* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

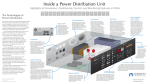

Download PowerHub 2 Power Distribution Unit

Phone connector (audio) wikipedia , lookup

Electrification wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Solar micro-inverter wikipedia , lookup

Stage monitor system wikipedia , lookup

Ground loop (electricity) wikipedia , lookup

Three-phase electric power wikipedia , lookup

Audio power wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Stray voltage wikipedia , lookup

Electric power system wikipedia , lookup

Transformer wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Power inverter wikipedia , lookup

Power over Ethernet wikipedia , lookup

Voltage optimisation wikipedia , lookup

Power MOSFET wikipedia , lookup

History of electric power transmission wikipedia , lookup

Two-port network wikipedia , lookup

Schmitt trigger wikipedia , lookup

Distribution management system wikipedia , lookup

Single-wire earth return wikipedia , lookup

Buck converter wikipedia , lookup

Surge protector wikipedia , lookup

Amtrak's 25 Hz traction power system wikipedia , lookup

Alternating current wikipedia , lookup

Transformer types wikipedia , lookup

Power engineering wikipedia , lookup

Power electronics wikipedia , lookup

Ground (electricity) wikipedia , lookup

Mains electricity wikipedia , lookup

Electrical substation wikipedia , lookup

Earthing system wikipedia , lookup

Circuit breaker wikipedia , lookup

Electrical wiring in the United Kingdom wikipedia , lookup