* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download the super-frs dipole project - Facility for Antiproton and Ion Research

Survey

Document related concepts

Transcript

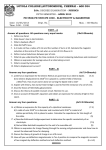

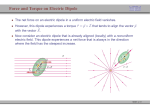

THE SUPER-FRS DIPOLE PROJECT Double Chooz ALICE Edelweiss HESS Herschel CMS Detecting radiations from the Universe. Super-FRS Dipôle « Vendor information meeting » | Lionel Quettier CONTRIBUTION CEA/Irfu CEA/Irfu contribution within the framework of the"Cooperation Agreement on the French contribution to the construction of the international Facility for Antiproton and Ion Research in Europe (FAIR) and on the German contribution to the construction of the SPIRAL2 Facility at GANIL” 2 CONTRIBUTION CEA/Irfu • CEA is responsible for the delivery of all 24 superferric SC-dipole magnets – 3 WPs – – – – Management Review of the existing design of the magnet Functional specification and conceptual drawings production Follow-up of the project including the production The information meeting organized today in related to WP1 only. 3 DIPOLES FOR THE SUPER-FRS Branched dipole Dipole Type D2 Number of dipoles Deflection angle Bending radius Effective length Good field region (horizontal with sagitta) Good field region (vertical) Integral field quality (relative) 3 11 12,5 2400 degree m mm mm mm D3, standard 18 9,75 12,5 2127 D3, branch 3 9,75 12,5 2127 ±190 ±29 ±190 ±23 ±190 ±23 ±70 ±70 ±70 ±3E-4 ±3E-4 ±3E-4 4 WP1 • WP1 covers the following items: – 3 long superferric dipoles with a bending radius of 11° (type D2 design) – 21 short superferric dipoles with a bending radius of 9,75° (type D3 design) • 18 short superferric • 3 special short superferric dipoles, having in addition a straight beam exit (“branched design”) – 1 spare cryostat including the cold mass for the long dipole – 1 spare cryostat including the cold mass for the short dipole • The electrical circuit and the external instrumentation are not part of the work package. • The spare cryostats are included in the engineering work. • The three special dipoles require special study including open coils and special branching vacuum chambers. Their realization requires yokes and coils from the serial production. • Each magnet must be equipped with an Hall probe (exact location to be determined by CEA). • The magnet testing is organized by GSI and realized by CERN. CEA/Saclay will participate to the commissioning and to the magnetic measurements of the magnets. 5 PRODUCT BREAKDOWN STRUCTURE Super-FRS Dipole Magnet Cryogenics distribution Magnet Electrical circuit MCS/MSS Conductor MCS Coils MSS Cryostat Internal cryogenics External instrumentation Yoke FAIR/GSI Current leads Assembly 6 PROJET ORGANISATION @ CEA SuperFRS Dipoles Project Irfu / SACM - SIS QA/QC - Documentation L. Vieillard / J. Munoz Garcia Planification J.D. Douarin Design Analysis Magnetic design L. Quettier / C. Pes Cooperation Agreement “French contribution to the SuperFRS components” GSI-FAIR M.Winkler Project Manager L. Quettier GSI H. Mueller Technical and Scientific Advisor C. Mayri Fabrication Testing Technical specifications and interfaces with GSI/CERN L. Quettier / J. Munoz Garcia Coordination L. Quettier GSI P. Schnitzer Cryogenic design and Vaccum C. Mayri / W. Abdel Maksoud Quench analysis L. Quettier / F.P. Juster Coordination with GSI/FAIR for the call for tender L. Quettier Conductor C. Berriaud Design office P. Manil Mechanical design Z.Sun/P. Graffin Internal instrumentation L. Quettier / J. Munoz Garcia Testing at CERN L. Quettier / J. Munoz Garcia Industrial follow-up V. Hennion 7 DESIGN EVALUATION Design work started @ CEA in January 2014 Reviews of the design organized by FAIR/GSI (”normal design”) • PDR hold July, 4th 2014 • FDR planned in November 2014 Review committee: External reviewers: Al Zeller (MSU) Tom Taylor (CERN) Luigi Serio (CERN) GSI members 8 General design of the magnet • Superferric magnet – iron dominated - warm iron yoke and warm bore • The magnet is made of two SC coils with a trapezoidal shape 52,1mm x 48,8 mm cross-section 560 turns (28 x 20) • Wire in channel NbTi conductor (7,5km per coil is required) 1,93mm x1,17 mm Copper/non copper ratio 9,9 55 filaments - 66µm diameter. • Vacuum impregnated 9 General design of the magnet The two coils are integrated into a common stainless steel case (top and bottom covers are welded): • The common casing is used to withstand the magnetic forces acting on the coils • The casing is also used as helium reservoir. 