* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download PPT

Electronic engineering wikipedia , lookup

Power inverter wikipedia , lookup

Power engineering wikipedia , lookup

Alternating current wikipedia , lookup

Mains electricity wikipedia , lookup

Audio power wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Buck converter wikipedia , lookup

Semiconductor device wikipedia , lookup

Opto-isolator wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Flexible electronics wikipedia , lookup

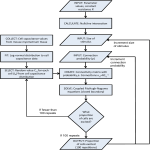

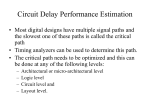

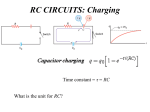

Statistical Timing Yield Improvement of Dynamic Circuits Using Negative Capacitance Technique Hassan Mostafa & M. Anis & M. Elmasry University of Waterloo, Ontario, Canada Outline Introduction and Background Motivation and Objectives Negative Capacitance Circuits Statistical Timing Yield Improvement Using Negative Capacitance Results and Discussions Conclusion Introduction and Background ISCAS 2010 Slide 2 Outline Introduction and Background Variability Wide Fan-in Dynamic OR gate Motivation and Objectives Negative Capacitance Circuits Statistical Timing Yield Improvement Using Negative Capacitance Results and Discussions Conclusion Introduction and Background ISCAS 2010 Slide 3 Variability Classification Die-to-Die (D2D) Affects all devices on the chip in the same way e.g., all devices on a chip have the same Vt Within-Die (WID) Variations within a single chip Affecting devices on the same chip differently e.g., devices on the same chip have different Vt D2D WID Die index Introduction and Background ISCAS 2010 Slide 4 Design Methodologies Design Methodology Performance Distribution Cost (e.g. power) (Overhead) Nominal FAIL Frequency 50% Timing Yield Corner-Based FAIL 100% Timing Yield Statistical FAIL >99.9% Timing Yield www.nowpublishers.com Introduction and Background ISCAS 2010 Slide 5 Process Variations Sources Random Dopant Fluctuations (RDF) As CMOS devices are scaled, number of dopant atoms decreases The number of dopant atoms has variations around its nominal value resulting in Vt variations σVt α (WL)-0.5 [1 ] As transistor area decreases with scaling, σVt increases Channel Length Variation Difficulty to control the critical dimensions at sub-wavelength lithography Large variations in the channel length (L) Vt α exp(-L) due to short channel effects A small variations in L results in large variations in Vt Sub-wavelength lithography 1 m Lithography Wavelength 365nm 248nm 193nm 180nm 130nm 100 nm 10 nm S. Borkar et al., DAC04 1980 1990 2000 Variations increase with technology scaling Introduction and Background ISCAS 2010 Gap 90nm 65nm` 45nm Generation 32nm Slide 6 13nm EUV 2010 2020 Variability and Yield Process variations causes the device parameters to have fluctuations around their nominal values Delay distribution The system parameters such as delay and power have a spread around their nominal values This result in a percentage of the systems does not meet the required function or the required parameter constraint Yield loss PASS FAIL Delay Target delay Variability results in Yield loss Introduction and Background ISCAS 2010 Slide 7 Wide Fan-in Dynamic OR Gate Used in the processor critical path Wide Fan-in (i.e., 16-input dynamic OR gate) Wide Fan-in Dynamic OR gates are essential for high performance processor modules Introduction and Background ISCAS 2010 Slide 8 Wide Fan-in Dynamic OR Gate Keeper transistor design Small W/L To avoid delay and power increase due to contention Large W/L To hold the floating output node at VDD against the increased leakage currents, especially, with technology scaling With technology scaling, the increased leakage and variability result in larger delay and power Introduction and Background ISCAS 2010 Slide 9 Wide Fan-in Dynamic OR Gate Timing yield improvement techniques Keeper control circuits Digitally controlled keeper sizing Large leakage Large keeper W/L Small Leakage Small keeper W/L Body bias controlled keeper sizing Large leakage Smaller keeper Vt Small leakage Larger keeper Vt These techniques utilize a leakage current sensor (analog) Analog to digital converter Digital control circuit Previous timing yield improvement techniques exhibit large area overhead Negative capacitance to the rescue Introduction and Background ISCAS 2010 Slide 10 Outline Introduction and Background Motivation and Objectives Negative Capacitance Circuits Statistical Timing Yield Improvement Using Negative Capacitance Results and Discussions Conclusion