* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download What has been presented?

Survey

Document related concepts

Transcript

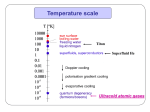

What has been presented? Classification of Matter Matter • has mass and • takes up space (has mass and volume) and • made up of atoms Atom - smallest particle of an element that has the properties of the element States of Matter: Solid Gas Liquid Plasma Phase Changes of Matter- due to changes in energy with and or without changes in temperature Types of Matter Elements Compounds Pure substances •Constant, defined compositions •Physically cannot be separated •Elements, compounds Mixtures Mixtures Composed of one or more elements or compounds Can be separated Know what an element, compound or mixture are Mixtures Homogeneous Heterogeneous Types of Elements Metals Nonmetals Metalloids (semimetals) Metals left side of periodic table most numerous solids lustrous conductors workable Non Metals right side of periodic table all 3 states of matter not lustrous (dull) tend not to be conductors brittle Metalloids (Semimetals) on border between metals and nonmetals (stair step line) fewest # of elements solids intermediate properties Structure of Materials Atomic structure: bonding between the atoms, arrangement of atoms Microstructure: crystalline structure -features that can be seen using a microscope Macrostructure Cracks, - can be seen by the naked eye Microstructure: Crystalline Materials Amorphous Materials Atoms Electrons Protons Neutrons Nucleus Atomic Mass Units Atomic Number Atomic Mass Isotopes Atomic Bonding Metallic Bonding bonding between atoms within metals Ionic Bonding a metal and a nonmetal ion through electrostatic attraction Covalent Bonding a chemical link between two atoms via sharing electrons Van der Waals attractive or repulsive forces between molecules Valence electrons Core electrons The Periodic Table •A representation of the elements •arranged by increasing atomic number •Rows called periods tells number of electron shells number them down the left side of the periodic table –1 through 7 •Columns called families or groups elements in same column have similar chemical properties same number of valence electrons Atoms tend to decrease in size as you go across a period Types of Elements in the Periodic Table Metals Nonmetals • 1 to 3 valence electrons • 5 to 8 valence electrons • givers of electrons • takers of electrons • lose electrons • gain electrons • make (+) ions • make (-) ions • left side of periodic table • right side of periodic table Ions Noble gases –full valence band - very stable –low reactivity - don’t want to form compounds or bonds - under standard conditions, they are all odorless, colorless, monatomic gases Halogens – have s2p5 electron configuration - want one more electron - most reactive nonmetals - Found as ions in compounds because of high reactivity alkali metals –1 s electron in valence band - want to give away one electron - most reactive metals – highly reactive with water Alkaline Earth Metals - React with halogens to form ionic salts - Form Oxides that are very stable at high temperatures - 2 electrons in s orbital Transition Metals - Have incomplete d subshells in valence orbitals - Multiple oxidation states –can form multiple compounds with same elements Properties of Metals Chemical Properties Physical Properties - Thermal Properties - Mechanical Properties Force – Stress – Strain – Workability Brittleness – Hardness - Elasticity Plasticity - Toughness - Strength Stresses and Forces Tension: the pulling force stretches materials Compression: a pushing force squashes materials Torsion: a twisting force Shear: opposing forces http://www.legoeducation.com/sharedimages/content/Large/L_cancrusher.gif www.global-b2b-network.com/direct/dbimage/502 Mechanical Properties • workability malleability – can be flattened ductility – can be drawn into wire (stretched), bent, or extruded • brittleness breaks instead of deforming when stress is applied • hardness resistance to denting or scratching Mechanical Properties • elasticity ability to return to original shape after being deformed by stress Young's modulus is a measure of the stiffness of an elastic material and is a quantity used to characterize materials • plasticity retains new shape after being deformed by stress • toughness – ability to absorb energy • strength – resistance to distortion by stress or force blogs.msdn.com/.../images/610897/original.aspx Absolute Temperature – Minimal Energy Phonons - Elastic Wave that transfer energy in materials Thermodynamics - First Law - ΔU = Q –W - Energy of Phonons – E = hc/l = hv Materials gain or lose heat by gaining or losing phonons - Heat Capacity - Energy required to raise the temperature of one mole of a material by one degree - Specific Heat - energy required to raise temperature of a mass of material by one degree - Thermal Expansion – As atoms gain energy they vibrate more, expanding the crystal lattice - Coefficient of Linear Expansion - DL = La DT If material expansion is restrained, thermal stress developed Causes of Thermal Stress Design of Materials - Joining of Materials Thermal Conductivity - Measure of the rate at which heat is transferred through a material (K) K DT/Dx = Q/A (Heat Flux) Heat Flux flows in the direction of decreasing temperature Electric Properties Thermal Properties: transport of heat through Phonons in a material Electrical Properties: transport of electrons through a material Electrical Conductivity: how well a material accommodates the movement of an electric charge Electrical Resistivity: opposition of a body or substance to the flow of electrical current through it Insulator vs. Conductor Insulators: materials are not good conductor. Minimal current exists when a potential is applied to the material Conductors: materials that conduct electricity. A current