* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Critical Design Review Wind Turbine with Gearbox

Survey

Document related concepts

Pulse-width modulation wikipedia , lookup

Fault tolerance wikipedia , lookup

Power inverter wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Electrical substation wikipedia , lookup

Stray voltage wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Alternating current wikipedia , lookup

Power electronics wikipedia , lookup

Voltage optimisation wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Mains electricity wikipedia , lookup

Intermittent energy source wikipedia , lookup

Opto-isolator wikipedia , lookup

Voltage regulator wikipedia , lookup

Buck converter wikipedia , lookup

Transcript

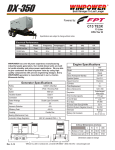

Critical Design Review Wind Turbine with Gearbox Team G: Nick Koerner (Lead), Meteb Almutairi, Chris Batsch, Mike Villamar Project Objectives ● The Main Goal is Control o The Arduino Mega Microcontroller will serve as the control center of the wind turbine. o Items that are being controlled by the microcontroller: Transistor Switching ● ● E-Brake Voltage Monitor Physical Hydraulic Brake Controlled by Servo Frequency Detection ● Simple Voltage regulator being used to protect microcontroller ● Efficiency and Power Output o High Efficiency is desired Switching Regulator o 5V, 2A, and 10W of Power Modes of Operation ● Generation Mode o The E-brake switch will be open, and voltage monitor switch will be closed. o This allows for the generator to spin freely, and the battery bank to connect to the generator. ● Shutdown Mode o The E-Brake switch will be closed, and the voltage monitor switch will be open. o The generator will be shorted: Slows down the generator and dumps energy into the dump load. o The hydraulic brake will be activated by the servo, and cause the wind turbine to come to a complete stop. o Generation will be reactivated after a delay, or battery bank needs charging, or manual override. Functional Decomposition Full Circuit Schematic Subassemblies Battery Bank Sub Specs: ● Batteries ○ Lithium Ion Battery ■ 2800mAh ○ Battery Bank provides ■ 9 V, 2.16 A ● Capacitor ○ 1000 uF Generator Sub Specs: ● Bridge Rectifier ○ RS402L ○ MAX: 100 V, 4 A ● IGBT ○ ISL9V3040P3 ○ MAX: 430 V, 17 A ● Power Resistor ○ 50W ● Generator ○ ElectriFly Ammo ● Frequency Detection Voltage Protection ○ 1N4742 Zener Diode ○ Max: 12 V, 1 W Subassemblies Load Sub Specs: ● Step Down Switching Regulator (2 Options) ○ L4978 IC ■ Requires 8 V to 55 V input ■ Produces 5 V and 2 A output ■ ~90% Efficient ■ Simple and all values given ○ NR887D IC ■ Requires 4.5 V to 18 V input ■ Produces 5 V and 2 A output ■ ~90% Efficient ■ Not all values given, further testing once obtained ● Voltage Monitor (R6 & R7) ○ Simple Voltage Divider for 5 V Analog Pin Brake Sub Specs: ● Turnigy Digital Metal Gear Servo ○ 6 V Input ○ Torque: 17 kg/cm Construction Plan ● Structural Hardware: o Much of the structural hardware used in the previous wind turbine project will be recycled in this current design, therefore the plan is to build on top of that. ● Previous components Used: o The Blades, Shaft, Gearbox, Generator, and Hydraulic Brake will be reused. ● Battery Bank o Brackets and metal tabs will be used to connect the batteries in the correct setup. ● The new components that are chosen will fit on the aluminum platform (shown on next slide). ● What does not fit, will rest a platform on the ground. Additional Fabrication Plans ● Proto-Boards o The current plan is to use the EECS shop provided vector proto-boards to place the circuits upon. ● The Goal o o To make custom PCB circuit boards using the EECS shop’s PCB milling machine. Depending on the time, and Eagle CAD training, the task can be completed before the deadline. Testing ● DC Motor for in Lab Wind Simulations ● Wind Tunnel for Final Testing o The Max Wind Speed Tested is 34 MPH ● Tests the Generation and Shutdown Modes o >40 MPH Shutdown Feature o Can or will be Adjusted ● Input/Output Efficiency In Lab Wind Simulation Data from Testing Wind Speed [MPH] Voltage [V] RPM of Generator [RPM] Frequency [Hz] 11.18 1.79 1005.82 16.76 22.37 3.46 2012.53 33.54 33.55 4.50 3018.35 50.31 Schedule Task Proposal DC Motor for Wind Simulation Preliminary Research Analyze Wind Turbine Design PDR Detailed Overview Research Circuit Schematic CDR Order Parts Programming Microcontroller Construction Wind Tunnel Testing Project Completion Projected Completion 2/4/2015 2/13/2015 2/20/2015 2/20/2015 2/20/2015 3/13/2015 3/13/2015 4/1/2015 4/3/2015 4/17/2015 4/17/2015 4/24/2015 5/6/2015 Org Chart Challenges/Risks Programming ● Programming the microcontroller will take some time and research. Scheduling ● Meeting times due to different schedules of everyone in group is a conflict. Batteries ● Potential risk of explosion and or fire. Components ● Size, rating, and cost must be considered for durability and because structure from last year is being used. Testing ● Availability of wind tunnel and making sure wind simulation matches actual wind tunnel performance. Questions?