* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download The Tracker Solenoid Conductor

Stray voltage wikipedia , lookup

Three-phase electric power wikipedia , lookup

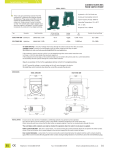

Ground loop (electricity) wikipedia , lookup

Loading coil wikipedia , lookup

Ground (electricity) wikipedia , lookup

Alternating current wikipedia , lookup

Earthing system wikipedia , lookup

Galvanometer wikipedia , lookup

Resonant inductive coupling wikipedia , lookup

Aluminium-conductor steel-reinforced cable wikipedia , lookup

Magnet Conductor Parameters and How They affect Conductor Selection for MICE Magnets Michael Green Lawrence Berkeley Laboratory Berkeley CA 94720, USA CM-18 June 2007 1 MICE Conductor Selection Criteria • Parameters of the Tracker Conductor and the Coupling Coil Conductor • Round versus Rectangular Conductor • Copper to Superconductor Ratio & Copper RRR • Superconductor Filament Diameter • Conductor Current Density • Why jc and n Value are Always Important • Coil Design Current, Conductor Size and the Coil Self Inductance • Comments about the Focusing Magnet Conductor CM-18 June 2007 2 The Tracker Solenoid Conductor CM-18 June 2007 3 The Tracker Conductor Selection Process • The INFN tracker magnet design had a much larger cross-section conductor but the number of turns was about the same as the LBL tracker magnet design. • Using a conductor with a lower copper to S/C ratio resulted in less conductor being used to fabricate the magnet, but the magnet margin wasn’t changed. • The smaller conductor resulted in thinner coils and a lower tracker magnet cold mass. As a result, the tracker magnet cost was reduced without sacrificing magnet performance. The conductor selected was one that LBL knew they could buy at a reasonable price of $1380 per kilometer. CM-18 June 2007 4 The Tracker Solenoid Conductor • The nominal cross-section dimensions of the tracker insulated conductor are 1.0 mm by 1.65 mm. It has rounded corners with a 0.2 mm radius. • The copper to superconductor ratio is 3.9 ± 0.4. The copper RRR = ~70. • The conductor has 222 filaments with a nominal filament diameter of about 41 microns. • The nominal conductor twist pitch is 19 ±3 mm. • The length delivered is 121.5 km, which is ~10 km short of four billets of conductor. • The conductor Ic > 760 A @ 5 T and 4.22 K CM-18 June 2007 5 Conductor Cross-section 1.65 mm 1.00 mm 41 mm Nb-Ti Filament RRR = 70 Copper CM-18 June 2007 6 Tracker Conductor Mechanical Characteristics Both tests look for filament breakup and defects in the filament bundle. The dimensions are acceptable. CM-18 June 2007 7 Tracker Conductor Electrical Characteristics The specified conductor critical current is >760 @ 4.2 K and 5 T. The specified conductor n value is >35. The specified conductor copper to S/C ratio is 3.9 ± 0.4. The RRR values for the conductor copper are acceptable. CM-18 June 2007 8 Critical Current Vs Magnetic Induction CM-18 June 2007 9 The Exposed Conductor Filaments ~2.5 mm Photo by LBNL The conductor twist pitch is within the specified range of values. CM-18 June 2007 10 A Closer Look at the Filaments Photo by LBNL There appears to be no sausaging of the filaments, which suggests the n value will be high. The surface of the filaments appears to be acceptable. It is likely that the conductor jc will be uniform across the conductor section. CM-18 June 2007 11 The Effect of Various Conductor Parameters on Magnet Performance CM-18 June 2007 12 Round versus Rectangular Conductor • A number of magnet vendors prefer winding round conductor because it is easier and faster to wind. The worst shape to wind is a square conductor. • The coil packing fraction for a coil wound with round conductor is lower than for rectangular conductor of the same thickness. (For the tracker solenoid the coil packing fraction is 0.64 vs. 0.81.) • For a given average coil current density and magnet temperature margin, the copper to superconductor ratio has to be reduced by twenty-five percent when the coil is wound with round conductor. • Wind rectangular conductors the easy way. CM-18 June 2007 13 Cu to S/C Ratio and Cu RRR • A conductor with large copper to superconductor ratio has increased dynamic stability, which means larger filaments can be used. • Modern MRI conductors typically have a Cu to S/C ratio of 4. MRI conductors are cheaper to buy than a low Cu