* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Lecture 10

History of electric power transmission wikipedia , lookup

Induction motor wikipedia , lookup

Stepper motor wikipedia , lookup

Wireless power transfer wikipedia , lookup

Skin effect wikipedia , lookup

Alternating current wikipedia , lookup

Ignition system wikipedia , lookup

Electric machine wikipedia , lookup

Transformer wikipedia , lookup

Lecture 10

Coils (Inductors)

Passive Electronic Components and Circuits (PECC)

V. Bande, Applied Electronics Department

www.ael.utcluj.ro (English version)-> Information for students

1

Coils

Coils

Short history

Electrical Properties

Constructive elements for coils

Parameters

Categories

Transformers

Short history

• 1821 – Michael Faraday reveals the magnetic field lines which occur

around a conductive material through which an electric current flows.

• 1825 – William Sturgeon builds the very first electromagnet.

• 1831 – independently, Michael Faraday and Joseph Henry discover the

magnetic induction law.

Afterwards, Faraday builds the first electrical engine, the first

electrical generator and the first transformer.

Henry builds the first telegraph improved later by Morse.

• 1876 – Bell invents the first telephone and the first electromagnetic

phonograph.

Coils

Coils

Short history

Electrical Properties

Constructive elements for coils

Parameters

Categories

Transformers

Electrical properties

• The inductance of a coil is strongly

dependent of the coil’s geometry and the

magnetic properties of the environment in

which it is placed.

• Equation 1 is suitable for the case in which

the length “l” of the coil is higher then its

diameter “2rc”.

A 2

L 0 r N

l

( 0 N 2 rc )

L

Henries

l

8r

L 0 N 2 rc {ln( c ) 2}

rw

2

• Equation 2 is suitable for the case in which

the length “l” of the coil is lower then its

diameter “2rc”. The “rw” quantity

represents the winding wire’s diameter.

(1)

(2)

0 4 10 7 [Wb A1 m 1 ]

Electrical properties

• The inductance is dependent of the coil’s geometry (l, d=2r, h in mm).

All the above formulas are available when the environment in which

the coil is placed is the air.

L 0,001

N 2d

l

0,44

d

[μH]

N 2d 2

L 0,008

[μH]

3d 9l 10h

Electrical properties

• The inductance is dependent of the

distance between its turns.

• The inductance is dependent of the

magnetic

properties

of

the

environment in which the coil is

placed – magnetic permeability, μ.

Air: 1.257x10-6H/m.

Ferrite U M33: 9.42x10-4H/m.

Nickel: 7.54x10-4H/m.

Iron: 6.28x10-3H/m.

Ferrite T38: 1.26x10-2H/m.

Orr: 5.03x10-2H/m.

Super Malloy: 1.26H/m.

Electrical properties

Equivalent circuit

ZL

R p jL

1 2LC p jR pCp

Electrical properties

Frequency characteristic

ZL

Rp Q

L

zona inductiva

10%

1

C

Rp

10%

2, 2 R p

L

0,3 0

0

1

LCp

Electrical properties

Dimensioning the inductance:

km

l

8

6

D

4

2

p/d

0

p

d

(ND) 2

L0

107 [H]

l 0,45 D

L1 L0 L

1

2

3

4

L k m N D 107 [H]

Electrical properties

The parasitic capacitance value calculus:

Cp[pF]

30

20

10

7

5

D=10cm

3

D=8cm

2

D=6cm

D=4cm

1

D=2cm

0,7

0,5

p/d

1 1,1

1,3 1,5

1,7

2

2,5

3

3,5

4

Electrical properties

Steps in designing a coil:

• The procedure starts from the

desired value for the inductance –

“L”, its diameter “D” and the

frequency domain in which it will

work – “ω0”.

L, 0 , D

C p max

1

L02

• From the last slide characteristic

the maximum value of the

parasitic capacitance is chosen.

• The turns number can be

calculated in respect with the coil’s

geometrical

dimensions

by

resolving the adjacent equation.

