* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download File

Josephson voltage standard wikipedia , lookup

Thermal runaway wikipedia , lookup

Schmitt trigger wikipedia , lookup

Radio transmitter design wikipedia , lookup

Transistor–transistor logic wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Galvanometer wikipedia , lookup

Operational amplifier wikipedia , lookup

Index of electronics articles wikipedia , lookup

Valve RF amplifier wikipedia , lookup

Current source wikipedia , lookup

Opto-isolator wikipedia , lookup

Surge protector wikipedia , lookup

Power MOSFET wikipedia , lookup

Current mirror wikipedia , lookup

Switched-mode power supply wikipedia , lookup

INVERTER

Chapter-1

INTRODUCTION

1.1 INTRODUCTION OF INVERTER

A device that converts DC power into AC power at desired output voltage and frequency is

called an Inverter. Phase controlled converters when operated in the inverter mode are called

line commutated inverters. But line commutated inverters require at the output terminals an

existing AC supply which is used for their commutation. This means that line commutated

inverters can’t function as isolated AC voltage sources or as variable frequency generators

with DC power at the input. Therefore, voltage level, frequency and waveform on the AC

side of the line commutated inverters can’t be changed. On the other hand, force commutated

inverters provide an independent AC output voltage of adjustable voltage and adjustable

frequency and have therefore much wider application.

Inverters can be broadly classified into two types based on their operation:

· Voltage Source Inverters (VSI)

· Current Source Inverters (CSI)

Voltage Source Inverters is one in which the DC source has small or negligible impedance. In

other words VSI has stiff DC voltage source at its input terminals. A current source inverter

is fed with adjustable current from a DC source of high impedance,i.e;from a stiff DC current

source. In a CSI fed with stiff current source, output current waves are not affected by the

load.

From view point of connections of semiconductor devices, inverters are classified as under

· Bridge Inverters

· Series Inverters

· Parallel Inverters

1

BIET, Dept. of Electrical Engg.

INVERTER

1.2 APPLICATIONS

· DC POWER SOURCE UTILIZATION

Inverter designed to provide 115 VAC from the 12 VDC source provided in an automobile.

The unit provides up to 1.2 Amps of alternating current, or just enough to power two sixty

watt light bulbs.

An inverter converts the DC electricity from sources such as batteries, solar panels, or fuel

cells to AC electricity. The electricity can be at any required voltage; in particular it can

operate AC equipment designed for mains operation, or rectified to produce DC at any

desired voltage.

Grid tie inverters can feed energy back into the distribution network because they produce

alternating current with the same wave shape and frequency as supplied by the distribution

system. They can also switch off automatically in the event of a blackout.

Micro-inverters convert direct current from individual solar panels into alternating current for

the electric grid.

1.3 UNINTERRUPTIBLE POWER SUPPLIES

An uninterruptible power supply is a device which supplies the stored electrical power to the

load in case of raw power cut-off or blackout. One type of UPS uses batteries to store power

and an inverter to supply AC power from the batteries when main power is not available.

When main power is restored, a rectifier is used to supply DC power to recharge the batteries.

It is widely used at domestic and commercial level in countries facing Power outages.

1.3.1 INDUCTION HEATING

Inverters convert low frequency main AC power to a higher frequency for use in induction

heating. To do this, AC power is first rectified to provide DC power. The inverter then

changes the DC power to high frequency AC power.

2

BIET, Dept. of Electrical Engg.

INVERTER

1.3.2 HVDC POWER TRANSMISSION

With HVDC power transmission, AC power is rectified and high voltage DC power is

transmitted to another location. At the receiving location, an inverter in a static inverter plant

converts the power back to AC.

1.3.3 VARIABLE-FREQUENCY DRIVES

A variable-frequency drive controls the operating speed of an AC motor by controlling the

frequency and voltage of the power supplied to the motor. An inverter provides the controlled

power. In most cases, the variable-frequency drive includes a rectifier so that DC power for

the inverter can be provided from main AC power. Since an inverter is the key component,

variable frequency drives are sometimes called inverter drives or just inverters.

1.3.4 ELECTRIC VEHICLE DRIVES

Adjustable speed motor control inverters are currently used to power the traction motor in

some electric locomotives and diesel-electric locomotives as well as some battery electric

vehicles and hybrid electric highway vehicles such as the Toyota Prius. Various

improvements in inverter technology are being developed specifically for electric vehicle

applications.[2] In vehicles with regenerative braking, the inverter also takes power from the

motor (now acting as a generator) and stores it in the batteries.

1.4 THE GENERAL CASE

A transformer allows AC power to be converted to any desired voltage, but at the same

frequency. Inverters, plus rectifiers for DC, can be designed to convert from any voltage, AC

or DC, to any other voltage, also AC or DC, at any desired frequency. The output power can

never exceed the input power, but efficiencies can be high, with a small proportion of the

power dissipated as waste heat.

Most medium to large scale solar power systems are designed to power everything from

mains type AC voltages "inverted" from the DC battery bank. The advantage this gives us is

that we can purchase conventional appliances from an electrical retailer. An energy efficient

light globe can be somewhat expensive in a 12 Volt DC version and having a 24 or 48 volt

lighting system makes finding a suitable light bulb even more difficult.

