* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download criteria for the selection of power cables

Current source wikipedia , lookup

Electric power system wikipedia , lookup

Ground loop (electricity) wikipedia , lookup

Control theory wikipedia , lookup

Solar micro-inverter wikipedia , lookup

Distributed control system wikipedia , lookup

Three-phase electric power wikipedia , lookup

Loading coil wikipedia , lookup

Electrical substation wikipedia , lookup

Power engineering wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Power over Ethernet wikipedia , lookup

Pulse-width modulation wikipedia , lookup

History of electric power transmission wikipedia , lookup

Stray voltage wikipedia , lookup

Voltage optimisation wikipedia , lookup

Power inverter wikipedia , lookup

Buck converter wikipedia , lookup

Telecommunications engineering wikipedia , lookup

Distribution management system wikipedia , lookup

Mains electricity wikipedia , lookup

Opto-isolator wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Control system wikipedia , lookup

Alternating current wikipedia , lookup

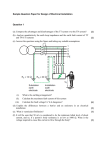

AN INDUSTRIAL TRAINNING REPORT AT “Universal Cables Limited, Satna (M.P.)” Submitted in Partial Fulfillment for the award of Bachelor of Engineering in Electronics &Communication Engineering (2014-2015) Submitted to RAJIV GANDHI PROUDYOGIKI VISHWAVIDYALAYA BHOPAL (M.P.) Submitted By: Neeraj Kumar Singh (0302EC111081) Approved By Under the Guidance of Mr. A.P. Singh Mr. R.K. Mishra (Head of the Department Electronics & Communication (H.O.D. OF INSTRUMENT DEPARTMENT) DEPARTMENT OF Electronics & Communication ENGINEERING VINDHYA INSTITUTE OF TECHNOLOGY AND SCIENCE SATNA (M.P.) 1 Rajiv Gandhi Proudyogiki Vishwavidyalaya,Bhopal(M.P) Vindhya Institute of Technology & Science Satna (M.P) CERTIFICATE This is to certify that the Industrial Training at “Universal Cables Limited” which has been completed & submitted by Neeraj Kumar Singh in partial fulfillment of the requirement for the award of the degree of Bachelor of Engineering in Electronics& Communication Engineering for the session 2011-2015 is a bonafied work by them and has been completed under my guidance and supervision. H.O.D Mr.A.P.Singh Guided By Mr. R.K. Mishra (Head of the E&C Department) (H.O.D. of Instrument Department) Principal Mr.R.C.Shrivastava 2 Rajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal (M.P) Vindhya Institute of Technology & Science Santa (M.P) CERTIFICATE This is to certify that the Industrial Training at “Universal Cables Limited ”which has been completed & submitted by Neeraj Kumar Singh in partial fulfillment of the requirement for the award of the degree of Bachelor of Engineering in Electronics & Communication Engineering for the session 2011-2015. (External Examiner) (Internal Examiner) 3 ACKNOWLEDGEMENT Though words are seldom sufficient to express gratitude and feelings, I would like to fulfill a fraction of my moral obligation by expressing a word of gratitude to all those who have profoundly contributed to this project. First of all I would like to thank Mr. Sudhir jain, (Asst. Vice President, Administration), Universal CablesLimited , Universal Cables Limited for accepting me as a trainee and giving me opportunity to visit in the company. I would also like to take this opportunity to convey my respect and special gratitude towards Mr. R.K Mishra(HOD of Instrument department ) and Mr. Akhil Pratap Singh (HOD of E&C Department VITS) who consider me worthy of doing project in their esteemed establishment and never failed to satisfy my over-zealous thirst to obtain information. I also want to say thanks to my whole faculty, whole UCL, friends and family. Under the guidance of Mr. R.K. Mishra (Head of department of Instrument department) at universal cables It was their knowledge, skills and professionalism which helped me. Their suggestions, encouragement has been instrumental in the study. Working on this project has been a great experience. I am thankful to all concerned people who have played active role in the successful completion of this project. DECLARATION 4 I hereby Declare that this project report has successfully done the training, in industry at Universal Cables Private Limited Satna (M.P.) , during the period June 09, 2014 to July 08, 2014.The project is based on the original study conducted and has not formed a basis for the award of any Degree/Diploma by any other University or Institution. The project is done for partial fulfillment of the B.E. from the aforesaid institute. Signature Name of student : Neeraj Kumar Singh B.E (VI-SEM) VITS (Satna) 5 PREFACE The following report is the outcome of my research project during the month of June and July. Provides an opportunity to demonstrate application of knowledge skill and competence required during the technical sessions. Research also helps to analyze the problem and suggest alternative solutions, to evaluate them and to provide feasibility recommendation on the provided data. Instrument plays an important role in every production unit. To improve it at every step is very important. The use of Instrument in many highly innovative companies in Scandinavian countries has been proven. This tool is suitable for all levels of employee within an organization. However, it will only succeed if it has genuine management involvement and full understanding throughout all levels of management and the organization concerning the multifaceted purposes served by the Instrument. INDEX 6 SECTION SECTION NAME PAGE NO. 1. COMPANY PROFILE 6-10 2. FACTORS INFLUENCING THE CHOICE OF CABLES 11-14 3. 15-21 4. MANUFACTURING PROCESS OF CABLES EHV & XLPE CABLES 5. TELECOMMUNICATION CABLES 28-29 6. ELECTRICAL&MACHANICAL MAINTENANCE 30 7. CONTROLLERS, AC DRIVES, UPS 31-37 8. INVERTERS 38-40 9. AC&DC MOTORS, CRO, FUNCTION 41-54 22-27 GENERATORS , AUTOMATION 10. PROFIBUS INTERACE 57 11. SOLID STATE RELAY 58 12. TELECOMMUNICATION - EPABX 59-60 13. NETWORK COMMUNICATION 61 14. CCTV ON LAN 62 15. IGBT 63-64 7 COMPANY PROFILE 8 Universal Cables Limited (UCL) was established in the year 1962 as a modern mass production unit to manufacture paper insulated power cables in technical collaboration with world's largest cable producer BICC, UK. Late Shri M.P. Birla, who had adorned the chair of the Company for over 25 years since its inception, enabled the Company to flourish in a highly competitive world, while distinguishing itself by the latest technological tie-ups with the foremost leaders in the world of this industry and the most up-to date technology. Universal Cables Limited entered into a collaboration agreement with ABB high Voltage Cables, Sweden in 1977 to manufacture cross-linked Polythene Power Cable for the first time in the country. The Company is the foremost manufacturer of XLPE Cables with modern dry cured dry cooled process for voltage range extending from 1.1 to Extra High Voltage up to 132 KV grade. Under the collaboration Agreement with ABB high Voltage Cables, Sweden, UCL brought in complete know how of compounding of Polymer and produced complete range of dielectrics presently used in all special cables. In 1983, UCL embarked on a joint venture with MPAVN to manufacture Jelly Filled Telephone Cable in technical collaboration with one of the world's leading manufacturers of Telephone Cable, Ericsson Cable AB, Sweden. This plant was incorporated as Vindhya Telelinks Limited (VTL) and is situated at Rewa, only 50 Kms away from its Power Cable Plant at Satna. 