* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download High Reliability Principles and Verifications in Solid

Portable appliance testing wikipedia , lookup

Buck converter wikipedia , lookup

Waveguide (electromagnetism) wikipedia , lookup

Mercury-arc valve wikipedia , lookup

Opto-isolator wikipedia , lookup

Electrical substation wikipedia , lookup

Stray voltage wikipedia , lookup

Printed circuit board wikipedia , lookup

Alternating current wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Non-radiative dielectric waveguide wikipedia , lookup

Thermal runaway wikipedia , lookup

Voltage optimisation wikipedia , lookup

Surge protector wikipedia , lookup

Mains electricity wikipedia , lookup

Distribution management system wikipedia , lookup

Electroactive polymers wikipedia , lookup

Surface-mount technology wikipedia , lookup

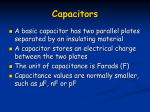

Capacitor types wikipedia , lookup

Ceramic capacitor wikipedia , lookup

Aluminum electrolytic capacitor wikipedia , lookup

Electrolytic capacitor wikipedia , lookup

Capacitor plague wikipedia , lookup

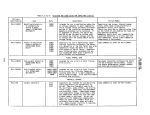

CARTS International 2014 March 31-April 3, 2014 High Reliability Principles and Verifications in Solid Tantalum Capacitors. A. Capacitor Manufacturing Processes Yuri Freeman and Phil Lessner KEMET Electronics Corporation, 2835 KEMET Way, Simpsonville, SC 29681, [email protected], (864) 228-4068 Electronic designs for military, aerospace, and medical equipment often require the highest levels of reliability and safety. This is especially important in the application of Tantalum (Ta) capacitors where the typical short circuit failure mode can lead to significant damage to the adjacent circuit board. Testing performed by Northrop Grumman and KEMET has shown that 50% voltage de-rating alone is not sufficient to address this problem. De-rating increases component size, surface area, and the dielectric thickness; thereby, increasing the probability of hidden defects in the dielectric. The end-user’s manufacturing process also affects Ta capacitor reliability. These collaborative papers present manufacturing principles adopted by the capacitor maker KEMET and end-user Northrop Grumman that greatly improve the reliability of Ta/MnO2 capacitors. Particularly on KEMET’s side this includes flawless technology (F-Tech) that eliminates hidden defects in the dielectric as well as simulated breakdown screening (SBDS) technique which enables 100% screening unreliable parts with low BDV without any damage to the population of the capacitors. On Northrop Grumman’s side it’s demonstrated that improvements in the capacitors quality can diminish by unintended damage to the Ta capacitor dielectric during end-user’s manufacturing processes. Test results will be provided to measure failure rate differences between conventional and F-Tech/SBDS solid Ta capacitors. The results provide evidence that the F-Tech/SBDS process along with the end-user process improvements provide the lowest component failure rates and the highest reliability. 1. Scientific Foundation Hi-Rel technology is based on deep understanding of the major degradation mechanisms in Ta capacitors that are responsible for the failures. The booklet Major Degradation Mechanisms in Tantalum and Niobium-based Capacitors by T. Tripp and Y. Freeman presents a broad overview of the data from the literature as well as the authors own results on this subject.1 The absolute majority of the papers cited in this booklet were peer reviewed and published by highly reputable scientific sources which distinguishes scientific publications from the nonscientific ones. According to this booklet, the most typical reason for the catastrophic failures of Ta capacitors at normal operation conditions is growth of crystalline inclusions in amorphous matrix of their dielectric. This results in the gradual increase of the mechanical stress in the dielectric due to the difference in density between the amorphous and crystalline phases and eventually causes the dielectric disruption and the capacitor failure (Fig. 1). Fig. 1. Crystalline inclusion rupturing amorphous matrix of the dielectric Ta2O5 film The amorphous structure of the anodic Ta2O5 film is critical