* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Function Of Starter

Spark-gap transmitter wikipedia , lookup

History of electric power transmission wikipedia , lookup

Electrical substation wikipedia , lookup

Opto-isolator wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Current source wikipedia , lookup

Transformer wikipedia , lookup

Electrical ballast wikipedia , lookup

Buck converter wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Voltage regulator wikipedia , lookup

Brushless DC electric motor wikipedia , lookup

Stray voltage wikipedia , lookup

Three-phase electric power wikipedia , lookup

Commutator (electric) wikipedia , lookup

Transformer types wikipedia , lookup

Alternating current wikipedia , lookup

Rectiverter wikipedia , lookup

Mains electricity wikipedia , lookup

Electric motor wikipedia , lookup

Voltage optimisation wikipedia , lookup

Capacitor discharge ignition wikipedia , lookup

Protective relay wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Electric machine wikipedia , lookup

Galvanometer wikipedia , lookup

Ignition system wikipedia , lookup

Brushed DC electric motor wikipedia , lookup

Stepper motor wikipedia , lookup

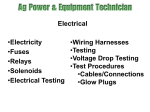

Design of starters for AC motors Group no - 3 Name Chaudhari Darshan M. Chaudhari Hardik D Chavda Mayur N. Joshi Ankur S. Pathak Dhaval K Enrolment no 130090109007 130090109008 130090109010 130090109024 130090109048 Guided By: Prof. Chetan K. Lad Prof. Hetal Patel C.K. PITHAWALA COLLAGE OF ENGINEERING & TECHNOLOGY Function Of Starter The device which is used to start the 3-phase induction motor is called a starter. Necessity Of Starter Function of starter is to limit the starting high current to a safe value. The magnitude of E2 depends upon the flux linking with the rotor conductors and its relative speed. The strength of the rotor flux depends upon the applied voltage. At the instant of applying rated voltage to the stator winding, rotor is stationery and as such the ship is unity. So if full rated voltage is given to the stator winding, then the magnitude of the emf induced in the rotor conductors will be high, because the relative speed between the rotor conductors and stator revolving flux is very high i.e. equal to the synchronous speed of the stator flux. Further the rotor conductors are short circuited and thus have low impedance. Hence, the current drawn by the stator winding or motor is very large, approximately 5 to 7 times the full load current. Direct- on- line starter (D.O.L. starter) Manual primary resistance starter Primary resistance automatic starter Automatic auto transformer starter Manual star – delta starter Automatic star – delta starter Manual rotor resistance starter Automatic rotor resistance starter L1, L2, L3 Lines M Main contacts MA Auxiliary or maintaining contact S1 START PUSH button S2 OFF PUSH button OLC Overload relay coil OL Overload relay contact C Magnetic coil or operating coil Fig (1) : DOL starter A starter which connects a motor directly across the line is called a DirectO3-Line starter , i.e. in this method, the motor is connected by means of a starter across the full supply voltage. Fig. (1) shows a wiring diagram of a push button type Direct-On-Line starter, which is commonly used. It is very simple, inexpensive, easy to install and maintain. It consists of a ‘START’ and ‘OFF’ push buttons, Electromagnetic contactor and overload relay. Switching by this starter is directly from line without any provision to control the starting current i.e. there is no device to reduce the starting current in this starter. Fig (2) Control Circuit Operation When the START push button ‘S1’ is pressed, the circuit is completed from L1 through S2, S1, C (operating coil) and normally closed contacts (O.L.) of the overload relay to L2. i.e. L1 – S2 – S1 – C - O.L. – L2 Thus, the coil C is energized, and it closes contacts M and connects the motor across the line. An Auxiliary or Maintaining contact MA is used to keep the holding or operating coil energized after the finger’s removed from the ‘’START’ push button S1. When the ‘OFF’ push button ‘S2’ is pressed, the supply through the contactor coil C is disconnected.Since the coil C is de-energised, the main contacts M are opened. The supply to the motor is disconnected and the motor stops. In this starter, there is no current limiting device to limit the starting high current, only protection against under voltage and overload is provided. Under Voltage Protection When the supply voltage is below a certain value or in the event of failure of power supply, the coil C is de-energized, therefore motor will be disconnected' from the main supply. Overload Protection The motor is protected against overload by a thermal overload relay which open circuits. The control circuit when over load occurs. In case of an overload on the motor, overload relay coils