* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download FORMATION, COMPOSITION AND SOME PROPERTIES OF

X-ray photoelectron spectroscopy wikipedia , lookup

Sessile drop technique wikipedia , lookup

Spinodal decomposition wikipedia , lookup

Ultrahydrophobicity wikipedia , lookup

Deoxyribozyme wikipedia , lookup

Nanofluidic circuitry wikipedia , lookup

Electrochemistry wikipedia , lookup

Rutherford backscattering spectrometry wikipedia , lookup

X-ray fluorescence wikipedia , lookup

Surface properties of transition metal oxides wikipedia , lookup

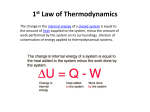

FORMATION, COMPOSITION AND SOME PROPERTIES OF Ni-, Cu- AND Pt-CONTAINING OXIDE LAYERS V.S. Rudnev, L.M. Tyrina, I.V. Lukiyanchuk, A.Y. Ustinov Institute of Chemistry FEB RAS, Vladivostok Abstract. At the present report the results of aluminium alloy composition effect on catalytic properties of coatings formed by micro arc oxidation (or plasma electrochemical oxidation, PEO) technique and containing nickel and copper and the data of platinum building-up into oxide layers on aluminium and titanium under PEO will be presented. The most activity in CO oxidation have been showed by the Ni-,Cu-containing oxide compositions based on aluminium alloys containing Cu, Mg and Mn simultaneously. The possibility of Pt introducing into PEO layers on aluminium and titanium has been established. The films have been investigated with EPXMA and XPS. The films obtained have been included up to 1 at. % Pt. It should be noted that the oxidation level of Pt is 0 (zero) in surface layers on aluminium and +2 in ones on titanium. The results show the possibility of PEO-deposition of catalytic activity coatings on different aluminium alloys. The obtaining films with Pt are promising for catalytic testing in different processes. INTRODUCTION The micro arc oxidation (or plasma electrochemical oxidation, PEO) is one of the methods of obtaining oxide layers of certain composition on the supports from valve metals (aluminium, titanium, magnesium etc.). The corrosion and wear protection of metals became the conventional field of PEO-layers application. In recent years field of potential use of PEO film/Al(Ti) compositions is expanding. For example such compositions can be used in catalysis as support (1) and as catalytic active system (2, 3). Previously we showed that deposited on aluminium alloy the coatings containing compounds of copper and nickel were active in oxidation of CO by O2 at 300-500С (4). Such catalytic active surface structures, being perspective for an environmental application, can be deposited on different parts of internal-combustion engines. So it is important to know the aluminum alloy nature affect on catalytic properties of such compositions. Another problem is related to the investigation of platinum building-up into oxide layers on aluminium and titanium under PEO, because it is of interest for catalytic application of PEO-structures. EXPERIMENTAL The Ni-, Cu- containing PEO layers on samples from aluminum (99.99 Al) and its alloys (AMg2 (1.8-2.8 Mg, 0.2-0.6 Mn), AMg5 (4.8-5.8 Mg, 0.5-0.8 Mn), AMts (1.01.6 Mn), D16 (3.8-4.9 Cu, 1.2-1.8 Mg, 0.3-0.9 Mn) were formed galvanostatically for 10 min at anodic polarization (effective current density iA = 0.1 A/cm2). Electrolytic cell, PBWNiCu-electrolyte preparation features and current power supply were described in (4). Pt-containing PEO layers on aluminum alloy AMts and titanium (99,9%Ti) samples (dimensions 2550.5 mm) were formed at iA = 0.1 A/cm2 during 63 6 and 10 min respectively in aqueous electrolytes included 0.049 mol/l Na6P6O18 and 1.9∙10-3 (I) or 2.9∙10-3 mol/l H2PtCl6 (II). Furthermore on aluminum alloys coatings were formed by alternating current of power frequency (50 Hz) at an effective current density of 0.2 A/cm2. The pretreatment of aluminum alloys samples included chemical polishing in mixture of concentrated acids H3PO4/H2SO4/HNO3=4:2:1 (by volume) at 110-120C. And the titanium samples were chemically polished in mixture HF/HNO3=1:3 at 70C. The polished samples were washed with distilled water and dried in air at 70C. The thickness of layers was determined using an eddy-current thickness gauge. Data on elemental composition and surface morphology were obtained on a JXA 8100 Electron Probe Microanalyzer (Japan) with INCA energy spectrum analyzer (the United Kingdom). X-ray