* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Speed Checker for Highways

Variable-frequency drive wikipedia , lookup

Flexible electronics wikipedia , lookup

Current source wikipedia , lookup

Electrical ballast wikipedia , lookup

Electronic paper wikipedia , lookup

Pulse-width modulation wikipedia , lookup

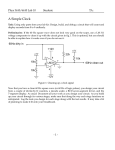

Flip-flop (electronics) wikipedia , lookup

Regenerative circuit wikipedia , lookup

Two-port network wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Fault tolerance wikipedia , lookup

Oscilloscope history wikipedia , lookup

Integrated circuit wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Buck converter wikipedia , lookup

Network analysis (electrical circuits) wikipedia , lookup

Time-to-digital converter wikipedia , lookup

Printed circuit board wikipedia , lookup

1 INDEX S. NO. PAGE NO. CONTENT 1. Introduction 2. Circuit diagram 3. Circuit diagram description 4. Components list 5. Construction and working 6. Component description 8. PCB fabrication 9. Application 10. Conclusion 11. references 2 INTRODUCTION While driving on highways, motorists should not exceed the maximum speed limit permitted for their vehicle. However, accidents keep occurring due to speed violations since the drivers tend to ignore their speedometers. This speed checker will come handy for the highway traffic police as it will not only provide a digital display in accordance with a vehicle’s speed but also sound an alarm if the vehicle exceeds the permissible speed for the highway. The system basically comprises two laser transmitter-LDR sensor pairs, which are installed on the highway 100 metres apart, with the transmitter and the LDR sensor of each pair on the opposite sides of the road. The installation of lasers and LDRs is shown . The s ystem displays the time taken by the vehicle in crossing this 100m distance from one pair to the other with a resolution of 0.01 second, from which the speed of the vehicle can be calculated as follows:As per the above equation, for a Speed (kmph) = Distance Time 3 0.1 km (Reading×0.01)/3600 = or, Reading (on display) = Speed 36000 4 speed of 40 kmph the display will read 900 (or 9 seconds), and for a speed of 60 kmph the display will read 600 (or 6 seconds). Note that the LSB of the display equals 0.01 second and each succeeding digit is ten times the preceding digit. You can similarly calculate the other readings (or time). 5 Circuit diagram 6 7 Circuit description Circuit description shows the circuit of the speed checker. It has been designed assuming that the maximum permissible speed for highways is either 40 kmph or 60 kmph as per the traffic rule. 8 The circuit is built around five NE555 timer ICs (IC1 through IC5), four CD4026 counter ICs (IC6 through IC9) and four 7-segment displays (DIS1 through DIS4). IC1 through IC3 function as monostables, with IC1 serving as count-start mono, IC2 as count-stop mono and IC3 as speed-limit detector mono, controlled by IC1 and IC2 outputs. Bistable set-reset IC4 is also controlled by the outputs of IC1 and IC2 and it (IC4), in turn, controls switching on/off of the 100Hz (period = 0.01 second) astable timer IC5. The time period of timer NE555 (IC1) count-start monostable multivibrator is adjusted using preset VR1 or VR2 and capacitor C1. For 40kmph limit the time period is set for 9 seconds using preset \VR1, while for 60kmph limit the time period is set for 6 seconds using preset VR2. Slide switch S1 is used to select the time period as per the speed limit (40 kmph and 60 kmph, respectively). The junction of LDR1 and resistor R1 is coupled to pin 2 of IC1.Normally, light from the lase keeps falling on the LDR sensor continuously and thus the LDR offers a low resistance and pin 2 of IC1 is high. 9 Whenever light falling on the LDR is interrupted by any vehicle, the LDR resistance goes high and hence pin 2 of IC1 goes low to trigger the monostable. As a result, output pin 3 goes high for the preset period (9 or 6 seconds) and LED1 glows to indicate it. Reset pin 4 is controlled by the output of NAND gate N3 at power-on or whenever reset switch S2 is pushed. For IC2, the monostable is triggered in the same way as IC1 when the vehicle intersects the laser beam incident on LDR2 to generate a small pulse for stopping the count and for use in the speed detection. LED2 glows for the duration for