* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Pisa_Mai_2012_IvanPeric

Framebuffer wikipedia , lookup

List of 8-bit computer hardware palettes wikipedia , lookup

Active shutter 3D system wikipedia , lookup

BSAVE (bitmap format) wikipedia , lookup

Apple II graphics wikipedia , lookup

Subpixel rendering wikipedia , lookup

Charge-coupled device wikipedia , lookup

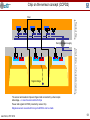

Active Pixel Sensors in high-voltage CMOS technologies for ATLAS Ivan Perić University of Heidelberg, Germany Ivan Peric, WIT 2012 1 Introduction: High-Voltage CMOS Pixel Detectors Ivan Peric, WIT 2012 2 HV CMOS detectors • • • • High-voltage particle detectors in standard CMOS technologies (or “smart diode arrays” - SDAs) are a new detector family that allows implementation of low-cost radiation-tolerant detectors with good time resolution. The deep n-well in a p-substrate is used as the charge-collecting electrode The entire CMOS pixel electronics are placed inside the deep n-well. PMOS transistors are placed directly inside the deep n-well, NMOS transistors are situated in their p-wells that are embedded in the deep n-well as well. A typical reverse bias voltage is 60 V and the depleted region depth ~15 m. Signal charge collection occurs mainly by drift. 2.5µm Input of the amplifier The use of a high voltage technology is not mandatory for the concept . A SDA structure has been also implemented in a low-voltage 65 nm technology Pixel size is 2.5µm! Ivan Peric, WIT 2012 Transistors Deep n-well SDA detector N-well contact Depleted p-substrate between and underneath n-wells (white area) Nine pixels of the SDAbased pixel detector implemented in 65nm CMOS technology. 3D presentation of the real layout. HV CMOS detectors Pixel “Smart” Diode n-Well Drift Potential energy (e-) ~15µm Depletion zone P-Substrate “Smart diode” array The third dimension illustrates electron potential energy. Ivan Peric, WIT 2012 4 Strong points • • • • • • • 1) Active sensor 2) CMOS in-pixel electronics – “intelligent “detectors. 3) Fast signal collection – ~15μm drift path, 50V 4) Thinning possible – Since the charge collection is limited to the chip surface, the sensors can be thinned. 5) Price and technology availability – Standard (HV) technology without any adjustment is used – Many industry relevant applications of HV CMOS technologies assure their long tern availability. – 180nm technology: 160k€ and 1.5k€/8 inch wafer (1 wafer ~ 200 cm2) – The structure can be also implemented in many low voltage technologies. 6) High tolerance to non-ionizing radiation damage – High drift speed – Short drift path 7) High tolerance to ionizing radiation – Deep submicron technology – Radiation tolerant design can be used. – PMOS transistors, that are more tolerant to radiation, can be used as well in contrast to standard MAPS. Ivan Peric, WIT 2012 5 Capacitive Coupled Pixel Detectors - CCPDs Ivan Peric, WIT 2012 6 CCPD Pixel Readout chip Glue Smart diode- or fully-depleted sensor Signal charge The signal from sensor chip is transmitted capacitively to the readout chip. The sensor and readout chips are flipped and glued . Ivan Peric, WIT 2012 7 CCPD – test chip Monolithic matrix CCPD matrix (sensor) Electrodes for capacitive transmission CCPD matrix (readout) Sensor and readout matrix implemented as same design (to save costs) Ivan Peric, WIT 2012 8 CCPD - test system wire bonds Chip A Sensor pixels chips Signal transmission PCBA Chip B Sensor pixels PCBB Readout pixels Sensor electrode E-field Readout electrode Readout pixels Ivan Peric, WIT 2012 9 High-Voltage CMOS Detectors for ATLAS Ivan Peric, WIT 2012 10 CCPD Concept Ivan Peric, WIT 2012 11 CCPD for ATLAS pixel detector • • Replacing the passive diode-based pixel