for its dielectric properties. Particularly, this high electric field strength is due to the high concentration of the traps for the current carriers and, thereby, low mobility of these carriers even in the strong electric field. At the same time all amorphous dielectrics are prone to ordering and crystallization, which occur spontaneously and are activated by temperature and electric field. The moving force for the crystallization is thermodynamic instability of the amorphous phase with disordered atoms and molecules, while ordering and crystallization reduce internal energy and provide thermodynamic stability to the system. Thick amorphous dielectrics are more prone to crystallization because excessive internal energy of their volumes is not compensated by the energy gain at the metal-dielectric interface. Eventually phase transformation from amorphous into crystalline phase will occur; however, the rate of crystallization is very different depending on the specific technology and application conditions. For the amorphous Ta2O5 film crystallization starts from crystalline seeds located on anode surface at the bottom of the film (Fig. 2) Fig. 2. Crystalline seeds at the bottom of the Ta2O5 film after removal of the amorphous matrix These crystalline seeds are typically originated by local contamination on the anode surface. Density and size of these seeds determine the rate of the crystallization process at given temperature and electric field. With large size and high density crystalline seeds crystallization progresses rapidly even at relatively low temperatures and voltages. On the other hand, when these seeds are wiped off the anode surface, the pace of crystallization is very low. That’s why the highest chemical purity Ta anodes are necessary for the manufacturing of Hi-Rel Ta capacitors. Besides chemical purity, mechanical robustness of the Ta anodes is also important since mechanical stress during manufacturing and in the field can also promote crystallization, damaging the dielectric in the capacitors. 1. Flawless Technology (F-Tech) Flawless technology (F-Tech) provides the highest chemical purity and mechanical robustness to the Ta anodes and, thereby, the highest reliability to Ta capacitors utilizing these anodes. Capacitor grade Ta powder usually is chemically pure with concentration of the metallic and most nonmetallic impurities in the ppm range. However, the powder can be contaminated first of all with carbon and oxygen during the anode manufacturing processes. The primary source of carbon in Ta anodes is organic lubricant added to Ta powder to improve the powder flow and density distribution in pressed anodes. Typically the lubricant is removed from Ta powder after the pressing by heat treatment in vacuum at temperatures exceeding thermal decomposition of the organic material. Some of the released carbon is trapped by Ta anode and later reacts with Ta at high sintering temperature forming local precipitates of tantalum carbide TaC. Tantalum carbide is difficult to oxidize since tantalum has strong chemical bond with carbon. This causes local thinning or partial pores (defects by Vermilyea) in the dielectric (Fig. 3). Fig. 3 Ta2O5 dielectric films formed on Ta anode enriched with carbon The source of oxygen in the volume of Ta anodes is native oxide on the surface of Ta particles. During the powder sintering in vacuum, oxygen from native oxide dissolves in the bulk of Ta particles, creating solid solution of oxygen in tantalum. When Ta anodes cool down after the sintering, solubility limit of oxygen in tantalum decreases, resulting in precipitates of crystalline tantalum oxide in local areas of anodes enriched with oxygen. Crystalline inclusions grow from these seeds causing cracks in the dielectric (Fig. 4). Fig. 4 Ta2O5 dielectric film formed on Ta anode enriched with oxygen Additional source of crystalline seeds in amorphous matrix of the Ta2O5 film is thermal oxide on anode surface, which forms when Ta anodes are exposed to air after their sintering in vacuum. Passivation, chemical reaction between tantalum and oxygen, is exothermic process with the release of energy in the form of heat. This heat causes the thermal oxide to grow thicker than the amorphous native oxide that forms