* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Hesham Mohsen - Smart Materials

Radiation damage wikipedia , lookup

Crystal structure wikipedia , lookup

Superconductivity wikipedia , lookup

Hall effect wikipedia , lookup

Ferromagnetism wikipedia , lookup

Work hardening wikipedia , lookup

Industrial applications of nanotechnology wikipedia , lookup

Fatigue (material) wikipedia , lookup

Metamaterial wikipedia , lookup

Negative-index metamaterial wikipedia , lookup

Viscoelasticity wikipedia , lookup

Energy applications of nanotechnology wikipedia , lookup

Colloidal crystal wikipedia , lookup

Strengthening mechanisms of materials wikipedia , lookup

Sol–gel process wikipedia , lookup

Materials Research Science and Engineering Centers wikipedia , lookup

Shape-memory alloy wikipedia , lookup

Nanochemistry wikipedia , lookup

History of metamaterials wikipedia , lookup

Semiconductor wikipedia , lookup

Multiferroics wikipedia , lookup

Energy harvesting wikipedia , lookup

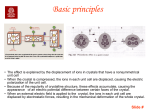

Hesham Mohsen Hussein – 1093233 Advanced Materials Engineering Introduction to Smart Materials Abstract Smart materials engineering is a relatively new and promising branch in modern materials engineering. Smart materials are materials which can produce various effects and results, when subject to various external effects, such as stress or heat. Such effects produced, mostly in the form of electrical charge, are manipulated to produce various practical applications, such as using piezoelectric materials to as motion sensors, for example. This essay is going to discuss the different types of smart materials, the manufacturing process of smart materials (specifically piezoelectric materials) and the different applications, and finally, the application of energy harvesting is discussed. History The pyroelectric effect, by which a material generates an electric potential in response to a temperature change, was studied by Carl Linnaeus and Franz Aepinus in the mid-18th century. Drawing on this knowledge, both René Just Haüy and Antoine César Becquerel posited a relationship between mechanical stress and electric charge; however, experiments by both proved inconclusive. The first demonstration of the direct piezoelectric effect was in 1880 by the brothers Pierre Curie and Jacques Curie. They combined their knowledge of pyroelectricity with their understanding of the underlying crystal structures that gave rise to pyroelectricity to predict crystal behavior, and demonstrated the effect using crystals of tourmaline, quartz, topaz, cane sugar, and Rochelle salt (sodium potassium tartrate tetrahydrate). For the next few decades, piezoelectricity remained something of a laboratory curiosity. More work was done to explore and define the crystal structures that exhibited piezoelectricity. This culminated in 1910 with the publication of Woldemar Voigt's Lehrbuch der Kristallphysik (Textbook on Crystal Physics), which described the 20 natural crystal classes capable of piezoelectricity, and rigorously defined the piezoelectric constants using tensor analysis. The first practical application for piezoelectric devices was sonar, first developed during World War I. In France in 1917, Paul Langevin and his coworkers developed an ultrasonicsubmarine detector. The detector consisted of a transducer, made of thin quartz crystals carefully glued between two steel plates, and a hydrophone to detect the returned echo. By emitting a high-frequency chirp from the transducer, and measuring the amount of time it takes to hear an echo from the sound waves bouncing off an object, one can calculate the distance to that object. The use of piezoelectricity in sonar, and the success of that project, has created intense interest in piezoelectric devices. Over the next few decades, new piezoelectric materials and new applications for those materials were explored and developed. During World War II, independent research groups in the United States, Russia, and Japan discovered a new class of synthetic materials, called ferroelectrics, which exhibited piezoelectric constants many times higher than natural materials. This led to intense research to develop barium titanate and later lead zirconate titanate materials with specific properties for particular applications. Types 1- Piezoelectric materials: Materials that give an electronic charge when stress is applied on them. 2- Shape memory alloys: Materials in which large deformation can be induced and recovered through temperature changes or stress changes 3- Magnetostrictive: Materials which show change in shape under the influence of magnetic field, and also a change in their magnetization under the influence of mechanical stress. 4- pH sensitive polymers: Materials that change in volume when the pH of their medium changes. 5- Temp-responsive polymers: Materials which change when subjected to a change in temperature. 6- Photomechanical materials: Materials which change shape when exposed to light. 7- Self-healing materials 8- Dielectric elastomers: Materials which produce large strains when subjected to an external electric field 9- Macrofibre composites: The Macro Fiber Composite (MFC) is the leading low-profile actuator and sensor offering high performance, flexibility and reliability in a cost competitive device. The MFC consists of rectangular piezo ceramic rods sandwiched between layers of adhesive, electrodes and polyimide film. This assembly enables in-plane poling, actuation and sensing in a sealed and durable, ready to use package. As a thin, surface conformable sheet it can be applied (normally bonded) to various types of structures or embedded in a composite structure. If voltage is applied it will bend or distort materials, counteract vibrations or generate vibrations. If no voltage is applied it can work as a very sensitive strain gauge, sensing deformations, noise and vibrations. The MFC is also an excellent device to harvest energy from vibrations. 