* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Multi-Cell Lithium Ion Battery Management System

History of electric power transmission wikipedia , lookup

Stray voltage wikipedia , lookup

Voltage optimisation wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Buck converter wikipedia , lookup

Alternating current wikipedia , lookup

Electric vehicle wikipedia , lookup

Mains electricity wikipedia , lookup

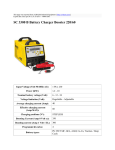

Electric vehicle conversion wikipedia , lookup

2010 Multi-Cell Lithium Ion Battery Management System -For Electric Vehicles Team: Sdmay11-04 Pramit Tamrakar Jimmy Skadal Matthew Schulte Hao Wang 10/12/2010 Table of Contents Definitions ..................................................................................................................................................... 4 Executive Summary ...................................................................................................................................... 5 Acknowledgement ........................................................................................................................................ 6 Statement and Approach ............................................................................................................................... 6 Problem Statement .................................................................................................................................... 6 Solution Approach .................................................................................................................................... 6 Operating Environment ................................................................................................................................. 6 Intended Users and Intended Uses............................................................................................................... 7 Intended Users .......................................................................................................................................... 7 Intended Uses ............................................................................................................................................ 7 Assumptions and Limitations ....................................................................................................................... 7 Assumptions.............................................................................................................................................. 7 Limitations ................................................................................................................................................ 7 Expected End Product ................................................................................................................................... 8 System Design Approach .............................................................................................................................. 8 Functional Requirements .......................................................................................................................... 8 Non Functional Requirements .................................................................................................................. 8 Market Alternatives .................................................................................................................................. 9 Proposed Approach and statement of work............................................................................................... 10 Proposed Approach ................................................................................................................................ 10 Constraints considerations ................................................................................................................. 10 Technology Consideration .................................................................................................................. 10 Technical Approach Consideration ..................................................................................................... 13 Testing Requirements Considerations ................................................................................................ 13 Security Consideration ........................................................................................................................ 14 Safety Consideration ........................................................................................................................... 14 Intellectual Property Consideration .................................................................................................... 14 Commercialization considerations...................................................................................................... 14 Possible risks and risk management ................................................................................................... 15 1 Project proposed milestones and evaluation criteria ......................................................................... 16 Project tracking procedures ................................................................................................................ 16 Hardware/Software Statement of work ................................................................................................. 17 Resources and Schedules ............................................................................................................................ 18 Resources ................................................................................................................................................ 