* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Test 2 Results - Senior Design

Survey

Document related concepts

History of electric power transmission wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Electric battery wikipedia , lookup

Stray voltage wikipedia , lookup

Distribution management system wikipedia , lookup

Charging station wikipedia , lookup

Voltage optimisation wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Rechargeable battery wikipedia , lookup

Power electronics wikipedia , lookup

Alternating current wikipedia , lookup

Opto-isolator wikipedia , lookup

Buck converter wikipedia , lookup

Portable appliance testing wikipedia , lookup

Transcript

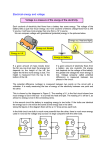

For Electric Vehicles Team Members: Pramit Tamrakar - EE Jimmy Skadal - EE Hao Wang - EE Matthew Schulte - EE William Zimmerman - EE Advisor: Ayman Fayed Client: Adan Cervantes Team-id: SdMay11-04 Problem Statement To develop an efficient and safe system for charging and monitoring of multicell series batteries in Electric Vehicles using a switching mode power supply. Concept Description Design a Lithium Ion Battery Charger that is capable of safely charging 16 parallel packs of 90 cells in series (Large Scale System). Successfully build an 18 cell charger that is capable of monitoring and balancing the cells. (Small Scale System) Operating Environment The large scale product must be able to operate inside an electric vehicle. Various vibration and temperatures may need to be considered. However, the scaled down version is a proof of concept, therefore, must operate in laboratory conditions. User interface description The user interface for this scaled down system will be the EVM GUI that displays the status of the batteries and the switch on the DC power supply. For the large scale system, the user will have the EVM GUI display inside the vehicle and only need to worry about plugging the vehicle in. Functional Requirements Constant-Current Constant-Voltage (CCCV) charging procedure Battery Gauging Temperature Monitoring Under Voltage and Over Voltage Detection Non-functional Requirements Should be usable by our client during the development of the scaled up version. The system should be reliable. Ensuring Safety The system should be robust and long-lasting. Charging Goal 18 Series Batteries, 2.3 Ah each 45 minute CCCV charge Market Survey Commercially available switching mode power supply for electric vehicles is offered by Brusa. The NLG5 provides a high voltage power source from a 120V or 240V wall outlet. Cost: over $2,000 Brusa does not have a Battery Management Systems. NLG503-light battery charger. 1.6 kW 200-540V, $2,145 Deliverables A presentation giving a general overview of Battery Charging System A written report detailing: o Small scaled system o Overall processes and means by which our system operates o A summary of the development process Small scaled prototype Resource Requirements Time A significant amount of time has been required to complete this project Money $569.24 has been spent on this project Parts Li-ion batteries MSP430 microcontrollers EVM boards and related software/code Inductors, diodes, power transistor, resistors, capacitors, perf boards and various other circuit equipment Tools and Lab Access Access to soldering equipment, suitable power supply and various other laboratory equipment Project Plan Work breakdown Task 1 – Problem Definition Task 2 – Acquire a suitable power source Task 3 – Boost Converter Design Task 4 – bq76PL536EVM-3BMS system design Task 5 – Building and Testing Task 6 – Documentation and Demonstration Project Schedule Risk Electric Shock: The risk of electric shock is possible when working with a charging system. System Component Damage: As power is being applied and the charging system is running, the risk of overheating, voltage/current spikes, and incorrect connections are possible. Mitigation Testing and Simulation: To prevent component damage and ensure proper design, the system will be modeled to test for expected results. Lower Volt System: With the 27V – 60V scaled down system, the risk a shock is reduced. Smart and Safe: By knowing how to be safe and building the system with human/component safety in mind will aid in avoiding risk. System Requirements Li-Ion Battery Management Constant-Current Constant-Voltage charging procedure Battery Gauging Temperature Monitoring Overcharge Protection CCCV Charging sequence for Lithium-Ion Batteries Functional Decomposition Large scaled system diagram Small scaled system diagram Hardware Specifications Boost Circuit Provide the needed voltage or current depending on the % PWM signal being input into it. Must take an input Voltage of 27 VDC and must have an output of 28.8 – 64.8VDC. (200 Watts