3

BIET, Dept. of Electrical Engg.

INVERTER

1.4.1 INVERTER RATINGS

The three ratings that you should look at when buying an inverter are:

1.

Continuous Rating: This is the amount of power you could expect to use

continuously without the inverter overheating and shutting down.

2.

Half Hour Rating: This is handy as the continuous rating may be too low to run a

high energy consumption power tool or appliance, however if the appliance was only to be

used occasionally then the half hour rating may well suffice.

3.

Surge Rating: A high surge is required to start some appliances and once running

they may need considerably less power to keep functioning. The inverter must be able to hold

its surge rating for at least 5 seconds. TVs and refrigerators are examples of items that require

only relatively low power once running, but require a high surge to start.

4

BIET, Dept. of Electrical Engg.

INVERTER

Chapter-2

TYPES OF INVERTERS

2.1 TYPES OF INVERTERS

There are basically two types of inverters: modified sine wave (aka modified square wave)

and true sine wave. The differences between these two types of inverters are subtle but

significant in the way they operate.

2.1.1 MODIFIED SINE WAVE INVERTERS

A modified sine wave inverter can adequately power some household appliances and power

tools. It is cheaper, but may present certain compromises with some loads such as computers,

microwave ovens, laser printers, clocks and cordless tool chargers. Virtually all low cost

inverters are "modified sine wave". A modified sine wave is easier and cheaper to produce

than a sine wave inverter.

These low cost inverters are generally available from electrical stores, hardware stores,

automotive store and electronic suppliers. They usually lack many features such as auto-start

or any type of tweaking ability. The devices are usually only about 70% efficient, so expect

some significant power losses if you are using a modified sine wave inverter in your system.

2.1.2 TRUE SINE WAVE INVERTERS

A true sine wave inverter is designed to replicate and even improve the quality of electricity

supplied by utility companies. To operate higher-end electronic equipment, a true sine wave

inverter is recommended. Efficiency has reached up to about 94% and the electricity from

these devices is of a higher quality than grid power almost anywhere in the world.

2.1.3 A HIGH QUALITY INVERTER

An auto-start system. An auto start allows an inverter to switch to a low power

consumption standby state when nothing is connected and turned on. This will save you a lot

of manual switching and/or wasted power

Tweaking ability. An ability to adjust parameters such as auto-start and battery depth

of discharge is also helpful.

5

BIET, Dept. of Electrical Engg.

INVERTER

High quality heavy-duty power transformer. A heavy inverter usually means a high

quality heavy-duty power transformer.

2.2 MODIFIED SINEWAVE OR TRUE SINEWAVE

Fig.1 Modified sine wave or true sine wave

Modified Sine Wave is a sales term used for a modified square wave type of AC power

which is not quite the same as power company electricity. Modified wave inverters are lower

cost, slightly more efficient, and almost all appliances work fine with them, though some may

hum louder. But a few sewing machine speed controls and some Apple computers have

difficulty on modified Sine Wave. It can also damage photocopy machines, laser printers, and

some cordless tool rechargers. Recently we found the first TV that would not run on any

modified wave inverter. Battery chargers in the DR model modified waveform inverters may

require the highest quality generator (about $3000 and up) to charge effectively.

TRUE SINE WAVE inverters supply power of better quality than the power company, and

work correctly with any appliance. Battery chargers in true sine wave inverters work well

with any generator. Xantrex SW+ series and Outback inverters can automatically start and

stop a generator when extra battery charge is needed. A low cost Simlex true sine wave

inverter might be used when you have just a few smaller appliances that require true sine

wave power.

6

BIET, Dept. of Electrical Engg.

INVERTER

The process of converting DC into AC is known as inversion. The device which Performs

this process is known as an INVERTER.

An inverter is used to produce an un-interrupted 220V AC or 110V AC (depending on the

line voltage of the particular country) supply to the device connected as the load at the output

socket. The inverter gives constant AC voltage at its output socket when the AC mains power

supply is not available.

7

BIET, Dept. of Electrical Engg.

INVERTER

Chapter-3

WORKING OF INVERTER

3.1 WORKING OF INVERTER

So how can an inverter give us a high voltage alternating current from a low voltage direct

current. Let's first consider how an alternator produces an alternating current. In its simplest

form, an alternator would have a coil of wire with a rotating magnet close to it. As one pole

of the magnet approaches the coil, a current will be produced in the coil. This current will

grow to a maximum as the magnet passes close to the coil, dying down as the magnetic pole

moves further away. However when the opposite pole of the magnet approaches the coil, the

current

induced

in

the

coil

will

flow

in

the

opposite

direction.

As this process is repeated by the continual rotation of the magnet, an alternating current is

produced.

Fig: 2 interfacing between coil and magnet

Now lets consider what a transformer does. A transformer also causes an electric current to

be induced in a coil, but this time, the changing magnetic field is produced by another coil

having an alternating current flowing through it. Any coil with an electric current flowing

through it will act like a magnet and produce a magnetic field. If the direction of the current

changes then the polarity of the field changes interfacing between coil and magnet.

Now, the handy thing about a transformer is that, the voltage produced in the secondary coil

is not necessarily the same as that applied to the primary coil. If the secondary coil is twice

the size (has twice the number of turns) of the primary coil, the secondary voltage will be

8

BIET, Dept. of Electrical Engg.

