* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download LED, LCD characteristics, Tunnel diode, Schottky diode

Electronic paper wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Stray voltage wikipedia , lookup

Mercury-arc valve wikipedia , lookup

Current source wikipedia , lookup

Voltage optimisation wikipedia , lookup

Power electronics wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Mains electricity wikipedia , lookup

Multi-junction solar cell wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Alternating current wikipedia , lookup

Power MOSFET wikipedia , lookup

Surge protector wikipedia , lookup

Rectiverter wikipedia , lookup

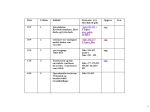

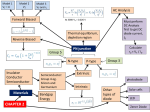

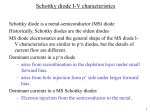

LED, LCD characteristics, Tunnel diode, Schottky diode 1.2.1 LED CHARACTERISTICS A light-emitting diode (LED) is a semiconductor device that emits visible light when an electric current passes through it. The light is not particularly bright, but in most LEDs it is monochromatic, occurring at a single wavelength. The output from an LED can range from red (at a wavelength of approximately 700 nanometers) to blue-violet (about 400 nanometers). Some LEDs emit infrared (IR) energy (830 nanometers or longer); such a device is known as an infraredemitting diode (IRED). An LED or IRED consists of two elements of processed material called P-type semiconductors and N-type semiconductors. These two elements are placed in direct contact, forming a region called the P-N junction. In this respect, the LED or IRED resembles most other diode types, but there are important differences. The LED or IRED has a transparent package, allowing visible or IR energy to pass through. Also, the LED or IRED has a large PN-junction area whose shape is tailored to the application. Benefits of LEDs, compared with incandescent and fluorescent illuminating devices, include: Low power requirement: Most types can be operated with battery power supplies. High efficiency: Most of the power supplied to an LED or IRED is converted into radiation in the desired form, with minimal heat production. Long life: When properly installed, an LED or IRED can function for decades. Operation:When the device is forward-biased, electrons cross the pn junction from the n-type material and recombine with holes in the p-type material. The free electrons are in the conduction band and at a higher energy than the holes in the valence band. The difference in energy between the electrons and the holes corresponds to the energy of visible light. When recombination takes place, the recombining electrons release energy in the form of photons. The emitted light tends to be monochromatic (one color) that depends on the band gap (and other factors). A large exposed surface area on one layer of the semiconductive material permits the photons to be emitted as visible light. This process, called electroluminescence, is illustrated in below. Various impurities are added during the doping process to establish the wavelength of the emitted light. The wavelength determines the color of visible light. Some LEDs emit photons that are not part of the visible spectrum but have longer wavelengths and are in the infrared(IR) portion of the spectrum. The forward voltage across an LED is considerably greater than for a silicon diode. Typically, the maximum VF for LEDs is between 1.2 V and 3.2 V, depending on the material. Reverse breakdown for an LED is much less than for a silicon rectifier diode (3 V to 10 V is typical). The LED emits light in response to a sufficient forward current, as shown in Figure. The amount of power output translated into light is directly proportional to the forward current, as indicated in graph. An increase in IF corresponds proportionally to an increase in light output. The light output (both intensity and color) is also dependent on temperature. Light intensity goes down with higher temperature as indicated in the graph. LED Semiconductor Materials: The semiconductor gallium arsenide (GaAs) was used in early LEDs and emits IR radiation, which is invisible. The first visible red LEDs were produced using gallium arsenide phosphide (GaAsP) on a GaAs substrate. The efficiency was increased using a gallium phosphide (GaP) substrate, resulting in brighter red LEDs and also allowing orange LEDs. Later, GaP was used as the light-emitter to achieve pale green light. By using a red and a green chip, LEDs were able to produce yellow light. The first super-bright red, yellow, and green LEDs were produced using gallium aluminum arsenide phosphide (GaAlAsP). By the early 1990s ultrabright LEDs using indium gallium aluminum phosphide (InGaAlP) were available in red, orange, yellow, and green. Blue LEDs using silicon carbide (SiC) and ultrabright blue LEDs made of gallium nitride (GaN) became available. High intensity LEDs that produce green and blue are also made using indium gallium nitride (InGaN). High-intensity white LEDs are formed using ultrabright blue GaN coated with fluorescent phosphors that absorb the blue light and reemit it as white light. Characteristics: An LED emits light over a specified range of wavelengths as indicated by the spectral output curves in Figure below. The curves in part (a) represent the light