on Ta surface at room temperature. Fig. 5 shows numerous crystalline inclusions in the thick thermal oxide of Ta which incorporates in Ta2O5 film during anodizing and forces crystallization and disruption of the dielectric.2-4 Fig. 5. Crystals in thermal oxide on Ta surface Flawless technology F-Tech eliminates contamination with carbon by utilizing organic lubricants that can be washed off the anodes at low temperatures. This provides carbon level in sintered anodes equal to that in the original powder. Carbon is tested in every production lot after the de-lubrication, and the process is repeated if carbon level is elevated in comparison to that in the original powder. F-Tech also uses de-oxidizing of sintered anodes by exposing them to Mg vapor. Mg has higher affinity to oxygen than that in Ta and extracts oxygen from Ta forming magnesium oxide MgO on the particle surface. Magnesium oxide is then leached off Ta anodes in diluted solution of sulfuric acid, leaving bulk of Ta particles practically free of oxygen. Additional emphasis is on special passivation process resulting in very thin native oxide on anode surface when anodes are exposed to air after the powder sintering. F-Tech also provides strong attachment of the Ta lead wire to the sintered powder by replacing traditional embedded lead wire with argon welded one having large and strong welded nagged at the anode egress. Combination of the highest chemical purity and mechanical robustness in Ta anodes manufactured with F-Tech eliminates crystallization seeds and provides flawless dielectrics in Ta capacitors with these anodes (Fig. 6). Fig. 6. Ta2O5 dielectric film formed on Ta anode manufactured with flawless technology F-Tech. The most important feature of Ta capacitors manufactured with F-Tech is exceptional long-term DCL stability even under accelerated voltage and temperature. Fig. 7 shows DCL distribution in Ta capacitors manufactured with traditional technology (control) vs. F-Tech (test) in virgin state just after the manufacturing (left) and after 2000 hours of accelerated Llife test (right). Fig. 7. DCL distribution in Ta/MnO2 capacitors D-case 22 uF – 20 V before (left) and after (right) 2000 hours of accelerated Life test at 85o C and 1.32 rated voltage. As one can see, DCL before the test is practically identical in Ta capacitors manufactured with traditional technology and F-Tech (Fig. 7 left). This is due to self-healing helping block current through the initial defects in the dielectric.5 During the accelerated testing the crystals continue to grow in amorphous matrix, causing DCL shift to higher values and significant number of failures in control parts with traditional technology (Fig. 7 right). At the same time DCL in capacitors with F-Tech is absolutely stable during the accelerated Life test without any change of failures. This is because crystallization seeds were wiped off by F-Tech and no defects progressed in the dielectric of these capacitors during the long accelerated testing. 2. BDV As Ultimate Indicator of the Dielectric Quality DCL is traditionally used to evaluate quality of the dielectric in Ta capacitors and screen non-reliable parts with damaged dielectric. When DCL is high, it indicates flaws in the dielectric; however, when DCL is low, it doesn’t guarantee flawless dielectric. As it was demonstrated in Fig. 7, initial DCL was low and practically identical in the capacitors with traditional technology and F-Tech; however, during the accelerated test DCL in the capacitors with traditional technology shifted to much higher values and 10% of these capacitors failed, while no change in DCL and no failures were detected in the capacitors with F-Tech. To explain specifics of the DCL behavior, Fig. 8 demonstrates current –voltage I(V) curves for two Solid Ta capacitors from the same production lot. Fig. 8. I(V) curves at room temperature for two D-case Ta capacitors 16 uF – 25 V According to Fig. 8, both capacitors #9 and #12 have identical DCL at rated voltage. When voltage increased above rated voltage, current increased rapidly in the capacitor #9 while it stayed low in the capacitor #12. On the atomic scale, capacitor #9 had hidden defects in the dielectric like crystalline seeds with much smaller size than