INVERTER

twice that of the voltage applied to the primary coil. We can effectively produce whatever

voltage we want by varying the size of the coils.

Fig. 3 step up voltage coil

If we connected a direct current from a battery to the primary coil it would not induce a

current in the secondary as the magnetic field would not be changing. However, if we can

make that direct current effectively change direction repeatedly, then we have a very basic

inverter. This inverter would produce a square wave output as the current would be changing

direction suddenly.

Fig 4 Continually change current direction mechanism

9

BIET, Dept. of Electrical Engg.

INVERTER

This type of inverter might have been used in early car radios that needed to take 12 volts

available in the car and produce the higher voltages required to run radio valves (known as

tubes

in

America)

in

the

days

before

transistors

were

widely

used.

A more sophisticated inverter would use transistors to switch the current. The switching

transistors are likely to be switching a small current which is then amplified by further

transistor circuitry. This will still be a square wave inverter.

3.2 THE SINE WAVE INVERTER

To get a sinusoidal alternating current from the output of our transformer, we have to apply a

sinusoidal

current

to

the

input.

For

this

we

need

an

oscillator.

An amplifying transistor can be made to oscillate by feeding some of the amplified output

back to its input as positive feedback. We will all have heard this effect at some time when

someone is setting up a PA or microphone system. If the microphone is too close to the

speaker, some of the output from the speaker is fed back to the microphone and inputted to

the amplifier again. The result is a how ling sound which is produced by sine wave inverter.

The positive feedback in an electronic circuit can be tuned using extra components to produce

the frequency we require (generally either 50 or 60 cycles per second to mimic mains

electricity). If a crystal is used to control this frequency, as in a battery watch or clock, the

frequency

can

be

very

accurately

controlled

by

the

sine

wave

inverter.

As with simpler switching transistor circuit, the oscillator will be producing a low current

output. This will then need to be amplified by what will be roughly equivalent to a powerful

audio amplifier to produce the high current for the primary coil of the transformer (the

frequency of mains AC current is roughly equivalent to the lowest notes on a bass guitar).

10

BIET, Dept. of Electrical Engg.

INVERTER

Fig. 5 Arrangement of inverter

The transformer, while being very useful, does not do something for nothing. While

increasing the voltage, the current will be reduced, and the power (voltage x current) will

stay the same (less any inefficiency of the transformer). In other words, to get 1Kw of high

voltage AC current out, you have put 1Kw of low voltage AC current in.

3.2.1 GRID TIED INVERTERS

If the above example were a grid tied inverter, ie able to feed power back into the national

grid, it would need to use a sample of the mains voltage to then be amplified within the

inverter, or to synchronise (oscillation of wave) the oscillator with that sample.

Grid tied inverters will also sense if there is a "power cut" and disconnect themselves from

the grid. If they did not have this facility, in the event of a power cut, your inverter would be

attempting to power all your neighbours houses and would present an electrocution risk to

anyone working on power lines that had supposedly been turned off.

3.3 METHOD OF CONNECTION

First of all we have to make some changes in transformer. If we are using 500 V transformer

then take 18 to 22 gauge copper wire and on the one side of transformer’s core make five

turn and put a point on it, and turn this point, and again turn the wire five times on the same

direction. In this way we get three terminals. If we are connect the transformer to 220 V

power supply then it gives 1.5 V on both terminals. Now put transformer D1047 on the palm

of our hand and turn it such a way that number appears our way. Now we will see three

11

BIET, Dept. of Electrical Engg.

INVERTER

points. The point on our left side is known as (B) Base, middle one is collector(C) and the

right one is (E) emitter .

Now first of all tight the 8 transistor in heat sink in series with the help of nut bolt. Connect

the base of all two transistors together and then join the points of collector together.

In the same way arrange the other five transistors individually and connect the collector (C)

of both sides of transistors with the outer terminal of secondary coil, after that connect the

both outer terminals of the third coil with the base of the both heat sinks of transistor. then

connect the (E) emitter of both side by wires n then connect the 500 ohm resistor on emitter

and resistor on either side. Now connect the middle terminal of primary coil by one to two ft

long wire and clip (crocodile) it and attach this terminal always by the positive terminal, and

with the negative terminal of battery connect the both (E) emitter of transistor.

After that the central point of the third coil and a wire attach it with emitter to connect using

a heavy ampere switch between both terminals of the Inverter primary coil to apply a

capacitor which will prevent the current from the sparking. Inverter will switch on as soon

as starting to work.

3.4 CIRCUIT DIAGRAM

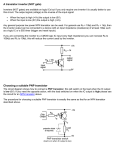

Fig. 6 Circuit diag. for low power

12

BIET, Dept. of Electrical Engg.

INVERTER

Fig. 7 Line diagram of inverter circuit

Fig. 8 Connection diagram for high power

13

BIET, Dept. of Electrical Engg.

INVERTER

Fig. 9 Connection diagram

Fig. 9 Connection diagram

14

BIET, Dept. of Electrical Engg.