18 Schedules ................................................................................................................................................ 19 Closure Material.......................................................................................................................................... 19 Project Team Information ........................................................................................................................... 20 Client’s Information ................................................................................................................................ 20 Faculty advisor Information .................................................................................................................... 20 Student Team Information...................................................................................................................... 20 Closing Summery ........................................................................................................................................ 21 References .................................................................................................................................................. 22 Appendix A .................................................................................................................................................. 25 2 Table of Figures Figure 1: The NLG503-light battery charger. 1.6 kW 200-540V, $2,145 ...................................................... 9 Figure 2: Hardware Functional Block Diagram ........................................................................................... 11 Figure 3: Software Functional Block Diagram ............................................................................................. 11 Figure 4: The series scalability of the bq76pl536........................................................................................ 13 3 Definitions Terms EV DC AC Fuel gauge Power Converter Feedback Overcharging BMS PWM PICCOLO Constant Current Constant Voltage Thermal Runaway Fast Charge SPI SMBus Level 1 Charging Definition Electric Vehicle Direct current Alternating current Device to measure overall status of the battery A Device for stepping up or down the voltage Used stabilize the signal of the output of the device Continuing to charge a fully charged battery Warning! Overcharging could lead to overheating which could cause explosion, damage, or shortened life of the cell. Battery Management System Pulse Width Modulation Digital Processing Chip The current is held a specific value(C = 3A) until a the adequate voltage is achieved The voltage is held at specific value (3.6V) until the cell is fully charged (current is 0.1C) Overheating of cell in relation to overcharging A condition where 10A is used to charge the cell in 15 minutes Serial Peripheral Interface - bus for device communication System Management Bus This is an industry standard Bus protocol Ac energy to the vehicle’s onboard charger from a typical 120V outlet. 120Vac; 16A (1.8kW) 4 Executive Summary Electric vehicles are one of the cleanest, most efficient, and most cost effective form of transportation. The market demand for electric vehicles has increased ever since the Toyota Prius was introduced as an alternative to traditional oil vehicles. (Wired) Other vehicle manufacturers are now introducing full electric vehicles, including Tesla Motors, Nissan, and Ford. A major complication in developing an electric vehicle is the battery management system. This project’s goal is to find an efficient and safe way to charge and monitor multi-cell series lithium ion batteries for an electric vehicle using AC to DC converters and monitoring microcontrollers The approach to accomplish this task is twofold: develop a charging system and develop a battery management system. In order to focus more on the battery management system, and to prevent from electric shock due to high voltage, we are scaling down the power supply from 120V AC to about 12-16 VAC. This is an agreement with our faculty advisor and the client. Therefore, when we have to bring the system to a large scale it will be just the matter of building up from smaller abstract systems. After intensive research and valuable advice from our advisor, the most efficient way to transform the 12-16V AC to 35V DC to completely charge the multi-cell series batteries will be by using a line filter, full-wave rectifier, AC-DC power Correction boost preregulator and a DC-DC buck converter.(UCC28019) An evaluation module from Texas Instruments using the UCC28019 PFC boost converter controller will be used to decrease development time for our initial project specifications. Focus will thus be directed at developing the battery management system. This system will monitor the charge of each individual cell in order to prevent the batteries from overheating, overcharging, or over discharging. The result of overheating, overcharging, or over discharging can include loss of cell functionality, fire, or even explosion. The approach used to handle this major problem is to use a fuel gauge to monitor the charge of the batteries while monitoring the temperature of the cells. The fuel gauge will keep track of how much power is remaining in the batteries, sending the information to the control unit for processing. The expected functionality of the design is to efficiently and safely charge multi-cell lithium ion batteries. It will take about 12V AC from the source and charge the series multi-cell lithium ion batteries while checking for overcharging and overheating. Once the fuel gauge senses the lithium ion batteries