the dielectric thickness. These defects are not detectable by DCL at rated voltage, but can be detected at high voltages approaching average BDV. The difference in DCL between capacitors #9 and #12 becomes even larger when the test is performed at a combination of high voltage and high temperature. However, there is a high probability to introduce new defects in the dielectric of the whole population of the capacitors by overstressing the capacitors above maximum acceleration factor in the Weibull grading according to the MIL-PRF-55365G. The most efficient way to detect hidden defects in the dielectric of Ta capacitors is breakdown voltage (BDV) test. Fig. 9 shows BDV distribution in Ta capacitors D-case 16 uF – 25 V. All the capacitors had low DCL before the test with small deviation from the average DCL value. Fig. 9. BDV distribution in Ta capacitors D-case 16 uF – 25 V In Fig. 9 low BDV indicates flaws in the dielectric, while high BDV close to the formation voltage indicates excellent flawless dielectric. BDV test of a representative sample from every manufacturing lot is included in FTech as an efficient way to monitor manufacturing process and to screen maverick lots with unreliable capacitors having hidden defect in the dielectric (Fig. 10) Fig. 10. Average BDV in production lots of Ta capacitors 75 uF – 75 V The target value of the average breakdown voltage in the BDV test is two times rated voltages. An additional 5% is subtracted due to the accuracy of the BDV measurement. As one can see from the Fig. 10, only one lot #5 had BDV average below this target value and was scraped. All other manufacturing lots had average BDV above the target value. There is a direct correlation between BDV and long-term reliability of Ta capacitors.6 That’s why the BDV test is also an efficient way to compare reliability of Ta capacitors from different manufacturers. Fig. 11 presents data obtained by Dr. A. Teverovsky from NASA for 50 V Solid Ta capacitors with MnO2 cathodes. The BDV average value marked by red square was obtained on the capacitors with F-Tech and simulated breakdown screening (SBDS) discussed in the next paragraph. Fig. 11. Average BDV in 50 V Solid Ta/MnO2 capacitors from different manufacturers (by A. Teverovsky, NASA). As one can see, Ta capacitors with flawless F-Tech and SBDS demonstrate the highest average BDV for given capacitance value, which indicates the highest long-term reliability in these capacitors. 3. 100% Simulated Breakdown Screening (SBDS) Even with the most advanced manufacturing technology, there is a probability that some of the finished capacitors have small hidden defects in their dielectrics that can’t be detectable by DC leakage during end-of-line (EOL) testing and can propagate and cause failures during the field application. Moreover, some overstressed EOL tests and burn-ins can induce new hidden defects into the dielectric without being detected by existing screening techniques. As it was shown earlier, the most efficient way to detect hidden defects in the dielectric is BDV test; however, it’s a destructive test and can’t be used for 100% screening. That’s why simulated breakdown screening (SBDS) was developed that allows screening of Ta capacitors with low BDV without any damage to the population of the capacitors.7 SBDS is based on the analysis of the charging curve, voltage vs. time, for the capacitor in series with the resistor Rs. Prior to the screening, BDV average is determined on a representative sample from every production lot and Rs is calculated from the I(V) characteristics as an average dynamic resistance of the capacitors in vicinity of the BDV average. Voltage equal to 1.3-1.5 BDV average is applied to the capacitor in series with Rs. This voltage is disconnected either when voltage drop on the capacitor reaches BDV average or after approximately 1 min of the charging. As an example, Fig. 12 shows charging curves for the capacitors #9 and #12 with I(V) characteristics shown in Fig. 8. Fig. 12. Charging curves for the capacitors #9 and #12 with I(V) characteristics shown in Fig. 8 From the Fig. 12, capacitor #9 achieved quickly BDV average and the test was terminated, while capacitor #12 couldn’t achieve BDV average due to significant voltage drop