INVERTER

Chapter-4

EQUIPMENT OF INVERTER

4.1 TRANSFORMER

A transformer is a power converter that transfers energy by inductive coupling between two

or more of its windings. A varying current in the primary winding creates a varying magnetic

flux in the transformer's core and thus a varying magnetic flux through the secondary

winding. This varying magnetic flux induces a varying electromotive force (EMF), or

"voltage", in the secondary winding. This effect is called inductive coupling.

If a load is connected to the secondary winding, current will flow in this winding, and

electrical energy will be transferred from the primary circuit through the transformer to the

load. Transformers may be used for AC-to-AC conversion of a single power frequency, or for

conversion of signal power over a wide range of frequencies, such as audio or radio

frequencies.

In an ideal transformer, the induced voltage in the secondary winding (Vs) is in proportion to

the primary voltage (Vp) and is given by the ratio of the number of turns in the secondary (Ns)

to the number of turns in the primary (Np) as follows:

By appropriate selection of the ratio of turns, a transformer thus enables an alternating current

(AC) voltage to be "stepped up" by making Ns greater than Np, or "stepped down" by making

Ns less than Np. The windings are coils wound around a ferromagnetic core, air-core

transformers being a notable exception.

Transformers range in size from a thumbnail-sized coupling transformer hidden inside a stage

microphone to huge units weighing hundreds of tons used in power stations, or to

interconnect portions of power grids. All operate on the same basic principles, although the

range of designs is wide. While new technologies have eliminated the need for transformers

in some electronic circuits, transformers are still found in nearly all electronic devices

designed for household ("mains") voltage. Transformers are essential for high-voltage electric

power transmission, which makes long-distance transmission economically practical.

15

BIET, Dept. of Electrical Engg.

INVERTER

Basic principal

Fig: 10 Magnetic coil in transformer

The transformer is based on two principles: first, that an electric current can produce a

magnetic field (electromagnetism) and second that a changing magnetic field within a coil of

wire induces a voltage across the ends of the coil (electromagnetic induction). Changing the

current in the primary coil changes the magnetic flux that is developed. The changing

magnetic flux induces a voltage in the secondary coil.

An ideal transformer is shown in the adjacent figure. Current passing through the primary

coil creates a magnetic field. The primary and secondary coils are wrapped around a core of

very high magnetic permeability, such as iron, so that most of the magnetic flux passes

through both the primary and secondary coils. If a load is connected to the secondary

winding, the load current and voltage will be in the directions indicated, given the primary

current and voltage in the directions indicated (each will be alternating current in practice).

4.1.1 INDUCTION LAW

The voltage induced across the secondary coil may be calculated from Faraday's law of

induction, which states that:

where Vs is the instantaneous voltage, Ns is the number of turns in the secondary coil and Φ is

the magnetic flux through one turn of the coil. If the turns of the coil are oriented

16

BIET, Dept. of Electrical Engg.

INVERTER

perpendicularly to the magnetic field lines, the flux is the product of the magnetic flux

density B and the area A through which it cuts. The area is constant, being equal to the crosssectional area of the transformer core, whereas the magnetic field varies with time according

to the excitation of the primary. Since the same magnetic flux passes through both the

primary and secondary coils in an ideal transformer,[34] the instantaneous voltage across the

primary winding equals

Taking the ratio of the two equations for Vs and Vp gives the basic equation for stepping up

or stepping down the voltage

Np/Ns is known as the turns ratio, and is the primary functional characteristic of any

transformer. In the case of step-up transformers, this may sometimes be stated as the

reciprocal, Ns/Np. Turns ratio is commonly expressed as an irreducible fraction or ratio:

for example, a transformer with primary and secondary windings of, respectively, 100 and

150 turns is said to have a turns ratio of 2:3 rather than 0.667 or 100:150.

Ideal power equation

Fig: 11 coupling between two coil

If the secondary coil is attached to a load that allows current to flow, electrical power is

transmitted from the primary circuit to the secondary circuit. Ideally, the transformer is

perfectly efficient. All the incoming energy is transformed from the primary circuit to the

17

BIET, Dept. of Electrical Engg.

INVERTER

magnetic field and into the secondary circuit. If this condition is met, the input electric power

must equal the output power:

Giving the ideal transformer equation

This formula is a reasonable approximation for most commercial built transformers today.

If the voltage is increased, then the current is decreased by the same factor. The impedance in

one circuit is transformed by the square of the turns ratio. For example, if an impedance Zs is

attached across the terminals of the secondary coil, it appears to the primary circuit to have an

impedance of (Np/Ns)2Zs. This relationship is reciprocal, so that the impedance Zp of the

primary circuit appears to the secondary to be (Ns/Np)2Zp.

Here the used transformer is of rating 12V input and 220V output transformer.

Fig: 12 step down transformer

18

BIET, Dept. of Electrical Engg.

INVERTER

Fig. 13 Transformer connection

Fig. 14 Transformer

4.2 TRANSISTOR

We should recall from an earlier discussion that a forward-biased PN junction is comparable

to a low- resistance circuit element because it passes a high current for a given voltage. In

turn, a reverse-biased PN junction is comparable to a high-resistance circuit element. By

using the Ohm's law formula for power (P = I2R) and assuming current is held constant, you

can conclude that the power developed across a high resistance is greater than that developed

19

BIET, Dept. of Electrical Engg.