diffraction patterns were measured on D8 Advance X-ray diffractometer (Germany) using CuK radiation. X-ray diffraction analysis was performed with the use of EVA retrieval program with PDF-2 database. X-ray photoelectron spectroscopy (XPS) was used for surface analysis. The XPS spectra were measured on Specs ultrahigh-vacuum system using a 150-mm electrostatic hemispherical analyzer. Ionization was performed using MgK radiation. The working vacuum was 210-7 Pa. The spectra were calibrated using the C1s lines of hydrocarbons, whose energy was taken equal to 285.0 eV. The bombardment by argon ions with 5000 eV energy has been used for etching of surface layers. Catalytic tests were performed using a BI-CAT flow 4.2(A) multipurpose flowtype system (Boreskov Institute of Catalysis, Siberian Branch, Russian Academy of Sciences). Finely cut wire samples of aluminum alloy or titanium (the geometric surface area of the coating on aluminum alloy was 20 cm2 and that on titanium alloy was 10 cm2) were placed in active zone (0.9 cm in diameter and 3 cm in height) of quartz tube reactor. The initial reaction mixture contained 5% CO and air. The gas flow rate was 50 ml/min. The outlet concentrations of CO and CO2 were determined using a PEM-2 IR gas analyzer. The test temperature range was 20-500C. RESULTS Ni-, Cu-containing PEO coatings on aluminum The elemental composition and thickness of films formed on samples from different aluminum alloys in PBWNiCu-electrolyte are given in Table 1. The thickness of coatings is 8-14 m. The concentration of Ni, Cu, Al, P, O and W in coatings weakly depends on the alloy composition. From alloying elements Mg (AMg2 and AMg5) and Mn (AMtsM) are detected in films. In spite of lack of relation between alloying additions and elemental composition of coatings, the catalytic activities of coatings are different (Fig. 1). Coatings, formed on aluminum alloy D16, simultaneously containing Cu, Mg and Mn as alloying elements, exhibited highest activity in CO oxidation. Compositions supported on AMg5 and AMg2, containing Mg and Mn, have less activity. And PEO layers on aluminum and aluminum alloy AMts are lowest active. In repeated cycles the catalytic activity of all samples increased. A hysteresis loop observed in curves indicates that all samples are activates in high-temperature interaction with the gas mixture. The activator is likely CO. It is known that manganese oxides are one of the most active in CO oxidation. In spite of manganese is detected only in PEO layers supported on AMts alloy they are 64 the least active. So the presence of Mn in lack of Mg and Cu is not improving the catalytic properties of compositions. Table 1. Effect of aluminum alloy on elemental composition (according to X-ray spectroscopic analysis data) and thickness of films formed in PBWNiCu-electrolyte Aluminum alloy Al AMts AMg2 AMg5 D16 h, m 11±2 13±2 14±1 8±1 Ni 3.3 3.2 4.6 4.8 3.2 Cu 0.4 0.4 0.6 0.6 0.5 Elemental composion, at % Al P W Mg 39.2 0.7 0.1 38.8 0.7 0.1 38.1 1.0 0.1 0.8 36.8 1.0 0.1 1.8 39.5 0.8 0.1 Mn 0.2 O 56.3 56.6 54.8 54.9 55.9 Fig. 1. The temperature dependence of the conversion of CO () for PEO layer/aluminum alloys compositions (data of first cycle of catalytic tests), formed in PBWNiCu-electrolyte: 1- aluminum, 2 – AMts, 3 – AMg2, 4 – AMg5, 5 – D16. Thus the nature of aluminum alloy effects on catalytic properties of compositions Ni-, Cu-containing PEO film/ aluminum alloy. In the case of CO oxidation into CO2 aluminum alloys on base of systems Al-Mg (AMg) and Al-Cu-Mg are more perspective for plasma electrolytic deposition for preparation of such compositions. Pt-containing PEO layers on aluminum and titanium The elemental and phase compositions of films on aluminum and titanium formed by PEO technique are given in Table 2. In addition to anodizing metal and oxygen obtained layers includes elements from electrolyte: P, Na and Pt. The platinum concentration is 0.04-0.08. % for coatings on aluminum alloy AMts and 0.2-0.5 at at % for those on titanium. The concentration of Pt in films slightly depends on current mode but increases when concentration of H2PtCl6 in electrolyte is rose. When the concentration of hexachloroplatinate-ions is more then using in experiments the electrolyte becomes unstable on application of current and flocks probable of metallic platinum appear in solution. In this case sparking on