* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Build well with waste

Survey

Document related concepts

Transcript

status of Environment and Related luues

VoI.2 No.9

Build well with waste

T

he construction industry in

India is growing fast. The

increase in the demand for

homes and commercial space has driven

the sector to a growth rate of 9.2 per cent

every year, against the global average of 5.5 per

cent. Of late, concerns have been raised over the

way residential apartments and commercial buildings are

designed and constructed. Most of these concerns pertain

to energy, environment, sustainable construction

methods and technology.

~

What is eco-friendly building material?

Eco-friendly construction material are those

that have a lower effect on human health

and the environment when compared

with competing products that serve

the same purpose.

Eco-Friendly

Construction

material

Eco-friendly construction

alternatives

Eco-friendly construction alternatives should necessarily

have the following properties:

+ Derived from renewable source: like agricultural

waste.

The most common raw material used in construction are

of waste product: use of fly ash, iron ore

+

Re-use

steel, cement, glass, aluminum, plastics, bricks, etc. All

these are energy-intensive material and need to be

tailings etc.

transported across vast distances leading to more energy

+ Easy availability: for material not locally available,

consumption. It is not possible to meet the ever-growing

transport costs could be significant, affecting costdemand for housing by using only traditional energyeffectiveness.

efficient material like mud, thatch, timber, bamboo, etc.

+ Reduction in air, land and water pollution: use of

a.l.w. h. i.ch

iiioiir.es.ul

iiiiii

ts. in

. less or no VOC emission,

or those which may not

Thus there is a need for ,.

Properties of eco-frlendly building materials and techniques

result in water and lor

optimum utilization 0

the available energy

Renewable source

air pollution.

resources and raw

\

JBiodegradable

+Durability & life span:

material to produce

material which are

simple, energy-efficient, ~~~.:;

d'Reuse/recycle

durable and require

environment-friendly

Eco-friendly materials

low maintenance

Embodied ~

and techniques

~

+

and sustainable building

energy...-v

~Aidsenergy

Energy efficient:

alternatives. It is in this

context that the eco~

A

~

efficiency in building

Those which require

friendly construction

"

1f

"'\

less energy for

Local availability

Durability and

d ti'

likepre•a

I'fa

proucon,

materl'al gal'n

Reduction in air, water

I span

importance.

and land pollution

cast slabs.

_______________.m

_a.ten

...·

~--------------------------------------~ +Bio-degradable:

The demand-supply gap

In the last 50 years, the country's population has risen

from 330 million to 1.07 billion. Between 1999 and 200 1,

there was a requirement for 4,61,600 million bricks and

24,700 million roof tiles, a need that could not be met.

Against a housing requirement of200 million units, only

175 million are currently available, leaving a huge gap

between the need and availability.

material constructed from farm waste etc.

+ Reuse / recycle: products like aluminum and iron can

be reused.

These alternatives may serve all or some of the above

mentioned criteria but generally they should be costeffective so as to be financially viable for a potential

customer. Cost-effectiveness may depend on a variety of

factors like availability of raw material, its use for other

According to India's national report, by 2021 the country would face a housing shortage of 44.9 million units

-

~hri. Subir Hart Singh, lAS,

Principal Secretary to Government

~ousing Department

~ikas Soudha

~angalore 560001

02-04-2007

MESSAGE

With increase in population, burgeoning urban growth and general improvement in the

standard of living of the people, the construction industry in the country is witnessing an

unprecedented growth. While glass-and-aluminium structures are often seen as signs of prosperity

and well-being, there are simple, energy-efficient, environment-friendly and sustainable building

alternatives available.

Eco-friendly construction materials derived from easily available, renewable sources that are

durable and bio-degradable is available as a less expensive option. Judiciously used, this allows the

discerning citizen to build aesthetically-pleasing and comfortable homes and other structures while

making a statement of his commitment to nurture environment.

In this backdrop, a word of caution to every citizen building his or her house is that they make

sure of proper and timely disposal of construction waste generated during building dream houses in an

environmentally friendly way.

~l

!A

(s!'ir~in~

purposes (competing uses), maintenance requirements

and durability.

Conventional eco-friendly building material

--Bamboo, bamboo-based particle board & ply board,

bamboo matting

.-Sun dried bricks

'-Pre-cast cement concrete blocks, lintels, slabs.