Motivation and Objectives ISCAS 2010 Slide 11 Motivation and Objectives Wide Fan-in dynamic OR gates are essential blocks in high performance processor modules The increased variability and leakage result in timing yield loss The existing timing yield improvement techniques exhibit large overhead (area and power) Main idea: Delay α Output Capacitance Dynamic Power α Output Capacitance Reducing the output capacitance reduces the delay and the dynamic power Negative capacitance breaks the power-performance trade-off Motivation and Objectives ISCAS 2010 Slide 12 Outline Introduction and Background Motivation and Objectives Negative Capacitance Circuits Statistical Timing Yield Improvement Using Negative Capacitance Results and Discussions Conclusion Negative Capacitance Circuits ISCAS 2010 Slide 13 Negative Capacitance Circuits 1- Miller effect based circuit Using A ≥ 1, A negative capacitance is realized Differential Amplifier Buffer Amplifier Negative Capacitance Circuits ISCAS 2010 Slide 14 Negative Capacitance Circuits 2- Negative Impedance Converter (NIC) based circuit For Current conveyor NIC, Current Conveyor Negative Capacitance Circuits ISCAS 2010 Slide 15 Negative Capacitance Circuits The buffer amplifier based negative capacitance circuit: A higher supply voltage is needed (VDDH) High Vt transistors to reduce the static power consumption VDDH VDDL VDDL Negative Capacitance Circuits ISCAS 2010 Slide 16 VDDH Outline Introduction and Background Motivation and Objectives Negative Capacitance Circuits Statistical Timing Yield Improvement Using Negative Capacitance Results and Discussions Conclusion Statistical Timing Yield Improvement ISCAS 2010 Slide 17 Statistical Timing Yield Improvement Using Negative Capacitance Timing yield improvement n = 3 for YO = 99.87% Statistical Timing Yield Improvement ISCAS 2010 Slide 18 Outline Introduction and Background Motivation and Objectives Negative Capacitance Circuits Statistical Timing Yield Improvement Using Negative Capacitance Results and Discussions Future Work Conclusions Results and Discussions ISCAS 2010 Slide 19 Results and Discussions 16-input OR gate is used The target delay (AO) = 102.4 psec and σ = 10.61 psec The output capacitance Cout = 9.38 fF and the constant ʒ = 10.92 psec/fF. The required negative capacitance CNEG = - 2.9 fF is realized by: Using the buffer amplifier, A= 30 and CF = 0.1 fF Using the differential amplifier, A= 3.9 and CF = 1 fF Using the current conveyor, CL = 2.9 fF Results and Discussions ISCAS 2010 Slide 20 Results and Discussions Target Delay 5000 Monte Carlo Timing yield = 100% Mean delay reduction by 31% OR gate power reduction by 10% Delay standard deviation reduction by 58% All the three proposed negative capacitance circuits provide similar results Results and Discussions ISCAS 2010 Slide 21 Results and Discussions Why the delay standard deviation reduction is reduced? ∆AO = ∆ʒ X Cout ∆A’O = ∆ʒ X C’out Since Cout > C’out ∆AO > ∆A’O Stability The OR gate becomes unstable when |CNEG| > Cout (i.e.,C’out< 0 ), which will not happen because A’O is always positive. Results and Discussions ISCAS 2010 Slide 22 Results and Discussions Power overhead: The buffer amplifier (CF = 0.1 fF) No power overhead (power saving of 5%) Dual supply voltage and high Vt transistors needed The differential amplifier (CF = 1 fF) Power overhead = 5% Limited by the constant gain-bandwidth product The current conveyor (CL = 2.9 fF) Power overhead = 30% Suitable for high frequency applications ( No constant gain-bandwidth product limitation) Results and Discussions ISCAS 2010 Slide 23 Outline Introduction and Background Motivation and Objectives Negative Capacitance Circuits Statistical Timing Yield Improvement Using Negative Capacitance Results and Discussions Conclusion Conclusion ISCAS 2010 Slide 24 Conclusion A negative capacitance circuit is introduced for timing yield improvement in wide fan-in dynamic OR gates. All the proposed negative capacitance circuits improve the timing yield (by reducing the mean delay), reduce the delay variability by 58%, and reduce the OR gate power by 10%. The buffer amplifier circuit exhibits no overhead (5% total power saving) but a dual supply voltage and high-Vt transistors are required. The differential amplifier and the current conveyor circuits have power overhead of 5% and 30%, respectively. Conclusion ISCAS 2010 Slide 25 THANK YOU ISCAS 2010 Slide 26 64-input OR gate Buffer Amplifier CNEG Differential Amplifier CNEG NO CNEG ISCAS 2010 Current Conveyor CNEG Slide 27 64-input OR gate ISCAS 2010 Slide 28