* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Thermometry - Texas A&M University

Survey

Document related concepts

Transcript

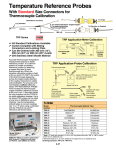

Thermocouples • Thomas Johann Seebeck, 1821, discovered that a circuit of two different metals with junctions at different temperatures produced an electromotive force (EMF), a voltage. • No external source of power is required. Power is self-generated. • Total Seebeck EMF is the manifestation of four distinct EMFs – Fourier Heat Conduction – Joule Heating - Peltier effect - Thomson effect • The net Seebeck EMF is given by: dT • dx Is the change in temperature along the wire. • eA and eB are Seebeck coefficients and are different for each type of wire. • When the wires are homogeneous, uniform in calibration across their length, then: TR ef Es T Jc t TJc t A dT T R ef B dT • If both wires begin at Tref and end at TJct, then: • For small temperature differences, we can use the average calibration: Es A B TJct T Re f AB TJct T Re f • The electromotive force can also be approximated by: Es T1 T2 T1 T2 ..... T1 T2 2 • And, if the reference temperature, T2, is 0oC and higher order constants are negligible, it becomes: Es T T 2 n • The most common thermocouple alloys for moderate temperatures are: – Iron-Constantan (Type J), – Copper-Constantan (Type T), Constantan (55% copper, 45% Ni), and – Chromel-Alumel (Type K). Chromel (90%Ni, 10% Chrome). Alumel (95% Ni, 3% Mn, 2% Al) – Chromel-Constantan [Type E]. Seebeck Coefficients for Various Thermocouples at Reference Temperature, ()oC Thermocouple Type Coefficient V/oC E 58.7 J 50.4 K 39.5 R 5.3 S 5.4 T 38.7 • The first named element of the pair is the positive element. • The negative wire is color coded red (current U.S. standards) • Type T is coded Red-blue, U.S. standard. • USA/CANADA UK FRANCE GERMANY • The calibration of Precision Grade thermocouple wire is guaranteed within ±3.8% or 1oC (2oF) which ever is the larger. • Most meteorological types are Type T (Copper-Constantan). Useful range: -60 to 100oC • They are slightly non-linear in output. • Typical output for Type T is about 40 V • Response time is 1 second or less. • Thermocouples require a Reference Temperature. • There are several different systems for establishing a reference temperature. – Ice Baths: A drug-store thermos flask will maintain 0oC for several hours if filled with finely crushed ice and then flooded with water. – Electronically Controlled Reference: Temperature of the reference connection is electronically controlled. These devices are available, both for high temperature and ice point. They require periodic calibration and generally are not as stable as ice-baths, but more convenient. – Compensated Reference Temperature System: Each wire from a thermocouple probe is terminated at a connection panel inside the chassis of the instrument. – The temperature at this point is measured by another means, e.g., a PRT or thermistor. – A compensation network is used to inject a signal which compensates for the temperature of the panel being different than 0oC before calculating the temperature at the probe. • Peltier Effect: – Reported by Jean Peltier in 1834. – Current forced to flow in one direction would warm the junction and release heat. – Current forced to flow in the opposite direction would cool the junction and absorb heat. – The heat transfer can be described by: qP d AB I – qP is the heat transfer in Watts – dAB is the Peltier coefficient for particular thermocouple materials. – Useful for heating and cooling material. – Used in moisture measuring instruments. • Thompson Effect: – This relates to the absorption or liberation of heat by a homogeneous conductor that has a temperature gradient in it due to a current flowing through it. qT I T1 T2 – qT = Thompson coefficient dependent on material of wire. – It has a small effect on a thermocouple due to the small currents produced by the thermoelectric effect. Thermoelectric Laws • Law of Homogeneous Materials: The thermal EMF of a thermocouple is unaffected by temperatures elsewhere in the circuit if the two metals used are homogeneous. – Thermocouple leads can be made out of thermocouple material. – EMF is determined by temperatures at the junctions, not elsewhere in the circuit. • Law of Intermediate Materials – If a third metal is inserted in either wire A or B and if the two junctions are at the same temperature, there will be no effect on the generated EMF by the addition of the third metal. • Allows the connection of the thermocouple to a voltmeter or an amplifier. • Allows the soldering of the joints of the thermocouple. • Law of Successive Intermediate Temperatures