are full, it will shut off the source of the 12Vac and monitor the charge levels of the batteries and output the signals for processing in the central control unit. 5 Acknowledgement We would like to acknowledge the client for this project, Adan Cervantes, from Element 1 Systems. He will be giving us direction, feedback, and guidance throughout the process of this project. He will also be contributing the vehicle to be tested, the bank of lithium ion batteries, the engine controller, and the engine. Adan will also provide financial aid for this project. Secondly, we would like to acknowledge our faculty advisor, Professor Ayman Fayed for giving valuable guidance and advice in order to achieve the goals of our project. Statement and Approach Problem Statement To develop an efficient, safe and scalable system for charging and monitoring multi-cell series batteries in electric vehicles using a switching mode power supply and a battery management system. The initial goal of this project was to charge the bank of lithium-ion batteries to 324 VDC supplied from a 120 VAC wall outlet. In order to focus more on the battery management system of this project, we are scaling down the power supply to 12-16 VAC and an output of 35 VDC, and developing a battery management system for 6-12 series batteries that can later be scaled to 90 series batteries. Solution Approach The first task to accomplishing this project is to find the most efficient way to bring 12V AC to 35V DC. This is accomplished by using an AC-DC power factor correction boost pre-regulator and a buck converter. (UCC28019) Tests will be run on the circuit design through computer simulations and also through carefully run physical tests via the department’s power lab. We will be using evaluation modules from Texas Instruments and microcontrollers to monitor the batteries. Operating Environment This product must operate in various conditions. It needs to handle dusty conditions, due to sitting in garages or driving down a gravel road. It will also need to be able to withstand typical summer and winter temperatures. The batteries and controllers will be shielded from the rain and wet conditions to prevent short circuits. The circuits and batteries will never be thrown or dropped since they will be semi-permanently fixed in the vehicle, but they will have to withstand shocks from the road. 6 Intended Users and Intended Uses Intended Users The users of the final design will be the vehicle owners, family members, friends, etc. They could range anywhere between 14 to 100 years old and could be of any sex. As long as they can pick up an extension cord and plug it into the outlet and to the vehicle, anyone could use this project. However, since this project is only a scaled down version of the prototype the intended user is the client, Element 1 Systems. Intended Uses The intended use of the project is to charge a bank of lithium ion batteries and manage their charge and discharge cycles. The high voltage supply is designed to operate as a constant-current constant-voltage lithium ion battery supply, and only for the specified A123 battery chemistry. Assumptions and Limitations Assumptions The user has a 120V outlet available to plug in the electric vehicle. The batteries are provided by the client and capable of operating and running the engine. The components in the design are expandable to handle more than rated power. This is only a prototype. The client is responsible for integration into the final system. Limitations High voltage control. Wall outlet power availability. The batteries and the circuits must fit into the vehicle. Safety: In order to develop a scalable abstract system, only 12 cells in series will be used in our design, rather than all 90 in series and 16 in parallel. The developed solution will be scalable in order to handle more series cells in the future. Parts availability. 7 Expected End Product The expected finished product will consist of the scaled down version of the original project, with the associated documentation, design, construction plans, and software necessary to complete the finalized product. The completed product will be delivered to Adan Cervantes from Element 1 Systems in May 2011. System Design Approach Functional Requirements The project goal is for the charger module to charge a battery bank with sixteen parallel branches, with each branch having 90 series cells. Our initial design will be limited to 12 series cells to ensure system functionality and scalability. A switching mode power supply will convert the input wall outlet power from 120Vac to 324dc (or 12Vac to 32Vdc for the scaled down version). The charging and discharging of these cells will be monitored with a battery management system to prevent overcharge, over discharge, and over temperature situations. Non Functional Requirements The scaled prototype should be usable by our client during the development of the scaled up version. The system should be reliable, even in the condition of a fault. System maintenance should be straightforward. Price should be as low as possible to ensure the product is a competitive market alternative. The system should be robust and long-lasting. Total weight should be kept to a minimum. The system should be using the most efficient methods available. The end product should be designed to ensure safety and prevent the user from coming into contact with high voltages and currents. 