10 General design of the magnet • The coil mass is integrated into a cryostat equipped with a thermal shield • The cold mass is supported by 14 tie rods (prototype version). • The cryostat shape is tailored to match the coil shape and to keep an open space for the beam and the yoke. 11 General design of the magnet • • • A yoke installed around the cryostat is also contributing to the required magnetic field map Yoke is made of thin sheets of steel One air trim slot to improve field quality Cross section of the lamination sheet BH curve of iron (low carbon steel) 12 Prototype magnet A prototype was built by FAIR China Group • Inst. of Plasma Physics, Hefei: cryostat and coil • Inst. of Electrical Engineering, Beijing: conceptual design • Inst. of Modern Physics, Lanzhou: yoke and tests Visit to IMP Lanzhou of Irfu and GSI people in April 2014 to review the prototype design and discuss the testing results 13 Design of the prototype magnet Prototype magnet specification Design Superferric H-type Min / Max dipole field 0,15 T / 1,6 T Bending angle 15° Curvature radius 8,125 m Effective path length 2,126 Useable horizontal aperture ±190 mm Sagitta 70 mm Total horizontal good field area ±225 mm Useable vertical gap height ±70 mm Vertical pole gap height ±85 mm Integral field quality (relative) Δ∫ Bdl/∫ Bdl Yoke ±3x10-4 Courtesy IMP Cold mass testing 14 Tests of the prototype @ IMP Magnetic flux: Bgap = 1.6 T @ I = 232 A (design value: I = 230 A) Required field quality: DB/B = 310-4 (over 190 mm, 5 mm steps) Measurement (cold test) Courtesy IMP -4 integral field homogeneity [10 ] 3 • field quality tests successful • quench tests successful • calculated: maximum hot spot ~100K, maximum coil to ground voltage ~300V • stored energy ≈ 400 kJ • inductance ≈ 15 H • heat load @ 4.2 K: 6.8-8.1 W (0-232A) 2 1 0 -1 1.6 T 1.3 T 0.8 T 0.16 T -2 -3 -200 -100 0 100 radius shift [mm] 200 15 Required modifications • Motion of the cryostat observed during the tests I = 278 A I=0A Courtesy IMP 16 Required modifications • Ensure the lack of physical interference between two successive magnets • Modifications on the magnet/yoke will be required for the branched dipole not studied yet • The cryogenic interfaces must be modified for the testing @ CERN and for the local cryogenics of the Super-FRS tunnel of FAIR 17 Magnet design Conceptual design for version D3 (standard dipole - short version) – main parameters Superconducting strands NbTi Dimension of conductor 1.432.23 mm2 Number of Sc filaments 55 Ratio of Cu and NbTi 10.7 RRR of Cu in core wire 133 Number of turns 28 x 20 turns Operating current 230 A Central field @ 230 A 1,6 T Coil dimensions 1133 mm (medium length) x 2256 mm Bending angle 9,75° Curvature radius 12,5 m Section size of coil 52.148.8 mm2 Coil (per coil) 155 kg Coil casing 755 kg Cold mass 1065 kg Peak field on the conductor @ 230 A 1,3 T Thermal shield 155 kg Inductance @ 230 A 18,3 H Vacuum vessel 650 kg Stored energy @ 230 A 484 kJ Vacuum vessel assembly 1870 kg 540 A Yoke 46 tons Critical current density for wire @ 5 T @4,2 K Overall mass 47 tons Length of conductor per coil 7,5 km Ground insulation requirements and tests 3 kV 18 Magnet design Magnet operation: • The dipoles are DC magnets and will be submitted to 3 triangular cycles in a row (from 0 to maximum field) with a cycle period of 240 s (ramp duration of 120s ). This requirement gives the possibility to change the separation cuts in the Super-FRS in acceptable time period. • The three dipoles of one stage will be powered in series. A small power supply for small adjustments is foreseen for each single magnet. Therefore two power cables have to be connected to each current lead. 19 Magnet design • Different curvature radii Good field region is +/- 190mm in the horizontal direction and +/- 70 mm in the vertical direction. Specification: Integral field quality (relative) Δ∫ Bdl/∫ Bdl ±3x10-4 20 Magnet design • End chamfer design (picture taken during the tests with a resistive coil) Courtesy IMP • Prototype design was updated with faceted end chamfers shape: – To take into account the new bending angle of 9,75° and 11° – To keep the field integral homogeneity in the useful area from B=0,15T to B=1,6T 21 Magnet design New mechanical design with reduced number of rigid cold to warm supports and transverse sliding guides 22 Magnet design Studies performed by CEA (main results will be included in the design report that will be part of the bidding package) • Mechanical design (calculations including gravity, cooldown, vacuum, and magnetic forces) • Quench analysis • Cryogenic design • Tolerance analysis: – Influence on the field quality of the coil positioning – Influence on the field quality of the pole geometry – Tolerances analysis (coil and yoke) also performed to verify the mechanical forces (loss of the symmetries) 23 SUPER FRS DIPOLE – ASSEMBLY SCENARIO Stage 1: Setting of the coil casing on mounting supports. Lower side Upper side. Studs supporting the coil casing. 