* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download GENERAL DESCRIPTION FEATURES

Survey

Document related concepts

Transcript

3/10

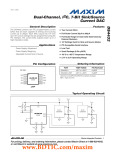

Abridged Data Sheet

DS2460

SHA-1 Coprocessor with EEPROM

www.maxim-ic.com

GENERAL DESCRIPTION

FEATURES

The DS2460 SHA-1 Coprocessor with EEPROM is a

hardware implementation of the ISO/IEC 10118-3

Secure Hash Algorithm (SHA-1), eliminating the need

to develop software to perform the complex SHA

computation required for authenticating SHA devices

and for performing the validation of digitally signed

service data. The DS2460 communicates with a

microcontroller through the popular I²C interface.

Applications include hosts of access control and

electronic payment systems for token authentication

and service data validation as well as generation of

one-time-use encryption keys for short message

encryption and decryption for messages not exceeding the length of a SHA-1 result, which is 20 bytes.

APPLICATIONS

License Management

Secure Feature Control

System Authentication

Clone Prevention

Door Locks

Utility Meters

ORDERING INFORMATION

PART

DS2460S

DS2460S/T&R

DS2460S+

DS2460S+T&R

TYPICAL OPERATING CIRCUIT

VCC

RP

TEMP RANGE

-40°C to +85°C

-40°C to +85°C

-40°C to +85°C

-40°C to +85°C

PIN-PACKAGE

8 SO (150 mils)

8 SO (150 mils)

8 SO (150 mils)

8 SO (150 mils)

+Denotes a lead(Pb)-free/RoHS-compliant package.

RP

Request full data sheet at:

www.maxim-ic.com/fullds/DS2460

VCC

SDA

SCL

µC

Dedicated Hardware-Accelerated SHA Engine

for Generating SHA-1 MACs

112 Bytes User EEPROM for Storing End

Equipment Property Data

I²C Host Interface, Supports 100kHz and 400kHz

Communication Speeds

Three Address Inputs for I²C Address

Assignment

Single-Byte to 8-Byte EEPROM Write

Sequences

64-Bit Unique Registration Number

EEPROM Endurance: 200k Cycles per 8-Byte

Block at 25°C

10ms max EEPROM Write Cycle

Wide Operating Range: 2.7V to 5.5V,

-40°C to +85°C

±4kV IEC 1000-4-2 ESD Protection Level on All

Pins

8-Pin SO (150 mils) Package

VCC

SDA

SCL

AD0

PIN CONFIGURATION

AD1

GND

AD2

GND

AD0

1

8

VCC

AD1

2

7

SCL

AD2

3

6

SDA

GND

4

5

N.C.

Note: Some revisions of this device may incorporate deviations from published specifications known as errata. Multiple revisions of any device

may be simultaneously available through various sales channels. For information about device errata, click here: www.maxim-ic.com/errata.

1 of 9

www.BDTIC.com/maxim

Abridged Data Sheet

DS2460

ABSOLUTE MAXIMUM RATINGS

Voltage Range on Any Pin Relative to Ground

Maximum Current Into Any Pin

Operating Temperature Range

Junction Temperature

Storage Temperature Range

Lead Temperature (soldering 10s)

Soldering Temperature (reflow)

-0.5V, +6V

±20mA

-40°C to +85°C

+150°C

-55°C to +125°C

+300°C

+260°C

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only,

and functional operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is

not implied. Exposure to the absolute maximum rating conditions for extended periods may affect device.

ELECTRICAL CHARACTERISTICS

(-40°C to +85°C, see Note 1)

PARAMETER

Supply Voltage

SYMBOL

CONDITIONS

VCC

MIN

TYP

2.7

Bus idle

MAX

UNITS

5.5

3

V

Standby Current

ICCS

Operating Current

Programming Current

ICCA

IPROG

SHA-1 Computation Current

ISHA

See full version of data sheet

mA

tSHA

See full version of data sheet

ms

Bus idle, +25°C

Bus active at 400kHz

(Note 9)

250

500

1

500

1000

µA

µA

µA

SHA-1 Engine

SHA-1 Computation Time

EEPROM

Programming Time

Endurance

tPROG

NCYCLE

Data Retention

10

At +25°C (Notes 2, 3)

tRET

At +85°C (Notes 4, 5, 6)

