. Localized resistance (connection) can cause excessive heat. Excessive heat can cause component failure. When extra long welding loads are used, the amperage must be increased to have the same heat at the weld. Dual Control Some weldors have controls for both the voltage and the amperage. Operator can set the harshness of the arc (voltage) and the amount of heat (amperage) independent of each other. Joints, Welds & Positions Electric arc welding uses five types of joints, five types of welds and five positions. Butt Five Joints: Corner Lap Edge T Five types of welds 1. Surface Welds 2. Groove Welds 3. Fillet Welds 4. Plug Welds 5. Slot Welds 1. Surface Welds • Surface welds are welds were a material has been applied to the surface of another material. May or may not be blended with the work piece. • Two common applications are for hard surfacing and padding. 2. Groove Welds Groove welds are used to fuse the sides or ends of two pieces of metal. The primary use of groove welds is to complete butt joints. 3. Fillet Welds Fillet welds have a triangular cross section and are used to fuse two faces of metal that are at a 90 degree angle to each other. T Joint Outside Corner Lap Joint 4. Plug Welds Plug welds are used to attach two surfaces together when a complete joint is not required and the design does not allow for any weld bead outside the dimensions of the metal. The holes can be made with a drill bit or punch. The weld is completed by establishing the arc on the bottom plate and then continuing to weld until the hole is full. 5. Slot Welds Slot welds are identical to plug welds except for the shape of the holes. For slot welds, slots are machined or stamped in the upper plate. They are complete the same as plug welds. Joints, Welds & Positions Flat Horizontal Vertical Up Vertical Down Overhead Weld Nomenclature Bead Penetration Base metal Joint Angle Reinforcement Bead Root Face Root Opening Excessive Penetration Weld Nomenclature-cont. Reinforcement Toe Face Throat Toe Leg Root Leg Weld Nomenclature-cont. In multiple pass welds, each pass has a specific function. Cover Pass A tack weld is used to hold the joint at the desired gap. If it is not used, the heat of the weld will cause the joint to close. Filler Pass Root Pass The root pass is used to fuse the root of the weld. Tack Weld The filler pass is used to fill in the joint. If the root pass does not have adequate penetration, it must be cut or gouged out before the weld is completed. A pattern bead or multiple stringer beads will be used. The cover pass doesn’t add very much strength to the weld. It is used for appearance and to fill in surface voids. Bead Patterns Pattern beads are used whenever a wider bead is needed. Hard Surfacing Filler pass Cover pass Reduce penetration Common patterns: Circle Crescent Figure 8 Protection of the Molten Weld Pool Molten metal reacts with the atmosphere: Oxides and nitrides are formed Discontinuities such as porosity Poor weld metal properties All arc welding processes employ some means of shielding the molten weld pool from the air. Welding Flux Three forms Granular Electrode wire coating Electrode core Fluxes melt to form a protective slag over the weld pool Other purposes Contain scavenger elements to purify weld metal Contain metal powder added to increase deposition rate Add alloy elements to weld metal Decompose to form a shielding gas Shielding Gas Shielding gas forms a protective atmosphere over the molten weld pool to prevent contamination. Inert shielding gases, argon or helium, keep out oxygen, nitrogen, and other gases Active gases, such as oxygen and carbon dioxide, are sometimes added to improve variables such as arc stability and spatter reduction. Argon Helium Oxygen Carbon Dioxide Turn to the person sitting next to you and discuss (1 min.): • What would happen if there was no flux on the wire to decompose into gas or no inert shielding gas was provided? • What would the weld metal look like? Shielded Metal Arc Welding (SMAW) Shielded Metal Arc Welding Equipments Magnetic Flux Motion Conductor Magnetic flux lines AWS SMAW Electrode Identification System Electrode Strength Position E XXXX Coating/Operating Characteristics AWS SMAW Electrode Identification System E XX YY E XX YY E XX YY Y=1 Y=2 Y=4 E XX YY Y=0, 1 Y=2, 3, 4 Y=5, 6, 8 Y=7 Y=9 نشاندهنده الكترود نشاندهنده مينيمم استحكام كشش ي فلزجوش نشاندهنده وضعيت جوشكاري قابل كاربرد درتمام وضعيت هاي جوشكاري قابل كاربرد دروضعيت هاي تخت و افقي قابل كاربرد درتمام وضعيت هاي جوشكاري و عمودي رو به پائين نشاندهنده نوع پوشش الكترود جوشكاري پوشش سلولزي پوشش روتيلي محتوي اكسيد تيتانيوم پوشش قليايي كم هيدروژن پوشش اكسيدي پوشش خاص Steel Alloy Suffixes for SMAW Electrodes Suffix Major Alloy Element(s) 1) A1 2) B1 3) B2 4) B3 5) B4 6) C1 7) C2 8) C3 9) D1 10) D2 11) G 0.5% Molybdenium 0.5% Molybdenium + 0.5% Chromium 0.5% Molybdenium + 1.25% Chromium 1.0% Molybdenium + 2.25% Chromium 0.5% Molybdenium + 2.0% Chromium 2.5% Nickel 3.5% Nickel 1.0% Nickel 0.3% Molybdenium + 1.5% Manganese 0.3% Molybdenium + 1.75% Manganese 0.2% Molybdenium + 0.3% Chromium + 0.5% Nickel + 1.0% Manganese + 0.1% Vanadium Weathering Steel 12) W . AWS SMAW Electrode Classification Example E7018 • E indicates electrode • 70 indicates 70,000 psi tensile strength • 1 indicates use for welding in all positions • 8 indicates low hydrogen E7018-A1-H8 = ? AWS Carbon and Low Alloy Steel Electrodes AWS: American Welding Society ANSI/AWS - 5.1 : Specification for Covered Carbon Steel ANSI/AWS - 5.5 : Specification for Low Alloy Steel ANSI/AWS - 5.4 : Specification for Corrosion Resistant Steel AWS Website: http://www.aws.org British Standard (BS) SMAW Electrode Identification System Electrode Classification: 1. Mandatory Part 2. Arbitrary Part Mandatory E AA BB C(C) DDD X Y (H) Arbitrary British Standard (BS) SMAW Electrode Identification System i. Mandatory Part : E AA BB C(C) 1. E Indicate Covered MMAW Electrode 2. AA Indicate Yield Strength of Electrode Core (MPa) 3. BB Indicate Electrode Elongation Percent 4. C(C) Indicate Type of Covering: A AR B C Acidic Routile Acidic Basic Cellulosic O R RR S Oxide Routile (Medium Cover) Routile (Thick Cover) Other Type British Standard (BS) SMAW Electrode Identification System ii. Arbitrary Part : DDD X Y H 1. DDD Indicate Nominal Electrode Recovery 2. X Indicate Electrode Usability: 1. All Positions 2. All Positions Expect V-Down 3. F for Groove and F, H, V for Fillet Welds 4. F 5. F, V-Down for Groove and H, V for Fillet Welds 6. Other Position Usability 3. Y Indicate Recommended Polarity and Voltage (Next Slide) 4. H Low Hydrogen Electrodes British Standard (BS) SMAW Electrode Identification System Recommended Ampere and Voltage Table Code Polarity Minimum Voltage 1 DCEN & DCEP 50 2 DCEN 50 3 DCEP 50 4 DCEP 70 5 DCEN 70 6 DCEP 70 7 DCEN & DCEP 90 8 DCEN 90 9 DCEP 90 British Standard (BS) SMAW Electrode Identification System Example: E 51 33 B 160 2 0 H E 51 33 B 160 2 1 H Covered MMAW Electrode Yield Strength (MPa) Elongation Percent Basic Cover Electrode Recovery All Positions Expect V-Down DCEN With Minimum 50 Volts Low Hydrogen Cover European Norm (EN) SMAW Electrodes Chemical Composition: European Norm (EN) SMAW Electrodes Symbols for Type of Electrode Covering: The type of covering of the electrodes determines to a large extent the usability characteristics of the electrode and the properties of the weld metal. Two symbols are used to denote the type of covering: - R : rutile covering - B : basic covering European Norm (EN) SMAW Electrodes Mechanical Properties: European Norm (EN) SMAW Electrodes Symbols for Weld Metal Recovery: European Norm (EN) SMAW Electrodes Symbols for Welding Position: The symbol below for welding positions indicates the positions for which the electrode is tested in accordance with EN 1597-3: 1: all positions; 2: all positions, except vertical down; 3: flat butt weld, flat fillet weld, horizontal vertical fillet weld; 4: flat butt weld, flat fillet weld; 5: vertical down and