on the Rs. In this case the test was terminated after 1 min. Monitoring the charging curves of the individual capacitors provides the final screening voltage which correlates with actual BDV. Example of the SBDS distribution is shown in Fig. 13a for D-case Ta/MnO2 capacitors 4.7 uF – 50 V. Fig.13b shows actual BDV distribution in a sample of these capacitors before and after SBDS. a b Fig. 13. SBDS distribution (a) and BDV before and after SBDS (b) in Ta/MnO2 capacitors 4.7 uF – 50 V As one can see in Fig. 13a, there is about 1% “tail” of low screening voltages in the SBDS distribution. Inset in Fig. 13a shows that DCL values before and after SBDS were low in all the capacitors including the “tail”. This is because high Rs value limits current through the capacitors during the SBDS which prevents any damage to the capacitors. Actual BDV distribution after the SBDS (Fig. 13b) confirms that the parts with low BDV were removed, while no damage (no change in BDV) was done to the parts from normal population. The Ta/MnO2 capacitors from the “tail” and from the normal population in the SBDS distribution were submitted to the accelerated life test (Fig. 14). WeakDCL Data - 064H128 - T495X107K016 - 20 pieces - Identified as 'WEAK' in Screening WeakDCL Data - 064H128 - T495X107K016 - 20 pieces - Identified as 'STRONG' in Screening 99.99% 99.9% 99.99% Pre-Lifetest. Median DCL: 1.60µA Post 24hrs at 1.32Vr, 85°C. Median DCL: 1.00µA Post 24hrs at 1.6Vr, 85°C. Median DCL: 1.05µA Post 24hrs at 1.88Vr, 85°C. Median DCL: 2.06µA 99.9% 99% 95% 95% 90% 90% 80% 80% 70% Normal Percentile Normal Percentile 99% Pre-Lifetest. Median DCL: 1.19µA Post 24hrs at 1.32Vr, 85°C. Median DCL: 0.32µA Post 24hrs at 1.6Vr, 85°C. Median DCL: 0.36µA Post 24hrs at 1.88Vr, 85°C. Median DCL: 0.39µA 50% 30% 70% 50% 30% 20% 20% 10% 10% 5% 5% 1% 1% 0.1% 0.1% JLP - 2/2/07 JLP - 2/2/07 0.01% 0.1 10 1000 0.01% 0.1 100000 DC Leakage (µA) 10 1000 100000 DC Leakage (µA) a b Fig. 14. DCL distribution during accelerated life test of the Ta/MnO2 capacitors from the “tail” (a) and normal population (b) in the SBDS distribution. According to Fig. 14, there were 7 catastrophic failures from 20 pcs tested (29%) in the “tail”, while no failures or DCL increase in the normal population. Fig. 15 shows circuit boards with “tail” parts (a) and normal population parts (b) before and after the accelerated testing a b Fig. 15. Circuit boards with “tail” (a) and normal population (b) after the accelerated test As one can see, there are seven damaged parts in the “tail” while no damage in normal distribution. The data in Fig. 14 and 15 confirm that the “tail” of the SBDS distribution represents unreliable parts with hidden defects in the dielectric not detectable by DCL, while normal population of the capacitors represents reliable parts not affected by the SBDS and capable of withstanding highly accelerated tests.. 4. Resistance to Reflow-Surge and Surge Step Stress Test (SSST) Thermal shock during board mounting and subsequent surge test can damage Ta capacitors and cause early (power on) failures. J. Prymak and J. Marshall developed surge step tress test (SSST) to evaluate failure rate at given application voltage.8 In this test the capacitors undergo one or several reflow steps followed by several short pulses when the current in the circuit is limited only by the very low internal resistance of the power supply. The amplitude of the pulses is gradually increasing until all the capacitors fail short which is indicated by the blown fuses. The failure rate vs. pulse voltage is graphed to determine the failure rate at a given applied voltage. The capacitor manufacturing processes affect strongly the SSST results. As an example Fig. 16 shows SSST results for two lots of Ta/MnO2 capacitors D-case 4.7 uF – 50 V having the same F-Tech anodes, dielectrics, and internal cathode layers, but different external top-coating layers. Fig. 16. SSST results for two lots Ta/MnO2 capacitors 4.7 uF – 50 V with different top-coatings From Fig. 16, there is a drastic difference in failure rate at rated voltage (below 0.1% vs. 50%) for these two lots. Cross sections of the capacitors from these lots are shown in Fig. 17. On these images light rectangular is porous Ta anode with the