* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

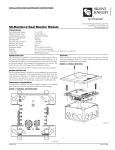

Download GV3000/SE AC Bookshelf Drive

Alternating current wikipedia , lookup

Buck converter wikipedia , lookup

Control system wikipedia , lookup

Voltage optimisation wikipedia , lookup

Mains electricity wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Two-port network wikipedia , lookup

Power electronics wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Opto-isolator wikipedia , lookup

Electrical wiring in the United Kingdom wikipedia , lookup