INVERTER

across a low resistance. Thus, if a crystal were to contain two PN junctions (one forwardbiased and the other reverse-biased), a low-power signal could be injected into the

Forward-biased junction and produce a high-power signal at the reverse-biased junction. In

this manner, a power gain would be obtained across the crystal. This concept, which is

merely an extension of the material covered, is the basic theory behind how the transistor

amplifies. With this information fresh in your mind, let's proceed directly to the NPN

transistor.

4.2.1 NPN TRANSISTOR OPERATION

Just as in the case of the PN junction diode, the N material comprising the two end sections

of the NPN transistor contains a number of free electrons, while the center P section contains

an excess number of holes. The action at each junction between these sections is the same as

that previously described for the diode; that is, depletion regions develop and the junction

barrier appears. To use the transistor as an amplifier, each of these junctions must be

modified by some external bias voltage. For the transistor to function in this capacity, the first

PN junction (emitter-base junction) is biased in the forward, or low-resistance, direction. At

the same time the second PN junction (base-collector junction) is biased in the reverse, or

high- resistance, direction. A simple way to remember how to properly bias a transistor is to

observe the NPN or PNP elements that make up the transistor. The letters of these elements

indicate what polarity voltage to use for correct bias. For instance, notice the NPN transistor

below:

Fig: 15 NPN transistor

20

BIET, Dept. of Electrical Engg.

INVERTER

1. The emitter, which is the first letter in the NPN sequence, is connected to the negative side

of the battery while the base, which is the second letter (NPN), is connected to the positive

side.

2. However, since the second PN junction is required to be reverse biased for proper

transistor

operation, the collector must be connected to an opposite polarity voltage

(positive) than that indicated by its letter designation(NPN). The voltage on the collector

must also be more positive than the base, as shown below:

Fig: 16 NPN Transistor working

We now have a properly biased NPN transistor.

In summary, the base of the NPN transistor must be positive with respect to the emitter, and

the collector must be more positive than the base.

4.2.2 NPN FORWARD-BIASED JUNCTION

An important point to bring out at this time, which was not necessarily mentioned

during the explanation of the diode, is the fact that the N material on one side of the forwardbiased junction is more heavily doped than the P material. This result in more current is being

carried across the junction by the majority carrier electrons from the N material than the

majority carrier holes from the P material. Therefore, conduction through the forward-biased

junction is mainly by majority carrier electrons from the N material (emitter).

21

BIET, Dept. of Electrical Engg.

INVERTER

Fig: 17 forward-biased junctions in an NPN transistor

With the emitter-to-base junction in the figure biased in the forward direction, electrons leave

the negative terminal of the battery and enter the N material (emitter). Since electrons are

majority current carriers in the N material, they pass easily through the emitter, cross over the

junction, and combine with holes in the P material (base). For each electron that fills a hole in

the P material, another electron will leave the P material (creating a new hole) and enter the

positive terminal of the battery.

4.2.3 NPN REVERSE-BIASED JUNCTION

The second PN junction (base-to-collector) or reverse- biased junction as it is called (fig. 26), blocks the majority current carriers from crossing the junction. However, there is a very

small current, mentioned earlier, that does pass through this junction. This current is called

22

BIET, Dept. of Electrical Engg.

INVERTER

minority current, or reverse current. As you recall, this current was produced by the electronhole pairs. The minority carriers for the reverse-biased PN junction are the electrons in the P

material and the holes in the N material. These minority carriers actually conduct the current

for the reverse-biased junction

When electrons from the P material enter the N material, and the holes from the N material

enter the P material. However, the minority current electrons (as you will see later) play the

most important part in the operation of the NPN transistor.

Figure: 18 reverse-biased junction in an NPN transistor

At this point you may wonder why the second PN junction (base-to-collector) is not forward

biased like the first PN junction (emitter-to-base). If both junctions were forward biased, the

electrons would have a tendency to flow from each end section of the N P N transistor

(emitter and collector) to the center P section (base). In essence, we would have two junction

diodes possessing a common base, thus eliminating any amplification and defeating the

purpose of the transistor. A word of caution is in order at this time.

If you should mistakenly bias the second PN junction in the forward direction, the excessive

current could develop enough heat to destroy the junctions, making the transistor useless.

Therefore, be sure your bias voltage polarities are correct before making any electrical

connections.

23

BIET, Dept. of Electrical Engg.

INVERTER

4.2.4 NPN JUNCTION INTERACTION

We are now ready to see what happens when we place the two junctions of the NPN

transistor in operation at the same time. For a better understanding of just how the two

junctions work together.

Fig: 19 NPN transistor operation.

The bias batteries in this figure have been labeled V CC for the collector voltage supply, and

VBB for the base voltage supply. Also notice the base supply battery is quite small, as

indicated by the number of cells in the battery, usually 1 volt or less. However, the collector

supply is generally much higher than the base supply, normally around 6 volts. As you will

see later, this difference in supply voltages is necessary to have current flow from the emitter

to the collector. As stated earlier, the current flow in the external circuit is always due to the

movement of free electrons. Therefore, electrons flow from the negative terminals of the

supply batteries to the N-type emitter.