sensor with an “intelligent” pixel sensor implemented in HV CMOS technology. Intelligence: the pixels are able to distinguish a signal from the background and to respond to a particle hit by generating an address information. Pixel readout chip (FE-chip) Pixel electronics based on charge sensitive amplifier Bump-bond pad Bump-bond Pixel length = 250 μm Pixel sensor Ivan Peric, WIT 2012 12 CCPD for ATLAS pixel detector • • The HVCMOS sensor pixels are smaller than the standard ATLAS pixels, for instance 25μm x 125μm - so that several such pixels cover the area of the original pixel. The HV pixels contain low-power (~5 μW) CMOS electronics based on a charge sensitive amplifier and a comparator. Pixel readout chip (FE-chip) Pixel electronics based on charge sensitive amplifier Coupling capacitance Bump-bond pad Glue Transmitting plate Pixel CMOS sensor Ivan Peric, WIT 2012 Summing line 62.5 or 125 μm 13 CCPD for ATLAS pixel detector • • • The electronics responds to a particle hit by generating a pulse. The signals of a few pixels are summed, converted to voltage and transmitted to the charge sensitive amplifier in the corresponding channel of the FE chip using AC coupling. For comparison and testing purposes, the signal transmission can – in addition to capacitive coupling – also be established by classical bump-bonding. Pixel readout chip (FE-chip) Pixel electronics based on charge sensitive amplifier Coupling capacitance Bump-bond pad Glue Transmitting plate Pixel CMOS sensor Ivan Peric, WIT 2012 Summing line 62.5 or 125 μm 14 CCPD for ATLAS pixel detector • • Each of the pixels that couple to one FE receiver can have its unique signal amplitude, so that the pixel can be identified by examining the amplitude information generated in FE chip. In this way, spatial resolution in - and z-direction can be improved. Ivan Peric, WIT 2012 15 Module concept -We plan to design multi-reticle modules. -We do not need electrical connections between reticles -The guard rings at the reticle edge s shouldn‘t lead to insensitivities. -The charge is collected from substrate to nearest pixels. Relicle Sensor1 Guard rings <100µm Relicle Sensor1 Sensor1 Module position in detector Sensor2 Sensor Wire bonds for sensor Pixel Guard ring FE chip PCB Ivan Peric, WIT 2012 Wire bonds for FE chips 16 Advantages compared to existing detectors • • • • • • • • No need for bump-bond connection between the sensor and readout chip – lower price, better mechanical stability, less material Commercial sensor technology – lower price No need for bias voltages higher than 60V Operation at temperatures above 0C is according to tests possible (irradiations to 1015 neq/cm2) Increased spatial resolution (e.g. 25m x 125m binary resolution) with the existing FE chip Smaller clusters at high incidence angles Possibility of sensor-thinning without signal loss. Since we do not use bumps and FE chips can be thinned as well, the amount of material would be very low. Interesting choice for other experiments where low-mass detectors are needed such as CLIC, ILC, CBM, etc... Ivan Peric, WIT 2012 17 Strip-like Concept Ivan Peric, WIT 2012 18 Pixel detector compatible to strip-readout electronics • Present LHC strip detectors consist of large-area strip sensors that are connected by wire bonds to multi-channel ASICs. Readout ASIC (such as ABCN) Comparator or ADC Ivan Peric, WIT 2012 CSA Wire-bonds Strip sensor Strip 19 Pixel detector compatible to strip-readout electronics • We replace a strip with a line of pixels in HVCMOS technology. Readout ASIC (such as ABCN) Comparator or ADC Ivan Peric, WIT 2012 Wire-bonds Pixels CMOS sensor CSA 20 Pixel detector compatible to strip-readout electronics • • Every pixel generates a digital pulse with unique