9 Since 1985, ABB High Voltage Cables, Sweden, is further assisting UCL to manufacture Fluroplastic Cables, specifically for very high temperature operation and high frequency signaling circuitry. In 1993, UCL & VTL jointly entered into the field of optical communication by way of manufacturing Optical Fibre Cables in technical and financial collaboration with Ericsson Cables AB, Sweden. This marked the birth of Birla Ericssion Optical Limited (BEOL). QUALITY CONSCIOUSNESS Whether conventional or specially designed to any Indian or International specification, UCL's products are put to the grill of rigorous in-process quality cheeks by stage inspection and testing Its quality is taken as standard in the world market. MEANS ARE AS IMPORTANT AS THE END UCL proudly claims to have the most sophisticated plant, equipment, laboratory and testing facilities available in the country. The entire plant is housed in dustproof pressurized building to ensure consistency in the product quality. CERTIFICATION The above claim is certified by various test authorities of the country like NTH, Calcutta and CPRI Bhopal & Bangalore and all consultants like Ell, DCPL, M.N. Dastur, Lloyds register of Shipping, MECON, Crown Agents and others. This confirms the dependability and reliability of UCL products. ISI MARKING 10 All standard UNISTAR cables are ISI marked. IS/ISO QUALITY CERTIFICATION UCL is accredited with IS/ISO 9001/2000 Quality Systems Certification in recognition of the High Quality Standard of its cables. The company is also accredited for its well-established environmental friendly activities and atmosphere. TECHNICAL SERVICES The Company welcomes enquiries on cable engineering problems and provides solutions through its design and development team. It also assists customers in cable design to suit their specific requirement. A team of experts is always ready to assist cable engineers for installation, laying and jointing cable systems through out the India. When requested the technical dept. of the company provides help to customers for fault location and other related problem. RESEARCH & DEVELOPMENT UCL emphasizes on in-house Research and Development. The R & D programme is mainly directed to applied research for product development, process development and technological up gradation. The R & D laboratory of UCL is a recognized unit of Department of Scientific and Industrial Research of Govt. of India. This laboratory has developed many new Cables for special applications such as FRLS Cables, Ship wiring, Air craft wiring, Radars, Submarine, Medical Equipments etc. CAPACITORS UCL set up its Capacitor Division in the year 1967, in technical collaboration with world renowned TOSHIBA, to manufacture Paper & Power Capacitors. In 1977 this division entered into a technical collaboration with General Electric Company of USA, to manufacture Mixed Dielectric Capacitors. Subsequently the collaboration was extended to include All Polypro- propylene (All-PP) Dielectric Capacitors impregnated with Non PCB oil. Today the Capacitor Division is rated 11 to be the foremost manufacturer of All-PP Power Capacitors in LT & HT range in the country. This division offers complete schemes for power factor improvement and can supply capacitors along with associated equipments on turnkey basis. It can also carry out harmonic analysis of Power System on request and design & supply Filter Banks. EXPORTS UCL also exports its products to various countries of the world and has earned due recognition for its export efforts. Universal Cables limited is a vibrant progressive company, a leader in its field of activities, serving the aspiration of the nation in the field of Power Development. . CRITERIA FOR THE SELECTION OF POWER CABLES The electrical current in a conductor causes a voltage drop and power losses. The temperature rise in the cable caused by the losses must be kept within certain limits in order not to shorten the service life of the cable. The temperature limit varies with the type of cable, or more precisely the type of insulation. The best way to keep the temperature within limits specified for the type of cable, is to choose the conductor cross-section so that the cable and its surroundings with the actual continuous load, achieve thermal balance at a temperature below or equal to the temperature limit recommended. Cable type and size should be selected keeping in view the following:(1) (2) (3) (4) (5) (6) (7) (8) 2. Application. Working voltage; earthed or unearthed neutral system. Load current, load factor, starting duty and frequency. Installation method. The environment in which the cable has to operate. Short circuit current and system protection. Acceptable voltage drop Economies. How the above factors influence on the choice of cable? 12 1) The application of the cable determines the basic factors for the choice of cable type and the rules according to which it must be manufactured. Following are the major factors for choice of cable type. (a) Conductor materials: No doubt copper is better conductor material owing to its high electrical conductivity and other electrical/mechanical properties but due to its high cost and scarcity, researches are being carried out to find other cheaper and abundant metals which may be a close substitute to copper in electrical application. Aluminium conductors are being used in place of copper conductors for the past many years and have proved to be quite satisfactory. The lower conductivity of a Aluminium (61 % of the annealed copper) results in increased dimensions of the cable and ultimately of conduits and fittings for the same current carrying capacity as that of a copper conductor cable. Aluminium conductor cables although bigger and somewhat stiffer when lower number of wires is used for the conductor than the equivalent copper conductor cables, are still flexible enough to be installed where a copper conductor cable was formerly used. The advantages of the lighter weight offset the disadvantages of larger sizes for a given capacity. The use of Aluminium conductor cables should be preferred as far as possible. The use of flexible copper conductor is recommended where very high degree of flexibility is required as in the case of mines etc. (b) Insulating materials: The right type of insulation material for a particular usage depends upon the voltage grade, operating temperature required, degree of flexibility, current capacity requirement and restrictions on size etc. and other climatic conditions. (C) Metallic Sheathing: Either pure lead or different lead alloys are used for Sheathing of PILC cables and each has it’s own advantages.The most common andmpopular alloy is lead Alloy 'E'. 13 (d) Bedding and Serving materials: In case of PVC cables the normal bedding and serving materials are PVC compound. The normal bedding and serving in case of PILC cables consist of a combination of an impregnated paper, cotton and Hessian tapes and bituminous compound. These materials provide protection against corrosion of armour and lead and are suitable in great majority of installations. However, in special cases where severe chemical corrosion is to be encountered, the use of PVC bedding and PVC serving is recommended. (D)Armouring: The purpose of armour is to provide mechanical protection to the cable and to facilitate earthling for safety requirements. This also carries phase to ground fault currents of the system safely. Double steel tape provides good mechanical protection but when in addition longitudinal stresses are encountered during the installation or in service, steel wire/strip armouring is recommended for vertical armouring should be preferred. Double wire runs, strip armouring is recommended for vertical armouring should be preferred. Double wire runs, river crossing, cables laid on bridges and mine shafts etc. where longitudinal stresses are expected. 2. The system voltage determines the voltage class of the cables. 3. The current rating is, in general, the decisive factors for fixing conductor crosssection. But in certain applications where intermittent load is required, it is more relevant to use the squared average r.m.s. current with a reduced cross section. 4. The power cables must be capable of carrying, the required normal full load current continuously under the site conditions throughout the year. Therefore, the current ratings specified must be corrected to site conditions by applying suitable derating/uprating factors depending upon - (a) (b) (c) Ground or ambient air temperature (max.). Thermal resistivity of soil during dry season. Depth of laying. 14 (d) Total number of cables/circuits in groups. 5. (A) Chemical substances in the environment might cause special stringent requirements on the outer covering. (B) If it is necessary to reduce the propagation of fire along cable route combined with low corrosivity, toxicity and smoke generation characteristics for cables, "FRLS' cables (Flame Retardant low Smoke) with thermoplastic or thermosetting material or fire survival cables with elastomeric material should be used. These types of cables are designed with special composition of protective sheath materials, and by using beat barrier tapes etc. for use in such critical fire risk installations. 