to S/C ratio conductor. • Reducing the Cu to S/C ratio from 4 to 2 increases the critical current by 67 percent, but this is done at the expense of conductor stability. As a result, finer S/C filaments are needed in the conductor. • It is desirable to have the copper RRR > 70. One pays more for a larger RRR. There is a trade-off between RRR and filament diameter. CM-18 June 2007 14 Superconductor Filament Diameter df • Low field MRI magnet conductors have larger Cu to S/C ratios (as high as 7) and df = ~80 microns. The higher field MRI magnets have magnet conductors with df < 50 microns for magnet stability. • A magnet with conductor with a smaller filament diameter has lower AC losses. This is important for magnet charging and discharging while on a cooler. • A conductor with a smaller filament diameter is more stable for a given Cu to S/C ratio and RRR. • Making the filament diameter too small increases the conductor cost and reduces the superconductor jc. There is an optimum filament size. CM-18 June 2007 15 Conductor Current Density • The current density in the conductor (matrix plus S/C) directly affects the quench performance of the magnet. For given coil dimensions, this is another reason to use rectangular conductor. • For a given coil current and inductance, the number of passive quench protection diode circuits will go up as the conductor current density to the m power, where 1 < m < 2. Higher RRR and Cu to S/C ratio are better in terms of quench protection. • The desired conductor current density is higher for solenoids with a smaller ID and where the current is squeezed due to other constraints. The magnet stored energy is less for smaller magnets. CM-18 June 2007 16 Why jc and n Value are Important • The key parameter for any superconductor is its critical current density (jc) at a given magnetic field and temperature. • Modern Nb-Ti has a design jc > 2750 A mm-2 at 5 T and 4.22 K. The tracker conductor jc > 2900 A mm-2 at 5 T and 4.22 K measured at a r = 10-14 W m. • The higher the conductor jc, the greater the magnet temperature margin. • The conductor n value is a measure of current sharing in the conductor. A conductor with a large n value is desirable. The n value is a measurement of superconductor uniformity. CM-18 June 2007 17 Coil Design Current, Conductor Size and the Magnet Self Inductance • The design current for all of the MICE channel magnets was set at less than 300 A. MICE will be powered using six 300-A power supplies (seven if MICE operates in the mixed flip and non-flip mode). Four 60 A power supplies are used for the trackers. • Because the coupling magnet has a larger stored energy (~12.4 MJ) than any of the other magnets, its worst-case design current was set at 210 A. • Increasing the conductor size and current appears to be desirable for coil quench protection. A study of this was done at ICST in Harbin. CM-18 June 2007 18 A Comparison of Possible Conductors Tracker Conductor • Insulated Dimensions 1.00 mm x 1.65 mm • Length = ~242 km* • Twist Pitch = 19 mm ± 3 • Copper RRR > 70 • Cu to S/C = 3.9 ± 0.4 • Filament Dia = ~41 mm • n > 35 @ 5T • Ic(4.2K, 5T) > 760 A Larger Conductor • Insulated Dimensions 1.15 mm x 1.90 mm • Length = ~182 km* • Twist Pitch = 19 mm ± 3 • Copper RRR > 70 • Cu to S/C = 3.9 ± 0.4 • Filament Dia = ~ 48 mm • n > 35 @ 5T • Ic(4.2K, 5T) > 1010 A * For two MICE coupling magnets and one MUCOOL coupling magnet CM-18 June 2007 19 Basic Parameters for a 285 mm Long Coupling Magnet with the Tracker Magnet Conductor Parameter Non-flip Flip Coil Length (mm) 285 285 Coil Inner Radius (mm) 744 744 102.5 102.5 96 96 No. Turns per Layer 166 166 Magnet J (A mm-2)* 90.11 95.53 Magnet Current (A)* 165.2 175.1 Magnet Self Inductance (H) ~564 ~564 Peak Induction in Coil (T)* 5.85 6.20 Magnet Stored Energy (MJ)* ~7.7 ~8.6 4.2 K Temp. Margin (K)* ~1.8 ~1.6 Coil Thickness (mm) Number of Layers •Design based on p = 200 MeV/c and beta = 420 mm. One would like to run the magnet up to 210 A in the flip mode. CM-18 June 2007 20 Basic Parameters for the 285 mm Long Coupling Magnet with a Larger Conductor Parameter Non-flip Flip Coil Length (mm) 285 285 Coil Inner Radius (mm) 744 744 102.1 102.1 84 84 No. Turns per Layer 144 144 Magnet J (A mm-2)* 90.47 95.89 Magnet Current (A)* 217.6 230.6 Magnet Self Inductance (H) ~325 ~325 Peak Induction in Coil (T)* 5.85 6.20 Magnet Stored Energy (MJ)* ~7.7 ~8.6 