* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

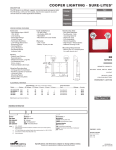

Download Chapter 4 | Lighting

Sustainable architecture wikipedia , lookup

Green building on college campuses wikipedia , lookup

Green building wikipedia , lookup

Light pollution wikipedia , lookup

Holiday lighting technology wikipedia , lookup

Daylighting wikipedia , lookup

Bicycle lighting wikipedia , lookup