position according to symbol 3. European Norm (EN) SMAW Electrodes Symbols for Hydrogen Content: European Norm (EN) SMAW Electrode Identification System Example: E CrMo1 B 4 4 H5 E CrMo1 B 4 4 Covered MMAW Electrode H5 Hydrogen Content (5 ml/100 gr. Weld Metal) Chemical Composition (Table 1) Type of Covering (Basic Cover) Recovery and Type of Current (Table 3) Welding Position (F Butt & F Fillet Welds) Coating Materials -Partial List a. Arc Stabilizers Titania TiO2 b. Gas-Forming Materials Wood Pulp, Limestone, CaCO3 c. Fluxing agents Cryolite, Witherite, Flurspar d. Slag-Forming Materials Alumina Al2O3 , TiO2 , SiO2 , Fe3O4 e. Slipping Agents to Aid Extrusion Clay , Talc, Glycerin f. Binding Agents Sodium Silicate , Asbestos , Starch , Sugar g. Alloying and Deoxidizing Elements Si, Al, Ti, Mn, Ni, Cr Materials Used in Coverings on Steel Electrodes for SMAW a. Arc Stabilizers: . Common Name 1. Titania Technical Name TiO2 Remarks Frequently used from purified titanium oxide 2. Potassium oxalate K2C2O4 Infrequently used 3. Lithium carbonate Li2CO3 Infrequently used . Materials Used in Coverings on Steel Electrodes for SMAW b. Gas-Forming Materials: . Common Name 1. Cellulose 2. Wood flour Technical Name Remarks . Purified wood pulp Principle ingredient in C6H10O5 “cellulosic” electrodes Raw wood pulp CnHnOn 3. Limestone CaCO3 Produces CO and CO2 during welding and forms basic slag Materials Used in Coverings on Steel Electrodes for SMAW c. Fluxing Agents: . Common Name Technical Name Remarks 1. Cryolite Na3AlFe6 Strong fluxing agent 2. Barium fluoride BaF2 3. Lithium fluoride LiF Very effective flux 4. Lithium chloride LiCl Infrequently used 5. Witherite BaCO3 Generates CO and CO2 gases, but then becomes strong flux 6. Flurspar Fluorite CaF2 Strong fluxing agent . Materials Used in Coverings on Steel Electrodes for SMAW d. Slag Forming Materials: . Common Name Technical Name Remarks 1. Bauxite Alumina Raises melting temp. and increases viscosity of slag 2. Feldspar Alkali type-KnNanAlSi3O8 Plagioclases-CaAl2Si2O8 3. Fluospar Fluorite CaF2 Markedly decreases viscosity of slag 4. Limenite FeTiO3 Impure from of titanium oxide 5. Rutile TiO2(10%Fe) Unrefined form of titanium oxide. Mainstay of “rutile” elctrodes . Materials Used in Coverings on Steel Electrodes for SMAW d. Slag Forming Materials-Cont.: . Common Name Technical Name 6. Silica Flour Cristobolite Remarks . Strong acid slag former 7. WollastoniteCalcium silicate CaSio3 8. Dolomite Magnesite Often used for forming slag when melting steel in furnace, but seldom included in electrodes coverings 9. Zirconia Zirconium oxide ZrO2 Infrequently used Materials Used in Coverings on Steel Electrodes for SMAW d. Slag Forming Materials-Cont.: . Common Name Technical Name Remarks 10. Magnetite Iron oxide Fe3O4 Magnetic iron oxide 11. Periclase Magnesium oxide Raises melting temp. and increases viscosity of molten slag 12. Pyrolusite Manganese dioxide MnO2 . Materials Used in Coverings on Steel Electrodes for SMAW e. Slipping Agents to Aid Extrusion: . Common Name Technical Name 1. Bentonite clay Montmorillonite 2. Kaoline clay Kaolinite Al2Si2O5(OH) 3. Mica Musovite KAl2(Si3Al)O10(OH)2 4. Talc Soapstone Mg3Si4O10(OH)2 5. Glycerine Glycerol C3H5(OH)3 Remarks Used where water of constitution can be tolerate Trihydric alchol . Materials Used in Coverings on Steel Electrodes for SMAW f. Binding Agents: . Common Name 1. Sodium silicate Technical Name Water glass Na2OnSiO2(OH)n Remarks Agent most often used 2. Potassium silicate K2OnSiO2(OH)n 3. Asbestos Crysotile 4. Dextrine Starch (C6H10O5) 5. Gum arabic Acacia (CnOnHn) 6. Sugar Cn(OH)n Improves durability baked covering and mixes with slag when melted during welding . Materials Used in Coverings on Steel Electrodes for SMAW g. Alloying and Deoxidizing Elements: . Common Name Technical Name Remarks 1. Ferrosilicon Usually 50% Si + Fe Silicon is deoxidizer and alloying element 2. Ferroaluminum Usually 85% Al + Fe Strong deoxidier 3. Ferrotitanium