N 2D

L[μH]

0,1k m ND

dp

0,44 N 1

Dd

p / d km

Calculate the length of a coil with a 2 cm diameter and an inductance

of 50 H which is executed in a single layer and will have a desirable

parasitic capacitance lower then 2pF.

Coils

Coils

Short history

Electrical Properties

Constructive elements for coils

Parameters

Categories

Transformers

Constructive elements for coils

• The winding (the turns).

• The casing.

• The impregnation (soak) material.

• The core.

without a core

Iron core

Ferrite core

Constructive elements for coils

The coil’s winding

• The most common used material for the conductive winding wire

is the copper (due to its electrical and mechanical properties) and

rarely aluminum.

• The conductive wires are being insulated to avoid short-circuits

between two adjacent turns. The materials used for the insulation

are enamels (ro: emailuri) – different composition varnishes, textile

fibers (silk, cotton) or mineral fibers (glass fiber). The insulating

material type is generally chosen in strong dependency with the

conductive wire’s estimated maximum temperature. The most

thermal resistant materials are the glass fibers, the most

susceptible ones are the textile fibers.

Constructive elements for coils

The coil’s winding

• The coil’s winding diameter can be estimated following 2 criteria:

The maximum estimated value of the current that passes through

the conductive materials is inferiorly limiting this parameter due

to excessive heating possibility.

The parasitic resistance maximum value introduces a

supplementary limitation for the windings diameter.

• At high frequencies, due to the pellicle effect, stranded (ro: litat) wires

are used (thin bundles of wires – ro: manunchiuri de fire) or silvered

copper wires.

• The conductive winding wires are being delivered by the producers

in a standardized fashion: 0.05 mm, 0.07 mm, 0.1 mm, … , 2 mm. The

thickness of the insulating material is not included in the above

values.

Constructive elements for coils

The coil’s casing

• The coil’s casing fulfill the role of keeping the stiffness of the

winding.

• The materials used must have adequate electrical (dielectric rigidity,

low dielectric losses) and mechanical properties (thermal and

humidity stability).

• Examples – ascending order of theirs performances: electroinsulating carton, pertinax, textolit, thermo-rigid materials (Bakelite),

thermo-plastic materials (polystyrene, polyethylene, Teflon) or

ceramic materials.

• From the geometrically point of view the material can be of different

cross-sections: circular, square, rectangular.

• At very high frequencies, the coils can be made without a casing.

Constructive elements for coils

The coil’s impregnation (soak) material

• The impregnation material has the role to protect the coil against

humidity and also realizes a supplementary stiffness (especially for

the cases when the coils are not using casings).

• The impregnation advantages:

Winding stiffness.

Improves heat dissipation.

Improves dielectric properties of the turns insulation.

Avoids humidity penetration between turns.

• The impregnation disadvantages: can concur to a higher parasitic

capacitance (by growing the electrical permittivity of the insulating

material between the turns).

Constructive elements for coils

The coil’s core

• To increase the obtained inductance, magnetic cores are being

displaced inside coil’s winding. So a magnetic circuit is created

which has the major contribution in concentrating the magnetic field

lines. In this way the magnetic flux increases, almost all the magnetic

lines intersect the turns, in conclusion the coil’s inductance increases.

• The magnetic materials have a non-linear behavior when are being

placed in an exterior magnetic field. This non-linearity is related

with the dependency of the magnetic induction “b” and the

magnetic field intensity “H”. The ratio between the above two

quantities is the environment's magnetic permeability:

B

1 B

; r

H

0 H

Constructive elements for coils

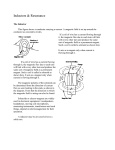

The magnetic materials properties – Hysteresis phenomena

• Hc – coercive field – cancels the

magnetic induction.

• Br

–

residual

induction.

B

Bs

Bm

magnetic

• Hs – the magnetic field intensity

at which saturation phenomena

occurs.

• Bs – the magnetic induction at

saturation point.