LOW Level Input Voltage

VIL

(Note 8)

HIGH Level Input Voltage

VIH

(Notes 8, 9)

Vhys

(Note 9)

ms

200k

40

years

I²C-Pins (Note 7) See Figure 6

Hysteresis of Schmitt Trigger

Inputs

LOW Level Output Voltage at

4mA Sink Current

Output Fall Time from VIhmin to

VILmax with a Bus Capacitance

from 10pF to 400pF

Pulse Width of Spikes that are

Suppressed by the Input Filter

Input Current Each I/O Pin with

an Input Voltage Between

0.1VCCmax and 0.9VCCmax

Input Capacitance

SCL Clock Frequency

Hold Time (Repeated) START

Condition. After this Period, the

First Clock Pulse is Generated.

LOW Period of the SCL Clock

HIGH Period of the SCL Clock

-0.5

0.7 ×

VCC

0.05 ×

VCC

(Note 9)

tSP

SDA and SCL pins only

(Note 9)

Ii

(Notes 8, 10)

Ci

fSCL

(Notes 8, 9)

V

V

V

0.4

V

250

ns

50

ns

-10

10

µA

0

10

400

pF

kHz

VOL

tof

0.3 ×

VCC

VCC +

0.5V

20 +

0.1Cb

tHD:STA

0.6

µs

tLOW

tHIGH

1.3

0.6

µs

µs

2 of 9

www.BDTIC.com/maxim

Abridged Data Sheet

PARAMETER

SYMBOL

Setup Time for a Repeated

START Condition

Data Hold Time

Data Setup Time

Setup Time for STOP Condition

Bus Free Time Between a

STOP and START Condition

Capacitive Load for Each Bus

Line

Note 1:

Note 2:

Note 3:

Note 4:

Note 5:

Note 6:

Note 7:

Note 8:

Note 9:

Note 10:

Note 11:

Note 12:

Note 13:

Note 14:

CONDITIONS

(Notes 11, 12)

(Note 13)

TYP

MAX

UNITS

µs

0.9

tBUF

CB

MIN

0.6

tSU:STA

tHD:DAT

tSU:DAT

tSU:STO

DS2460

100

0.6

µs

ns

µs

1.3

µs

(Note 14)

400

pF

Specification at -40°C is guaranteed by design and characterization only and not production tested.

Write-cycle endurance is degraded as TA increases.

Not 100% production-tested; guaranteed by reliability monitor sampling.

Data retention is degraded as TA increases.

Guaranteed by 100% production test at elevated temperature for a shorter amount of time;

equivalence of this production test to data sheet limit at operating temperature range is established by

reliability testing.

EEPROM writes can become nonfunctional after the data-retention time is exceeded. Long-term

storage at elevated temperatures is not recommended; the device can lose its write capability after 10

years at +125°C or 40 years at +85°C.

All values are referred to VIHmin and VILmax levels.

Applies to SDA, SCL, AD2, AD1, AD0.

Guaranteed by simulation only, not production tested.

I/O pins of the DS2460 do not obstruct the SDA and SCL lines if VCC is switched off.

The DS2460 provides a hold time of at least 300ns for the SDA signal (referred to the VIHmin of the SCL

signal) to bridge the undefined region of the falling edge of SCL.

The maximum tHD:DAT has only to be met if the device does not stretch the LOW period (tLOW) of the

SCL signal.

A Fast-mode I²C-bus device can be used in a standard-mode I²C-bus system, but the requirement

tSU:DAT 250ns must then be met. This is automatically the case if the device does not stretch the LOW

period of the SCL signal. If such a device does stretch the LOW period of the SCL signal, it must

output the next data bit to the SDA line tr max + tSU:DAT = 1000 + 250 = 1250ns (according to the

standard-mode I²C-bus specification) before the SCL line is released.

CB = total capacitance of one bus line in pF. If mixed with HS-mode devices, faster fall-times according

to I²C-Bus Specification v2.1 are allowed.

PIN DESCRIPTION

PIN

1

2

3

4

5

6

7

8

NAME

AD0

AD1

AD2

GND

NC

SDA

SCL

VCC

FUNCTION

I²C Address Inputs; must be tied to VCC or GND. These inputs determine the I²C slave

address of the device, see Figure 5.