Usually 40% Ti + Fe Strong deoxidier and grain refining agent 4. Zirconium alloy 40% Zr + 40% Si + Fe Deoxidier 5. Electro manganese Mn = 100% Most common alloying element 6. Chromium metal Cr = 100% 7. Ferromanganese Std. type (80%Mn + Fe) . Typical Covering Formulas for Steel SMAW Electrodes Part I: Material Formulas (Parts by Weight Percent) E 7015 E 7018 Limestone 40 30 Fluorspar 15 10 10 8 5 2 Cellulose E 6010 E 6012 25 5 Rutile E 6020 55 20 10 15 Iron oxide 1 30 Clay 10 5 Titania 12 Asbestos 15 Iron Powder 35 Ferrosillicon 2 2 2 5 5 Ferromanganese 4 4 6 4 4 Sodium silicate 60 40 70 25 Potassium silicate 25 Typical Covering Formulas for Steel SMAW Electrodes Part II: Chemical Composition (Percent After Baking) E 6010 E 6012 E 6020 CaO TiO2 10.1 46.0 47.0 Al2O3 MgO 3.2 E 7018 25.5 14.4 15.2 11.0 15.4 CaF2 SiO2 E 7015 23.6 40.0 20.0 20.5 5.0 2.3 2.8 2.0 2.0 2.8 1.2 2.0 5.7 5.0 Na3AlF3 FeO 1.3 7.0 30.7 Na2O 5.1 2.4 3.3 1.7 K2O 1.2 Si 1.5 1.5 1.0 2.8 2.5 Mn 2.8 2.5 4.0 2.0 1.8 Fe 2.8 28.5 CO & CO2 20.2 12.0 0.1 0.1 Volatile Matter 25.0 5.0 Moisture 4.0 2.0 0.5 SMAW Advantages Easily implemented Inexpensive Flexible Not as sensitive to part fit-up variances Advantages Equipment relatively easy to use, inexpensive, portable Filler metal and means for protecting the weld puddle are provided by the covered electrode Less sensitive to drafts, dirty parts, poor fit-up Can be used on carbon steels, low alloy steels, stainless steels, cast irons, copper, nickel, aluminum Quality Issues Discontinuities associated with manual welding process that utilize flux for pool shielding Slag inclusions Lack of fusion Other possible effects on quality are porosity, and hydrogen cracking Limitations Low Deposition Rates Low Productivity Operator Dependent Other Limitations Heat of welding too high for lead, tin, zinc, and their alloys Inadequate weld pool shielding for reactive metals such as titanium, zirconium, tantalum, columbium Turn to the person sitting next to you and discuss (1 min.): • Wood (cellulose) and limestone are added to the coating on SMAW Electrodes for gas shielding. What gases might be formed? • How do these gases shield? Electrode Required Test According to AWS Electrode Required Test: Chemical Analysis Note 9: The minimum completed pad size shall be at least four layers m height (H) with length (L) and width (W) sufficient to perform analysis, The sample for analysis shall be taken at least 1/4 in. (6.4 mm) above the original base metal surface. Electrode Required Test: Chemical Analysis Weld Block for Chemical Analysis Electrode Required Test: Chemical Analysis Chemical Composition Requirements for Weld Metal Electrode Required Test: Tension & Impact Test Assembly Showing Location of Test Specimen E7018M Orientation and Location of Impact Test Specimen Orientation and Location of AllWeld Metal Tension Test Specimen Electrode Required Test: Tension & Impact Tension Test Specimen: Tension Test Specimen for E 6022: Electrode Required Test: Tension & Impact Tension Test Requirements: Electrode Required Test: Tension & Impact Impact Test Specimen: Impact Test Requirements: Electrode Required Test: Fillet Weld Test Positions of Test Plates for Welding Fillet Weld Test Specimens Electrode Required Test: Fillet Weld Test Requirements for Preparation of Fillet Weld Test Assemblies Dimensional Requirements for Fillet Weld Usability Test Specimen Electrode Required Test: Fillet Weld Test Alternative Methods for Facilitating Fracture of the Fillet Weld Electrode Required Test: Transverse Tension Test Electrode Required Test: Bend Test Electrode Required Test: Radiographic Test Grade 1 Radiographic Soundness Requirements Grade 2 Electrode Required Test: Moisture Content Test Percent Moisture=(A-B)/Weight of Sample A: B: Final Weight of Moisture Absorb System Primary Weight of Moisture Absorb System Electrode Required Test: Moisture Content Test Moisture Content Limits in Electrode Coverings T=27°C Relative Humidity=80% T=9hr SMAW Technical Points