Br

-Hs -Hm

0

-Hc

H c Hm H s

-Br

-Bm

-Bs

H

Constructive elements for coils

The magnetic materials properties – Hysteresis phenomena

• The magnetic materials have atoms with an own magnetic

moment, and the neighbor atomic moments are being orientated

identically, so the material will have a residual magnetization.

• When applying an exterior magnetic field, a reorientation of the

magnetic domains occurs. The exterior field intensity at which

the magnetic induction is canceling is called coercive field. When

“H” increases, the saturation phenomena occurs (“B” remains

constant).

• The phenomena are dependent with the direction on which the

magnetic field changes (hysteresis).

• The residual magnetization exhibits until a certain temperature

(Curie temperature) at which the thermal agitation destroys the

well-ordered orientation domains.

Constructive elements for coils

Magnetic materials applications

• Soft magnetic materials – Hc<80A/m (narrow hysteresis)

• Rough magnetic materials – Hc>80A/m (wide hysteresis)

• Soft magnetic materials with the ratio Br/Bm (ratio which

characterizes the hysteresis inclination) lower then 0.5 are used

for constant inductances, the ones with 0.5< Br/Bm<0.8 for

common used cores, the ones with Br/Bm>0.8 (rectangular

hysteresis) are used in switching and memorizing applications.

• Rough magnetic materials with the ratio Br/Bm<0.4 are used for

magnetically recording the information and the ones with

Br/Bm>0.4 for permanent magnets fabrication.

Constructive elements for coils

Core constructive types

• Core-trays (ro: tole), bands, columns, coatings for transformers

magnetic circuits.

• Cylindrical bars for high frequencies inductances (also for

adjustable inductances).

• Torus (ro: miezuri toroidale) and pots (miezuri tip “oala”) for high

frequency and pulses applications.

• Different forms of yokes (ro: miezuri tip “jug”)

• For high frequency applications, the cores are being obtained by

compressing magnetic powders. That results in obtaining

magneto-electric cores (the magnetic powder is a ferromagnetic

material) or magneto-ceramic cores (ferrites).

Constructive elements for coils

Designing a core coil

• If a coil without a core has the “L0” inductance, the core

displacements inside its windings changes its inductance:

L ef L0

• The effective magnetic permeability, μeff, is dependent with the

material’s relative permeability, with its geometry and with the

relative position in respect with the winding.

• The ferrite producers indicate in the datasheets a so called

inductance factor, AL, having the following meaning: the

inductance factor is the obtain inductance if on the ferrite core is

made only 1 turn (nH/turn or μH/turn). Using this parameter ,

the total inductance can be obtained:

L AL N 2

Coils

Coils

Short history

Electrical Properties

Constructive elements for coils

Parameters

Categories

Transformers

Parameters

• The inductance and its tolerance.

• The coil’s own resistance.

• The loss-angle tangent.

• The quality factor.

• The temperature coefficient.

tg L

vRL

vL

QL

RL

L

L

RL

1 dL

L

L dT

Coils

Coils

Short history

Electrical Properties

Constructive elements for coils

Parameters

Categories

Transformers

Categories

Constructive types

• Toroidal (A).

• Cylindrical (B).

• Encapsulated (C).

• Adjustable (D, E).

Categories

Spiral circular plane coil

3,2 10 2 a 2 N 2

L

[ μH ]; where

6a 10c

d a di

d a di

a

[ m] c

[ m]

4

2

Categories

Spiral square plane coil

0,0122 l 2 N 2

L

[μH];

4l 11c

c – trace width

Coils

Coils

Short history

Electrical Properties

Constructive elements for coils

Parameters

Categories

Transformers

Transformers

• A transformer is an electrical component which consists on two

coils mounted on the same magnetic core.

• The magnetic core links the magnetic flux,ФB , from the two coils.