are energised. The normally closed contacts DOL Is opened and the contactor coil C is de-energized the motor from the supply. In this method of starting. The rate of temperature rise is high and motor may get damaged if the starting period is large, which may be due to excessive load or excessive voltage drop in the supply lines. So small size squirrel cage inductor. Motors up to 5 kW may be this method. Fig(1) : Manual Primary resistance starter In this method of starting of 3- phase induction motor, primary resistances are connected in all the three phase of the stator winding, as a result the applied voltage across the stator winding at the instant of starting is reduced to a fraction K of the rated voltage of the motor. Therefore the initial high starting current will also reduce by the same fraction. The purpose of primary or starting resistors is to drop some voltage and hence reduce the voltage applied across the motor terminals. The torque developed by the motor is directly proportional to the square of applied voltage, so if the voltage applied across the motor terminals is reduced by fraction K, but the starting torque is reduced by a fraction K@ of that obtainable with direct switching. The drawbacks of this method of starting is reduced starting torque and large power consumption and heating of resistors. Hence this method of starting is used for small motors only. L1, L2, L3 Lines S1,S2 Start contents SA Auxiliary or maintaining contact Cs Magnetic coil or operating coil for start contacts Cr Magnetic coil for running contacts TRc Time delay relay coil TR Time delay contact R1, R2, R3 Running contacts R1, r2, r3 primary resistors OLC Overload relay coil OL Overload relay contact PB1 START push button PB2 STOP push button Fig (1) : Primary diagram of a primary resistance automatic starter Operation When the ‘START’ push button PB1 is pressed, the circuit is completed from L1 through PB2, PB1, coil Cs and normally closed contacts (OL) of the overload relays to line L2. i.e. L1 - PB2 – PB1 - Cs – OL – L2 Thus, the coil Cs ( operating coil for start contacts) is energized and it closes all starting contacts S1, S2, S3 and SA. The auxiliary or maintaining contact SA is used to keep the operating coil Cs energized after the finger id removed from this START push button PB1. The primary resistors r1, r2, and r3 in series with line will reduce the starting current drawn from the line. Also, at the same time, the coil TRc of a time delay relay connected across a and b is energized and set the time mechanism. After a definite time delay, contact TR close and circuit is completed through operating coil CR. Pressing the ‘STOP’ push button de-energizes all contactors and thus the supply to the motor Is disconnected and the motor stops. This coil CR becomes energized, close the run contacts . The primary resistors now bypassed, thus connected the motor across the line. Pressing the ‘STOP’ push button de – energizes all contactors and thus the supply to the motor is disconnected and the motor stops. Fig (1) : Manual auto transformer starter In this method, 3-phase auto transformer with fixed tappings is used to obtain reduced voltage for starting the 3-phase induction motors. Normally 50% to 60% tappings can be used to obtain a safe value of starting current. Thus, 50% to 60% of the rated voltage is applied at starting and the auto transformer is cut out of the motor circuit, when the motor has picked up the speed about 70% to 80% of the normal speed. Hence, during normal running condition, the voltage across the stator winding is of rated value. Fig (1) shows the schematic diagram of. Manual auto transformer starter. One problem that occurs with a primary resistor starter is that all the voltage that is dropped through the resistors is turned into heat. The amount of heat may become very large and cause problem, Auto transformer starter is able to provide The same type of voltage reduction without building up large amount of heat. Further in this method of starting, the voltage is reduced by transformation and not by dropping voltage in the resistors and hence the current and power drawn from the supply are also reduced in comparison to primary resistance starter. This starter also provides the large amount of torque per ampere of line current. This method are use in both star and delta connected motors. L1, L2, L3 Lines S1,S2 Start contents SA Auxiliary or maintaining contact Cs Operating coil for Start contacts R1, R2, R3 Running contacts Cr Magnetic coil or operating coil for start contacts ST start contacts Cst Operating coil for start contacts TR Pneumatic timer T.O. Time opening Contact T.C. Time closing contact OLC Overload relay coil OL Overload relay contact PB1 START push button PB2 STOP push button Fig (1) : Automatic auto transformer starter Control Circuit Operation When the ‘START’ push button PB1 is pressed, the circuit