output versus wavelength for typical visible LEDs, and the curve in part (b) is for a typical infrared LED. The wavelength is expressed in nanometers (nm). The normalized output of the visible red LED peaks at 660 nm, the yellow at 590 nm, green at 540 nm, and blue at 460 nm. The output for the infrared LED peaks at 940 nm. The graphs in Figure below show typical radiation patterns for small LEDs. LEDs are directional light sources (unlike filament or fluorescent bulbs). The radiation pattern is generally perpendicular to the emitting surface; however, it can be altered by the shape of the emitter surface and by lenses and diffusion films to favor a specific direction. Directional patterns can be an advantage for certain applications, such as traffic lights, where the light is intended to be seen only by certain drivers. Figure(a) shows the pattern for a forward-directed LED such as used in small panel indicators. Figure(b) shows the pattern for a wider viewing angle such as found in many super-bright LEDs. A wide variety of patterns are available from manufacturers; one variation is to design the LED to emit nearly all the light to the side in two lobes. Applications: Typical applications include: Indicator lights: These can be two-state (i.e., on/off), bar-graph, or alphabetic-numeric readouts. Standard LEDs are used for indicator lamps and readout displays on a wide variety of instruments, ranging from consumer appliances to scientific apparatus. A common type of display device using LEDs is the seven-segment display. Combinations of the segments form the ten decimal digits as illustrated in Figure below. Each segment in the display is an LED. By forward-biasing selected combinations of segments, any decimal digit and a decimal point can be formed. Two types of LED circuit arrangements are the common anode and common cathode as shown. Traffic Signals: LEDs are quickly replacing the traditional incandescent bulbs in traffic signal applications. Arrays of tiny LEDs form the red, yellow, and green lights in a traffic light unit. An LED array has three major advantages over the incandescent bulb: brighter light, longer lifetime (years vs. months), and less energy consumption (about 90% less). LED traffic lights are constructed in arrays with lenses that optimize and direct the light output. Figure below illustrates the concept of a traffic light array using red LEDs. A relatively low density of LEDs is shown for illustration. The actual number and spacing of the LEDs in a traffic light unit depends on the diameter of the unit, the type of lens, the color, and the required light intensity. With an appropriate LED density and a lens, an 8- or 12inch traffic light will appear essentially as a solid-color circle. LEDs in an array are usually connected either in a series-parallel or a parallel arrangement. A series connection is not practical because if one LED fails open, then all the LEDs are disabled. For a parallel connection, each LED requires a limiting resistor. To reduce the number of limiting resistors, a series-parallel connection can be used, as shown in Figure . LCD panel backlighting: Specialized white LEDs are used in flat-panel computer displays. Fiber optic data transmission: Ease of modulation allows wide communications bandwidth with minimal noise, resulting in high speed and accuracy. Remote control: Most home-entertainment "remotes" use IREDs to transmit data to the main unit. 1.2.2 LCD Characteristics LCD (liquid crystal display) is the technology used for displays in notebook and other smaller computers. Like light-emitting diode (LED) and gas-plasma technologies, LCDs allow displays to be much thinner than cathode ray tube (CRT) technology. LCDs consume much less power than LED and gas-display displays because they work on the principle of blocking light rather than emitting it. An LCD is made with either a passive matrix or an active matrix display display grid. The active matrix LCD is also known as a thin film transistor (TFT) display. The passive matrix LCD has a grid of conductors with pixels located at each intersection in the grid. A current is sent across two conductors on the grid to control the light for any pixel. An active matrix has a transistor located at each pixel intersection, requiring less current to control the luminance of a pixel. For this reason, the current in an active matrix display can be switched on and off more frequently, improving the screen refresh time (your mouse will appear to move more smoothly across the screen, for example). Some passive matrix LCD's have dual scanning, meaning that they scan the grid twice with current in the same time that it took for one scan in the original technology. However, active matrix is still a superior technology. Construction: Simple facts that should be considered while making an LCD: The basic structure of LCD should be controlled by changing the applied current. We must use a polarized light. Liquid crystal should able be to control both of the operation to transmit or can also able to change the polarized light. As mentioned above that we need to take two polarized glass pieces filter in the making of the liquid crystal. The glass which does not have a polarized film on the surface of it must be rubbed with a special polymer which will create microscopic