10- 1-3 Composites: 1-3 Piezo Composites have become the material of choice for many high performance ultrasound transducer since it was invented by R.E. Newnham and L.E. Cross in the late 1970's. A variety of piezocomposite materials can be made by combining piezo ceramic elements with a passive polymer such as epoxy or active polymer. Piezo-composites are classified according to their connectivity (such as 2-2, 1-3, 0-3 etc.,). Connectivity is defined as the number of dimensions through which the material is continuous. It is conventional for the first digit to refer to the piezoelectrically active phase. Today the most piezo composites on the market are with the 1-3 and 2-2 connectivity used in ultrasound transducers, actuators and sensors. The biggest single market for the 1-3 piezo composite is the medical diagnostic ultrasound market which is using more 1-3 piezo composite than the other markets combined. Today's medical ultrasound imaging systems would be not possible without the advancements in 1-3 piezo composites. Manufacturing of Piezoelectric Materials Bulk Process Piezoceramic bulk elements are manufactured from spray-dried granular material by mechanical hydraulic presses. The compacts are either manufactured true to size, taking into account the sintering contraction, or with machining excesses which are then reworked to achieve the required precision. The bulk process starts with mixing and ball milling of the raw materials. Next, the mixture is heated to 75% of the sintering temperature to accelerate reaction of the components. The polycrystalline, calcinated powder is ball milled again to increase its reactivity. Granulation with the binder is next to improve processing properties. After shaping and pressing the (green) ceramics is heated to 750 to burn out the binder. The next phase is sintering at temperatures between 1250° C and 1350° C. The sintered ceramic material is hard and can be sawn cut, ground, polished, lapped, etc., to the desired shape and tolerance if required. Screen printing is used to metallize the piezoelements and sputtering processes (PVD) are employed for thin metallizing layers (electrodes are applied). The sintered elements are then polarized. The last step is the poling process which takes place in a heated oil bath at electrical fields up to several kV/mm. Thin Film Multilayer Process Multilayer Piezo actuators require a different manufacturing process. After milling a slurry is prepared. A foil casting process allows layer thickness down to 20 µm. Next, the sheets are screen printed and laminated. A compacting process increases density of the "green" ceramics and removes air trapped between the layers. The final steps are the binder burnout, sintering (co-firing) at temperatures below 1100 C, end termination and poling. All processes, especially the heating and sintering cycles must be controlled to very tight tolerances. The smallest change affects quality and properties of the Piezo material. 100% final testing of the piezo material and components at PI Ceramic guarantees the highest product quality. Applications of Piezoelectric Materials Energy Harvesting Energy harvesting of piezoelectric materials is a promising branch of research. Anything that induces mechanical stress can be used to apply stress to a piezoelectric material, causing it to give electric charge. Although the electricity produced from such stresses is fairly small (usually measured in milliwatts), but it has lots of applications, like charging electronic devices such as cellphones. Some applications have had successful integration of piezoelectric materials in clothing; most commonly shoes. Sensors A piezoelectric sensor is a device that uses the piezoelectric effect to measure pressure, acceleration, strain or force by converting them to an electrical charge. Piezoelectric sensors have proven to be versatile tools for the measurement of various processes. They are used for quality assurance, process control and for research and development in many different industries. Although the piezoelectric effect was discovered by Pierre Curie in 1880, it was only in the 1950s that the piezoelectric effect started to be used for industrial sensing applications. Since then, this measuring principle has been increasingly used and can be regarded as a mature technology with an outstanding inherent reliability. It has been successfully used in various applications, such as in medical, aerospace, nuclear instrumentation, and as a pressure sensor in the touch pads of mobile phones. In the automotive industry, piezoelectric elements are used to monitor combustion when developing internal combustion engines. The sensors are either directly mounted into additional holes into the cylinder head or the spark/glow plug is equipped with a built in miniature piezoelectric sensor. The rise of piezoelectric technology is directly related to a set of inherent advantages. Even though piezoelectric sensors are electromechanical systems that react to compression, the sensing elements show almost zero deflection. This is the reason why piezoelectric sensors are so rugged, have an extremely high natural frequency and an excellent linearity over a wide amplitude range. Additionally, piezoelectric technology is insensitive to electromagnetic fields and radiation, enabling measurements under harsh conditions. Some materials used (especially gallium phosphate or tourmaline) have an extreme stability even at high temperature, enabling sensors to have a working range of up to 1000 °C. Tourmaline shows pyroelectricity in addition to the piezoelectric effect; this is the ability to generate an electrical signal when the temperature of the crystal changes. Actuators As very high electric fields correspond to only tiny changes in the width of the crystal, this width can be changed with better-than-µm precision, making piezo crystals the most important tool for positioning objects with extreme accuracy — thus their use in actuators. Multilayer ceramics, using layers thinner than 100 µm, allow reaching high electric fields with voltage lower than 150 V. These ceramics are used within two kinds of actuators: direct piezo actuators and Amplified piezoelectric actuators. While direct actuator's stroke is generally lower than 100 µm, amplified piezo actuators can reach millimeter strokes. Piezoelectric Motors Motors are made in both linear and rotary types. Of these, one drive technique is to use piezoelectric ceramics to push a stator. These piezoelectric motors use three groups of crystals: two of which are Locking and one Motive, permanently connected to either the motor's casing or stator (not both) and sandwiched between the other two, which provides the motion. These piezoelectric motors are fundamentally stepping motors, with each step comprising either two or three actions, based on the locking type. Another mechanism employs the use of surface acoustic waves (SAW) to generate linear or rotational motion. A second drive technique is illustrated by the Squiggle motor, in which piezoelectric elements are bonded orthogonally to a nut and their ultrasonic vibrations rotate and translate a central lead screw. This is a direct drive mechanism. References Gautschi, G. (2002). Piezoelectric sensorics. Springer Berlin, Heidelberg, New York. p. 3 http://www.physikinstrumente.com/tutorial/4_16.html Katzir, S. (2012-06-20). "Who knew piezoelectricity? Rutherford and Langevin on submarine detection and the invention of sonar". http://www.smart-material.com/MFC-product-main.html http://www.smart-material.com/13CompOverview.html http://www.slideshare.net/SlavaAlexey/piezomotors Srinivasan (2001). Smart Structures- Analysis and Design. Wikipedia Youtube