* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Material Selection - Web Services Overview

Viscoelasticity wikipedia , lookup

Metamaterial wikipedia , lookup

Microelectromechanical systems wikipedia , lookup

Tunable metamaterial wikipedia , lookup

Radiation damage wikipedia , lookup

Carbon nanotubes in interconnects wikipedia , lookup

Industrial applications of nanotechnology wikipedia , lookup

Fatigue (material) wikipedia , lookup

Energy applications of nanotechnology wikipedia , lookup

Negative-index metamaterial wikipedia , lookup

Condensed matter physics wikipedia , lookup

Sol–gel process wikipedia , lookup

Work hardening wikipedia , lookup

History of metamaterials wikipedia , lookup

Semiconductor wikipedia , lookup

Shape-memory alloy wikipedia , lookup

Nanochemistry wikipedia , lookup

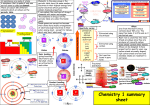

Selection Criteria • Most designers select materials with equal consideration of: – Properties – Availability – Cost Properties • Mechanical – – – – – – – – – – – Yield strength (ductile) / Ultimate strength (brittle) Fatigue (endurance limit) Stiffness or rigidity (modulus of elasticity) Hardness (Rockwell, Brinell) Impact strength (fracture toughness) Toughness (sharpy test) Ductility (% reduction is area) Hardenability Creep (elevated temperature properties) High/Low temperature properties Wear characteristics Properties • Physical – Density – Electrical properties – Thermal properties (conductivity) – Magnetic – Melting point – Thermal expansion – Flamability – Optical • Chemical – Corrosion resistance – Oxidation resistance – Toxicity – Resistance to radiation – Resistance to elements • Dimensional – Dimensional stability – Surface finish Availability • Important questions: – Is the material available in the desired form? • Gage 10 sheets of 304L stainless steel? – If not available, can it be obtained? – Do we have to order 100,000 lbs? – Is the material available from multiple suppliers? COST • The primary factor in material selection in industry • Comparative cost of engineering metals per pound Material Cast irons Carbon steels Low alloy steels Aluminum Copper alloys Stainless steels Magnesuim Tool steels Nickle alloys Price $ .15 .25 .30 .60 .80 1.25 1.5 1.75 4.00 Material Cobalt Titanium Tungsten Silver Beryllium Gold Price 12 17 30 75 200 6100 COST • Cost per volume may be a better choice. The following table is $/in3 Material Cast irons Carbon steels Low alloy steels Magnesuim Aluminum Copper alloys Stainless steels Tool steels Nickle alloys Price $ .04 .07 .09 .10 .10 .22 .35 .50 1.25 Material Titanium Cobalt Beryllium Silver Gold Price 2 4 15 31 4257 Other Cost Factors • What is the cost of material in relation to the production cost or selling price? – Is it orbiting satellite, B1 bomber, or a hammer? • What is the production volume? – A one of a kind design, or graden weisel? • What is the anticipated service life? – A toy is expected to last for a year or two, low quality gears and other components do fine. – Tooling materials for a one-year production can wear more quickly Other Cost Factors • Manufacturability (Fabricability) – If considerable machining is required, it may well be more economical to choose a more expensive material with higher machinability rating than a lower cost material with lower machinability. – Some materials can not be machined at all (ceramics). – A “non-common” metal may require more lead time, different tooling and set up, or special techniques for fabrication. – Only softer materials with good formabilty can be easily formed. Manufacturability • The size and weight of a part can limit its formability. • Part size and geometry limit parts fabricated with PM technology • Materials to be heat treated for strength must have sufficient hardenability. • Materials that require heat treatment may have to go through further processes. • Hot rolled materials may require further processing. • Cold-rolled materials may distort when machined • Casting processes have weight, wall thickness, size, accuracy, surface finish, and material limitations. Manufacturing • Parts fabricated by welding require good material weldability. • Most metals can be welded but with a wide range of methods and very different costs. Low alloy steels cost the least, high strength steels cost more, and tool steels are most expensive to weld. • Some materials require pre and post-weld heat treatment. • Welding induces distortion in parts, further processing may be required. • It is difficult to join aluminum and steels together. Designer’s Repertoire • Know about the properties of a few carbon steels – 1010, 1030, 1050, 1080, B1112 • Know about the properties of a few cast irons: – Class 20, Class 60, Ductile 60-45-18 • Know about the properties of a few alloy steel: – 4140, 4340, 9310 • Know about the properties of a few tool steels: – 01, A2, D2, S1, H13, M2 • Know about the properties of a few stainless steels: – 304, 304, 316,420,440C, 17-4 PH Designer’s Repertoire • Know about the properties of a few Aluminum alloys: – 3003, 5052, 6061, 7075 • Know about the properties of a few nickel alloys: – Monel, Inconel • Know about the properties of a few copper alloys: – C36000 yellow brass, C52100 phosphor bronze • Know about the properties of a few titanium alloys • Know about the properties of a few Magnesium alloys Designer’s Repertoire • Know about the properties of a few ceramics: – – – – – Aluminum oxides Silicon nitride / Silicon carbide Cemented carbides Carbon products Ceramic coatings (Chromium oxide, Tungsten carbide) • Know about the properties of a few plastics: – – – – – Polyethylene / Polyimides / Polyamides Polycarbonate PVC /ABS Nylons Elastomers Example • Suppose a designer has created a drawing for a shaft of a hypothetical device. The list of operational conditions have been determined as follows: – – – – 1.25” diameters are to fit ball bearings The shaft is subjected to maximum shear stress of 10 ksi There is possibility of moderate shock load Small end must resist damage from frequent removal of a keyed gear. – There are no inertial requirements. – Surface roughness to be 32 micro inches max. – Diameters must be concentric to 0.001 inch. Example • Based on the operational requirements, time constraint, and cost, the following selection factors have been established: – – – – – – – – – Hardness of at least 30 HRC Fatigue strength of 30 ksi Impact strength must be high Stiffness must be high The part must not rust in 50% RH room air. Must be dimensionally stable. Parts are needed in one week. Three units are required. Expected service life is 5 years Example