Structural and non-structural modular elements

'-Calcined phospho-gypsum wall panels

'-Calcium silicate boards and tiles

'-Cellular light weight concrete blocks

'-Cementpaint

'-Clay roofing tiles

'-Water, polyurethane and acrylic-based chemical

admixtures for corrosion removal, rust prevention,

waterproofing

'-Epoxy resin system, flooring, sealants, adhesives and

admixtures

'-Ferro-cement boards for door and window shutters

'-Ferro-cement roofing channels

'-Fly-ash sand lime bricks and paver blocks

'-Gypsum board, tiles, plaster, blocks, gypsum plaster

fibre jute / sisal and glass fibre composites

'-Laminated wood plastic components

'-Marble mosaic tiles

'-MDFboards and mouldings

'-Micro concrete roofing tiles

'-Particle boards

'-Polymerised waterproofcompound

'-Portland pozzolana cement fly-ash / calcinated clay

based

'-Portland slag cement

2

~!>roximate

'-RCC door frames

'-Readymix cement concrete

'-Rubberwood fingerjoint board

'-Stonedust

'-Waterproofcompound, adhesive, polymer powder

Eco-friendly material / techniques and resource

centres

~ Bagasse board- BMTPC

}> Bricks from coal washery rejects CBRI, Roorkee

}> Building blocks from mine waste SERC

}> Burnt clay flyash bricks CBRI, Roorkee

}>Coircementboard CBRI,Roorkee

}>Compressed earth blocks BMTPC

}> EPS composites and door shutters CBRI, Roorkee

}> Fibre flyash cement boards BMTPC

}> Fibre-reinforced concrete pre-cast elements, wall

panels, blocks, manhole covers SERC

}> Fibrous gypsum plaster boards CBRI, Roorkee

}> Flyash cellular concrete, flyash cement brick, blocks

BMTPC

Kamataka Rajya Nirmana Kendra

(KARNIK), a Government ofKamataka

enterprise, is promoting cost-effective

building technologies through its

network of'Nirmiti Kendras' in the State.

It received a Government of India award

for utilization of fly ash as an innovative

building material on World Habitat Day

2006.

100 million tonnes of fly ash is generated in india's thermal power plant per annum

President A P J Abdul

KaJam's VISion of construction in tbe

Hon'ble

fntnre

''The building of the future will have

many new features of aesthetics and

convenience. Their energy sources will

be cleaner, based on solar power and

hydrogen. The glass panes of windows

and doors may have conducting polymers to regulate transmission of

solar rays into the room. The leakages during the monsoon will be a

thing of the past due to improved design and construction methods.

Above all, the time taken for construction ofhouses may be cut down to

several weeks or a few months instead of years. This would be

achieved thorough the use ofprefabricated structures and various other

factory-manufactured parts like advanced composite doors".

pollution. At present, fly ash is disposed

of by mixing it with bottom ash and large

quantities of water. The resultant slurry is

sluiced to settle in a setting pond. This

method makes heavy demand on land

and has the potential to cause ground

water pollution.

A remedy to this malady is to use fly ash

for the manufacture of bricks, Portland

pozzolana cement blocks, tiles, light

weight aggregates and hollow blocks.

Consisting mostly of silica, alumina and

iron, fly ash is a pozzolana a substance

containing aluminous and silicious

material that forms cement in the

presence ofwater. When mixed with lime

and water, it forms a compound similar to

Issues to be addressed by the construction industry include:

portland cement. The spherical shape of

. . Minirnizjng the use ofhigh energy material

the particles reduces internal friction

. . Use ofenvironment-friendly technologies

thereby increasing the concrete's

. . Minimize transportation ofmaterial

consistency. Improved workability also

. . Maximize the use oflocal material and resources

means less water is needed, resulting in

less segregation of the mixture. Though

. . Utilization of industrial and mine wastes for the production of

fly ash cement itself is less dense than

building material

portland cement, it results in a smoother

surface with sharper detail.