6) Short circuit current together with duration of short circuit determines the short circuit energy the cable insulation has to with stand thermally.ln certain cases a larger size of cable then the cable required for normal full load current may be needed to match system short circuit current levels. Voltage drop is also a major factor in deciding the conductor size of the cable. The cross section of the cable should be chosen such that voltage drop of the cable for the given route length does not exceed the statutory requirement. 7) Naturally, the most economical construction and the size of the cable consistent with required current carrying capacity and laying condition has to be selected. Thus the selection of particular type of cable i.e. PVC, XLPE, PILC or rubber and the particular material for screening, sheathing, bedding, armouring or serving etc. out of many choices available depends upon the usages, laying and climatic conditions. The design of the cable for a particular application must be optimized taking into account all the above-mentioned factors. In case expert guidance in this respect is desired, please contact UCI Technical Service Division. UCL SATNA 15 MANUFACTURING PROCESS OF CABLES 16 The over all stages of manufacturing consists of the following different types of processes :- Wire Drawing - Annealing Tinning Bunching Stranding Insulation Paper/PVC/Rubber/XLPE/Fluroplastic/Polythelene Laying Impregnation Lead Sheathing Bedding – Extruded/wrapped/fibrous lapping Armoring Round wire/Flat strip/Steel tape Sheathing/ Serving Extruded/Fibrous lapping 17 The details of above manufacturing processes are as given here under :CONDUCTOR: Wires of different sizes are drawn from Aluminium/Copper rods on wire-drawing machines. The size(diameter) of wire depends upon the over all cross sectional area of the ultimate cable under manufacture as well as the flexibility requirement. Annealed copper Wires for flexible rubber cables are then tinned before they are released for next process. The tinning is done by passing the cleaned cu. wires seated with the flux through molten tin both. The excess of tin adhering to wire surface is wiped out by means of wipers Stranding - The Al or Cu. wires or tinned copper wires as the case may be are bunched/stranded together. The direction of stranding of alternate layers is always kept in opposite direction in order to have tight and balanced configuration of wires. The standard Conductor may be compact circular or shaped as per the cable construction. 18 INSULATION (1) PVC:- Different type of PVC compounds are used for required Physical & electrical properties and continuous operating temperature of cables. PVC compound extruded over conductor by extrusion process on differe. (2) The sizes of extruders as per the size of conductor. In line to extrusion process H.V. testing (Spark testing) is being done to check the quality of extruded core. 2. Rubber - Natural or synthetic rubber based compounds are prepared to meet the physical & Elec. properties and continues operating temp. of cable. Various types of rubber compounds are then extruded over the conductor as per the requirement of the customer. 3. Paper insulation - In this case insulated paper tapes are lapped on conductor. The thickness of insulation is built up by required number of paper tapes according to voltage grade of cables. The top layer of paper tapes is suitably numbered for core identification. 4. XLPE – XlPE cables have become very much popular now a day. These cables are replacing paper-insulated cables right from low voltage grade to extra high voltage grade. In these cables two types of constructions are used ie screened and unscreened. 11 KV and above grade cables are all screened. Conductor screen, insulation and insulation screen are generally applied in one operation called dualtandem process. M/s Universal Cables Ltd is one of the pioneer cable manufacturers of XLPE cable up to 132 KV grade cables in INDIA. Vulcanization/Cross-linking: Rubber and XLPE cables are vulcanized after extrusion. This process is done just after extrusion on CV/CCV/PLCV lines. This process is done to improve the electrical and physico-mechanical properties of rubber and polyethylene compounds. In some cases batch vulcanization is carried out for rubber cables and low voltage XLPE cables. 19 Laying up of cables. The insulated cores are laid up along with filling material and twisted to get approximate circular Cable. A binding tape is also provided to hold the fillers and maintain the circularity of laid up cables. In case of paper-insulated cables if the cables are belted type, belt insulation is done along with laying up process by providing required no. of paper tapes and in screened type cables copper woven fabric tape is provided over laid up cores. Impregnation Process :Paper insulated cables need a special process known as impregnation. The function of this process is to extract moisture out of paper insulation and impregnate the insulation with moisture resistant insulating compound. Heating the Cable under vacuum for some period and then filling the insulating compound over cable within the impregnating vessel do this process. The cycle of drying flooding and cooling etc. depends on size and voltage grade of cables. By impregnation the electrical properties of paper insulation are enhanced. Procedure adopted for drying and impregnation of paper-insulated cables comprises the following stages :Rewinding the cables in impregnation trays Loading the trays in the impregnation tanks Heating the cables under vacuum Impregnating of cables with impregnation compound for required period Unloading the cable-trays from the tanks after impregnation. The compound used for impregnation is a petroleum product and has excellent electrical and mechanical properties. 20 Lead sheathing After impregnation, lead sheath is applied over the paper-insulated cables. This process is done by sleeve extrusion (pipe extrusion). The object of Lead sheathing is to prevent the entry of moisture in the impregnated cable while maintaining the flexibility of cable. Inner Sheathing/Bedding PVC and Rubber insulated cables are provided with inner sheathing over laid up cores as bedding for armoring. In case on PVC cables inner sheathing may be done by lapping PVC/PE tapes or by PVC extrusion but in case of rubber insulated cables rubber extrusion is done for this purpose. Armoring The armoring is provided to provide mechanical protection of cables during handling and installation. This is done by providing galv. round steel wires or galvanized steel strips or double steel tapes over the bedded cables. Though the main function of armoring is to protect the cable from outside mechanical damages to the cable but it also serves the purpose of carrying the short circuit current produced during system failure or any type of short circuit in the system. 21 Sheathing/Serving:After armoring or in case of un-armored cables, the laid and bedded cables are provided with a protective sheathing of extruded PVC or PE sheath. Paper insulated cables are generally provided with a fibrous lapped serving but PVC or any other type of extruded sheath can also be given if required. 