Ground Reference

Not Connected

I²C Serial Data Input/Output; must be tied to VCC through a pullup resistor.

I²C Serial Clock Input; must be tied to VCC through a pullup resistor.

Power Supply Input

OVERVIEW

The block diagram in Figure 1 shows the relationships between the major control and memory sections of the

DS2460. The DS2460 communicates with a host processor through its I²C bus interface in standard-mode or in

fast-mode. The logic state of three address pins determines the I²C slave address of the DS2460, allowing up to 8

devices to operate on the same bus segment without requiring a hub. For more information (including Figure 2)

refer to the full version of the data sheet.

3 of 9

www.BDTIC.com/maxim

Abridged Data Sheet

DS2460

Figure 1. Block Diagram

64-bit Unique

Number

SCL

SDA

ADx

2-wire

Function

Control

MAC Output

Buffer

64-Byte Input

Buffer

Command Buffer

and SHA-1

Engine Control

SHA-1

Engine

S-Secret

E-Secret1

E-Secret2

8-Byte EEPROM

Write Buffer

E-Secret3

112-Byte User

EEPROM

DETAILED REGISTER DESCRIPTION

For this section (including Figure 3) please refer to the full version of the data sheet.

DEVICE OPERATION

The typical use of the DS2460 in an application involves writing, reading, running the SHA-1 engine, transferring

secrets and comparing MACs. All these activities are controlled through the I²C serial interface.

I²C Serial Communication Interface

General Characteristics

The I²C bus uses a data line (SDA) plus a clock signal (SCL) for communication. Both SDA and SCL are bidirectional lines, connected to a positive supply voltage through a pullup resistor. When there is no communication, both

lines are HIGH. The output stages of devices connected to the bus must have an open-drain or open-collector to

perform the wired-AND function. Data on the I²C bus can be transferred at rates of up to 100kbps in the Standardmode, up to 400kbps in the Fast-mode. The DS2460 works in both modes.

A device that sends data on the bus is defined as a transmitter, and a device receiving data as a receiver. The

device that controls the communication is called a “master.” The devices that are controlled by the master are

“slaves.” To be individually accessed, each device must have a slave address that does not conflict with other

devices on the bus.

Data transfers may be initiated only when the bus is not busy. The master generates the serial clock (SCL),

controls the bus access, generates the START and STOP conditions, and determines the number of data bytes

transferred between START and STOP (Figure 4). Data is transferred in bytes with the most significant bit being

transmitted first. After each byte follows an acknowledge bit to allow synchronization between master and slave.

4 of 9

www.BDTIC.com/maxim

Abridged Data Sheet

DS2460

Slave Address

The slave address to which the DS2460 responds is shown in Figure 5. The logic states at the address pins AD0,

AD1 and AD2 determine the value of the address bits A0, A2, and A4. The address pins allow the device to

respond to one of eight possible slave addresses. The slave address is part of the slave-address/control byte. The

last bit of the slave-address/control byte (R/W) defines the data direction. When set to a 0, subsequent data will

flow from master to slave (write access mode); when set to a 1, data will flow from slave to master (read access

mode).

Figure 4. I²C Protocol Overview

R/W

MS-bit

ACK

bit

ACK

bit

SDA

Slave Address

Acknowledgment

from Receiver

SCL

1

Idle

2

6

7

8

9

Repeated if more bytes

are transferred

1

2

8

ACK

ACK

START

Condition

9

STOP Condition

Repeated START

Condition

Figure 5. DS2460 Slave Address

7-Bit Slave Address

A6

A5

A4

A3

A2

A1

1

0

AD2

0

AD1

0

Most Significant Bit

AD2, AD1, AD0

Pin States

A0

AD0 R/W

Determines

Read or Write

I²C Definitions

The following terminology is commonly used to describe I²C data transfers. The timing references are defined in

Figure 6.

Bus Idle or Not Busy

Both, SDA and SCL, are inactive and in their logic HIGH states.

START Condition

To initiate communication with a slave, the master has to generate a START condition. A START condition is

defined as a change in state of SDA from HIGH to LOW while SCL remains HIGH. A valid slave address must be

sent by the master and acknowledged by the slave before subsequent START conditions are recognized.