Building technologies meeting these principles could become

Mechanized manufacture of fly ash lime

sustainable and facilitate sharing or resources especially in using

bricks has already been undertaken in

energy more efficiently. This could minimize damage to the

many

parts of the country. The aim is to

environment.

utilize bulk quantities of fly ash and help

bridge the huge shortfall of bricks and

other building material required by the

}> Flyash lime cellular concrete CBRI, Roorkee

construction industry. At present in India, fly ash is being

}> Flyash lime gypsum brick BMTPC

used to manufacture ash blocks, floor tiles, terrazzo tiles,

cellular lightweight concrete (CLC), MCR tiles, door and

}> Insulating bricks from rice husk ash Central Glass

window

frames, interlocking blocks and flowerpots.

and Ceramic Research Institute, Kolkata

}> Jute fibre polyester BMTPC

}> Non-erodable mud plaster CBRI, Roorkee

}> Ploytiles CBRI, Roorkee

}>Timber from trees such as poplar, rubber, eucalyptus

BMTPC

}> Precast wall and roofing components CBRI, Roorkee

}> Prefab brick panel system CBRI, Roorkee

Let's now take a look at some of the eco-friendly

construction material which are in use in India.

Fly ash bricks

Almost 70 per cent ofthe total power generated in India is

through coal-based plants. This translates into 70 million

tones of fly ash generation every year and the production

may increase in the years to come. Management offly ash

is a huge problem as it is light weight and can travel by air

and result in reduced agricultural productivity and water

Fly ash products

There are about 50,000 tile and brick industries in the country.

3

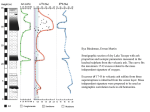

Agro wastes generated in India (million tonnes / year)

90

Million tonnes / year

80

90

70

60

50

40

20

30

14

20

12

11

2

0

Series1

Bagasse

Rice husk

Jute

90

20

14

Rice wheat Groundnut

Straw

shell

12

11

1.4

1.6

10

Saw mill

waste

Coconut

husk

cotton stalk

2

1.6

1.4

Source: www.ics.trieste.it

4

A model house from unconventional building material

Cost comparison of buildings constructed

by conventional method and by using

Iron ore waste tailings products

Nam. of building

Pilot plant

Demonstration unns

•

•b

2. D.

dra

a Model house

Model house in R&D centre, Surathkal

Total

Totolcostof

Total cost of

building

constructed

using iron-ore

wut8talling

products

building If

constructed

Over'llil

savings

33.08.000

.01 of

conventlona'

prod....

36.00.000

135000

169000

1,49.000

1.87.000

34000

38.000

1.33.000

37 000

1.67.000

4123000

34.00.000

398000

2.92.000

The house has clean lines and a compact design. It looks like any other well-designed urban, low-cost housing

effort. What is different however is that it has been constructed out of unconventional building material. The doors

are made out of a wood substitute, the walls from iron tailing blocks, and the ceiling sports rafters made from ferrocement. A living room, a bedroom, a kitchen and bath-toilet make up the accommodation available in the house.

The house can comfortably accommodate a family of four members (see table for cost comparison between

constructing

with iron ore waste tailing products and conventional products).

,

The model house has demonstrated that iron tailing products work well; additionally, the technology can also be

replicated wherever there is a requirement for low-cost housing options. It offers, thus, a ray of hope for the

housing sector and economically backward sections of society.

bonded particle board which can bring down the use of

cement and brick. The cement board uses only 60 per cent

of cement and the remainder 40 per cent is eucalyptus

flakes and other agricultural waste. These boards can

withstand the damage caused by fIre and earthquake and

are waterproof too. They have four times the strength of

ordinary cement and require less water to set. Bricks

made from agricultural wastes are bio-degradable and

lastionger.

muddy red residue consists of alumina, iron oxide,

titanium oxide and small quantities of silica, calcium

oxide and alka\i. India generates over 4 million tonnes

of this by-product annually which is not otherwise put

to any use. Red mud is usually disposed of in ponds.

During the monsoon months this could lead to

contamination of ground water.

Red mud utilization

and 11.3 per cent liguin from its jute component Gute is

15 per cent of the total volume of the shutter).

RFPC is particularly suitable for door shutters, ensuring

siguifIcant savings in initial as well as maintenance

costs. There is a huge market for composite doors and

panels, with the potential waiting to be tapped both in

developing and developed countries.

Red mud jute fibre polymer composite: RFPC is a

substitute for wood-based panel products. It is made up

of easily available raw material like red mud, polymers

and natural fIbres. During aluminum production,

bauxite ore is digested with caustic soda, when most of

the aluminum passes into solution as aluminate. The

Sisal plant

RFPC composite contains ferric oxide, alumina and

titanium oxide from red mud, 82.5 per cent cellulose

Sisal fibre

-

Red mud jute fibre polymer products

Estimated agricultural waste generated in India exceeds 500 million tones Jler year.