8 Market Alternatives Since only a handful of electric vehicles have been successfully implemented on a large scale, there are few existing commercial solutions. As for the switching mode power supply the only commercially available solution designed specifically for electric vehicles is offered by Brusa. The NLG5 is a battery charger that provides a high voltage power source from a 120V or 240V wall outlet. The only problem with using a Brusa battery charger is cost; their simplest charger costs over $2,000. (Brusa) Figure 1: The NLG503-light battery charger. 1.6 kW 200-540V, $2,145 (Brusa) As for battery management systems, even Brusa is still developing a commercial solution. Thus, there are no market alternatives to building a custom BMS. (Brusa) 9 Proposed Approach and statement of work Proposed Approach Constraints considerations Lithium ion batteries require a protection system to maintain safe voltage and current levels. They may suffer thermal runaway and cell rupture if overheated or overcharged. Furthermore, over-discharge can irreversibly damage a battery. To reduce these risks, we have to design a circuit that shuts down when the lithium ion cells vary outside the safe range of 1.6–3.6 V. The amount of power a typical 120V wall outlet in the United States can provide is limited to about 1.8 kW, which is defined to be level 1 charging. (Electric) This will constrain our charging time, as the battery will typically only be able to draw 1.8 kW. Since our battery pack holds about 11 kW-hr, the minimum charging time will be about 6 hours. Technology Consideration An MSP430 will be used to control the charging process in three stages; As demonstrated in Appendix A: Slow charge: Pre- charging stage using current of 0.1C (where C is 3A). Constant-current charging stage: Using current of 1C. Constant voltage charging stage: Maintaining the nominal max battery voltage until the minimum current is supplied, which is 0.1C As shown in Figure 2 the microcontroller is used to control the buck converter by increasing or decreasing the voltage to maintain the current during the slow charge and constant current charging stages, and it will maintain a constant voltage during the constant voltage charging stage. 10 Figure 2: Hardware Functional Block Diagram The microcontroller software will be implemented according to the software functional diagram in Figure 3 using either C or Assembly language. Figure 3: Software Functional Block Diagram 11 A comparison of two similar integrated circuits from Texas Instruments: bq78PL114 According to the TI data sheet slua495 for the bq78PL114 “The minimum number of parallel cells is 1. The maximum number of parallel cells is limited by the system capacity which is a16-bit unsigned integer.” This data sheet only refers to parallel configurations of the bq78PL114. Nowhere does it talk about an implementation of a series configuration. The bq78PL114 with the bq76PL102 allow for charging 12 series cells alone. The ability to charge more than 12 cells with this design may be possible, but very difficult to achieve. With no SMBus built into this IC, a series configuration of more than 12 cells may be very difficult to implement. Also TI would have to write a custom TMAP file for each bq78PL114 to assign an address for SMBus compatibility. The bq78PL114 requires communication with a computer using the .Net communication protocol, which we would we have to use to simulate the bq78PL114 API on a microcontroller. With these many requirement and setbacks, we looked to find a more suitable IC that would supply features more suitable for the design. (BQ78PL114) bq76PL536 After running into many issues with the bq78PL114 design we decided on the bq76PL536 to give us the needed features that the previous configuration did not. According to the TI data sheet, “The bq76PL536 can be stacked vertically to monitor up to 192 cells without additional isolation components between ICs. A high-speed serial peripheral interface (SPI) bus operates between each bq76PL536 to provide reliable communications through a high-voltage battery cell stack.” This device can run at a Continuous 36 V Peak with respect to the voltage of the bottom most cell in the series. Charging 6 cells at 3.6 V the voltage required is 21.6 V, and so the bq76PL536 can handle the capacity of our supplied cells. With the ability to connect up to 192 cells in series, the bq76PL536 is the perfect choice for this project. Also another advantage to using the bq76PL536 is that there is already a SMBus built in to this IC which will allow easy communication of series configurations. With the bq76PL536 hooked up in series one Host interface is required to communicate with the system which is a lot easier than the previous design. (Battery) 12 Figure 4: The series scalability of the bq76pl536 Technical Approach Consideration Since the bq76PL536 is designed to balance 6 series battery cells we have to combine 15 of them to monitor and manage 90 series cells. The battery management system relies on the MSP430 and the Texas Instruments bq76PL536 microcontroller to implement the design requirements. These microcontrollers and integrated circuits exceed all of our requirements for undervoltage, over-voltage, and over-temperature protection. Programming of these integrated circuits includes learning the SMBus protocol which is a set of industry defined standards allows a host controller to easily obtain large amounts of data from the battery over a single communication interface. In our case, we will be using SPI with an MSP430 to gather the data and make decisions based on battery conditions. Testing Requirements Considerations The input voltage is 120 Vac. Since we are scaling the conditions down by a factor of 10, the output for our testing simulation with 6 cells will be between 9.6V and 22.8V. The goal of scaling this system means we will also be testing with an additional 6 cells managed by a separate