STOP Condition

To end communication with a slave, the master has to generate a STOP condition. A STOP condition is defined as

a change in state of SDA from LOW to HIGH while SCL remains HIGH. A valid slave address must be sent by the

master and acknowledged by the slave before subsequent STOP conditions are recognized.

5 of 9

www.BDTIC.com/maxim

Abridged Data Sheet

DS2460

Repeated START Condition

Repeated starts are commonly used for read accesses to select a specific data source or address to read from.

The master can use a repeated START condition at the end of a data transfer to immediately initiate a new data

transfer following the current one. A repeated START condition is generated the same way as a normal START

condition, but without leaving the bus idle after a STOP condition.

Data Valid

With the exception of the START and STOP condition, transitions of SDA may occur only during the LOW state of

SCL. The data on SDA must remain valid and unchanged during the entire high pulse of SCL plus the required

setup and hold time (tHD:DAT after the falling edge of SCL and tSU:DAT before the rising edge of SCL, see Figure 6).

There is one clock pulse per bit of data. Data is shifted into the receiving device during the rising edge of the SCL

pulse.

When finished with writing, the master must release the SDA line for a sufficient amount of setup time (minimum

tSU:DAT + tR in Figure 6) before the next rising edge of SCL to start reading. The slave shifts out each data bit on

SDA at the falling edge of the previous SCL pulse and the data bit is valid at the rising edge of the current SCL

pulse. The master generates all SCL clock pulses, including those needed to read from a slave.

Acknowledge

Usually, a receiving device, when addressed, is obliged to generate an acknowledge after the receipt of each byte.

The master must generate a clock pulse that is associated with this acknowledge bit. A device that acknowledges

must pull SDA LOW during the acknowledge clock pulse in such a way that SDA is stable LOW during the HIGH

period of the acknowledge-related clock pulse plus the required setup and hold time (tHD:DAT after the falling edge of

SCL and tSU:DAT before the rising edge of SCL).

Not Acknowledged by Slave

A slave device may be unable to receive or transmit data, e.g., because it is busy performing a real-time function,

such as MAC computation or EEPROM write cycle. In this case the slave device will not acknowledge its slave

address and leave the SDA line HIGH.

A slave device that is ready to communicate will acknowledge at least its slave address. However, some time later

the slave may refuse to accept data, e.g., because of an invalid command or access mode, or to signal a nonmatching MAC. In this case the slave device will not acknowledge any of the bytes that it refuses and will leave

SDA HIGH. In either case, after a slave has failed to acknowledge, the master first needs to generate a repeated

START condition or a STOP condition followed by a START condition to begin a new data transfer.

Not Acknowledged by Master

At some time when receiving data, the master must signal an end of data to the slave device. To achieve this, the

master does not acknowledge the last byte that it has received from the slave. In response, the slave releases

SDA, allowing the master to generate the STOP condition.

Figure 6. I²C Timing Diagram

SDA

tBUF

tHD:STA

tF

tLOW

tSP

SCL

tHD:STA

tR

tSU:STA

tHIGH

tHD:DAT

tSU:DAT

Repeated

START

STOP START

6 of 9

Spike

Suppression

tSU:STO

NOTE: Timing is referenced

to VILMAX and VIHMIN.

www.BDTIC.com/maxim

Abridged Data Sheet

DS2460

Read and Write

This section discusses the read and write behavior of the various registers and the EEPROM. Please refer to the

full data sheet for details.

SHA-1 Engine Control

This section describes the user’s view of the SHA-1 engine and how to operate it. For details refer to the full data

sheet (includes Figures 7 to 9 and Tables 1 and 2).

SHA-1 COMPUTATION ALGORITHM

This description of the SHA computation is adapted from the Secure Hash Standard SHA-1 document that can be

downloaded from the NIST website (www.itl.nist.gov/fipspubs/fip180-1.htm). Further details are found in the full

version of the data sheet.

Application Information

SDA and SCL Pullup Resistors

SDA is an open-drain output on the DS2460 that requires a pullup resistor (Figure 10) to realize high logic levels.