amplitude of logic one. The pixel outputs are summed, converted to voltage signal and transmitted to readout ASIC. Summing line Readout ASIC (such as ABCN) Comparator or ADC Ivan Peric, WIT 2012 Wire-bonds Pixels CMOS sensor CSA 21 Pixel detector compatible to strip-readout electronics • • • • • • • • A large area CMOS sensor can be produced by stitching several 2cm x 2cm wafer reticles. Any arbitrary pixel group pattern is possible. Advantages: Commercial sensor technology – lower price per unit area Intrinsic 2D spatial resolution (e.g. 25 m x 125 m binary resolution) No need for bias voltages higher than 60V Operation at temperatures above 0C is according to tests possible (irradiations to 1015 neq/cm2) Thinning possible Ivan Peric, WIT 2012 22 Simultaneous readout from two 2D sensitive layers • Simultaneous readout from two 2D sensitive layers. Signals from two sensor layers can be easily combined in a single readout ASIC. CSA Ivan Peric, WIT 2012 Comparator or ADC 23 Test Chip HV2FEI4 Ivan Peric, WIT 2012 24 HV2FEI4 • • • Pixel matrix: 60x24 pixels Pixel size 33 m x 125 m 21 IO pads at the lower side for CCPD operation 40 strip-readout pads (100 m pitch) at the lower side and 22 IO pads at the upper side for strip-operation Pixel contains charge sensitive amplifier, comparator and tune DAC We have received the chips last week – first results very soon. IO pads for strip operation Pixel matrix 4.4mm • • • Strip pads IO pads for CCPD operation Ivan Peric, WIT 2012 25 Pixel electronics Amplifier CCPD electrode G SFOut Filter Comparator (CR filter) A D Cap. Injection Output stage In<0:3> RW G D G Select 4-bit DAC CCPD bus Programmable current Strip bus Ivan Peric, WIT 2012 26 CCPD Operation FEI4 Pixels Signal transmitted capacitively CCPD Pixels Bias A 2 2 Bias B 3 3 Bias C 1 Ivan Peric, WIT 2012 1 27 6 Pixels – Layout Electrode Digital part Tune DAC Ivan Peric, WIT 2012 Amplifier Test setup HVCMOS FEI4 PCB PCB HVCMOS FEI4 Ivan Peric, WIT 2012 29 Experimental Results with other Prototypes Ivan Peric, WIT 2012 30 Efficiency and Signal Amplitude Ivan Peric, WIT 2012 31 Rolling Shutter Detector LVDS digital I/Os Single ramp ADC Analog pads ADC channel Pixel matrix 2.7 mm 2-stage switched capacitor difference amplifier Ivan Peric, WIT 2012 32 Test-beam results Spatial resolution Sigma: 3.823m Telescope resolution of 2.3m is not subtracted Y pixel Efficiency vs pixel xy-coordinates (Mean value = 0.9761) X pixel Ivan Peric, WIT 2012 Seed pixel SNR = 27 number of signals Seed pixel SNR SNR 33 Signal Measurements 3250 55 3000 60 Na Co MIPs 2750 Single pixel signal 1200 e Most probable signal [e] 2500 2250 Cluster signal 2000 e 2000 1750 1500 1250 1000 750 500 250 0 1 2 3 4 5 6 7 Number of pixels High energy particle signals depending on number of pixels in cluster. Ivan Peric, WIT 2012 34 CCPD Operation Ivan Peric, WIT 2012 35 CCPD2 detector - photograph Power supply and cont. signals for the readout chip 1.5 mm Power supply and cont. signals for the sensor Readout chip (CAPPIX) Sensor chip (CAPSENSE) Ivan Peric, WIT 2012 36 Noise measurement and efficiency Response probability of all pixels in the matrix to test pulses that generate from 0 to 2000 electrons Threshold scan used to measure noise – noise 23e 100% above ~300e Response probability Fit: Mean = 271e Sigma = 23e 1.0 1.0 0.8 0.8 Response probability Efficiency Efficiency - window 800ns 0.6 0.4 0.2 0.6 0.4 0.2 0.0 0.0 0 500 1000 Signal [e] Ivan Peric, WIT 2012 1500 2000 220 240 260 280 300 320 340 360 380 Signal [e] 37 Radiation Tolerance (CCPD2 Sensor) Ivan Peric, WIT 2012 38 Irradiation with protons (1015 neq/cm2, 300 MRad) 55Fe spectrum and RMS noise Not irradiated Room temperature 1.0 RMS Noise 12 e RMS Noise 0.5mv (12e) Fe 70mV (1660e) Room