• Taking into consideration the Faraday law:

d B

VP N P

dt

d B

VS N S

dt

VS

NS

The transformer’s equation

VP N P

N S N P Voltage increasing transformers

N S N P Voltage decreasing transformers

Transformers

Ideal transformer

• An ideal transformer doesn’t have losses, so:

Input Power = Output Power

VP I P VS I S

I S VP N P

I P VS

NS

Real transformers can reach an efficiency

higher then 99%

• A transformer makes its job only if the voltage/current varies

through one of its windings. This variation will generate a variable

flux which will lead to a variable voltage into the second winding.

Transformers

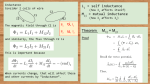

Mutual inductance

• The time variation of the current from the

primary winding determines the occurrence of

a induced voltage in the secondary winding.

Obviously, the current through the second

winding appears only if at the second

windings terminals, a load is connected.

• Let us consider the coil 1 with N1 – turns number and coil 2 with N2

– turns number and Ф21 – the magnetic flux in the second coil

occurred due to the current that flows through the first coil:

N221 i1 N221 (constanta ) i1 M 21i1

N 2 21

M 21

i1

Mutual inductance

Unit – Henry

1H=Vs/A=Ωs

Transformers

Mutual inductance

• The induced voltage in the second coil can be expressed:

d 21

v2 N 2

dt

21

M 21

i1

N2

d 21 M 21 di1

dt

N 2 dt

M 21 di1

di1

v2 N 2

M 21

N 2 dt

dt

Transformers

Mutual inductance

• Similar, it can be shown that the induced voltage into the first coil

by the second coil’s current variation is:

v1 M 12

di2

dt

• But, generally M21=M12 and can be written as follows, where k –

coupling factor:

M M M k Lp Ls

2

21

2

12

2

2

• In conclusion:

di2

v1 M

dt

di1

v2 M

dt

Transformers

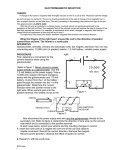

The transformer – circuit analysis

Ro

vo

ip

vp

vs

Primar

Secundar

NP

LP

NS

LS

is

Rl

• The transformer has two coils (as the symbol from the circuit above).

The one from the circuit where the Vo source is applied is called

primary coil and has the Lp inductance, and the one from the circuit

where the Rl – load resistance is , is called secondary coil and has the

Ls inductance.

• Both inductances work on theirs designated circuit as was presented

before, but supplementary the inductances are being magnetically

coupled through the mutual inductance, M.

Transformers

The transformer – circuit analysis

Ro

vo

ip

vp

vs

Primar

Secundar

NP

LP

NS

LS

• The voltage across the primary coil will be:

vp jLP ip jMis

• The voltage across the secondary coil will be:

vs jLSis jMip

is

Rl

Transformers

The transformer – circuit analysis

Ro

vo

ip

vp

vs

Primar

Secundar

NP

LP

NS

LS

is

• Applying the KVL in the primary winding:

vo Ro ip jLPip jMis

• Applying the KVL in the secondary winding:

0 Rl is jLSis jMip

Rl

Transformers

The transformer – circuit analysis

Ro

vo

ip

vp

vs

Primar

Secundar

NP

LP

NS

LS

is

Rl

• Extracting, from the second equation, the is current

dependent of the ip current and introducing it in the first

equation (KVL for the primary winding), and also

taking into consideration that:

• It can be obtained that:

LP N P

LS N S

2

N

vo Ro ip jLP || Rl S ip

NP

2

Transformers

The transformer – constructive types

• Cylindrical (solenoidal)

• Torus

• Yoke

Important formulas

Resistors

Capacitors

l

l

R Cu r

S

S

A

C 0 r

d

A

2

L 0 r N

l

Cu=5,344 x 10-7 -cm

0=8,8542·10-12 F/m

0=4·π·10-7 H/m

Coils

Problem

Using a copper wire (φCo = 5.344x10-7 Ωm) with 1 mm diameter, a

winding of 40 turns is being executed on insulated cylindrical support

with the diameter of 10 mm.

Please determine the electrical parameters of the realized coil.

What is the modulus of the coil’s impedance at 50Hz? What is

the modulus of the coil’s impedance at 500kHz?