grooves on the surface of the polarized glass filter. The grooves must be in the same direction of the polarized film. Now we have to add a coating of pneumatic liquid phase crystal on one of the polarized filter of the polarized glass. The microscopic channel cause the first layer molecule to align with filter orientation. When the right angle appears at the first layer piece, we should add a second piece of glass with the polarized film. The first filter will be naturally polarized as the light strikes it at the starting stage. Thus the light travels through each layer and guided on the next with the help of molecule. The molecule tends to change its plane of vibration of the light in order to match their angle. When the light reaches to the far end of the liquid crystal substance, it vibrates at the same angle as that of the final layer of the molecule vibrates. The light is allowed to enter into the device only if the second layer of the polarized glass matches with the final layer of the molecule. Operation: Liquid crystal displays (LCDs) are a passive display technology. This means they do not emit light; instead, they use the ambient light in the environment. By manipulating this light, they display images using very little power. This has made LCDs the preferred technology whenever low power consumption and compact size are critical. Liquid crystal (LC) is an organic substance that has both a liquid form and a crystal molecular structure. In this liquid, the rod-shaped molecules are normally in a parallel array, and an electric field can be used to control the molecules. Most LCDs today use a type of liquid crystal called Twisted Nematic (TN). A Liquid Crystal Display (LCD) consists of two substrates that form a "flat bottle" that contains the liquid crystal mixture. The inside surfaces of the bottle or cell are coated with a polymer that is buffed to align the molecules of liquid crystal. The liquid crystal molecules align on the surfaces in the direction of the buffing. For Twisted Nematic devices, the two surfaces are buffed orthogonal to one another, forming a 90 degree twist from one surface to the other, see figure below. This helical structure has the ability to control light. A polarizer is applied to the front and an analyzer/reflector is applied to the back of the cell. When randomly polarized light passes through the front polarizer it becomes linearly polarized. It then passes through the front glass and is rotated by the liquid crystal molecules and passes through the rear glass. If the analyzer is rotated 90 degrees to the polarizer, the light will pass through the analyzer and be reflected back through the cell. The observer will see the background of the display, which in this case is the silver gray of the reflector. The LCD glass has transparent electrical conductors plated onto each side of the glass in contact with the liquid crystal fluid and they are used as electrodes. These electrodes are made of Indium-Tin Oxide (ITO). When an appropriate drive signal is applied to the cell electrodes, an electric field is set up across the cell. The liquid crystal molecules will rotate in the direction of the electric field. The incoming linearly polarized light passes through the cell unaffected and is absorbed by the rear analyzer. The observer sees a black character on a sliver gray background, see figure below. When the electric field is turned off, the molecules relax back to their 90 degree twist structure. This is referred to as a positive image, reflective viewing mode. Carrying this basic technology further, an LCD having multiple selectable electrodes and selectively applying voltage to the electrodes, a variety of patterns can be achieved. Many advances in TN LCDs have been produced. Super Twisted Nematic (STN) Liquid Crystal material offers a higher twist angle (>=200° vs. 90°) that provides higher contrast and a better viewing angle. However, one negative feature is the birefringence effect, which shifts the background color to yellow-green and the character color to blue. This background color can be changed to a gray by using a special filter. The most recent advance has been the introduction of Film compensated Super Twisted Nematic (FSTN) displays. This adds a retardation film to the STN display that compensates for the color added by the birefringence effect. This allows a black and white display to be produced. Advantages: LCD’s consumes less amount of power compared to CRT and LED LCD’s are consist of some microwatts for display in comparison to some mill watts for LED’s LCDs are of low cost Provides excellent contrast LCD’s are thinner and lighter when compared to cathode ray tube and LED Disadvantages: Require additional light sources Range of temperature is limited for operation Low reliability Speed is very low LCD’s need an AC drive Applications: Liquid crystal technology has major applications in the field of science and engineering as well on electronic devices. Liquid crystal thermometer Optical imaging The liquid crystal display technique is also applicable in visualization of the radio frequency waves in the waveguide Used in the medical applications 1.2.3 TUNNEL DIODE Tunnel diode is a highly doped semiconductor device and is used mainly for low voltage high frequency switching applications. It