5

-

Indo-Norwegian Environment Programme

Indo-Norwegian Environment Programme (INEP) is a

collaborative venture between the Government of India and the

Government of Norway. Through an agreement with the

Department of Economic Affairs, the two governments have

initiated pilot project in two Indian states, namely Karnataka and

Himachal Pradesh. The pilot programmes are designed to create

awareness on, and demonstrate corrective actions for serious and

~ent environment issues.

A project taken up in Karnataka under the INEP has addressed

Iron ore waste tailings problem in an effective way. As part of

this programme, the R&D Centre of the Karnataka Regional

R&D Centre, NITK, Surathkal

Engineering College at Surathkal has undertaken a project to

Key contributors .nd tMlr rot. for 1M Im. .m....lon of Iron

develop a technology for using the abundantly-available iron ore

0 ... lailing baed building products.

as raw material in the construction industry. The products already

...,."

manufactured include bricks, tiles and other material. The

of pIrt of 1hc ftmd

following products were developed at the R&D Centre with iron

ore waste tailings:

• Coloured bricks

• Roofmg tiles

• Glazed roofing tiles

• Bricks

• Studio pottery

• Hollow blocks

• Wall tiles

• Pavement bricks

• Floor tiles

Outcome of the project:

> Environ Charitable Trust' a special purpose vehicle for

technology transfer, entrepreneur development and

dissemination of information set up under Deputy

Commissioner, Dakshina Kannada and Udupi.

> Environmental protection and ecological balance by

converting industrial waste into useful building material

> Over coming the paucity of clay

> Preservation of topsoil for agricultural purposes.

> Promotion of scope for rura1 based industries.

> Transfer of technology to existing and new entrepreneurs.

Techno development in Iron Ore Waste Tailings based

building products such as Roofing tile, Decorative tile, Bricks,

Demo house constructed at

Pavement blocks, Wall tiles, Floor Tiles.

Nirmithi Kendra, Dakshina #Cannada

> Spinn off technologies like custom designed RCC & FCC

using Iron ore waste tailings products

rafters developed.

RFPC can also be used for furniture, flooring, electrical

switch box and insulation sheets for housing.

Plastic waste as building material:

With constant urbanization and industrialization, the

problem of discarded items and their disposal through

garbage has become a cause for concern. Items like

plastic bags and related material abound in garbage

dumps. The solution lies in recycling of plastic waste

after segregation.

Mixed and multilayer plastics containing several grades

of plastic material can be made into pallets. The pallets

can take the shape of tile flooring, waste containers,

planks, profiles, railway sleepers etc.

6

Plastic that cannot be further recycled can be used with

fillers for processing composites useful for applications

like fence posts, park benches, pallets and street furniture

as substitute to timber and concrete products.

Recycled PET: Unsaturated polyester resin from

recycled PET can replace the conventional high cost resin

for use in GRP products, polymer concrete / polymer

mortar, and industrial floorings.

Phospho-gypsum as building material:

Phospho-gypsum is waste generated by phosphoric acid,

ammonium phosphate and hydrofluoric acid-producing

plants. The fluoride content of phosphor-gypsum is a

source of land and water pollution. It is possible to

profitably utilize this pollutant for making cement,

In Kamataka, the requirement of clay for the tile and brick industries is about 3 million tonnes per annum,

Products developed at the R&D centre with iron ore waste tailings.

Interlocking Pavers

Hollow Blocks

Wall tiles

Penholders

gypsum board, partitions, ceiling tile, artificial marbles

and fiberboards.

Phospho-gypswn can be gainfully utilized in the

manufacture of expansive or non-shrinking cement,

super-sulphated and anhydride cement, simultaneous

manufacture of cement and sulphuric acid, as a hydraulic

binder, as set controller in the manufacture of Portland

cement, as mineraliser and in making gypswn plaster

boards and slotted tiles.

Pre-cast concrete frames:

Pre-cast concrete frame is one of the substitutes for

timber. Traditionally timber has been a vital building

material. Excessive deforestation is leading to an

Decorative pottery

ecological imbalance which could spell large-scale

disaster for mankind. In fact, adverse effects of

deforestation are already being felt in many parts of the

globe. It is necessary to take urgent steps to conserve our

forests. A substantial portion of wood is consumed in the

construction industry directly or indirectly. It is

imperative to reduce the consumption of timber in

building applications by identification, development and

promotion of alternate material which can partially /

completely substitute wood.