Because the DS2460 uses SCL only as input (no clock stretching) the master can drive SCL either through an

open-drain/collector output with a pullup resistor or a push-pull output.

Figure 10. Application Schematic

VCC

RP

VCC

RP

To additional

2-wire devices

SDA

SCL

µC

SDA

SCL

VCC

AD0

AD1

GND

AD2

Example

slave

address =

100 0101

GND

Pullup Resistor RP Sizing

According to the I²C specification, a slave device must be able to sink at least 3mA at a VOL of 0.4V. This DC

condition determines the minimum value of the pullup resistor: RPMIN = (VCC - 0.4V)/3mA. With an operating voltage

of 5.5V, the minimum value for the pullup resistor is 1.7k. The "Minimum RP" line in Figure 11 shows how the

minimum pullup resistor changes with the operating (pull-up) voltage.

For I²C systems, the rise time and fall time are measured from 30% to 70% of the pullup voltage. The maximum

bus capacitance CB is 400pF. The maximum rise time must not exceed 300ns. Assuming maximum rise time, the

maximum resistor value at any given capacitance CB is calculated as: RPMAX = 300ns/(CB*ln(7/3)). For a bus

capacitance of 400pF the maximum pullup resistor would be 885.

7 of 9

www.BDTIC.com/maxim

Abridged Data Sheet

DS2460

Since a 885 pullup resistor, as would be required to meet the rise time specification at 400pF bus capacitance, is

lower than RPMIN at 5.5V, a different approach is necessary. The "Max. Load…" line in Figure 11 is generated by

first calculating the minimum pullup resistor at any given operating voltage ("Minimum RP" line) and then calculating

the respective bus capacitance that yields a rise time of 300ns.

Only for pullup voltages of 3V and lower can the maximum permissible bus capacitance of 400pF be maintained. A

reduced bus capacitance of 300pF is acceptable for pullup voltages of 4V and lower. For fast speed operation at

any pullup voltage, the bus capacitance must not exceed 200pF. The corresponding pullup resistor value at the

voltage is indicated by the "Minimum RP " line.

Figure 11. I²C Fast Speed Pullup Resistor Selection Chart

Max. Load at Min. Rp fast mode

2000

500

1600

400

1200

300

800

200

400

100

0

Load (pF)

Minimum Rp (Ohms)

"Minimum Rp"

0

1

2

3

4

5

Pull-up Voltage

I²C Bus Compliance

Although the I²C protocol definition does not explicitly forbid a START - STOP - START sequence, the DS2460

does not tolerate it. If a START, STOP, START sequence has been issued, transmit the following sequence before

communicating with the DS2460: START, 10xxxxxx byte (x = don’t care bits), ACK/NACK bit, STOP.

PACKAGE INFORMATION

For the latest package outline information and land patterns, go to www.maxim-ic.com/packages. Note that a “+”, “#”, or “-“ in the package code

indicates RoHS status only. Package drawings may show a different suffix character, but the drawing pertains to the package regardless of

RoHS status.

PACKAGE TYPE

PACKAGE CODE

DOCUMENT NO.

8 SO

S8+4

21-0041

8 of 9

www.BDTIC.com/maxim

Abridged Data Sheet

DS2460

REVISION HISTORY

REVISION

DATE

4/09

8/07

3/10

DESCRIPTION

Original release

PAGES

CHANGED

—

Extended Storage Temperature Range to -55°C to +125°C,

Added Note 6 to tRET and changed specification value to 40 years minimum.

2, 3

Soldering temperature changed from referencing JEDEC J-STD-020 to

actual temperatures for soldering and reflow.

Note 9 added to IPROG specification.

Below Figure 11, inserted section I²C Bus Compliance.

2, 9

9 of 9

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. Maxim cannot assume

responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are implied. Maxim reserves

the right to change the circuitry and specifications without notice at any time.

M a x i m I n t e g r a t e d P r o d u c t s , 1 2 0 S a n G a9b of

r i e9l D r i v e , S u n n y v a l e , C A 9 4 0 8 6 4 0 8 - 7 3 7 - 7 6 0 0

www.BDTIC.com/maxim

© 2010 Maxim Integrated Products. Maxim is a registered trademark of Maxim Integrated Products, Inc.