Max) MSP430 Must provide the PWM for the charging cycle. Must receive information about the system. voltage/current and make decisions based on data collected. Must track faults May be used for cell balancing Battery Management System Must collect voltage and temperature data for cell stack. In conjunction with the Aardvark interface and a PC, it is for cell balancing User interface specification Must tell user when the batteries are charging and also indicate when system is fully charged. Can display voltage of cells for user charging and driving purposes. Test plan Test stacked communication of EVMs without cells hooked up. Test Boost Converter circuit with PWM from signal generator and low voltages. Hook up small scale voltage and current circuit to test MSP430 code for CCCV. Test EVMs with Cells connected and ensure PC software can see all devices. Test Boost Converter with MSP430 PWM control at high voltage/current. Do a complete system test with discharged cells. Simulation / prototyping Used PSpice for initial switching mode power supply design. Assemble each section of the system and tested the components in a low voltage and limited current condition. Implementation/Testing Boost Converter Soldered circuit components together on a circuit board which consist of inductors, capacitors, a Power MOSFET, a MOSFET Driver, and voltage divider for ADC use. Test 1: Low voltage/current (6 VDC & 0 - 1.25A) input and test PWM control of output with various loads. Test 2: Efficiency test of output with various loads. Test 3: High voltage/current input (27 VDC & 0 A – 8 A) with 25 ohm power resistor to simulate battery load. Test 3 Setup Test Result Test 1 Results: Successfully output 6-15 Volts at .01-.5A at about 80% duty cycle depending on the load. Test 2 Results: Average 87% (Range of 77% - 99%) Test 3: Results: Successfully output 65.6 VDC at 3.3 A with a 61% duty cycle. Test 1 Test 3 DC Input Test 2 Test 3 Duty % & Output Implementation/Testing Battery Management System Changed resistors on boards the two boards to configure one to be in Host Mode and the other in Slave mode. Test 1: Hooked up each EVM to three DC supplies at 20V. This test will allow a controlled setting for EVM data communication. Test 2: This EVM stacking test will show that communication can be established to all 6 devices while being hooked up to the 18 Li-Ion Cells. Test 1 Setup Test 1 Setup Diagram Test Result Test 1 Results: Successfully displayed the 20V input for each device on the EVM Software GUI with the PC. Test 2 Results: Successfully recognized all 6 devices in the EVM stack while all devices were hooked up to the Li-Ion Cells. Test 2 Setup Test 1 Results: V BRICK shows the 20V DC input Test 2 Results: Displaying expected results Implementation/Testing MSP430 Test 1:The fault line was tested to ensure proper input to the MSP430 Test 2: A constant voltage was applied to the ADC to ensure proper charging during the constant voltage phase (Program was set to regulate at 35 VDC) Test 3: A voltage proportional to the current was applied to the ADC to ensure proper charging during the constant current phase (Program was set to regulate at 1.5 A) Test 2 & 3 Setup Test Result Test 1 result: proper input voltage was detected at the fault line Test 2 result: the proper PWM output was detected and the 35 VDC was kept constant. Test 3 results: the proper PWM output was detected and a 1.5 A output was kept constant. Test 2 PWM Waveform Conclusion / Lesson Learned With global demand for oil increasing and supplies more difficult to obtain, the price of oil based fuels for transportation is expected to rise. The need to find a viable alternative to oil necessitates researching in electric alternatives. Electric vehicles have to be convenient, safe, and affordable to meet the needs of consumers without major sacrifices in perceived quality of life. Lithium ion batteries support a high energy density and are the preferred source of mobile electric power. This project implements a solution for a battery management system for a large number of lithium ion cells. Integration of several smaller complex systems to create a successful overall design is a time consuming process Theoretical models don’t always work as expected so flexibility is necessary The technical aspects of the charging cycles of lithium ion batteries Future Work Our prototype system charges 18 series cells using two EVMs The next step is to develop a large scale system that charges 90 cells and 16 parallel packs Project Success The individual components have been successfully built and tested Boost Converter EVM boards The programming of MSP430 to control the charging cycle Final Testing All discrete components integrated Partial battery charge with cell balancing successful Questions ?