22 Power and control cables 23 Introduction:Universal cables Ltd manufactures PVC cables up to 11 KV grade to Indian as well as international standards. Both utilities and domestic users find them suitable for power distribution, control system, utility network, railway signaling installations, switching stations, textile mills, chemical plants, and machine shops etc. Normal PVC insulated cables are suitable for an operating conductor of 700C and HR PVC insulated cables are suitable for an operating conductor temperature of 850C. PVC CABLES 24 VCV PLANT EXTRA HIGH VOLTAGE CABLES VCV PLANT 25 Introduction:UNIVERSAL CABLES LTD, the pioneer of XLPE cables in India, manufactures Extra High Voltage (EHV) XLPE cables in the range of 66-220 kV using ‘Vertical Continuous Vulcanizing (VCV) technology in technical collaboration with World Leader in Cable manufacturing, FURUKAWA ELECTRIC CO. LTD. (In association with VISCAS Corporation, Japan). This technology for EHV XLPE Cable manufacturing process is the only of its kind in the Country. EHV Underground Power Transmission is the solution for meeting today’s growing power demand of the power starved Metro Cities. Underground Power Transmission System requires highest reliability to ensure uninterrupted power supply. Unistar EHV cable, manufactured using VCV technology with proven know-how from FURUKAWA ELECTRIC CO. LTD and also having in-house engineering expertise for system designing, cable jointing and installation, can guarantee this requirement. The main cutting edge features of this technology as True simultaneous triple extrusion with single (common) cross-head, Dry cure dry cooled process, 26 Dimensional accuracy for perfect geometry with Zero eccentricity/ ovality of the insulation, Class 1000 cleanliness level with completely closed material handling system, Online X-Ray monitoring system, Direct gravitational feeding of XLPE compound, Control and Monitoring in production process using SCADA, all add up to unmatched quality standard to ensure reliable and efficient performance of the cable throughout its service life. The main cutting edge features of this technology are:- 1. True simultaneous triple extrusion with single (common) cross head - conductor screen, insulation and insulation shield applied in single process. This provides perfect bonding of insulation and semicon layers with smooth boundary and free of protrusions. Insulation extruder operates with tight screen of 400 mesh for filtering. 2. Dry cure dry cooled process - Prevents formation of micro voids and eliminates moisture contents in the XLPE insulation - Prevents electro-chemical tree formation in the insulation and capable to withstand higher stress voltage. 3. Dimensional accuracy - perfect geometry with Zero eccentricity/ovality of the insulation. This enables uniform stress distribution over the insulation. 4. Class 1000 cleanliness level in manufacturing with completely closed material handling system - prevents insulation contamination which is an imperative for Extra High Voltage Cables enabling high impulse and breakdown voltage levels. 5. Cables of longer lengths and larger sizes can be offered to economize the system cost. Other special features include:• Online X-Ray monitoring system with a fully computerized control system including Programmable Logic Control. 27 Cross link polyethelene(XLPE OR PEX) Plant:- SPECIFICATIONS:The extrusion of cross linked polyethylene shall be carried out on a dual tandes continuous catenary vulcanization(ccv) line using nitrogen gas curing system. The insulations of 1.1kv-3.3kv range cables shall extruded in a single layer in natural colour, using only insulation extruation. The insulation of 6.6kv-132 kv range cables shall be coextruded in natural colour together with semiconducting layer using three extruders. 28 Telecommunication Cables 29 Apart from power and control cables, telephone cables are also manufactured. These cables are generally called PIJF cables meaning Polyehylene Insulated Jelly Filled cables. In these cables copper wire of suitable size is insulated with Polyethylene. Two insulated wires are twisted together to form a pair. Required numbers of such pairs are grouped together and filled with special moisture resistant jelly. The filled cable is than screened with polythene laminated aluminum foil and sheathed with LDPE compound. The cable is finally armoured with galvanized double steel tapes and jacketed with LDPE compound. Final testing:All cables are rewound in proper size wooden/steel reels and sent to testing section where all the cables are subjected to rigorous electrical and physical tests. Both the ends of cables after testing are sealed and given a unique identification number. These are then handed over to marketing department for onward dispatch to relevant customer Quality control In universal cables quality is maintained by following a in built quality system which is based on international specification IS/ISO 9001. A property organized system of control of quality of product and process is followed for the efficient production of product acceptable in all respects to the customer. Products are tested and processes are controlled at all stages of manufactures from raw material to the finished stage. In addition certain standards procedures are adopted in order to ensure that product successfully fulfils the customer requirement. 30 ELECTRICAL & MECHANICAL MAINTENANCE Electrical and mechanical departments are responsible for the periodic maintenance of all machines and equipments. A comprehensive schedule of PPM is followed to avoid breakdowns and thereby loss of machine and men hours. Both these departments are also looking after break down maintenance and installation &commissioning of new machines and instruments. These departments also carry out calibration of various electrical and mechanical instruments. TEMPERATURE CONTROLLER:Temperature Controller: What is a Temperature Controller? As the name implies a temperature controller is an instrument used to control temperature. The temperature controller takes an input from a temperature sensor and has an output that is connected to a control element such as a heater or fan. 31 Introduction to Temperature Controllers:How do Temperature Controllers work? To accurately control process temperature without extensive operator involvement, a temperature control system relies upon a controller, which accepts a temperature sensor such as a thermocouple or RTD as input. It compares the actual temperature to the desired control temperature, or setpoint, and provides an output to a control element. The controller is one part of the entire control system, and the whole system should be analyzed in selecting the proper controller. The following items should be considered when selecting a controller: Type of input sensor (thermocouple, RTD) and temperature range Type of output required (electromechanical relay, SSR, analog output) Control algorithm needed (on/off, proportional, PID) Number and type of outputs (heat, cool, alarm, limit) What Are the Different Types of Controllers, and How Do They Work? There are three basic types of controllers: on-off, proportional and PID. Depending upon the system to be controlled, the operator will be able to use one type or another to control the process. On/Off Control:An on-off controller is the simplest form of temperature control device. The output from the device is either on or off, with no middle state. An on-off controller will switch the output only when the temperature crosses the setpoint. For heating control, the output is on when the temperature is below the setpoint, and off above setpoint. Since the temperature crosses the setpoint to change the output state, the process temperature will be cycling continually, going from below setpoint to above, and back below. In cases where this cycling occurs rapidly, and to prevent damage to contactors and valves, an on-off differential, or “hysteresis,” is added to the controller operations. This differential requires that the temperature exceed setpoint by a certain amount before the output will turn off or on again. On-off differential prevents the output from “chattering” or making fast, continual 32 switches if the cycling above and below the setpoint occurs very rapidly. On-off control is usually used where a precise control is not necessary, in systems which cannot handle having the energy turned on and off frequently, where the mass of the system is so great that temperatures change extremely slowly, or for a temperature alarm. One special type of on-off control used for alarm is a limit controller. This controller uses a latching relay, which must be manually reset, and is used to shut down a process when a certain temperature is reached. Proportional Control:Proportional controls are designed to eliminate the cycling associated with on-off control. A proportional controller decreases the average power supplied to the heater as the temperature approaches set point. This has the effect of slowing down the heater so that it will not overshoot the set point, but will approach the set point and maintain a stable temperature. This proportioning action can be accomplished by turning the output on and off for short time intervals. This "time proportioning" varies the ratio of “on” time to "off" time to control the temperature. The proportioning action occurs within a “proportional band” around the set