which pin 3 of IC2 is high. The outputs of IC1 and IC2 are fed to input pins 2 and 1 of NAND gate N1, respectively. When the outputs of IC1 and IC2 go high simultaneously (meaning that the vehicle has crossed the preset speed limit), output pin 3 of gate N1 goes low to trigger monostable timer IC3. The output of IC3 is used for driving piezobuzzer PZ1, which alerts the operator of speed-limit violation. Resistor R9 and capacitor C5 decide the time period for which the piezobuzzer sounds. The output of IC1 triggers the bistable (IC4) through gate N2 at the leading edge of the count-start pulse. When pin 10 2 of IC4 goes low, the high output at its pin 3 enables astable clock generator IC5. Since the count-stop pulse output of IC2 is connected to pin 6 of IC4 via diode D1, it resets clock generator IC5. IC5 can also be reset via diode D2 at power-on as well as when reset switch S2 is pressed. IC5 is configured as an astable multivibrator whose time period is decided by preset VR3, resistor R12 and capacitor C10. Using preset VR1, the frequency of the astable multivibrator is set as 100 Hz. The output of IC5 is fed to clock pin 1 of decade counter/7- segment decoder IC6 CD4026. IC CD4026 is a 5-stage Johnson decade counter and an output decoder that converts the Johnson code into a 7-segment decoded output for driving DIS1 display. The counter advances by one count at the positive clock signal transition. The carry-out (Cout) signal from CD4026 provides one clock after every ten clock inputs to clock the succeeding decade counter in a multidecade counting chain. This is achieved by connecting pin 5 of each CD4026 to pin 1 of the next CD4026. A high reset signal clears the decade counter to its zero count. Pressing switch S2 provides a reset signal to pin 15 of all CD4026 ICs and also IC1 and IC4. Capacitor C12 and resistor R14 generate the power-on- 11 reset signal. The seven decoded outputs ‘a’ through ‘g’ of CD4026s illuminate the proper segment of the 7-segment displays (DIS1 through DIS4) used for representing the decimal digits ‘0’ through ‘9.’ Resistors R16 through R19 limit the current across DIS1 through DIS4, respectively. Fig. 3 shows the circuit of the power supply. The AC mains is stepped down by transformer X1 to deliver the secondary output of 15 volts, 500 mA. The transformer output is rectified by a bridge rectifier comprising diodes D3 through D6, filtered by capacitor C14 and regulated by IC11 to provide regulated 12V supply. Capacitor C15 bypasses any ripple in the regulated output. Switch S3 is used as the ‘on’/‘off’ switch. In mobile application of the circuit, where mains 230V AC is not available, it is advisable to use an external 12V battery. For activating the lasers used in conjunction with LDR1 and LDR2, separate batteries may be used. construction and working 12 Assemble the circuit on a PCB. An actual-size, single-side PCB layout for the speed checker is shown in Fig. 4 and its component layout in Fig. 5.Before operation, using a multimeter check whether the power supply output is correct. If yes, apply power supply to the circuit by flipping switch S3 to ‘on.’ In the circuit, use long wires for connecting the two LDRs, so that you can take them out of the PCB and install on one side of the highway, 100 metres apart. Install the two laser transmitters (such as laser torches) on the other side of the highway exactly opposite to the LDRs such that laser light falls directly on the LDRs. Reset the circuit by pressing switch S2, so the display shows ‘0000.’ Using switch S1, select the speed limit (say, 60 kmph) for the highway. When any vehicle crosses the first laser light, LDR1 will trigger IC1. The output of IC1 goes high for the time set to cross 100 metres with the selected speed (60 kmph) and LED1 glows during for period. When the vehicle crosses the second laser light, the output of IC2 goes high and LED2 glows for this period. Piezobuzzer PZ1 sounds an alarm if the vehicle crosses the distance between the laser set-ups at more than the selected speed (lesser period than preset period). The counter starts counting when the first laser beam is intercepted and stops when the second laser beam is intercepted. The time taken by the vehicle to cross both the laser beams is displayed on the 7-segment display. For 60kmph speed setting, with timer frequency set at 100 Hz, if the display count is less than ‘600,’ it means that the vehicle has crossed the speed limit (and simultaneously 13 the buzzer sounds). Reset the circuit for monitoring the speed of the next vehicle. Note. This speed checker can check the speed of only one vehicle at a time. 14 Parts List Semiconductors: IC1-IC5 - NE555 timer IC6- IC9 - CD4026 decade counter/7-segment decoder IC10 - CD4011 NAND gate IC11 - 7812 12V regulator D1, D2 - 1N4148 switching diode D3-D6 - 1N4007 rectifier diode LED1 - Green LED LED2, LED3 - Red LED DIS1-DIS4 - LTS543 common-cathode, 7-segment display Resistors (all ¼-watt, ±5% carbon): R1, R4 R2, R5, R6, 100-kilo-ohm 15 R8, R10, R11, R14 - 10-kilo-ohm R3, R7, R13, R16-R19 - 470-ohm R9 - 470-kilo-ohm R12, R15 - 1-kilo-ohm VR1, VR2 - 100-kilo-ohm preset VR3 - 20-kilo-ohm preset Capacitors: C1 - 100µF, 25V electrolytic C2, C4, C6, C8, C11 - 0.01µF ceramic disk C3, C13, C15 - 0.1µF ceramic disk C5 - 10µF, 25V electrolytic C7 - 0.47µF, 25V electrolytic C9 - 0.2µF ceramic disk C10 - 1µF, 25V electrolytic C12 - 47µF, 25V electrolytic C14 - 1000µF, 35V electrolytic 16 Miscellaneous: X1 - 230V AC primary to 0- 15V, 500mA secondary transformer PZ1 - Piezobuzzer LDR1, LDR2 - LDR S1, S2 - Push-to-on switch S3 - On/Off switch - Pointed laser ligh 17 Components used IC555 TIMER One of the most versatile linear ICs is the 555 timer which was first introduced in early 1970 by Signetic Corporation giving the name as SE/NE 555 timer. This IC is a monolithic timing circuit that can produce accurate and highly stable time delays or oscillation. Like other commonly used op-amps, this IC is also very much reliable, easy to use and cheaper in cost. It has a variety of applications including monostable andastable multivibrators, dc-dc converters, digital logic probes, waveform generators, analog frequency meters and 18 tachometers, temperature measurement and control devices, voltage regulators etc. The timer basically operates in one of the two modes either as a monostable (one-shot) multivibrator or as an astable (freerunning) multivibrator.The SE 555 is designed for the operating temperature range from – 55°C to 125° while the NE 555 operates over a temperature range of 0° to 70°C. The important features of the 555 timer are : It operates from a wide range of power supplies ranging from + 5 Volts to + 18 Volts supply voltage. Sinking or sourcing 200 mA of load current. The external components should be selected properly so that the timing intervals can be made into several minutes Proper selection of only a few external components allows timing intervals of several minutes along with the frequencies exceeding several hundred kilo hertz. It has a high current output; the output can drive TTL. It has a temperature stability of 50 parts per million (ppm) per degree Celsius change in temperature, or equivalently 0.005 %/ °C. The duty cycle of the timer is adjustable with the maximum power dissipation per package is 600 mW and its trigger and reset inputs are logic compatible. 19 2. IC Pin Configuration 555 Timer IC Pin Configuration The 555 Timer IC is available as an 8-pin metal can, an 8-pin mini DIP (dual-in-package) or a 14-pin DIP. This IC consists of 23 transistors, 2 diodes and 16 resistors. The explanation of terminals coming out of the 555 timer IC is as follows. The pin number used in the following discussion refers to the 8-pin DIP and 8-pin metal can packages. 20 CD4026B CD4026B and CD4033B each consist of a 5-stage Johnson decade counter and an output decoder which converts the Johnson code to a 7segment decoded output for driving one stage in a numerical display. These devices are particularly advantageous in display applications where low power dissipation and /or low package count are important. Inputs common to both types are CLOCK, RESET, & CLOCK INHIBIT; common outputs are CARRY OUT and the seven decoded outputs (a, b, c, d, e, f, g). Additional inputs and outputs for the CD4026B include DISPLAY ENABLE input and DISPLAY ENABLE and UNGATED "C-SEGMENT" outputs. Signals peculiar to the 21 CD4033B are RIPPLE-BLANKING INPUT AND LAMP TEST INPUT and a RIPPLE-BLANKING OUTPUT. A high RESET signal clears the decade counter to its zero count. The counter is advanced one count at the positive clock signal transition if the CLOCK INHIBIT signal is low. Counter advancement via the clock line is inhibited when the CLOCK INHIBIT signal is high. The