* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Table of Contents - UCF EECS - University of Central Florida

Mercury-arc valve wikipedia , lookup

Wireless power transfer wikipedia , lookup

Electrical ballast wikipedia , lookup

Electrification wikipedia , lookup

Telecommunications engineering wikipedia , lookup

Ground (electricity) wikipedia , lookup

Current source wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Electric power system wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Power inverter wikipedia , lookup

Stray voltage wikipedia , lookup

Amtrak's 25 Hz traction power system wikipedia , lookup

Electrical substation wikipedia , lookup

Single-wire earth return wikipedia , lookup

Voltage regulator wikipedia , lookup

Earthing system wikipedia , lookup

Power over Ethernet wikipedia , lookup

Power engineering wikipedia , lookup

Three-phase electric power wikipedia , lookup

Buck converter wikipedia , lookup

Resonant inductive coupling wikipedia , lookup

Power MOSFET wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Power electronics wikipedia , lookup

Surge protector wikipedia , lookup

Distribution management system wikipedia , lookup

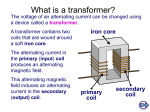

Transformer wikipedia , lookup

Voltage optimisation wikipedia , lookup

History of electric power transmission wikipedia , lookup

Network analysis (electrical circuits) wikipedia , lookup

Mains electricity wikipedia , lookup

Alternating current wikipedia , lookup