point temperature. Outside this band, the controller functions as an on-off unit, with the output either fully on (below the band) or fully off (above the band). However, within the band, the output is turned on and off in the ratio of the measurement difference from the set point. At the set point (the midpoint of the proportional band), the output on:off ratio is 1:1; that is, the on-time and off-time are equal. if the temperature is further from the set point, the on- and off-times vary in proportion to the temperature difference. If the temperature is below set point, the output will be on longer; if the temperature is too high, the output will be off longer. PID Control:The third controller type provides proportional with integral and derivative control, or PID. This controller combines proportional control with two additional adjustments, which helps the unit automatically compensate for changes in the system. These adjustments, integral and derivative, are expressed in time-based units; they are also referred to by their reciprocals, RESET and RATE, respectively. The proportional, integral and derivative terms must be individually adjusted or “tuned” to a particular system using trial and error. It provides the most accurate and stable control of the three controller types, and is best used in systems 33 which have a relatively small mass, those which react quickly to changes in the energy added to the process. It is recommended in systems where the load changes often and the controller is expected to compensate automatically due to frequent changes in set point, the amount of energy available, or the mass to be controlled. OMEGA offers a number of controllers that automatically tune themselves. These are known as autotune controllers. Standard Sizes: Since temperature controllers are generally mounted inside an instrument panel, the panel must be cut to accommodate the temperature controller. In order to provide interchangeability between temperature controllers, most temperature controllers are designed to standard DIN sizes. The most common DIN sizes are shown below. 34 AC DRIVES AC drives are AC motor speed control systems. Slip controlled drives control the speed of an induction motor by increasing a motor's slip. This is accomplished by reducing the voltage applied to the motor or increasing the resistance of the rotor windings. Because they are generally less efficient than other types of drives, slip controlled drives have lost popularity and have recently been used only in special situations. Adjustable-frequency drives (AFD) control the speed of either an induction motor or a synchronous motor by adjusting the frequency of the power supplied to the motor. Adjustable frequency drives are also known as variable-frequency drives (VFD). When changing the frequency of the power supplied to an AC motor, the ratio of the applied voltage to the applied frequency (V/Hz) is generally maintained at a constant value between the minimum and maximum operating frequencies. Operation at a constant voltage (reduced V/Hz) above a given frequency provides reduced torque capability and constant power capability above that frequency. The frequency or speed at which constant-voltage operation begins is called the base frequency or speed. Whether to applied voltage is regulated directly or indirectly, the V/Hz tends to follow the general pattern described for the performance described. The variable-frequency drive article provides additional information on electronic speed controls used with various types of AC motors. 35 Operating principle Variable frequency drives operate under the principle that the synchronous speed of an AC motor is determined by the frequency of the AC supply and the number of poles in the stator winding, according to the relation: where RPM = Revolutions per minute f = AC power frequency (hertz) p = Number of poles (an even number) Synchronous motors operate at the synchronous speed determined by the above equation. The speed of an induction motor is slightly less than the synchronous speed. 36 UNINTERRUPTIBLE POWER SUPPLY (UPS) SYSTEMS Principles of static UPS systems The basic static UPS system consists of a rectifier-charger, inverter, static switch, and battery as Shown in figure. The rectifier receives the normal alternating current (ac) power supply, provides direct current (dc) power to the inverter, and charges the battery. The inverter converts the dc power to ac power to supply the intended loads. The dc power will normally be provided from the rectifier, and from the battery upon failure of the primary ac power source or the rectifier. The inverter will supply the loads under normal conditions. In the event of the failure of the inverter, the static switch transfers the load to an alternate ac source. Single phase & 3 phase UPS:3 phase in refers to a 440/480 voltage supply. It's generally used to power heavy industrial equipment that runs 3 phase electrical motors more efficiently. Single phase is like household wall outlet voltage. Unless you're running equipment that requires a 3 phase voltage, you're going to need to stick with single phase Normal operation. During normal operation, the rectifier converts the ac input power to dc power with regulated voltage. The rectifier output is normally set at the battery float voltage to charge the battery while supplying dc power to the inverter. The rectifier output voltage is periodically set at the battery equalize voltage to maintain the battery capacity. The dc filter (inductor) is provided for smoothing out the rectifier output current to reduce the current ripple content. The battery acts as a capacitor and in conjunction with the filter, smoothes out the output voltage and reduces the dc voltage ripple content. The inverter converts the dc power to ac power with regulated voltage and frequency. An internal oscillator maintains the inverter 37 frequency by controlling the timing of the silicon controlled rectifier (SCR) firing signals and matches the ac input frequency. The filters at the output transformer secondary are provided to filter out the harmonics in the inverter output. Tuned LC filters are used - when required - to filter out the 5th and 7th harmonics while a capacitor is adequate for filtering out the higher order harmonics. 38 INVERTERS 39 An inverter converts the DC electricity from sources such as batteries, solar panels, or fuel cells to AC electricity. The electricity can be at any required voltage; in particular it can operate AC equipment designed for mains operation, or rectified to produce DC at any desired voltage. Inverter designed to provide 115 VAC from the 12 VDC source provided in an automobile. The unit shown provides up to 1.2 Amps of alternating current, or just enough to power two sixty watt light bulbs. Grid tie inverters can feed energy back into the distribution network because they produce alternating current with the same wave shape and frequency as supplied by the distribution system. They can also switch off automatically in the event of a blackout. Micro-inverters convert direct current from individual solar panels into alternating current for the electric grid. Early inverters From the late nineteenth century through the middle of the twentieth century, DCto-AC power conversion was accomplished using rotary converters or motorgenerator sets (M-G sets). In the early twentieth century, vacuum tubes and gas filled tubes began to be used as switches in inverter circuits. The most widely used type of tube was the thyratron. Induction heating Inverters convert low frequency main AC power to a higher frequency for use in induction heating. To do this, AC power is first rectified to provide DC power. The inverter then changes the DC power to high frequency AC power. 