4.2 K Temp. Margin (K)* ~1.8 ~1.6 Coil Thickness (mm) Number of Layers •Design based on p = 200 MeV/c and beta = 420 mm. One would like to run the magnet up to 277 A in the flip mode. CM-18 June 2007 21 Coupling Magnet Quench Protection • The coupling magnet has a conducting mandrel, which promotes quench back. Quench back reduces the coupling magnet hot spot temperature but has only a small effect on the voltages in the coil. • The coupling magnet must be subdivided. Across each subdivision are diodes and resistors. The diodes and resistors reduce the magnet voltages. The peak voltage across the coil (a voltage to ground) must be less than 2 kV. The layer-to layer voltages must be less than 350 V. The magnet inductance determines the number of coil subdivisions. A larger conductor means fewer coil subdivisions and a lower hot spot temperature during a quench. CM-18 June 2007 22 No Quench Back Study by X. L Gou of ICST CM-18 June 2007 23 No Quench Back Study by X. L Gou of ICST CM-18 June 2007 24 No Quench Back Study by X. L Gou of ICST CM-18 June 2007 25 No Quench Back Study by X. L Gou of ICST CM-18 June 2007 26 Study by X. L Gou of ICST CM-18 June 2007 27 Study by X. L Gou of ICST CM-18 June 2007 28 Results of the ICST Quench Study • The use of a larger conductor results in lower internal voltages, lower layer-to-layer voltages, and lower magnet hot spot temperatures. Fewer magnet subdivisions are needed. • Quench back from the mandrel reduces the hot spot temperature, but it may increase the internal voltage and the layer-to layer voltage because the magnet quench time constant is shorter. • The resistance in series with the diodes is important. More resistance yields lower internal voltages, lower layer-to-layer voltages, and a lower conductor hot spot temperature. CM-18 June 2007 29 Coupling Coil Conductor Selection • The larger conductor results in lower quench hot spot temperatures and fewer coil subdivisions. • A larger conductor is faster to wind into the coil and there are fewer leads brought out of the coil. • The larger conductor carries a higher current, which means the heat leak into the first stage is higher. The resulting first stage temperature increase increases the heat flow into the 4 K region. • Even though the larger conductor is better from a quench standpoint, the tracker conductor was selected in order to reduce the total heat load. This may allow the magnet to be cooled using one cooler. CM-18 June 2007 30 What about the AFC magnet conductor? • The Lab G solenoid is a model for the AFC magnet. The Lab G magnet has a conductor that is almost identical to the tracker and coupling coil conductor. • The AFC magnet quench protection system consists of quench back plus a single diode and resistor pack across each of the coils. The diode and resistor pack can be located at 300 K, because each AFC coil lead is brought out to 300 K. • The tracker and coupling coil conductor is relatively cheap and it fits the design of the AFC magnet very well. The reduced filament size (41 microns) will result in lower AC losses. Why not use the same conductor as the other magnets in MICE? CM-18 June 2007 31 How much conductor is needed? • Each tracker solenoid requires about 54 km of conductor. Both tracker magnets use 108 km of conductor. Four billets of conductor was purchased. • Each coupling magnet will use about 81 km of the tracker magnet conductor. The two MICE coupling magnets will use about 162 km of tracker magnet conductor. Eight billets of conductor will be purchased for three coupling magnets. • Each AFC magnet requires about 37 km of the tracker magnet conductor. The three AFC magnets will use about 111 km of tracker magnet conductor. Expect to purchase four billets of conductor. CM-18 June 2007 32 MICE Conductor Summary • The tracker magnet conductor was set to reduce the magnet cost w/o affecting temperature margin. • Rectangular conductor is better than round. • It is always better to have a higher Cu to S/C ratio and smaller filaments, but one should use a standard conductor if possible. Jc and n are important. • While a larger conductor is desirable for a quench standpoint, a smaller conductor results in a magnet with lower heat loads on both cooler stages. • The coupling magnet conductor is the same as the tracker magnet conductor. The conductor for the AFC magnet can be the same too. CM-18 June 2007 33