Pre-cast concrete frames are made out of cement, sand

aggregates and steel reinforcement. Fly ash and blast

furnace slag can also be used as raw material.

Commercial levels ofproduction can be taken up at a low

level of investment and with minimal labour training.

Advantages ofpre-cast concrete frames:

'-Conservation offorestreserves oftimber

'-Tennite-proof

'-Highquality and durable

'-Much cheaper than timber alternatives

'-Minimal requirement of raw material and high rate of

production

'-Water and fireproof

Gypsum board:

Lakkya dam in Kudremukha, completely

filled with iron ore waste tailings

Gypsum board is the generic name for a family of paneltype products consisting of a non-combustible core,

primarily of gypswn, with a paper surfacing on the face,

back, and long edges. Gypswn board is often called

drywall, wallboard, or plasterboard and differs from

The world's urban population is growing 2.5 times faster than the rural po!'ulation.

7

products such as plywood,

hardboard, and fiberboard

because of its noncombustible core.

Gypsum is a mineral found

in sedimentary rock

formations in a crystalline

form knows as calcium

sulfate dehydrate. One

hundred pounds of gypsum

rock contains

approximately 21 pounds

of chemically combined

water.

Gypsum rock is

mined or quarried and then

crushed. The crushed rock

is then ground into a fine

powder and heated to about 350 degrees F, driving off

three fourths of the chemically-combined water in a

process called calcining. The calcined gypsum is then

used as the base for gypsum plaster, gypsum board and

other gypsum products.

To produce gypsum board, the calcined gypsum is mixed

with water and additives to form slurry which is fed

between continuous layers of paper on a board machine.

As the board moves down a conveyer line, the calcium

sulphate recystallizes or rehydrates, reverting to its

original rock state. The paper becomes chemically and

mechanically bonded to the core. The board is then cut to

length and conveyed through dryers to remove any free

moisture.

Gypsum is also used as a raw material for some of the

products briefed as below:

Glass reinforced gypsum boards:

In building material, I wood can partially be replaced by

the use of glass reinforced gypsum (GRG). It is made

from glass fibre distributed evenly in gypsum matrix to

yield boards of 2m x 1m size with a thickness of4mm and

beyond. The material is pseudo-ductile in nature with a

flexural strength in the range of 20-35 Mpa and impact

strength of 10-26 N/mrn2. The boards can be utilized for

making door and window panels, false ceilings, partitions,

furniture, etc. These can be easily cut, drilled and other

wood working operations carried out as with the

conventional wood working tools. GRG boards can be

painted, polished and decorated by conventional means.

GRG offers advantages over wood and other

conventional board material, such as:

Pre-cost concrete frames

"'" It can be made to the required size and thickness

thereby reducing labour, wastage and jointing cost.

"'"Being isotropic in nature, it has eqnal strength in all

directions.

~ Any ornamental design can be incorporated at

nominal cost.

"'"GRG panels are about 50 per cent cheaper than teak

wood: the cost also compares favourably with

plywood and particle boards. Industrial wastes like

phosphor-gypsum and fibres from waste glass cu11ets

can be utilized to further reduce the cost.

Medium density fibre boards:

Various types of agro and agro-industrial wastes are

converted into fibers of the required size. The material is

mixed with a thermosetting binder and pressed in a

hydraulic press under specified conditions oftemperature,

pressure and time and the resultant boards are trimmed to

the required size. The product is waterproof, termite

resistant and fire resistant.

Source:

[1] Convertiog waste to wealth-Published by INEP

[2] Article of Dr.Rajendra Jagdale, Director-General,

Science & Techoology Park, University ofPune

[3] Wikipedia.org

[5] www.ics.trieste.it

[4]TERI

ENVISTeam:

Chakravarthi Mohan K.A.S., Co-ordinator, ENVIS

Centre,

Vijay Bhat, Programme Manager, INEP,

K.N. Koushik, IT Assistant.

ENVIS Centre - Karnataka

Department of Forests, Ecology & Environment, Govemment of Kamataka

010 Indo Norwegian Environment Programme, 2nd noor, Parisara Bhavan ,

No 49, Church street Banga/ore - 560 001. /{amataka

Ph: 080-2559 1515

email: [email protected] URL: http://www.parisaramahiti.kar.nic.in