40 Basic designs In one simple inverter circuit, DC power is connected to a transformer through the centre tap of the primary winding. A switch is rapidly switched back and forth to allow current to flow back to the DC source following two alternate paths through one end of the primary winding and then the other. The alternation of the direction of current in the primary winding of the transformer produces alternating current (AC) in the secondary circuit. The electromechanical version of the switching device includes two stationary contacts and a spring supported moving contact. The spring holds the movable contact against one of the stationary contacts and an electromagnet pulls the movable contact to the opposite stationary contact. The current in the electromagnet is interrupted by the action of the switch so that the switch continually switches rapidly back and forth. This type of electromechanical inverter switch, called a vibrator or buzzer, was once used in vacuum tube automobile radios. A similar mechanism has been used in door bells, buzzers and tattoo guns. Three phase inverters 3-phase inverter with wye connected load Three-phase inverters are used for variable-frequency drive applications and for high power applications such as HVDC power transmission. A basic three-phase inverter consists of three single-phase inverter switches each connected to one of the three load terminals. For the most basic control scheme, the operation of the three switches is coordinated so that one switch operates at each 60 degree point of the fundamental output waveform. This creates a line-to-line output waveform that has six steps. The six-step waveform has a zero-voltage step between the positive and negative sections of the square-wave such that the harmonics that are multiples of three are eliminated as described above. When carrier-based PWM techniques are applied to six-step waveforms, the basic overall shape, or envelope, of the waveform is retained so that the 3rd harmonic and its multiples are cancelled. 41 AC and DC Motors A motor creates a rotational force when a current is circulated through a magnetic field. In a DC motor, the magnetic field, also called the magnetic flux or just flux, is generated by a separate magnetic circuit called the motor field. The magnetic flux is dependent on the core material, the number of windings, and the amps circulated through these windings. An AC induction motor has only one circuit for both flux- and torque-producing current. The vector summation of flux current and torque current represents total current. A DC motor runs when DC voltage is supplied to the armature. As it spins, it also generates voltage inside itself like a generator. This internal voltage is called the counter electromotive force or CEMF. CEMF is dependent on the field current (flux) and the motor speed. The speed of an AC motor depends on its construction. The higher the input frequency, the faster it spins. This is because the input frequency determines the speed of the rotating field inside the motor that is generated by the stator windings. The speed is determined as: When an AC motor has a mechanical load, it is no longer synchronized with the input frequency. The speed difference between no-load speed and full load speed is called slip. It is expressed as a percentage. 42 Cathode-Ray Oscilloscope(CRO):- electronic-display device containing a cathode-ray tube (CRT) that generates an electron beam that is used to produce visible patterns, or graphs, on a phosphorescent screen. The graphs plot the relationships between two or more variables, with the horizontal axis normally being a function of time and the vertical axis usually a function of the voltage generated by the input signal to the oscilloscope. Because almost any physical phenomenon can be converted into a corresponding electric voltage through the use of a transducer, the oscilloscope is a versatile tool in all forms of physical investigation. The German physicist Ferdinand Braun developed the first cathode-ray oscilloscope in 1897. Speed of response is the cathode-ray oscilloscope’s chief advantage over other plotting devices. General-purpose oscilloscopes have plotting frequencies of up to 100 megahertz (MHz), or 100 million cycles per second. Response times as rapid as 2,000 MHz are achievable with special-purpose high-speed oscilloscopes. The central component in this device, the cathode-ray tube, consists of an evacuated glass container with a phosphorescent coating at one end (similar to that of a television screen) and an electron gun and a system for focusing and deflecting the beam of electrons at the other. The electron beam emerging from the electron gun passes between pairs of metal plates mounted in such a way that they deflect the beam horizontally and vertically to control the production of a luminous pattern on the screen. The screen image is a visual representation of the voltages applied to the deflection plates. Alternatively, the beam may be deflected magnetically by varying the currents through externally 43 mounted deflection coils. Thus, almost any graph can be plotted on the screen by generating horizontal and vertical deflection voltages or currents proportional to the lengths, velocities, or other quantities being observed. It is sometimes necessary or desirable to plot more than one waveform at the same time on the screen of an oscilloscope. With the use of a variety of techniques, four or more plots can be simultaneously shown. With a dual-trace amplifier and a single electron gun, two signals may be shown at what appears to be the same time. Actually, the amplifier electronically switches rapidly between the two observed signals. In a split-beam CRT the electron beam from a single gun is split, with the two parts receiving different vertical deflections. A dual-gun CRT uses two separate electron guns, each having its own focus and brightness controls. By combining two dual-trace amplifiers with a dual-gun CRT, four individual plots can be obtained. The cathode-ray oscilloscope is one of the most widely used test instruments; its commercial, engineering, and scientific applications include acoustic research, television-production engineering, and electronics design. 44 An oscilloscope is a test instrument which allows you to look at the 'shape' of electrical signals by displaying a graph of voltage against time on its screen. It is like a voltmeter with the valuable extra function of showing how the voltage varies with time. A graticule with a 1cm grid enables you to take measurements of voltage and time from the screen. The graph, usually called the trace, is drawn by a beam of electrons striking the phosphor coating of the screen making it emit light, usually green or blue. This is similar to the way a television picture is produced. Oscilloscopes contain a vacuum tube with a cathode (negative electrode) at one end to emit electrons and an anode (positive electrode) to accelerate them so they move rapidly down the tube to the screen. This arrangement is called an electron gun. The tube also contains electrodes to deflect the electron beam up/down and left/right. The electrons are called cathode rays because they are emitted by the cathode and this gives the oscilloscope its full name of cathode ray oscilloscope or CRO. A dual trace oscilloscope can display two traces on the screen, allowing you to easily compare the input and output of an amplifier for example. It is well worth paying the modest extra cost to have this facility. Function generator:- A function generator is usually a piece of electronic test equipment or software used to generate different types of electrical waveforms over a wide range of frequencies. Some of the most common waveforms produced by the function generator are the sine, square, triangular and sawtooth shapes. These waveforms can be either repetitive or single-shot (which requires an internal or 45 external trigger source). Integrated circuits used to generate waveforms may also be described as function generator ICs. Specifications:Typical specifications for a general-purpose function generator are: Produces sine, square, triangular, sawtooth (ramp), and pulse output. Arbitrary waveform . generators can produce waves of any shape. It can generate a wide range of frequencies. For example, the Tektronix FG 502 (ca 1974) covers 0.1 Hz to 11 MHz. Frequency stability of 0.1 percent per hour for analog generators or 500ppm for a digital generator. Maximum sine wave distortion of about 1% (accuracy of diode shaping network) for analog generators. Arbitrary waveform generators may have distortion less than -55dB below 50 kHz and less than -40dB above 50 kHz. Some function generators can be phase locked to an external signal source, which may be a frequency reference or another function generator. AM or FM modulation may be supported. Output amplitude up to 10V peak-to-peak. Amplitude can be modified, usually