works on the principle of Tunneling effect. The tunnel diode was discovered by a Ph.D. research student named Esaki in 1958 while he was investigating the properties of heavily doped germanium junctions for use in high speed bipolar transistors. Then in 1973, Esaki received the Nobel prize for Physics for his work on the tunnel diode. After the work by Esaki, other researchers demonstrated that other materials also showed the tunnelling effect. Holonyak and Lesk demonstrated a Gallium Arsenide device in 1960, and others demonstrated Indium tin, and then in 1962 the effect was demonstrated in materials including Indium Arsenide, Indium Phosphide and also Silicon. The circuit symbol of Tunnel diode is shown below. The tunnel diode is a two terminal device with p type semiconductor acting as anode and n type semiconductor as cathode. Construction: The tunnel diode is similar to a standard p-n junction in many respects except that the doping levels are very high. Densities of the order of 5x10^19 cm^-3 are common. The main difference is that the depletion region is the area between the p-type and n-type areas. As the depletion region is so narrow this means that if it is to be used for high frequency operation the diode itself must be made very small to reduce the high level of capacitance resulting from the very narrow depletion region. In terms of the material used for these diodes, the favoured semiconductor is germanium. Tunnel diodes are usually fabricated from germanium, gallium or gallium arsenide. These all have small forbidden energy gaps and high ion motilities. Silicon is not used in the fabrication of tunnel diodes due to low (Ip,I v)value. A small tin dot is soldered or alloyed to a heavily doped pellet of n-type Ge, GaSb or GaAs. The pellet is then soldered to anode which is also used for heat dissipation. The cathode contact is connected to the tin dot via a mesh screen used to reduce inductance. The diode has a ceramic body and a hermetically sealing lid on top. Tunnel diode structures generally fall into one of three basic structures: Ball alloy: This type of tunnel diode format is fabricated as a mesa structure. To achieve this form of structure, the fabrication technique involves bringing an alloy containing the required dopants into contact with a heavily doped substrate. The temperature used is around 500°C at which point the dopants quickly melt and diffuse into the substrate. The overall structure geometry is then defined by etching the diode to the required proportions. Pulsed bond: This is a relatively straightforward structure to create, although careful process control is required during the fabrication process. The diode is created by using a wire coated with an alloy containing the required dopants. This is pressed hard onto the heavily doped substrate, and then a voltage pulse is applied. The effect of this is that the junction forms by a process of local alloying. Despite this, there are drawbacks to this process because it can only produce a small junction, and the exact properties, including the area of the junction cannot be controlled tightly. Planar structure: Planar technology can be used to create the diode. Using this approach for the fabrication process, the heavily doped n+ substrate is masked off by an insulating layer to leave a small area exposed. This exposed area is then open to become the active area of the diode. Tunnel diode planar structure The doping for the area can be introduced by one of a number of means. It can be introduced by diffusion, alloying or epitaxial growth. Alternatively it is possible to grow an epitaxial layer over the whole surface and then etch away those areas that are not required to leave a mesa structure. All three structures enable high performance diodes to be obtained. Although these are three popular structures for tunnel diodes, new developments are occurring using different materials and also involving new structures that offer a greater variety of characteristics, or they may be tailored to the needs of a particular material that may be used. Operation: According to the classical laws of physics a charged particle in order to cross an energy barrier should possess energy at least equal to the energy barrier. Hence the particle will cross the energy barrier if its energy is greater than the barrier and cannot cross the barrier if its energy is less than the energy barrier. But quantum mechanically there exists non zero probability that the particle with energy less than the energy barrier will cross the barrier as if it tunnels across the barrier. This is called as Tunneling effect. The probability increases with the decreasing barrier energy. P α exp (-A*Eb *W) Where P is the probability that the particle crosses the barrier, Eb is the barrier energy , W is the barrier width. In normal PN junction diodes the doping levels will be of the order 1 dopant atom in 108 atoms of Si (or) Ge. If the doping levels are increased to 1 in 103, the depletion layer width is of the order of 10 nm. In such a PN junction tunneling effect is significant, such PN junction devices are called Tunnel diodes. Current components in a tunnel diode: The total current in a tunnel diode is given as It = Itun + Idiode + Iexcess. The diode current in a tunnel diode is same as that for normal