CLOCK INHIBIT signal can be used as a negative-edge clock if the clock line is held high. Antilock gating is provided on the JOHNSON counter, thus assuring proper counting sequence. The CARRY-OUT (Cout) signal completes one cycle every ten CLOCK INPUT cycles and is used to clock the succeeding decade directly in a multi-decade counting chain. The seven decoded outputs (a, b, c, d, e, f, g) illuminate the proper segments in a seven segment display device used for representing the decimal numbers 0 to 9. The 7-segment outputs go high on selection in the CD4033B; in the CD4026B these outputs go high only when the DISPLAY ENABLE IN is high. The CD4026B- and CD4033B-series types are supplied in 16-lead dualin-line plastic packages (E suffix), 16-lead small-outline packages (NSR suffix), and 16-lead thin shrink small-outline packages (PW and PWR suffixes). 22 Features Counter and 7-segment decoding in one package Easily interfaced with 7-segment display types Fully static counter operation: DC to 6 MHz (typ.) at VDD = 10 V Ideal for low-power displays Display enable output (CD4026B) "Ripple blanking" and lamp test (CD4033B) 100% tested for quiescent current at 20 V Standardized, symmetrical output characteristics 5-V, 10-V, and 15-V parametric ratings Schmitt-triggered clock inputs Meets all requirements of JEDEC Tentative Standard No. 13B, "Standard Specifications for Description of ’B’ Series CMOS Devices" Applications o Decade counting 7-segment decimal display o Frequency division 7-segment decimal displays o Clocks, watches, timers (e.g. ÷60, ÷60, ÷ 12 counter/display) o Counter/display driver for meter applications 23 RESISTANCE Resistance is the opposition of a material to the current. It is measured in Ohms ( no conductor is 100% efficient. To control the electron flow (current) in a predictable manner, we use resistors. Electronic circuits use calibrated lumped resistance to control the flow of current. Broadly speaking, resistor can be divided into two groups viz. fixed & adjustable (variable) resistors. In fixed resistors, the value is fixed & cannot be varied. In variable resistors, the resistance value can be varied by an adjuster knob. It can be divided into (a) Carbon composition (b) Wire wound (c) Special type. The most common type of resistors used in our projects is carbon type. The resistance value is normally indicated by colour bands. Each resistance has four colours, one of the band on either side will be gold or silver, this is called fourth band and indicates the tolerance, others three band will give the value of resistance (see table). For example if a resistor has the following marking on it say red, violet, gold. Comparing these coloured rings with the colour code, its value is 27000 ohms or 27 kilo ohms and its tolerance is ±5%. Resistor comes in various sizes (Power rating). The bigger, the size, the more power rating of 1/4 watts. The four colour rings on its body tells us the value of resistor value as given below. 24 COLOURS CODE Black -------------------------------------- 0 Brown ------------------------------------- 1 Red ---------------------------------------- 2 Orange ------------------------------------ 3 Yellow ------------------------------------ 4 Green -------------------------------------- 5 Blue---------------------------------------- 6 Violet -------------------------------------- 7 Grey --------------------------------------- 8 White -------------------------------------- 9 25 The first rings give the first digit. The second ring gives the second digit. The third ring indicates the number of zeroes to be placed after the digits. The fourth ring gives tolerance (gold ±5%, silver ± 10%, No colour ± 20%) In variable resistors, we have the dial type of resistance boxes. There is a knob with a metal pointer. This presses over brass pieces placed along a circle with some space b/w each of them.Resistance coils of different values are connected b/w the gaps. When the knob is rotated, the pointer also moves over the brass pieces. If a gap is skipped over, its resistance is included in the circuit. If two gaps are skipped over, the resistances of both together are included in the circuit and so on.A dial type of resistance box contains many dials depending upon the range, which it has to cover. If a resistance box has to read upto 10,000Ω, it will have three dials each having ten gaps