oxide dielectric, dark layer on anode surface is external MnO2 coating with thin carbon layer, and above that are light silver layer, silver adhesive, and lead-frame. Fig. 17. Cross sections of the capacitors from the two lots with SSST distributions shown in Fig. 16. As one can see, the top-coating on the left image is thin and non-uniform which was caused by a misprocess during the capacitor manufacturing. In some local areas silver penetrates the top-coating and can come in direct contact with the dielectric under thermal and mechanical stress during reflow and surge. In contrast to that, the image on the right shows normal uniformly thick external coating without silver penetration. SSST supplements FTech and SBDS to make sure that uniformly thick and dense external coating is applied to Ta capacitors to protect dielectric from thermal and mechanical stress during reflow and surge and avoid power-on failures. Conclusions The high reliability principles in manufacturing of Solid Ta/MnO2 capacitors with MnO2 cathodes include: 1. Scientific foundation – deep understanding of the major degradation mechanisms responsible for the failures. Scientific results are presented in peer reviewed publications in reputable scientific sources. The major reason for the catastrophic failures of Solid Ta/MnO2 capacitors at normal operation conditions is growth of the crystalline inclusions in amorphous matrix of the dielectric Ta2O5 film. 2. Flawless Technology (F-Tech) – a complex of the manufacturing processes that eliminates hidden defects in the dielectric, like crystalline seeds, that can progress in the field causing disruption of the dielectric and the capacitor failure. 3. BDV as an ultimate indicator of the dielectric quality – monitoring manufacturing lots and screening maverick lots by the BDV test of the representative sample from every production lot. DCL at normal conditions can’t detect small hidden defects in the dielectric, while overstress above maximum acceleration factor in the Weibull grading can induce new hidden defects in the dielectric of the whole population of the capacitors. 4. 100% simulated breakdown screening (SBDS) – screening of the unreliable parts with low BDV without any damage to the population of the capacitors.. 5. Resistance to reflow-surge and Surge Step Stress Test (SSST) –protecting the dielectric in the capacitors from thermal and mechanical shock related to reflow and surge. The major focus to address this issue in the capacitor manufacturing is on uniform, thick, and dense cathode top-coating. As it is shown in the companion paper, Solid Ta/MnO2 capacitors manufactured under these principles and used with the best end-user’s manufacturing processes demonstrate the highest reliability needed for the most critical applications. The customers have never reported any failures in these capacitors. Acknowledgment The authors would like to thank KEMET’s Ed Jones for promoting new types of Solid Tantalum capacitors with FTech and SBDS for Hi-Rel applications. References: 1. T. Tripp and Y. Freeman. Major Degradation Mechanisms in Tantalum and Niobium-based Capacitors. Components Technology Institute, 2008 2. Y. Pozdeev-Freeman, Y. Rosenberg, A. Gladkikh, M. Karpovski and A. Palevski. Critical Oxygen Content in Porous Anodes of Solid Tantalum Capacitors. Journal of Materials Science: Materials in Electronics. 9 (1998) 309-311 3. Y. Pozdeev-Freeman, A. Gladkikh, M. Karpovski and A. Palevski. Effect of Dissolved Oxygen on Thermal Oxidation in Ta2O5/Ta Sandwich. Journal of Electronic Materials. Vol. 27, No. 9 (1998) 1034-1037 4. Y. Pozdeev Freeman and A. Gladkikh. Effect of Thermal Oxide on the Crystallization of the Anodic Ta2O5 Film. Journal of electronic Materials, Vol. 30, No. 8 (2001) 931-936 5. H. Haring, Summit, and R.L Taylor. Dry Electrolytic Device. US Patent No. 3,166,693 6. A. Teverovsky. “Degradation Leakage Currents in Solid Tantalum Capacitors Under Steady-State Bias Conditions”, 60th Electronic Component and Technology Conference, Las Vegas, NV, 2010 7. Y. Freeman. Screening of Electrolytic Capacitors, US Patent No 7,671, 603 B2 8. J. Prymak and J. Marshall. “Surge Step Stress Testing (SSST) of Tantalum Capacitors”, Proceedings CATRS USA 2001, P. 181, Las Vegas, NV