This combined movement of electrons is known as emitter current (IE). Since electrons are

the majority carriers in the N material, they will move through the N material emitter to the

emitter-base junction. With this junction forward biased, electrons continue on into the base

region. Once the electrons are in the base, which is a P-type material, they become minority

24

BIET, Dept. of Electrical Engg.

INVERTER

carriers. Some of the electrons that move into the base recombine with available holes. For

each electron that recombines, another electron moves out through the base lead as base

current IB (creating a new hole for eventual combination) and returns to the base supply

battery V BB. The electrons that recombine are lost as far as the collector is concerned.

Therefore, to make the transistor more efficient, the base region is made very thin and lightly

doped. This reduces the opportunity for an electron to recombine with a hole and be lost.

Thus, most of the electrons that move into the base region come under the influence of the

large collector reverse bias. This bias acts as forward bias for the minority carriers (electrons)

in the base and, as such, accelerates them through the base-collector junction and on into the

collector region. Since the collector is made of an N-type material, the electrons that reach

the collector again become majority current carriers. Once in the collector, the electrons

move easily through the N material and return to the positive terminal of the collector supply

battery VCC as collector current (IC).

To further improve on the efficiency of the transistor, the collector is made physically larger

than the base for two reasons: (1) to increase the chance of collecting carriers that diffuse to

the side as well as directly across the base region, and (2) to enable the collector to handle

more heat without damage.

In summary, total current flow in the NPN transistor is through the emitter lead. Therefore, in

terms of percentage, IE is 100 percent. On the other hand, since the base is very thin and

lightly doped, a smaller percentage of the total current (emitter current) will flow in the base

circuit than in the collector circuit.

Usually no more than 2 to 5 percent of the total current is base current (IB) while the

remaining 95 to 98 percent is collector current (IC). A very basic relationship exists between

these two currents:

IE = IB + I C

In simple terms this means that the emitter current is separated into base and collector

current. Since the amount of current leaving the emitter is solely a function of the emitterbase bias, and because the collector receives most of this current, a small change in emitterbase bias will have a far greater effect on the magnitude of collector current than it will have

on base current. In conclusion, the relatively small emitter- base bias controls the relatively

large emitter-to-collector current.

25

BIET, Dept. of Electrical Engg.

INVERTER

The transistor used here is D1047.

Fig: 20 transistor IC

4.3 HEAT SINK

In electronic systems, a heat sink is a passive heat exchanger component that cools a device

by dissipating heat into the surrounding air. In computers, heat sinks are used to cool central

26

BIET, Dept. of Electrical Engg.

INVERTER

processing units or graphics processors. Heat sinks are used with high-power semiconductor

devices such as power transistors and optoelectronic devices such as lasers and light emitting

diodes (LEDs), wherever the heat dissipation ability of the basic device package is

insufficient to control its temperature.

A heat sink is an essential component for cooling high-power integrated circuits. This heat

sink is a combination of aluminum fins and copper heat pipes for cooling high-heatdissipation processors (As shown is Freezer Xtreme from Arctic).

A heat sink is designed to increase the surface area in contact with the cooling medium

surrounding it, such as the air. Approach air velocity, choice of material, fin (or other

protrusion) design and surface treatment are some of the factors which affect the thermal

performance of a heat sink. Heat sink attachment methods and thermal interface materials

also affect the eventual die temperature of the integrated circuit. Thermal adhesive or thermal

grease fills the air gap between the heat sink and device to improve its thermal performance.

Theoretical, experimental and numerical methods can be used to determine a heat sink's

thermal performance.

Fig. 21 Heat Sink

4.4 PCB

Electronic circuits in schools and industry are normally manufactured through the use of

PCBs (Printed Circuit Boards). The boards are made from glass reinforced plastic with

27

BIET, Dept. of Electrical Engg.

INVERTER

copper tracks in the place of wires. Components are fixed in position by drilling holes

through the board, locating the components and then soldering them in place. The copper

tracks link the components together forming a circuit. The animation shows the components

arranged on the 'component side' of the PCB and as it rotates, the copper tracks are also

shown.

The two diagrams below show the track side of a PCB (normally the underneath side) and the

component side (normally the top side) of the same circuit. The relay and integrated circuit

are ready to be placed in position and soldered.

Fig 22 PCB Design

This allows individual components such as resistors, integrated circuits and capacitors to be

dragged onto the screen and connected together, forming a complete circuit. The finished

circuit can then be simulated on screen. If the circuit is not correct it can be altered until it

works in the desired way.

This allows you to test the circuit on the computer and correct any mistakes or make

improvements. This saves time as there is no need to build the circuit with real components.

28

BIET, Dept. of Electrical Engg.

INVERTER

Fig 23 circuit on breadboard

Circuits can also be built on a breadboard using real components. This is a time consuming

method and often mistakes occur as many components are small and it is easy to connect

components incorrectly, causing a circuit to fail. Also, breadboards are prone to damage as

the small connections on the breadboards (circuit connection) are quite delicate.

Using simulation software such as Crocodile Technology® is recommended as it is a much

more reliable and accurate method of testing a circuit.

4.5 RESISTOR

A resistor is a passive two-terminal electrical component that implements electrical resistance

as a circuit element.