i.e. ten resistance coils each of resistance 10Ω. The third dial will have ten resistances each of 100Ω. 26 DIODE The simplest semiconductor device is made up of a sandwich of P-type semiconducting material, with contacts provided to connect the p-and ntype layers to an external circuit. This is a junction Diode. If the positive terminal of the battery is connected to the p-type material (cathode) and the negative terminal to the N-type material (Anode), a large current will flow. This is called forward current or forward biased. If the connections are reversed, a very little current will flow. This is because under this condition, the p-type material will accept the electrons from the negative terminal of the battery and the N-type material will give up its free electrons to the battery, resulting in the state of electrical equilibrium since the N-type material has no more electrons. Thus there will be a small current to flow and the diode is called Reverse biased. Thus the Diode allows direct current to pass only in one direction while blocking it in the other direction. Power diodes are used in concerting AC into DC. In this, current will flow freely during the first half cycle (forward biased) and practically not at all during the other half cycle (reverse biased). This makes the diode an effective rectifier, which convert ac into pulsating dc. Signal diodes are used in radio circuits for detection. Zener diodes are used in the circuit to control the voltage. 27 Some common diodes are:1. Zener diode. 2. Photo diode. 3. Light Emitting diode. 28 CAPACITORS It is an electronic component whose function is to accumulate charges and then release it. To understand the concept capacitance, consider a pair of of metal plates which all are placed near to each other without touching. If a battery is connected to these plates the positive pole to one and the negative pole to the other, electrons from the battery will be attracted from the plate connected to the positive terminal of the battery. If the battery is then disconnected, one plate will be left with an excess of electrons, the other with a shortage, and a potential or voltage difference will exists between them. These plates will be acting as capacitors. Capacitors are of two types: - (1) fixed type like ceramic, polyester, electrolytic capacitors-these names refer to the material they are made of aluminium foil. (2) Variable type like gang condenser in radio or trimmer. In fixed type capacitors, it has two leads and its value is written over its body and variable type has three leads. Unit of measurement of a capacitor is farad denoted by the symbol F. It is a very big unit of capacitance. 29 Small unit capacitor are pico-farad denoted by pf (Ipf=1/1000,000,000,000 f) Above all, in case of electrolytic capacitors, it's two terminal are marked as (-) and (+) so check it while using capacitors in the circuit in right direction. Mistake can destroy the capacitor or entire circuit in operational. 30 PCB FABRICATION The first step of assembling is to produce a printed circuit board. The fabrication of the program counter plays a crucial role in the electronic field. The success of the circuit is also dependent on the PCB. As far as the cost is concerned, more than 25% of the total cost is for the PCB design and fabrication. The board is designed using a personal computer. The layout is drawn using the software “Adobe PageMaker 6.5”. The layout is printed in a “buffer sheet” using a laser procedure. First, a negative screen of the layout is prepared with the help of a professional screen printer. Then the copper clad sheet is kept under this screen. The screen printing ink is poured on the screen and brushed through the top of the screen. The printed board is kept under shade for few hours till the ink becomes dry. The etching medium is prepared with the un-hydrous ferric chloride water. The printed board is kept in this solution till the exposed copper dissolves in the solution fully. After that the board is taken out and rinsed in flowing water under a tap. The ink is removed with solder in order to prevent oxidation. Another screen, which contains component side layout, is prepared and 31 the same is printed on the component side of the board. A paper epoxy laminate is used as the board. Both the component and the track layout of the peripheral PCB is given at the end of this