* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Rectification - NYCC SP-01

Survey

Document related concepts

Opto-isolator wikipedia , lookup

Electrical ballast wikipedia , lookup

History of electric power transmission wikipedia , lookup

Stray voltage wikipedia , lookup

Current source wikipedia , lookup

Buck converter wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Mains electricity wikipedia , lookup

Rectiverter wikipedia , lookup

Cavity magnetron wikipedia , lookup

List of vacuum tubes wikipedia , lookup

Video camera tube wikipedia , lookup

Photomultiplier wikipedia , lookup

Alternating current wikipedia , lookup

Vacuum tube wikipedia , lookup

Tube socket wikipedia , lookup

Transcript

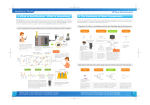

Chapter 4 Rectification and Rectification Systems Rectification The premise of rectification is to convert indirect current into direct current. We have already seen how the x-ray tube operates but we were assuming that the current being supplied to it (to fulfill the second requirement for x-ray production) was such as to make the anode positive in respect to the cathode. This is diagrammed as follows: Rectification What would be the result if we were to connect this tube into the circuit in just the opposite way or if it was connected to alternating current? There would be no attraction for the electrons at the anode target so there would be no flow of electricity and no x-ray production. This may also be very damaging to the tube. Rectification This is therefore the incorrect way to hook up the x-ray tube. But stop a minute- what kind of current is available for us to use on the x-ray machine? It is a 60 cycle alternating current. Alternating current means that the current flow keeps reversing direction and 60 cycle means that there are 60 pairs of reversals per second. Thus the state of the x-ray tube keeps changing from the first diagram to the second and back again at a great rate of speed. Rectification The first part of the cycle may be termed useful voltage; the second part, useless or inverse voltage. We may do one of two things with this inverse voltage: a) Eliminate it as best we can. b) Make it work for us. Any time we eliminate it we have half-wave rectification (this is unidirectional and very inefficient). Rectification When we make it work for us we have full-wave rectification. Both half-wave and full-wave rectification are direct current. Rectification is the process whereby an alternating current is transformed to a pulsating direct current. A device that does this is a rectifier. Rectification There are four basic rectification methods: Self-rectification Mechanical rectification Valve-tube rectification Solid state rectification Rectification Self- Rectification: During the first half-cycle the anode is positive in relation to the cathode so current flows and x-rays are produced. During the second halfcycle the anode is negative so there is no current flow and no x-ray production. This is self-rectification because the tube does its own rectification and is half-wave rectification since only half of the current wave is utilized. Rectification Self-rectification is usually limited to dental and portable units. The highest limits are about 30 MA. at 90 kV. They are limited so because overstepping these bounds can cause temperature rise in the anode target to the point of thermionic emission. In this event the inverse voltage can drive these available electrons towards the cathode filament with consequent damage or destruction of the tube. Although the concept of self-rectification is important, it is all but obsolete today. Rectification ADVANTAGES OF SELF-RECTIFICATION 1. Lowest in price. 2. Less bulk - can be portable. DISADVANTAGES OF SELFRECTIFICATION 1. Limitation of MA. capacity. 2. Constant danger of tube destruction. Rectification MECHANICAL RECTIFICATION Is all but obsolete today, having been replaced by the valve-tube method. In this system a mechanical device inserted in the circuit between the secondary coil of the step-up transformer and the electrodes of the x-ray tube is responsible for the rectification of the current. This mechanical devise is a disc or wheel attached by a shaft to a synchronous motor which is driven by the same current that is applied to the primary coil of the step-up transformer. Rectification There are four contact points on this wheel, connected in two pairs. There are two contacts at the ends of the secondary coil of the step-up transformer. There two contacts make electrical connection during exposure with two of the four wheel contacts. Rectification The rectifying wheel or disc directs the flow of electrons in the following manner so that the anode is always positive in respect to the cathode. Mechanical rectification is therefore full-wave rectification. Advantages of full wave rectification over half-wave rectification includes the fact that the electrons flow in a shorter period of time to get to the desired affect. The time of exposure is decreased close to 50%. Rectification ADVANTAGES OF MECHANICAL RECTIFICATION 1.) It is full-wave rectification and higher MA. is possible 2.) The x-rays produced are uniform because only peak voltage is applied to the tube. This is because contact points are touching only at the moment of peak current and are moving together or moving apart as the current is building or falling. Rectification DISADVANTAGES OF MECHANICAL RECTIFICATION 1.) Noise during exposure caused by sparking across the gap 2.) Ionization of air results in noxious gases as well as making the tube gassy and inefficient 3.) They require a large amount of space 4.) They are not shockproof 5.) The contact points constantly wear out Rectification VALVE-TUBE RECTIFICATION A valve-tube (or thermionic rectifier or kenetron) is similar to a stationary anode xray tube in some respects. It is a highly evacuated glass tube with a tungsten filament in one end (cathode) surrounded by a piece of molybdenum (focussing cup). The valve-tube serves the same purpose as does solid state rectification. Rectification The filament is heated to approximately 2000 degrees Celsius by current from the secondary coil of a filament transformer. As high tension voltage is applied with the anode being positive in respect to the cathode current flows through the tube. No current flows if the current is applied in the reverse direction. Valve tubes are used in rectifying systems by inserting one or more into the machine circuit between the secondary coil of the step-up transformer and the terminals of the x-ray tube. Rectification THERMIONIC RECTIFICATION WITH ONE TUBE: In single tube rectification one tube is inserted into the circuit connected in series with the x-ray tube to prevent the inverse voltage from being applied to the tube. Single tube rectification permits the use of 100 MA. and 100 kV. It is half-wave rectification. THERMIONIC RECTIFICATION WITH TWO TUBES: In two tube rectification the two tubes are hooked up in series with the x-ray tube. One on either side of the xray tube. It is half wave rectification. Rectification THERMIONIC RECTIFICATION WITH FOUR TUBES: Four-valve-tube rectification enables us to use the inverse voltage for the production of x-rays and is therefore full-wave rectification. Rectification The four kenetrons are arranged in a square formation; the anodes of two tubes are connected to each other and to the cathode of the x-ray tube, the cathodes of the other two tubes are connected to each other and to the anode of the x-ray tube. The opposite electrodes of two tubes are attached to one side of the secondary coil of the step-up transformer; the opposite electrodes of the other two tubes are attached to the other side. Rectification ADVANTAGES OF FOUR VALVE-TUBE RECTIFICATION: 1. High MA. capacity 2. Full-wave rectification 3. Eliminates all the disadvantages of mechanical rectification even though the same function is served DISADVANTAGES OF FOUR VALVE-TUBE RECTIFICATION: 1. High cost ($250 per valve-tube)