electrode surface is absent 65 because of the change of solution composition and state and the increase of concentration of aggressive chloride ions. Under using concentrations of H2PtCl6 the solution of electrolyte turn into colloid after long time plasma electrochemical treatment of metals. When alternative current is applied the electrolyte is more stable than under direct current application. It should be noted that Pt, P and Na content in films on titanium exceeds that on aluminum. It is related with various titanium phosphates formation in layers under plasma electrochemical treatment of titanium in phosphate electrolytes. For example, when Na6P6O18 solution is used, NaTi2(PO4)3 and TiP2O7 are received in the composition of PEO films on titanium, while minor quantity of AlPO4 is obtained in PEO layers on aluminum (5). Table 2. Elemental composition (according to X-ray spectroscopic analysis data) and phase composition of PEO coatings formed in Pt-containing electrolyte. Metal, electrolyte Al, I Al, II Al, I Ti, I Ti, II regime AC AC DC DC DC Pt 0.04 0.08 0.06 0.2 0.5 Elemental composition, at % P Na Al Ti 1.1 0.04 34.6 1.3 0.06 37.9 1.8 0.1 34.4 12.3 0.1 17.2 13.6 0.1 14.9 O 64.2 60.7 63.6 70.2 70.9 Phase composition γ- Al2O3 γ- Al2O3 γ- Al2O3 TiO2 (anatase), Pt TiO2 (anatase), Pt Notes: AC – alternating current of power frequency (50 Hz), DC - direct current. Crystal phases of oxides of metals under treatment such as -Al2O3 on aluminum alloy and TiO2 (anatase) on titanium are formed in PEO films. In addition in films on titanium metallic platinum is detected by XPD, Fig 2. Fig. 2. X-ray diffraction pattern of coating on titanium. Investigations of aluminum and titanium films surface have been carried out using XPS. The example of surface and near-surface (30Å deep, after etching) layers compositions for coating on aluminum is given in Table 3. Considerable quantity of carbon is contained in film surface. The carbon content decrease, when film surface is 66 etched by argon ions beam. So it is possible that carbon located on the surface is adsorbed from air or appeared as contamination. In comparison with elemental composition determined by XSA (Table 2), the content of phosphorus and platinum is higher in surface and near-surface layers. According to binding energy (71.6 eV for Pt4f7/2) platinum present on the aluminum film surface has oxidation level 0. At the same time on titanium film surface platinum appears as Pt2+ (Fig. 3), its binding energy is about 73 eV. It should be noted that under films etching the oxidation level of platinum in PEO films on aluminum is not changed, but Pt0 is present in PEO films on titanium along with Pt2+. The last is agreed with the presence of metallic platinum on X-ray diffraction patterns (Fig. 2). However it is impossible to except the some platinum reduction in near-surface layer under etching by argon ions beam. Table 3. Concentrations of elements in the surface and near-surface layers of films formed in Pt-containing electrolyte on aluminum (Al, II) and binding energy (E) according to XPS data. Element Elemental composition, at % O C P Al Surfacec layer 52.8 14.7 9.1 21.7 Near-surface layer 53.6 2.0 7.1 34.5 Pt 1.7 2.7 E, eV 532.3 (O1s) 285.0 (C1s) 134.7 (P2p) 75.0 (Al2p) 71.6 (Pt4f7/2) Notes: Binding energy is given for initial surface. Fig. 3. X-ray electron spectra of films surface on aluminum alloy (a) and titanium (b). 67 Figure 4 depicts scanning electron micrographs of PEO layers in phase representation. On the SEM-images surface sites with heavy elements appear clearer than others. The films on aluminum and titanium differ in morphology. The films on titanium have bigger surface fragments including pores. Grain-placer mines of clear particles in characteristic dimensions of 1m can be seen on the surface of films on titanium (Fig. 4 c). Fig. 4. Scanning electron micrographs (a phase representation) of Pt-containing PEO layers formed on aluminum alloy (a) and on titanium (b). The surface fragment of film with dispersed particles (c) formed on titanium. 