PN junction diode which is given as Idiode = Ido*(exp (V/ (η *Vt))-1) Where Ido is reverse saturation current and will be very high in tunnel diode compared to PN junction diode due to high doping concentrations, V is voltage applied across diode, Vt is the voltage equivalent of temperature, η is correction factor 1 for Ge and 2 for Si, For Voltages less than the cut in voltage of the diode this current is negligible.The excess current is an additional current due to parasitic tunneling via impurities which determines the valley point. The tunneling current in given as Itun = (V/Ro)*exp (-(V/Vo)m) Where m= 1 to 3 and VO = 0.1 to 0.5 volts, RO is the tunnel diode resistance. Peak voltage, Peak current of tunnel diode: The peak voltage of a tunnel diode can be found as follows: At peak voltage current through the tunnel diode is maximum. Typically the peak voltage will be less than cut in voltage of tunnel diode and hence the diode current and excess current can be considered negligible. Hence for maximum or minimum diode current V=Vpeak, dItun/dV = 0 which is Vpeak = ((1/m)(1/m))*Vo , Ipeak = ((1/m)(1/m))*Vo*exp(-1/m). Characteristics: For small forward voltages owing to high carrier concentrations in tunnel diode and due to tunneling effect the forward resistance will be very small. As voltage increase she current also increases till the current reaches Peak current. If the voltage applied to tunnel diode is increased beyond the peak voltage the current will start decreasing. This is negative resistance region. It prevails till valley point. At valley point the current through the diode will be minimum. Beyond valley point the tunnel diode acts as normal diode. In reverse biased condition also Tunnel diode is an excellent conductor due to its high doping concentrations. Tunnel diodes are made from Germanium or gallium arsenide due to their highest peak voltage to valley point swing. The ratio of high peak current to valley current quantifies the maximum voltage swing allowed in negative resistance region. The IV characteristics of the tunnel diode is shown below Advantages : High speed of operation due to the fact that the tunnelling takes place at the speed of light. Low cost Low noise Environmental immunity Low power dissipation Simplicity in fabrication Longevity Disadvantages : Low output voltage swing Because it is a two terminal device, there is no isolation between input and output. Applications : Some of the applications of Tunnel diode are Tunnel diodes are used as very high speed switches Used as high frequency micro wave oscillator 1.2.4 SCOTTKY DIODE A Schottky barrier diode is a metal semiconductor junction formed by bringing metal in contact with a moderately doped n type semiconductor material. A Schottky barrier diode is also called as known as Schottky or hot carrier diode. It is named after its inventor Walter H. Schottky, barrier stands for the potential energy barrier for electrons at the junction. It is a unilateral device conducting currents in one direction (Conventional current flow from metal to semiconductor) and restricting in the other. A Schottky barrier diode is a two terminal device with metal terminal acting as anode and semiconductor terminal acting as anode. The circuit symbol of Schottky barrier diode is shown in the figure. Construction : It is a metal semiconductor junction diode without depletion layer. On one side of junction a metal like gold, silicon, platinum is used and other side N type doped semiconductor is used. For protection purpose metal layer is surrounded by gold or silver layer. The metal film forms the positive electrode and semiconductor is the cathode A Schottky barrier diode is shown in the figure below Operation: Operation is due to the fact that the electrons in different material have different potential energy. N type semiconductors have higher potential energy as compare to electrons of metals. When these two are brought together in contact, there a flow of electron in both direction across the metal-semiconductor interface when contact is first made. A voltage is applied to the schottky diode such that the metal is positive with respect to semiconductor. The voltage will oppose the built in potential and makes it easier to current flow. Current components in Schottky diode: In a Schottky barrier diode current conduction is through majority carriers which are electrons in N type semiconductor. The current in Schottky barrier diode current is IT = IDiffusion+ITunneling+IThermionic emission Where IDiffusion is diffusion current due to concentration gradient and Diffusion current density Jn= Dn*q* dn/dx for electrons, where Dn is the diffusion constant for electrons, q is electronic charge = 1.6*10-19 Coulombs, dn/dx is the concentration gradient for electrons. ITunneling is the tunneling current due to quantum mechanical tunneling through the barrier. This current is directly proportional to the probability of tunneling. The probability of tunneling increases with the decreasing barrier or built in potential and decreasing depletion layer width. IThermionic emission is current due to thermionic emission. Due to thermal agitation some of carriers which have energy equal to or larger than the conduction band energy at the metal-semiconductor interface, contribute to the current flow. This