bq76PL536 circuits. The battery voltage range for this configuration will be between 19.2V and 45.6V. 13 The charging current C is defined to be 3A. This is a high current, and our initial design will be limited to 1A to ensure components do not unnoticeably overheat or explode in the case of an accident. Security Consideration The bq76PL536 integrates dedicated overcharge and under-voltage fault detection for each cell and two over-temperature fault detection inputs for our device. The protection circuits use a separate band-gap reference from the ADC system and operate independently. The protector also uses separate I/O pins from the main communications bus, and therefore is capable of signaling faults in hardware without intervention from the host MSP430. Safety Consideration When dealing with high voltages: 1. Keep one hand in a pocket to prevent conduction channel through the heart. 2. Set up a work area away from possible grounds. 3. If circuit boards need to be removed from its mountings use insulating material. 4. Discharge high voltage capacitors appropriately. 5. Remove metal objects such as jewelry. 6. Prove that exposed metal surfaces are grounded, as are outlet grounds. 7. Do not assume insulation integrity. 8. Do not leave an experiment unattended. 9. Do not work on an experiment while tired or not alert. 10. Ensure that someone is trained in CPR. (Notes) Intellectual Property Consideration The design for this project could potentially be patented, trademarked, and copyrighted. Patent protection can be applied for with the U.S. Copyright Office, which handles copyright registration in order to ensure a market claim to the product. However, we need to check to see if a patent is already registered. Commercialization considerations Our design is a prototype for our client; it could potentially become a commercial venture. 14 Possible risks and risk management Risks have been identified throughout the project and tracked for resolution and mitigation. A risk register is used to identify risk to the project: Risk Register: No Risk Risk Description 1 High power systems Generate 324 VDC for electrical car motor 2 Electric shock 3 IC replacement The risk of electric shock is possible when working with a charging system In case any small part of the system malfunctions. 4 Over-temperature Over-voltage Under-voltage 5 Weight 6 Cost Cells may suffer thermal runaway and cell rupture if overheated or overcharged The mass of the system. Cost should be as low as possible Mitigation Run simulations before physically testing. Start at a lower voltage level to test the components before using it at the higher voltage level. Be careful when doing the circuit testing, follow the rules listed in the safety consideration. Disconnect the problem section and determine if further shut down is necessary. Replace the faulty component. The bq76PL536 provided by TI is available for protecting our system. Ensure lightweight components are utilized when possible Only purchase necessary components. Introduces risk with schedule if replacement contingency parts are not available. 15 Project proposed milestones and evaluation criteria We have lists of weekly tasks that need to be accomplished which are then checked off by the group members. The tasks accomplished by the group are evaluated by the team and our advisor. Project tracking procedures Project planning will be performed using the Gantt chart schedule and our progress will be tracked using the following schedule: 16 Hardware/Software Statement of work Task 1 - Problem Definition: Design a charger and battery management system operating from a 12 Vac source. Subtask 1a – Define the problem Subtask 1b – Identify the intended audience and End-Use Subtask 1c – Define the constraints Task 2 – PFC Boost Converter design: Boost the input 12Vac to 35Vdc. Subtask 2a – Compare similar topologies. Subtask 2b – Design or purchase the PCB and schematic Task 3 – Buck Converter design Buck the output of the PFC boost from 35V to between 14.4V and 32.4V. Subtask 3a – Select component values Subtask 3b – Simulate Subtask 3c – Code an MSP430 to control the PWM Task 4 – BQ76PL536 BMS system design Implement a scalable battery management system using two BQ76PL536 boards to monitor six series cells each. Subtask 4a – Design a scalable PCB. Subtask 4b – Select appropriate component values Subtask 4c – Code an MSP430 to control the cell balancing. Task 5 – Building and Testing Build and test the systems designed in Tasks 2 through 4 Subtask 5a – Gather materials and components Subtask 5b – Fabricate PCBs Subtask 5c – Code the various MSP430’s Subtask 5d – Test each system individually and together for complete functionality. Task 6 – Documentation and Demonstration Provide End-Project Documentation and Project Reporting, as well as demonstrate the project to faculty. Subtask 5a – Write End-Project Documentation Subtask 5b – Write Project Report Subtask 5c – Develop a project poster Subtask 5d – Weekly reporting 17 Resources and Schedules Resources Item W/O Labor With Labor Parts and Materials: a. Previous school sessions $402.51 $402.51 b. Printed Circuit Boards $50.00 $50.00 c. Discrete components $100.00 $100.00 $0 $0 $50.00 $50.00 $150.00 $150.00 $752.51 $752.51 a. oscilloscope, function generator, digital multimeter $0 $0 b. soldering equipment $0 $0 $0 $0 d. Texas Instruments ICs e. TI PFC boost converter f. MSP430 programming board Subtotal: Test and Build equipment Subtotal: Labor at $20.00/hour: a. Previous school sessions $28,000 b. Hao Wang $4,000 c. Pramit Tamrakar $4,000 d. Matt Schulte $4,000 e. Jimmy Skadal $4,000 Subtotal: $0 $44,000 Texas Instruments endowment: ($200) ($200) Total: $552.51 $88,752.51 18 Schedules PROJECT TIMELINE Tasks August Year: 2010 September October November December January February Year 2011 March April May Understand Problem Research PFC Boost Converter design and modeling Testing Buck Converter design and modeling Testing Battery Management System bq76pl series circuit design MPS430 programming Testing Complete System Testing of scaled version Scaling up low volt design Testing of scaled version Prototype Final Assembly Final Testing Final Prototype and Drive Car Documentation Project Design Final Documentation 19 Closure Material Project Team Information Client’s Information Adan R. Cervantes Principle system Engineer Email Address: [email protected] 3286 North Center Point Road, Marion, IA 52302 Phone: (319) 270-4357 www.element1system.com Faculty advisor Information Ayman A. Fayed Assistant Professor Email Address: [email protected] Dept. of Electrical & Computer Engineering Iowa State University 2117 Coover Hall Ames, IA 50011 Phone: (515) 294-6112 Fax: (515) 294-8432 http://home.eng.iastate.edu/~aafayed/ Student Team Information Pramit Tamrakar Major: Electrical Engineering Email Address: [email protected] 918 NE Crestmoor Place Apt 306, Ankeny, IA 50021 Phone: 515-203-5291 Jimmy Skadal Major: Electrical Engineering Email Address: [email protected] 3819 Tripp St Unit 7, Ames, IA 50014 Phone: 563-320-6878 Matthew Schulte Major: Electrical Engineering Email Address: [email protected] 3223 Frederiksen Ct, Ames, IA 50010 Phone: 319-396-9959 Hao Wang Major: Electrical Engineering Email Address: [email protected] 230 Raphael Ave Unit 9, Ames, IA 50014-6711 Phone: 515-520-1787 20 Closing Summary With almost every vehicle manufacturer striving to come out with an electric car, the competition to develop a commercially viable solution is high. The world’s dependence on oil makes transitioning to fully electric technology very difficult. The ability to get away from such a need for oil comes by charging batteries instead of filling up with gasoline or diesel. Battery technology has improved, but the ability to charge those batteries is the major setback across the industry. Electric vehicles have to be easy, safe, affordable, and have an ability to fulfill the needs of consumers. With a number of electric vehicles and charging stations speculated to be on the market within the next few years, this project is on the forefront of technology. There are still many problems to solve when charging an electric vehicle and the goals for this project are to find the best solutions for those problems. The use of 120VAC outlet would be ideal for home charging, but means that we must work with the restrictions of home outlets. Home charging is a very important problem to solve for this project. Scaling down problems and focusing on solving each step is going to be essential to successfully building this charger. Scaling down allows the team to focus on developing a working solution without dealing with dangerous voltage levels during conception. Our project goal is to successfully implement a lithium-ion battery charger prototype for the electric vehicle owned by Adan Cervantes and Element 1 Systems. 21 References "A123Systems :: Products." A123Systems. 2009. Web. 10 Oct. 2010. <http://www.a123systems.com/a123/products>. "Battery Management - Battery Fuel Gauge - BQ76PL102 - TI.com." TI.com. Texas Instruments, Oct.-Nov. 2009. Web. 10 Oct. 2010. <http://focus.ti.com/docs/prod/folders/print/bq76pl102.html>. "Battery Management - Lithium Ion Protection - BQ76PL536 - TI.com." TI.com. Texas Instrument, July-Aug. 2010. Web. 10 Oct. 2010. <http://focus.ti.com/docs/prod/folders/print/bq76pl536.html>. Baxter, Tyler, Brian Chee, Liam Keams, Philip Leo, and Philip Schmitz. Lithium Ion Battery Charging: Portable Renewable Power Module. May 10-15 Senior Design Project, Fall 2009. Sept.-Oct. 2010. <http://seniord.ece.iastate.edu/may1015/>. "Block Diagram (SBD) - Battery Management: High Cell Count for HEV - TI.com." TI.com. Texas Instruments. Web. 11 Oct. 2010. <http://focus.ti.com/docs/solution/folders/print/599.html>. "BQ78PL114 BQ76PL102 Evaluation Kit - BQ78PL114EVM-001 - TI Tool Folder." TI.com. Texas Instruments, 14 Jan. 2010. Web. 10 Oct. 2010. <http://focus.ti.com/docs/toolsw/folders/print/bq78pl114evm-001.html>. “Brusa.” Brusa. 2010. Web. 10 Oct. 2010. < http://www.brusa.biz/e_welcome.html>. "Li-Ion Battery Charger Solution Using the MSP430 Microcontrollers Slaa287 - TI.com." TI.com. Texas Instruments, Dec.-Jan. 2005. Web. 10 Oct. 2010. <http://focus.ti.com/lit/an/slaa287/slaa287.pdf>. "Linear Technology - LTC6802-1 - Multicell Battery Stack Monitor." Linear Technology - Linear Home Page. Linear.com, 2009. Web. 10 Oct. 2010. <http://www.linear.com/pc/productDetail.jsp?navId=H0,C1,C1003,C1037,C1786, P86662#descriptionSection>. "NOTES ON HIGH VOLTAGE SAFETY." Nanoscience at UNM. Web. 14 Oct. 2010. <http://nnin.unm.edu/safety/Hi_Voltage_Safety.html>. “Supply and Demand, Prius Style.” Wired Magazine. 2008. Web. 10 Oct. 2010. <http://www.wired.com/autopia/2008/07/supply-and-dema/>. “UCC28019 Evaluation Module.” TI.com. Texas Instruments, 01 Mar 2007. Web 10 Oct 2010. < http://focus.ti.com/docs/toolsw/folders/print/ucc28019evm.html>. 22 "USB Interface Adapter EVM - USB-TO-GPIO - TI Tool Folder." TI.com. Texas Instruments, Aug.-Sept. 2006. Web. 10 Oct. 2010. <http://focus.ti.com/docs/toolsw/folders/print/usb-to-gpio.html>. 23 "Electric Car." Wikipedia, the Free Encyclopedia. Web. 14 Oct. 2010. <http://en.wikipedia.org/wiki/Level_1,_2,_and_3_charging#Level_1.2C_2.2C_an d_3_charging>. 24 Appendix A Below is information about charging a lithium-ion battery from the TI data sheet SLAA287 25