temperature 55 55Fe spectrum and RMS noise Irradiated 20C 1.0 RMS Noise 270 e 0.8 ~number of signals ~ number of signals 0.8 RMS Noise, 13mv (270e) Fe, 80mV (1660e) Temperature 20C 15 Irradiated with protons to 10 neq 55 0.6 0.4 0.2 0.6 0.4 0.2 0.0 0.0 0.00 0.02 0.04 0.06 0.08 0.10 0.00 0.02 0.04 signal amplitude [V] 0.06 0.08 0.12 signal amplitude [V] 55Fe 55Fe spectrum, RMS noise Irradiated 10C RMS Noise 77 e 1.0 RMS Noise, 2.8mv (77e) Fe, 60mV (1660e) Temperature 10C 15 Irradiated with protons to 10 neq RMS Noise, 2.4mv (40e) Fe, 100mV (1660e) Temperature -10C 15 Irradiated with protons to 10 neq 55 55 1.0 spectrum, RMS noise Irradiated -10C RMS Noise 40 e 0.8 ~number of signals 0.8 ~number of signals 0.10 0.6 0.4 0.2 0.6 0.4 0.2 0.0 0.0 0.00 0.02 0.04 0.06 signal amplitude [V] Ivan Peric, WIT 2012 0.08 0.10 0.00 0.02 0.04 0.06 0.08 0.10 0.12 0.14 0.16 signal amplitude [V] 39 Time Resolution Ivan Peric, WIT 2012 40 Mu3e Detector • • • • • Mu3e experiment at PSI (study of the lepton flavor violating decay mu -> eee) Proposed: four layers of pixels ~ 80x80m2 size – monolithic pixel detector in HVCMOS technology Time stamping with < 100ns resolution required to reduce the number of tracks in an image. Sensors will be thinned to ~50 m Thinned chips Triggerless readout 250 pixel rows (80 μm pitch) 2cm Kapton PCB 1cm ~125 pixel rows (80 μm pitch) Pixels – active region ~0.3 – 0.5 mm EoC logic The figure shows one reticle Ivan Peric, WIT 2012 41 Mu3e Detector • • More details can be seen in poster session: Dirk Wiedner: “A tracker for the novel mu3e experiment based on high voltage monolithic active pixel sensors” Ivan Peric, WIT 2012 42 Mu3e Test Chip in 180nm Technology 39m 1.8mm 42x36 pixels 30m Analog pixels Digital channels Ivan Peric, WIT 2012 0.7m 2 metal layers Analog pixel layout Pixel detector chip with CMOS pixel (42x40 pixels) matrix Pixel size 39x30 micrometers Separated digital and analog block Signal time measurements possible 43 Collection time measurement • • Charge collection time – IR laser, comparison with the fast capacitive injection. No measurable delay versus the capacitive test pulse. Test pulse IR laser - 850nm 0.810 0.810 0.805 0.805 Threshold[V] Threshold[V] Test pulse IR laser - 850nm 0.800 0.795 0.790 0.800 0.795 0.790 0 20 40 60 80 Delay time[ns] Ivan Peric, WIT 2012 100 120 140 0 1000 2000 3000 4000 5000 Time[ns] 44 Time walk measurement • • • In-time efficiency vs. signal amplitude (40ns time window) Detection of signals > 1230 e with 40ns time resolution possible. Power consumption of the pixel 7.5µm. B 40ns window 1.0 Efficiency 0.8 0.6 0.4 0.2 0.0 0 1000 2000 3000 4000 5000 6000 Signal[e] Ivan Peric, WIT 2012 45 Pixel detector in 65nm technology • Pixel size - 2.5µm 55Fe measurement Shadow of 16m thick golden bonding wire 255 0.5000 250 16µm 245 240 1.500 235 2.500 230 3.500 Pixel Zeile 225 220 4.500 215 5.500 210 205 200 195 190 185 180 175 5 10 15 20 25 30 Pixel Spalte Pixel matrix (32x256) Pixel Ivan Peric, WIT 2012 46 Experimental results - overview HVPixel1 – CMOS in-pixel electronics with hit detection Binary RO Pixel size 55x55μm Noise 60e MIP seed pixel signal 1800 e Time resolution 200ns Capacitive coupled hybrid detector CCPD2 -capacitive coupled pixel detector Pixel size 50x50μm Noise 30-40e Time resolution 300ns MIP SNR 45-60 Irradiations of test pixels 60MRad – MIP SNR 22 at 10C (CCPD1) 1015neq MIP SNR 50 at 10C (CCPD2) HV2FEI4 chip (first test next week!!!) CCPD for ATLAS pixel detector Readout with FEI4 chip Reduced pixel size: 33x125μm RO type: capacitive and strip like 3 pixels connected to one FEI channel Monolithic detector – continuous readout with time measurement MuPixel – Monolithic pixel sensor for Mu3e experiment at PSI Charge