The current through a resistor is in direct proportion to the voltage across the resistor's

terminals. This relationship is represented by Ohm's law:

Where I is the current through the conductor in units of amperes, V is the potential difference

measured across the conductor in units of volts, and R is the resistance of the conductor in

units of ohms.

The ratio of the voltage applied across a resistor's terminals to the intensity of current in the

circuit is called its resistance, and this can be assumed to be a constant (independent of the

voltage) for ordinary resistors working within their ratings.

29

BIET, Dept. of Electrical Engg.

INVERTER

Resistors are common elements of electrical networks and electronic circuits and are

ubiquitous in electronic equipment. Practical resistors can be made of various compounds and

films, as well as resistance wire (wire made of a high-resistivity alloy, such as nickelchrome). Resistors are also implemented within integrated circuits, particularly analog

devices, and can also be integrated into hybrid and printed circuits.

The electrical functionality of a resistor is specified by its resistance: common commercial

resistors are manufactured over a range of more than nine orders of magnitude. When

specifying that resistance in an electronic design, the required precision of the resistance may

require attention to the manufacturing tolerance of the chosen resistor, according to its

specific application. The temperature coefficient of the resistance may also be of concern in

some precision applications. Practical resistors are also specified as having a maximum

power rating which must exceed the anticipated power dissipation of that resistor in a

particular circuit: this is mainly of concern in power electronics applications. Resistors with

higher power ratings are physically larger and may require heat sinks. In a high-voltage

circuit, attention must sometimes be paid to the rated maximum working voltage of the

resistor.

Practical resistors have a series inductance and a small parallel capacitance; these

specifications can be important in high-frequency applications. In a low-noise amplifier or

pre-amp, the noise characteristics of a resistor may be an issue. The unwanted inductance,

excess noise, and temperature coefficient are mainly dependent on the technology used in

manufacturing the resistor. They are not normally specified individually for a particular

family of resistors manufactured using a particular technology. A family of discrete resistors

is also characterized according to its form factor, that is, the size of the device and the

position of its leads (or terminals) which is relevant in the practical manufacturing of circuits

using them.

Here we use the 1k Ω that is used to prevent the breaker in flow of high current.

30

BIET, Dept. of Electrical Engg.

INVERTER

4.5.1 HOW TO READ THE CODE

Resistors are color coded for easy reading. Imagine how many blind technicians there would

be otherwise.

To determine the value of a given resistor look for the gold or silver tolerance band and rotate

the resistor as in the photo on the left. (Tolerance band to the right-- refer to the tolerance

chart below for exact values.). Look at the 1st color band and determine its color. This maybe

difficult on small or oddly colored resistors. Now look at the chart and match the "1st & 2nd

color band" color to the "Digit it represents". Write this number down.

First the code...

Multipli

er

Blac

Bro

Re

Oran

Yello

Gree

k

wn

d

ge

w

n

0

1

2

3

4

5

1

10

10,00

100,0

0

00

10

0

1,000

Blue

Violet

Gray

6

7

8

1,000,0 10,000,0

00

00

100,000,

000

Whi

te

9

...

Table 1 How to read Resistor Color Codes

Now look at the 2nd color band and match that color to the same chart. Write this number

next to the 1st Digit.

The last color band is the number you will multiply the result by. Match the 3rd color band

with the chart under multiplier. This is the number you will multiply the other 2 numbers by.

Write it next to the other 2 numbers with a multiplication sign before it. Example : 2 2 x

1,000.

To pull it all together now, simply multiply the first 2 numbers (1st number in the tens

column and 2nd in the ones column) by the Multiplier.

Read the number as the '% Failure rate per 1000 hour' This is rated assuming full wattage

being applied to the resistors. (To get better failure rates, resistors are typically specified to

have twice the needed wattage dissipation that the circuit produces) 1% resistors have three

31

BIET, Dept. of Electrical Engg.

INVERTER

bands to read digits to the left of the multiplier. They have a different temperature coefficient

in order to provide the 1% tolerance.

Tolerance Explained Resistors are never the exact value that the color codes indicate.

Therefore manufacturers place a tolerance color band on the resistor to tell you just how

accurate this resistor is made. It is simply a measurement of the imperfections.

Tolerance

Rating

Red = 2%

Gold = 5%

Silver = 10%

No band = 20%

Fig. 24 Resistor

32

BIET, Dept. of Electrical Engg.

INVERTER

4.6 ELECTROLYTIC CAPACITOR

An electrolytic capacitor is a capacitor that uses an electrolyte (an ionic conducting liquid) as

one of its plates to achieve a larger capacitance per unit volume than other types, but with

performance disadvantages. All capacitors conduct alternating current (AC) and block direct

current (DC) and can be used, amongst other applications, to couple circuit blocks allowing

AC signals to be transferred while blocking DC power, to store energy, and to filter signals

according to their frequency. Most electrolytic capacitors are polarized; hence, they can only

be operated with a lower voltage on the terminal marked "-" without damaging the capacitor.

This generally limits electrolytic capacitors to supply-decoupling and bias-decoupling, since

signal coupling usually involves both positive and negative voltages across the capacitor. The

large capacitance of electrolytic capacitors makes them particularly suitable for passing or

bypassing low-frequency signals and storing large amounts of energy. They are widely used

in power supplies and for decoupling unwanted AC components from DC power connections.