24 SUPER FRS DIPOLE – ASSEMBLY SCENARIO Stage 2: Integration of the lower coil into the coil casing. Lower Coil Shim made of G10 Output electrical conductors. 25 SUPER FRS DIPOLE – ASSEMBLY SCENARIO Stage 3: Tightening the coils used with joints. integration of external faces Clamping forces Welding the outer faces Welding the outer faces 26 SUPER FRS DIPOLE – ASSEMBLY SCENARIO Stage4: Welding of the lower cover Helium volume inside the vessel is 28 liters. Lower cover Output electrical conductors. Studs supporting the coil casing. 27 SUPER FRS DIPOLE – ASSEMBLY SCENARIO Stage5: Rotation of the assembly Output electrical conductors. Lower cover Studs supporting the coil casing. 28 SUPER FRS DIPOLE – ASSEMBLY SCENARIO Stage 6: Integration and setting of the upper coil. Upper coil Output electrical conductors. Studs supporting the coil casing. Shim made of G10 Passage for the connection between the coils (helium and conductors) 29 SUPER FRS DIPOLE – ASSEMBLY SCENARIO Stage 7: Tightening the coils used with joints. integration of external faces. Clamping forces Welding the outer faces Welding the outer faces 30 SUPER FRS DIPOLE – ASSEMBLY SCENARIO Stage8: Welding of the upper cover and of the Helium tank Helium tank Output electrical conductors. Top cover Studs supporting the coil casing. Implementation of accessories in the Helium tank. 31 SUPER FRS DIPOLE – ASSEMBLY SCENARIO Stage9: Welding of the helium pipe. Helium pipe Mass of the coil casing = 755 Kg Mass of the two coils = 310 Kg Studs supporting the coil casing. 32 SFRS DIPOLE – SCENARIO ASSEMBLY Stage10: Assembly of the thermal shield. Integration shims G10 The thickness of the thermal shield is 2 mm. Integration shims G10 Studs supporting the thermal shield. 33 SFRS DIPOLE – SCENARIO ASSEMBLY Stage 11: Temporary pads used to install the coil casing 34 SFRS DIPOLE – SCENARIO ASSEMBLY Stage 12: Integration of the coil casing into the thermal shield. Coils casing Thermal shield Studs supporting the coil casing. Studs supporting the thermal shield. 35 SFRS DIPOLE – SCENARIO ASSEMBLY Stage 13: Closure of the thermal shield thermal shield covers thermal shield chimney Sides Studs supporting the Thermal shield Studs supporting the coils casing Setting the screen relative to the coil casing 36 SFRS DIPOLE – SCENARIO ASSEMBLY Stage 14: Cooling tubes spot welding Mass of thermal shield = 155 Kg Cooling Flex clamp 37 SFRS DIPOLE – SCENARIO ASSEMBLY Stage 15: Installation of the superinsulation outside the thermal shield. Insulation thickness of 5 mm. 38 SFRS DIPOLE – SCENARIO ASSEMBLY Stage 16: vacuum vessel assembly vacuum vessel thickness of 8 mm. Studs supporting the vacuum vessel 39 SFRS DIPOLE – SCENARIO ASSEMBLY Stage 17: Integration of the thermal shield and the coil casing inside the vacuum vessel Sling for handling 40 SFRS DIPOLE – SCENARIO ASSEMBLY Stage 16: Bolting of interface pads for cold to warm supports. Bolted flanges Interface pads for cold to warm supports. 41 SFRS DIPOLE – SCENARIO ASSEMBLY Stage 17:Installation and adjustment of the coils casing depending on the vacuum vessel. Mounting guiding system Mounting and welding of warm support 42 SFRS DIPOLE – SCENARIO ASSEMBLY Stage 18:. welding of the cover welding of the slot sets Mass of vacuum vessel assembly = 1870 Kg 43 SFRS DIPOLE – SCENARIO ASSEMBLY Stage 19: Installation of the chimney with its accessories chimney 44 SFRS DIPOLE – SCENARIO ASSEMBLY Stage 20: Mounting of the vacuum vessel in the lower yoke vacuum vessel assembly Lower YOKE 45 SFRS DIPOLE – SCENARIO ASSEMBLY Stage 20: Mounting of upper yoke upper yoke Lower yoke vacuum vessel assembly 46 Branched magnet design Dipole Type Number of dipoles Deflection angle Bending radius Effective length Good field region (horizontal with sagitta) Good field region (vertical) Integral field quality (relative) • Same SC coils used for the standard D3 magnets • Modification of the coil case (not compatible with the new design) • Modification of the cryostat • Modification of the iron yoke • Dedicated vacuum chambers degree m mm mm mm D3, standard 18 9,75 12,5 2127 D3, branch 3 9,75 12,5 2127 ±190 ±23 ±190 ±23 ±70 ±70 ±3E-4 ±3E-4 No detailed studies at this stage 47