sensitive amplifier in pixels Hit detection, zero suppression and time measurement at chip periphery Pixel size: 39x30 μm (test chip) (80 x 80 μm required later) MIP seed signal 1500e (expected) Noise: ~40 e (measured) Time resolution < 40ns Power consumption 7.5µW/pixel 1. Technology 350nm HV – substrate 20 cm uniform 2. Technology 180nm HV – substrate 10 cm uniform 3. Technology 65nm LV – substrate 10 cm/10 m epi Ivan Peric, WIT 2012 Monolithic detector frame readout PM2 chip - frame mode readout Pixel size 21x21μm 4 PMOS pixel electronics 128 on-chip ADCs Noise: 21e (lab) - 44e (test beam) MIP signal - cluster: 2000e/seed: 1200e Test beam: Detection efficiency >98% Seed Pixel SNR ~ 27 Cluster signal/seed pixel noise ~ 47 Spatial resolution ~ 3.8 m HPixel - frame mode readout In-pixel CMOS electronics with CDS 128 on-chip ADCs Pixel size 25x25 μm Noise: 60e (preliminary) MIP signal - cluster: 2100e/seed: 1000e (expected) SDS - frame mode readout Pixel size 2.5x2.5 μm 4 PMOS electronics Noise: 20e (preliminary) MIP signal (~1000e - estimation) 47 Conclusion • • • • • • • • • We have developed a new pixel sensor structure (smart diode array) for high energy physics that is implemented in high voltage CMOS technologies. The advantages over conventional silicon sensors include lower cost, lower mass, lower operating voltage, smaller pitch, and smaller clusters at high incidence angles, all with comparable radiation hardness. We have implemented various test structures in 350nm and 180nm technologies and measured excellent detection and radiation properties. Measured time resolution < 40ns (IR laser), detection efficiency ~98% (test beam) Irradiated up to 1015 neq/cm2 and dose 300MRad We would like to integrate our sensors into existing ATLAS readout systems, for this we have two concepts: Capacitive coupled pixel detectors -> readout with pixel readout chips like FEI4 Strip-like sensors -> readout with strip readout AISCs We have designed a test detector (in 180nm HV CMOS technology) to test the two concepts – first measurements soon. Ivan Peric, WIT 2012 48 Thank you Ivan Peric, WIT 2012 49 Backup Slides Ivan Peric, WIT 2012 50 HV2FEI4 - Architecture 12x2 Column control IO pads for strip operation Matrix Cap. Injection SFOut Test Pad 20x3 Column control Strip Pads Bias DACs IO pads for CCPD operation Ivan Peric, WIT 2012 51 Strip and Test-Operation Column control SR Strip bus R2 R2 L2 L2 R1 R1 L1 L1 R0 R0 L0 L0 Bias A Pad Bias B Pad Bias C 3 3 SelectL=0 SelectR=0 Row control SR Mon Pad 33um 125um Ivan Peric, WIT 2012 52 Chip on the sensor concept (CCPD2) Pixel Readout chip Bump for power supply Smart diode- or fully-depleted sensor Signal charge The sensor and readout chips are flipped and connected by a few bumps Advantage – no need to wire-bond both chips Power and signals for ROC provided by sensor chip Edgeless sensor covered with many small ROCs can be made Ivan Peric, WIT 2012 53 CCPD2 – photographs of the chips CAPPIX Power and signal bumps Ivan Peric, WIT 2012 CAPSENSE 54 CCPD2 detector - photograph Power supply and cont. signals for the readout chip 1.5 mm Power supply and cont. signals for the sensor Readout chip (CAPPIX) Sensor chip (CAPSENSE) Ivan Peric, WIT 2012 55 Collection time measurement • Digital part ToT is proportional to collected charge Does not depend on collection speed Test signal Ampl. out del1 1400e Window Comp out Penetration depth of 850nm light ~14um? Similar distribution of charge generation as for MIPs? del2 IR laser signal N-well 5u m Ampl. out 10u m 1400e 60% drift Comp out Window 40% diffusion Ivan Peric, WIT 2012 56 Time walk measurement • Digital part Test signal Test signal Ampl. out Ampl. out Comp out del1 Comp out Window Window del2 Ivan Peric, WIT 2012 57