by a calibrated attenuator with decade steps and continuous adjustment within each decade. Some generators provide a DC offset voltage, e.g. adjustable between -5V to +5V. An output impedance of 50 ohms. 46 AUTOMATION WHAT IS AUTOMATION?? Automation refers to a process of optimization of energy consumption (Heat, Light, Fuels, water etc.), and optimization of operation and maintenance cost through a closed loop direct digital and analog control. Supervision and regulation of the various service equipments, using computer network with field interface units (I/O Modules) and signal conditioners (Sensors and signal converters). It facilitates in remote operation of equipments. It replaces hardware wired annunciaters, mimic panels, and local control desks. IMPORTANCE OF AUTOMATION The manufacturing process which considered to be highly dynamic as variances occur at each stage of input. An expert operator is, however, required to run the plant in a stable condition at all times. Moreover, each operator response to given situation may be different. Hence, a software solution consisting of fuzzy logic, regression analysis, neural networks are required to capture the expert knowledge to take action well in advance to achieve optimization on a continuous basis. Components in Automation Components in Automating a System. PLC NETWORK SCADA DCS CONTROLLERS 47 Introduction to PLC A PLC is a device that was invented to replace the necessary sequential relay circuits for machine control. A PLC can be considered as a versatile version of such a controller. It is a device, which can accept multiple inputs, of different kinds, of different voltage levels, from various different devices and different parts of a process or a machine. Based upon the state of these inputs the PLC acts further. It controls various devices by turning on/off the outputs that these devices are connected. The logic on which the inputs are related to the outputs or the Logic by which the devices connected to PLC are controlled can be programmed, thus the name Programmable Logic Controller. The programming of a PLC is generally done through programming software or a dedicated programming terminal. Because of this flexibility of programming that a PLC offers a PLC finds many different, almost endless applications in the industry. A PLC can be programmed and reprogrammed to suit to just about any application that one can think of. PLC's have a wide area of applicability, in Machining, Material Handling, Automation etc. PLC ARCHITECTURE Memory Section Stores user logic, state RAM, system overhead in battery backed CMOS RAM & system’s executive firmware in nonvolatile ROM. CPU Section Solves the user logic program based on the current input values in state RAM, then updates the output values in state RAM. I/O processing Section Directs the flow of signals from input modules to state RAM and provides a path over which output signals from CPU’s logic solve are sent to output module. 48 Communication Section Allows PLC to communicate with programming panels, host computers, hand-held diagnostic tools, and other peripheral (master) devices as well as with other PLCs and nodes on a communication network. Block Diagram of PLC Basic Block Diagram of PLC 49 Basic PLC operation PLCs consist of input modules or points, a Central Processing Unit (CPU), and output modules or points. An input accepts a variety of digital or analog signals from various field devices (sensors) and converts them into a logic signal that can be used by the CPU. The CPU makes decisions and executes control instructions based on program instructions in memory. Output modules convert control instructions from the CPU into a digital or analog signal that can be used to control various field devices (actuators). A programming device is used to input the desired instructions. These instructions determine what the PLC will do for a specific input. An operator interface device allows process information to be displayed and new control parameters to be entered. 50 Introducing the S7-200 Micro PLC The S7-200 series is a line of micro-programmable logic controllers (Micro PLCs) that can control a variety of automation applications. Figure 1-1 shows an S7-200 Micro PLC. The compact design, expandability, low cost, and powerful instruction set of the S7-200 Micro PLC make a perfect solution for controlling small applications. In addition, the wide variety of CPU sizes and voltages provides you with the flexibility you need to solve your automation problems. Figure 1-1 S7200 Micro PLC. 51 ADVANTAGES Smaller physical size than hard-wire solutions. Easier and faster to make changes. PLCs have integrated diagnostics and override functions. Diagnostics are centrally available. Applications can be immediately documented. Applications can be duplicated faster and less expensively. Ladder Logic Elements Symbols Meaning -| |- Normally open contact -| \ |- Normally closed contact -|P|- Positive Transition contact -|N|- Negative Transition contact -( )- Normal Coil -(L)- Latched Coil EXAMPLE OF LADDER LOGIC 52 Circuit Diagram SW1 SW2 COIL BATTERY Coil will activate when both switches are ON Ladder Diagram 53 WHAT IS A NETWORK ? A Network is a working arrangement between independent systems created to share resources themselves so as to generate a overall system which is more powerful than the combined power of all the systems put together. HMI A human–machine interface or HMI is the apparatus or device which presents process data to a human operator, and through this, the human operator monitors and controls the process. Human–machine interface:- 54 SCADA SCADA - Supervisory Control And Data Acquisition System It is a Human Machine Interface which links between Operator and Machine through PLC. It provides the User with mimic resembles real Plan for the easy control of operation. Plant control by driving out values to the control Equipment. Overview of the current values of all real time data. Alarm display and acknowledgement Maintenance logging of plant equipment Historical data analysis for reviewing stored historical Data. Distributed Control System Earlier days PLC were primarily used for control of Discrete signal ( ON/OFF). Analog signals were Processed Separately by individual analog controllers. With the Advancement in the field of PLC’s processing analog signals but do not have an embedded HMI. To Integrate the HMI & I/O systems in one single Package, DCS evolved. 55 Disadvantages of PLC : PLC were Designed for Relay Logic Ladder and have Difficulty with some Smart Devices. To maximize PLC performance and Flexibility, a number of Optional Modules must be added 56 Profibus PROFIBUS, developed by Siemens, is a powerful communications system for lowcost applications. It provides all the known advantages of a bus system and meets all the requirements for flexible, cost-effective networking of programmable logic controllers and computers in an industrial environment. PROFIBUS is based on the ISO/OSI reference model, but does not implement all seven layers. For reasons of performance and to reduce costs, only layers 1 (Physical Layer / RS485) and 2 (Data Link Layer / FDL) for the physical bus characteristics and access techniques and layer 7 (Application Layer) as the user interface are implemented. The attachment of layer 7 to layer 2 is controlled by the lower layer interface (LLI). This provides all the required layer 3 to 6 functions. Profibus interface 57 Solid-state relay:A solid-state relay (SSR) is an electronic switching device in which a small control signal controls a larger load current or voltage. It consists of a sensor which responds to an appropriate input (control signal), a solid-state electronic switching device which switches power to the load circuitry, and some coupling mechanism to enable the control signal to activate this switch without mechanical parts. The relay may be designed to switch either AC or DC to the load. It serves the same function as an electromechanical relay, but has no moving parts. Solid state relays D L 58 ,Advantages over mechanical relays:Most of the relative advantages of solid state and electromechanical relays are common to all solid-state as against electromechanical devices. SSRs are faster than electromechanical relays; their switching time is dependent on the time needed to power the LED on and off, of