Super capacitors provide the highest capacitance of any practically available capacitor, up to

thousands of farads, with working voltages of a few volts. Electrolytic capacitors range

downwards from tens (exceptionally hundreds) of thousands of microfarads to about 100

nano-farads smaller sizes are possible but have no advantage over other types. Other types of

capacitor are available in sizes typically up to about ten microfarads, but the larger sizes are

much larger and more expensive than electrolytic (film capacitors of up to thousands of

microfarads are available, but at very high prices). Electrolytic capacitors are available with

working voltages up to about 500V, although the highest capacitance values are not available

at high voltage. Working temperature is commonly 85°C for standard use and 105° for hightemperature use; higher temperature units are available, but uncommon.

Unlike other types of capacitor, most electrolytic capacitors require that the voltage applied to

one terminal (the anode) never become negative relative to the other (they are said to be

"polarized"), so cannot be used with AC signals without a DC polarizing bias (non-polarized

electrolytic capacitors are available for special purposes).

Leakage current, capacitance tolerance and stability, equivalent series resistance (ESR) and

dissipation factor are significantly inferior to other types of capacitors, and working life is

shorter. Capacitors can lose capacitance as they age and lose electrolyte, particularly at high

temperatures. A common failure mode which causes difficult-to-find circuit malfunction is

33

BIET, Dept. of Electrical Engg.

INVERTER

progressively increasing ESR without change of capacitance, again particularly at high

temperature. Large ripple currents flowing through the ESR generate harmful heat.

Two types of electrolytic capacitor are in common use: aluminum and tantalum. Tantalum

capacitors have generally better performance, higher price, and are available only in a more

restricted range of parameters. Solid polymer dielectric aluminum electrolytic capacitors have

better characteristics than wet-electrolyte types in particular lower and more stable ESR and

longer life at higher prices and more restricted values.

Fig. 25 Capacitors

4.7 CHARGING CIRCUIT

The charging circuit includes four diode and two capacitors, the diodes are used for

conversation of AC into DC and the capacitors are used for remove AC harmonics from

circuit to charge the battery.

Fig.26 Charging circuit

34

BIET, Dept. of Electrical Engg.

INVERTER

Chapter- 5

WAVEFORM OF TRANSFORMER OUTPUT

5.1 OUTPUT WAVEFORMS

This output shows the final output of our 12V DC circuit. The sine wave, fully summed

together shows the approximation of a 2.5Vptp sine wave. Important issues to note. First, the

wave is non-problematic and non-attenuating for loads of 10k~50k ohms. With further tuning

of the circuit these ranges could be made larger. Secondly, the “impurities” of the sine wave

seem to be due to capacitive elements of the input waveforms. This could either come from

Fig: 27 waveform of transformer

Current that the step up voltage winding is drawing (issues from the circuit itself) or from the

windings and properties of the transformer. We will be able to fix this by purchasing/making

a transformer with more time and more tailored to the needs of our circuit.

35

BIET, Dept. of Electrical Engg.

INVERTER

CONCLUSION

“I think we’re uncomfortable when problems don’t have neat solutions”. When the real world

frustrates us, we make assumptions and propose simple models that may or may not capture

the true behavior with all the work done so far, I believe some progress has been made in

settling the problem with systems addressed in the introduction.

With the help of a battery 12v DC is given to transistor D1047. With the help of fast

switching operation we can obtain sinusoidal wave. The simple circuit topology supports a

low cost and high efficiency power converter. The proposed inverter circuitry has a low

component count with only two transistors, one resistor and one transformer. An inverter is

used to produce an un-interrupted 220V AC (depending on the line voltage of the particular

country) supply to the device connected as the load at the output socket. The inverter gives

constant AC voltage at its output socket when the AC mains power supply is not available.

The 100 Watt inverter applicable for home application and light load.

36

BIET, Dept. of Electrical Engg.

INVERTER

REFERENCE

Power Electronics: Energy Manager for Hybrid Electric Vehicles".

Laboratory Review (U.S. Department of Energy)

Rodriguez, Jose; et al. (August 2002). "Multilevel Inverters: A Survey of Topologies,

Controls, and Applications". IEEE Transactions on Industrial Electronics (IEEE)

Power Stream. 2006 "Inverter FAQ".

. http://www.powerstream.com/inFAQ.htm

Owen, Edward L. (January/February 1996). "Origins of the Inverter". IEEE Industry

Applications Magazine: History Department (IEEE).

D. R. Grafham and J. C. Hey, editors, ed. SCR Manual (Fifth Ed.). Syracuse, N.Y. USA:

General Electric..

How to make homemade ups www.paksc.org

General references

Bedford, B. D.; Hoft, R. G. et al. (1964). Principles of Inverter Circuits. New

York: John Wiley

Mazda, F. F. (1973). Thyristor Control. New York: Halsted Press Div. of John

Wiley & Sons.

Dr. Ulrich Nicolai, Dr. Tobias Riemann, Prof. Jürgen Petzoldt, Josef Lutz:

Application Manual IGBT and MOSFET Power Modules.

37

BIET, Dept. of Electrical Engg.