is termed as thermionic emission current. It is suitable for high-speed switching applications because the forward voltage is low and the reverse recovery time is short. The reverse recovery time is solely dependent on junction capacitance which will be of the order of Pico farads. Characteristics: The VI characteristics of Schottky barrier diode is shown below From the VI characteristics it is obvious that the VI characteristics of Schottky barrier diode is similar to normal PN junction diode with the following exceptions The forward voltage drop of Schottky barrier diode is low compared to normal PN junction diode. The forward voltage drop of Schottky barrier diode made of silicon exhibits a forward voltage drop of 0.3 volts to o.5 volts. The forward voltage drop increases with the increasing doping concentration of n type semiconductor. The VI characteristics of Schottky barrier diode is Steeper compared to VI characteristics of normal PN junction diode due to high concentration of current carrier. Advantages: Schottky diodes are used in many applications where other types of diode will not perform as well. They offer a number of advantages: Low turn on voltage: The turn on voltage for the diode is between 0.2 and 0.3 volts for a silicon diode against 0.6 to 0.7 volts for a standard silicon diode. This makes it have very much the same turn on voltage as a germanium diode. Fast recovery time: The fast recovery time because of the small amount of stored charge means that it can be used for high speed switching applications. Low junction capacitance: In view of the very small active area, often as a result of using a wire point contact onto the silicon, the capacitance levels are very small. Applications:The Schottky barrier diodes are widely used in the electronics industry finding many uses as diode rectifier. Its unique properties enable it to be used in a number of applications where other diodes would not be able to provide the same level of performance. In particular it is used in areas including: RF mixer and detector diode: The Schottky diode has come into its own for radio frequency applications because of its high switching speed and high frequency capability. In view of this Schottky barrier diodes are used in many high performance diode ring mixers. In addition to this their low turn on voltage and high frequency capability and low capacitance make them ideal as RF detectors. Power rectifier: Schottky barrier diodes are also used in high power applications, as rectifiers. Their high current density and low forward voltage drop mean that less power is wasted than if ordinary PN junction diodes were used. This increase in efficiency means that less heat has to be dissipated, and smaller heat sinks may be able to be incorporated in the design. Power OR circuits: Schottky diodes can be used in applications where a load is driven by two separate power supplies. One example may be a mains power supply and a battery supply. In these instances it is necessary that the power from one supply does not enter the other. This can be achieved using diodes. However it is important that any voltage drop across the diodes is minimised to ensure maximum efficiency. As in many other applications, this diode is ideal for this in view of its low forward voltage drop. Schottky diodes tend to have a high reverse leakage current. This can lead to problems with any sensing circuits that may be in use. Leakage paths into high impedance circuits can give rise to false readings. This must therefore be accommodated in the circuit design. Solar cell applications: Solar cells are typically connected to rechargeable batteries, often lead acid batteries because power may be required 24 hours a day and the Sun is not always available. Solar cells do not like the reverse charge applied and therefore a diode is required in series with the solar cells. Any voltage drop will result in a reduction in efficiency and therefore a low voltage drop diode is needed. As in other applications, the low voltage drop of the Schottky diode is particularly useful, and as a result they are the favoured form of diode in this application. Clamp diode - especially with its use in LS TTL: Schottky barrier diodes may also be used as a clamp diode in a transistor circuit to speed the operation when used as a switch. They were used in this role in the 74LS (low power Schottky) and 74S (Schottky) families of logic circuits. In these chips the diodes are inserted between the collector and base of the driver transistor to act as a clamp. To produce a low or logic "0" output the transistor is driven hard on, and in this situation the base collector junction in the diode is forward biased. When the Schottky diode is present this takes most of the current and allows the turn off time of the transistor to be greatly reduced, thereby improving the speed of the circuit. An NPN transistor with Schottky diode clamp In view of its properties, the Schottky diode finds uses in applications right through from power rectification to uses in clamp diodes in high speed logic devices and then on to high frequency RF applications as signal rectifiers and in mixers.Their properties span many different types of circuit making them almost unique in the variety of areas and circuits in which they can be used.