will be generated when a potential is applied to a material Ohm’s Law – V = IR Resistivity - resistance dependent on material properties resistivity - ρ of a material: resistance (R) per unit length (L)and cross-sectional area (A) r = RA/L Conductivity s = 1/r Power P= V I Crystals Many materials used in technological applications are made up of one or more crystals Crystalline Materials have Long Range Order Classification of Solids Metals: Steel sheets to make cars or Copper wire Ceramics: Tableware, components in cell phones, glass Polymers: Plastics (short-range order and long-range order) Semiconductors: Electronics Crystallography - science of the arrangement of atoms in solids (or crystals) - physical properties are often controlled by crystalline structure and differences in structure Crystal Lattices and Crystal Structures Crystal Lattices –set of points (atoms) arranged in a repeating manner Crystals are THREE DIMENSIONAL (3D) Crystal Lattices and Structures Structures are obtained by placing one or more atoms at each crystal point Unit Cell The smallest piece of a crystal lattice that contains all the information to make the whole lattice is called a Unit cell, also called the “Single repeating unit” in the lattice Three Basic Cubic Lattices Cubic Lattice Structures A simple cubic lattice consists of one lattice point on each of the eight corners…few materials have this configuration A body-centered cubic lattice consists of a lattice point on each of the corners with one additional lattice point associated n the middle of the lattice. Some Elements: Fe, Mo, W A face-centered cubic lattice consists of eight lattice points located at the corners and has an additional lattice point on each face of the cube in its center. Some Elements: Cu, Pt, Ni Miller Indices for Cubic Structures Lattice planes –planes in crystal structures that cut through the unit cell in different ways. Miller indices use the x, y, z to describe directions in crystal coordinates and to describe the planes. Crystallographic Planes • (110) plane is shaded in grey • Plane is in z direction Atomic Positions in Crystals - For each plane, the atoms have a particular arrangement - EXAMPLE: FCC (100) Number of Atoms in a Unit Cell There are different number of lattice points associated with the unit cells of different lattices. •The corner of each lattice are shared by eight unit cells. Subsequently, ONLY one eighth of each corner atom belongs to any one unit cell. Atomic Packing Atomic Packing informs us of how many atoms that can be places in a given space or volume. We are going to determine the amount of used volume in a cubic from placing the “round” atoms in it. FCC Unit Cell Since there are 6 faces each face shares a unit atom with an adjoining cubic lattice, so there are 3 atoms per unit cell. Body Centered Cubic: Packing Density 68% filled Face Centered Cubic ……….74% filled Defects in Crystals Three main types: Point Defects Line Defects Interfacial Defects Crystal Defects Simplest point defect is a vacancy. A vacancy is merely a missing atom in the crystal Three types of Point Defects Substitution Interstitial Vacancy Dislocation (Line Defects) regions in crystals where atoms are not perfectly aligned – an extra partial plane Defects can move a small number make a metal more workable a large number make a metal harder to work dislocations can get “jammed” or “pinned” makes the metal harder = work-hardening The most common type of line defect is a dislocation. Plane of atoms that does not extend all the way through the crystal but terminates abruptly in the crystal As the distance from the dislocation increases, atom positions become closer and closer to their lattice sites Shear stress applied to a dislocation will result in the formation of a step Dislocation is now on outside of crystal Grains –portion of a material within which the arrangement of atoms is identical Grain Boundaries –interface where grains of a polycrystalline material meet Interfacial Defects A grain boundary is the interface between two grains in a polycrystalline material. Grain boundaries disrupt the motion of dislocations through a material, so reducing crystallite size is a common way to improve strength Grain Sizes Sample Preparation can affect grain sizes. Quick Cooling -smaller grain size Slow Cooling –larger grain sizes Smaller Grain sizes →more grain boundaries Larger Grain sizes →fewer grain boundaries At low temperatures: Smaller grains increases the strength of a material because the amount of grain boundaries increases. Grain boundaries act as barriers to dislocation movement (at regular temperatures) At high temperatures: Smaller grains decreases the strength of a material because grain boundary sliding may occur. Grain boundaries become regions of weakness Grain boundaries can affect other materials properties. High energy –sites for onset of corrosion Corrosion Can improve strength by reducing dislocation movement Decrease the electrical and thermal conductivity What is Diffusion? Mechanism by which matter is transported through matter Diffusion Speed Gases > Liquids > Solids Diffusion required for: Heat treatment of metals Manufacture of ceramics Solidification of materials Types of Diffusion Self-diffusion: movement of atoms through their own lattice Interdiffusion (impurity diffusion): diffusion of species not part of the crystal structure Example: movement of Ni through the lattice of Cu Mechanisms of Diffusion Vacancy: involves vacancies in crystal structure Interstitial: involves atoms in interstitial locations in crystal Conditions for atom migration: empty adjacent site. Atom must have enough energy to break bonds and cause lattice distortion during displacement. Interstitial Diffusion Migration of interstitial atoms from and interstitial position to adjacent empty one •Diffusing atoms are small compared to atoms in crystal–