report. A printed circuit board (PCB) mechanically supports and electrically connects electronic components using conductive tracks, pads and other features etched from copper sheets laminated onto a non-conductive substrate. PCB's can be single sided (one copper layer), double sided (two copper layers) or multi-layer. Conductor on different layers are connected with plated-through holes called vias. Advanced PCB's may contain components - capacitors, resistors or active devices - embedded in the substrate. Printed circuit boards are used in all but the simplest electronic products. Alternatives to PCBs include wire wrap and point-to-point construction. PCBs are more costly to design but allow automated manufacturing and 32 assembly. Products are then faster and cheaper to manufacture, and potentially more reliable. Much of the electronics industry's PCB design, assembly, and quality control follows standards published by the IPC organization. When the board has only copper connections and no embedded components it is more correctly called a printed wiring board (PWB) or etched wiring board. Although more accurate, the term printed wiring board has fallen into disuse. A PCB populated with electronic components is called a printed circuit assembly (PCA), printed circuit board assembly or PCB assembly (PCBA). The IPC preferred term for assembled boards is circuit card assembly (CCA), for assembled backplanes it is backplane assemblies. The term PCB is used informally both for bare and assembled boards. 33 Design A board designed in 1967; the sweeping curves in the traces are evidence of freehand design using self-adhesive tape. Printed circuit board artwork generation was initially a fully manual process done on clear mylar sheets at a scale of usually 2 or 4 times the desired size. The schematic diagram was first converted into a layout of components pin pads, then traces were routed to provide the required interconnections. Pre-printed non-reproducing mylar grids assisted in layout, and rub-on dry transfers of common arrangements of circuit elements (pads, contact fingers, integrated circuit profiles, and so on) helped standardize the layout. Traces between devices were made with 34 self-adhesive tape. The finished layout "artwork" was then photographically reproduced on the resist layers of the blank coated copper-clad boards. Modern practice is less labor intensive since computers can automatically perform many of the layout steps. The general progression for a commercial printed circuit board design would include: 1. Schematic capture through an electronic design automation tool. 2. Card dimensions and template are decided based on required circuitry and case of the PCB. Determine the fixed components and heat sinks if required. 3. Deciding stack layers of the PCB. 1 to 12 layers or more depending on design complexity. Ground plane and power plane are decided. Signal planes where signals are routed are in top layer as well as internal layers. 4. Line impedance determination using dielectric layer thickness, routing copper thickness and trace-width. Trace separation also taken into account in case of differential signals. Microstrip, stripline or dual stripline can be used to route signals. 5. Placement of the components. Thermal considerations and geometry are taken into account. Vias and lands are marked. 6. Gerber file generation for manufacturing. 35 In the design of the PCB artwork, a power plane is the counterpart to the ground plane and behaves as an AC signal ground, while providing DC voltage for powering circuits mounted on the PCB. In electronic design automation (EDA) design tools, power planes (and ground planes) are usually drawn automatically as a negative layer, with clearances or connections to the plane created automatically. Application It will maintain the softy of human life on the road. It can also be used on the bridge for the control of the speed. It can be used on the highway express, highway. Conclusion Here we implemented the “SPEED CHECKER FOR HIGHWAY” from point of view of safety on the mega highway. We feel that if mega highway is supported with such on faithful system then it will not only help to maintain the traffic rules also reduces 36 accident.As circuit is compact and friendly one man can handle the system efficiently. References www.wikipedia.com www.google.com www.kitsnspares.com