the order of microseconds to milliseconds. Lower (if any) minimum output current (latching current) required Increased lifetime, particularly if activated many times, as there are no moving parts to wear . Output resistance remains constant regardless of amount of use Clean, bounceless operation Decreased electrical noise when switching No sparking, allowing use in explosive environments where it is critical that no spark is generated during switching Totally silent operation Inherently smaller than a mechanical relay of similar specification (if desired may have the same "casing" form factor for interchangeability). Much less sensitive to storage and operating environment factors such as mechanical shock, vibration, humidity, and external magnetic fields Disadvantages:Voltage/current characteristic of semiconductor rather than mechanical contacts: When closed, higher resistance (generating heat), and increased electrical noise When open, lower resistance, and reverse leakage current (typically µA range) Voltage/current characteristic is not linear (not purely resistive), distorting switched waveforms to some extent. An electromechanical relay has the low ohmic (linear) resistance of the associated mechanical switch when activated, and the exceedingly high resistance of the air gap and insulating materials when open. 59 DC load must observe polarity (− and + not interchangeable) to avoid an undesirable "always conducting" state that does not depend on switching input. Electromechanical relays do not depend on polarity. Possibility of spurious switching due to voltage transients (due to much faster switching than mechanical relay) Isolated bias supply required for gate charge circuit Higher transient reverse recovery time (Trr) due to the presence of Body diode More likely to fail in the "closed" state compared to electromechanical relays which are more likely to fail in the "open" state. 60 TELECOMMUNICATION EPABX 61 Telecommunication is the transmission of information over significant distances to communicate. In earlier times, telecommunications involved the use of visual signals, such as beacons, smoke signals, semaphore telegraphs, signal flags, and optical heliographs, or audio messages such as coded drumbeats, lung-blown horns, and loud whistles. In modern times, telecommunications involves the use of electrical devices such as the telegraph, telephone, and teleprinter, as well as the use of radio and microwave communications, as well as fiber optics and their associated electronics, plus the use of the orbiting satellites and the Internet. The world's effective capacity to exchange information through two-way telecommunication networks grew from 281 petabytes of (optimally compressed) information in 1986, to 471 petabytes in 1993, to 2.2 (optimally compressed) exabytes in 2000, and to 65 (optimally compressed) exabytes in 2007.[1]This is the informational equivalent of 2 newspaper pages per person per day in 1986, and 6 entire newspapers per person per day by 2007.[2] Given this growth, telecommunications play an increasingly important role in the world economy and the worldwide telecommunication industry's revenue was estimated to be $3.85 trillion in 2008.[3] The service revenue of the global telecommunications industry was estimated to be $1.7 trillion in 2008, and is expected to touch $2.7 trillion by 2013.[ EPABX EPABX (electronic private automatic branch exchange): These are solid state digital systems. Our EPABX mainly have the following features: Establishing connections (circuits) between the telephone sets of two users (e.g. mapping a dialed number to a physical phone, ensuring the phone isn't already busy) 62 Maintaining such connections as long as the users require them (i.e. channeling voice signals between the users) Disconnecting those connections as per the user's requirement Providing information for accounting purposes (e.g. metering calls) Time and attendance or Workforce Management clocks: we have many varieties of clocks that suit every customer like electronic tags, barcode badges, magnetic stripe cards, (hand, fingerprint, or facial), and touch screens. We also have electrical time recorders, digital keyboard time recorders and industrial time recorders. Online/Offline UPS: We have different UPS units either to protect a single computer or to large units powering entire data centers, buildings etc. Offline UPS offers surge protection and battery backup. Typical protection time is 20 minutes and the switchover time is just 25 milliseconds. The Online UPS units provide 5–30 minutes of protection time and the capacity expansion is for several hours. We have units ranging from 500 watts or less to 10 kW. Mobiles Air conditioners Computers Laptops Printers CCTVs Telephones, Cordless etc 63 Wireless CCTV The use of CCTV to protect our environment and assets has seen a massive increase in demand. Wireless Networks are at the forefront of delivering high quality communications infrastructure suitable for these bandwidth hungry application. CCTV is undergoing a rebirth from the old analogue and video cassette recorder systems of the past, with many users upgrading or installing digital CCTV systems. The advantages to digital systems are endless, with images being encoded for transportation across IP networks, and storage on modern computer systems. IP networks similar to other digital services such as the Internet and email allow the user to view and retrieve images from any network connected computer. The ability to quickly retrieve archived of these systems. Wireless LAN MAN has a vast experience of installing, managing and maintaining wireless CCTV systems for UK Local Authorities. The systems installed have been proven to be reliable, and far more cost effective that traditional analogue alternatives. Typical installation time for full CCTV network is a matter of weeks as opposed to the months of planning, and heavy civil works required to install cabled systems. Wireless LAN MAN seeks to allay security risks or concerns raised through the use of wireless transportation techniques by only deploying CESG approved radio apparatus for CCTV Networks. Wireless LAN MAN has sought to demonstrate itself as a serious IPCCTV networks installer & consultant, and is now a Platinum Partner for open sourced IPCCTV networks giant Milestone Systems. Freedom and Mobility As everyone knows CCTV cameras tend to act as a deterrent for crime, pushing offenders away from areas where they know CCTV coverage exists. Wireless LAN MAN has designed a range of mobile cameras and supporting radio networks that allow CCTV cameras to be easily moved, relocated and connected within hours. This new mobile policy has allowed Local Authorities to deploy the CCTV deterrent to far wider areas than could normally be considered, and has kept offenders on the move. 64 Insulated gate bipolar transistor(IGBT):- Cross section of a typical IGBT cell. 65 Equivalent circuit for IGBT The insulated gate bipolar transistor or IGBT is a three-terminal power semiconductor device primarily used as an electronic switch and in newer devices is noted for combining high efficiency and fast switching. It switches electric power in many modern appliances: electric cars, trains, variable speed refrigerators, air-conditioners and even stereo systems with switching amplifiers. Since it is designed to turn on and off rapidly, amplifiers that use it often synthesize complex waveforms with pulse width modulation and low-pass filters. In switching applications modern devices boast pulse repetition rates well into the ultrasonic range— frequencies which are at least ten times the highest audio frequency handled by the device when used as an analog audio amplifier. The IGBT combines the simple gate-drive characteristics of the MOSFETs with the high-current and low–saturation-voltage capability of bipolar transistors by combining an isolated gate FET for the control input, and a bipolar power transistor as a switch, in a single device. The IGBT is used in medium- to high-power applications such asswitched-mode power supplies, traction motor control and induction heating. Large IGBT modules typically consist of many devices in parallel and can have very high current handling capabilities in the order of hundreds of amperes with blocking voltages of 6000 V, equating to hundreds of kilowatts. 66