is completed from L1 through OFF push button PB2, PB1, operating coil Cs and normally closed contacts (OL) of the overload relays to line L2. i.e. L1 – PB2 – PB1 – Cs - OL – L2 Thus, the coil Cs ( operating coil for start contacts) is energized and it closes all the starting contacts S1, S2, S3 and SA. Further, on staring pressing the ‘START’ push button PB1,at the same time, one alternative path is completed as follows: L1 - PB2 – PB1 – T.O. - CsT – OL – L2 Hence, start coil CST et energized, which closes start contacts ‘ST’. The star contacts connected the three coil ends of the auto transformer together to from the start point and auto transformer connected in series with the motor. Thus the voltage is reduced. After a per – determined time, the pneumatic timing relay opens the star contactors and simultaneously closes time closing switch T.C. At the same time operating coil CR get energized by following path: L1 – PB2 - Auxi. Contact SA – T.C. – ST – CR – OL - L2 All the run contacts (r1, r2 and r3) are than closed placing the motor directly across the line and motor runs with full supply voltage. Pressing the OFF push button PB2 or in case of an overload on the motor de –energized all contactors and therefore disconnect the motor from the supply line. Fig (1) : Manual Star – Delta Starter L1, L2, L3 Lines S Start contents Cs Operating coil for Start contacts D Delta contacts Cd Operating coil for Delta contacts M Line contacts CM operating coil for contacts M TR Pneumatic timer TO Time opening Contact TC Time closing contact OLC Overload relay coil OL Overload relay contact PB1 START push button PB2 STOP push button Fig (1) : Wiring diagram and control circuit of automatic star-delta starter The operating coil CM get energized by following path: ‘ L1 – PB2 – PB1 – CM – OL – OL – OL – L2’ At the same time, the operating coil Cs get energized by following path : ‘ L1 – PB2 – PB1 – TO –D –CS – OL – OL – OL – L2’ The operating coil CD is energized by following path 'L1 - PB2 –MA – TC – S – CD – OL – OL – OL - L2' Pressing the OFF PUSH button, de-energizes all contactors and disconnects the motor from the line. 3 – Phase Ac Supply Fig (1) : Manual rotor resistance starter This method of starting Is only used for slip ring induction motors because in case of squirrel cage induction motors, rotor has copper bars, which are short circuited at both ends. Hence it is not possible to add any external resistance in the rotor circuit. In case of slip ring induction motors, rotor has 3-phase star connected winding whose terminals are connected to three respective slip rings. In rotor resistance starter the three terminals of the rotor winding are connected to a variable external resistances through slip rings. Full supply voltage is applied across the stator. Resistances are fully in the circuit at starting, so that the starting current is reduced. The External variable resistance connected in each phase of the rotor circuit not only reduces the current at starting but increases the starting torque also due to improvement in power factor. The rotor circuit resistance is gradually cut out, as the motor speeds up and during normal running condition, the rotor circuit resistance is completely cut out and the sliprings are short circuited. Fig (1) : Manual rotor resistance starter Fig. (2) Control circuit L1, L2, L3 Lines S Starting contacts Cs Operating coil or Magnetic coil for starting contacts R Running contacts CR Operating coil for running contacts CTR Time delay relay coil TR Time delay relay contact SA Auxiliary starting contact OLC Overload relay coil OL Overload relay contact PB1 START push button PB2 OFF push button Operation Fig (1) shows the wiring diagram of an automatic rotor resistance starter which is commonly used for starting slip ring induction motors and Fig (2) shows its control circuit. This starter consists of start and run contactors, time delay relay, overload relays, START and OFF push buttons. When the START push button PB, is pressed, the circuit is completed from line L1 through OFF push button PB2, PB1 operating coil Cs and normally closed contacts of overload relays of L2. Therefore, the operating coil Cs is energized, closing the starting contacts S and auxiliary contact SA and the motor starts with external starting resistances in rotor circuit which will limit the starting current and improve the starting torque. At the same time, the coil CTR of a time delay relay is also energized and set the timing mechanism. After a predetermined time, contact TR will close and the operating coil for running contacts CR will energized through following path : ‘L1 – pb2 –SA –TR –CR – OL – OL – OL – L2’ Thus, coil CR is energized and causes running contacts R to close and short circuit the starting resistances. Thus external starting resistances get short circuited during running condition and motor runs with full rated speed.