* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

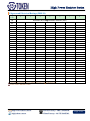

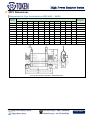

Download High Power Resistor Series

Survey

Document related concepts

Skin effect wikipedia , lookup

Electrification wikipedia , lookup

Buck converter wikipedia , lookup

Thermal runaway wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Mains electricity wikipedia , lookup

Power engineering wikipedia , lookup

Power MOSFET wikipedia , lookup

Current source wikipedia , lookup

Rectiverter wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Lumped element model wikipedia , lookup

Potentiometer wikipedia , lookup

Alternating current wikipedia , lookup

Distribution management system wikipedia , lookup

Surface-mount technology wikipedia , lookup

Transcript