68 According to XSA the film site with dispersed particles includes next elements, at %: 1.4 Pt, 22.4 Ti, 11.8 P, 64.4 O, i.e. the concentrations of platinum and titanium in dispersed particles (micrograines) are higher that those in the film. According to (6) conditions for formation of amorphous or crystal dispersed particles appear in the field of oversaturated solutions located near anode/electrolyte interface under electric discharges. Colloidal particles of oxidizing titanium may serve as nucleation centers. Colloidal particles are formed as result of interaction of titanium ejected from the base material and hydroxide ions in near-anode layer. Electrophoretic deposition of micrograines with the next their conversion by discharges is one of the possible mechanism of formation of multiphase and multicomponent anodic oxide films by PEO technique. The temperature dependences of CO conversion for Pt-containing PEO layer/AMts-alloy compositions formed under DC regime (Al, I and Al, II, table 2) are shown in Fig. 5. PEO coatings formed in Na6P6O18 electrolyte in lack of H2PtCl6 were not active in CO oxidation (curve 1). The catalytic activity of PEO coatings containing 00.4 and 0.08 at % Pt was weakly different. Sharp leap in CO conversion was observed in the temperature range 300-350C. This leap is typical of Ptcontaining catalysts. The activity of the coatings increased upon cooling (hysteresis). Fig. 5. The temperature dependence of the conversion of CO () for Pt-containing PEO layer/aluminum alloys compositions (data of first cycle of catalytic tests), formed in electrolyte with Na6P6O18. The content of Pt in coatings, at %: 1 – 0, 2 – 0.04, 3 – 0.08. The catalysts containing noble metals are traditionally obtained in several stages using different variants of penetration method or filling with noble metal compounds of support, for example of oxide systems or films. Then operations of drying, calcination and reducing of noble metals should be carried out. Data of this work show that plasma electrolytic oxidation technique allows forming surface structures containing noble metals in addition to support metals oxides in one stage. The regime variation and addition of noble metal compounds, not enough aggressive as H2PtCl6, for example platinum nitrate, sulfate or acetate will allow to change the composition and characteristics of surface structures. 69 CONCLUSIONS Along with published data (2, 3), the results obtained in this work demonstrated that the PEO process is promising for the manufacture of catalysts supported on metal substrates, which are active in various reactions. In the case of CO oxidation aluminum alloys on base of the system Al-Mg (AMg) and Al-Cu-Mg (AMts) are more perspective for obtaining the catalytic activity compositions Ni, Cu-containing film/ aluminum alloy. Using the Pt-containing electrolyte allows build-up about 0.08 at % Pt into PEO-layers on aluminum and about 0.5 at % into those on titanium. Platinum is concentrated in surface and near-surface layers of films and affect the catalytic activity of films in CO oxidation. ACKNOWLEDGMENTS We are grateful to Cand. Sci. (Chem.) P.M. Nedozorov for her assistance in performing elemental analysis. This work was supported in part by the Russian Foundation for Basic Research (project no. 06-03-32184) and the Presidium of the Far East Division of the Russian Academy of Sciences (grant nos. 06-I-PV-012 and 06-01-OKhNM-137). REFERENCES 1. Tikhov S.F., Chernykh G.V., Sadykov V.A., Salanov A.N., Alikina G.M., Tsybulya S.V., Lysov V.F.: ‘Honeycomb catalysts for clean-up of diesel exhausts based upon the anodic-spark oxidized aluminium foil’. Catalysis Today 1999 53 (4) 639-46. 2. Patcas F., Krysmann W.: ‘Efficient Catalysts with Controlled Porous Structure Obtained by Anodic Oxidation under Spark-discharge’ Applied Catalysis A: General 2007 316 (2) 240–9. 3. Rudnev V.S., Vasilyeva M.S., Kondrikov N.B., Tyrina L.M.: ‘Plasma-electrolytic formation, composition and catalytic activity of manganese oxide containing structures on titanium’. Applied Surface Science 2005 252 (5) 1211-20. 4. Tyrina L.M., Rudnev V.S., Lukiyanchuk I.V., Ustinov A.Yu., Sergienko V.I., Vasil’eva M.S., Kondrikov N.B. Ni- and Cu-containing oxide layers on aluminum: formation, composition and catalytic properties’. Doklady Physical Chemistry 2007 415 (1) 183-5. 5. Rudnev V.S., Boguta D. L., Nedozorov P. M., Kaidalova T. A.: ‘Anodic layers formed in polyphosphate electrolytes on rectifying metals’ Russian Journal of Applied Chemistry 2006 79 (2) 256-63. 6. Khokhryakov Ye. V., Butyagin P. I., Mamaev A. I.: ‘Formation of dispersed particles during plasma oxidation’ Journal of Materials Science 2005 40 (11) 3007–8. 70