* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Chapter 3 Fe2O3- the material for gas sensors

Survey

Document related concepts

Transcript

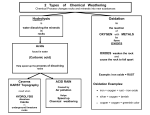

Chapter 3 Fe2O3- the material for gas sensors 3.0 Introduction ……………………………………………………………………….. 97 3.1 Iron [Fe] …………………………………………………………………………… 97 3.1.1 Thermal properties …………………………………………………………. 98 3.1.2 Electrical properties ………………………………………………………... 98 3.1.3 Chemical properties …………………………………………………………98 3.1.4 Ionization potential ………………………………………………………… 99 3.1.5 Oxidation states ……………………………………………………………. 99 3.1.6 Crystal structure ……………………………………………………………. 99 3.2 Iron Compounds ………………………………………………………………….. 99 3.2.1 Haemoglobin ………………………………………………………………..99 3.2.2 Iron (II) sulfate ……………………………………………………………...99 3.2.3 Iron (III) chloride …………………………………………………………. 100 3.2.4 Iron (III) oxide ……………………………………………………………. 100 3.3 Reactions …………………………………………………………………………. 100 3.3.1 Reaction with air ………………………………………………………….. 100 3.3.2 Reactions with acids………………………………………………………. 101 3.4 Chemiresistive sensor material- Iron Oxide …………………………………… 101 3.5 Gas-sensing metal oxides ………………………………………………………... 102 References ……………………………………………………………………………. 106 95 Figure captions Sr. No. Descriptions Page No. Fig. 3.1 Unit cell of α-Fe2O3 rhombohedral crystal structure. 101 Fig. 3.2 Corundum crystal structure. 101 96 Chapter 3 Fe2O3- the material for gas sensors 3.0 Introduction From the viewpoint of the basic research in the field of gas sensor, being a transition metal, iron (III) oxide is one of the important compound for the study. The existence of amorphous Fe2O3 and four polymorphs (alpha, beta, gamma, epsilon) is well established [1]. The most frequent polymorphs, the hexagonal corundum structure “alpha” and cubic spinel structure “gamma”, have been found in nature as hematite and maghemite minerals. The other polymorphs, the cubic bixbyite structure “beta” and orthorhombic structure “epsilon”, as well as nanoparticles of all forms, have been synthesized and extensively investigated in recent years [1,2]. Gamma and epsilon type Fe2O3 are ferromagnetic; α-Fe2O3 is an antiferromagnetic while beta type Fe2O3 is a paramagnetic material. On account of the attractive scientific and industrial applications of α-Fe2O3 nanoparticles, novel methods for their synthesis and new approaches in their characterization have been reported in recent years. It has been reported [3, 4] that different techniques of preparation lead to different phases or mixtures of phases and different degrees of size control. Furthermore the correlation of the preparation route with size and magnetic properties, such as the moment and coercivity, is still a subject of debate. This chapter briefly introduces the origin of iorn oxide and their concerning parameters necessary for understanding in the field of research. 3.1 Iron [Fe] At. no. : 26 (Neutron 30) At. wt. : 55.845 (2) g/mol Group No : 8 Group Name : Transition metals Block : d-block Period : 4 State : solid at 298 K 97 Colour : lustrous, metallic, greyish tinge Classification : Metallic Boiling Point : 3134K (2861°C) Melting Point : 1811K (1538 °C) Density 7.86g/cm3 : Source: Ninety percent of all mining of metallic ores is for the extraction of iron! Industrially, iron is produced starting from iron ores, principally haematite (nominally Fe2O3) and magnetite (Fe3O4). Electrons per shell 3.1.1 3.1.2 3.1.3 : 2,8,14,2 Electron Configuration: [Ar] 3d6 4s2 Ground state : 5 Atomic Volume : 7.1 cm3 mol-1 Electronegativity : 1.83 Magnetic ordering : Ferromagnetic D4 Thermal properties Enthalpy of Atomization : 414.2 kJ mol-1 @ 25°C Enthalpy of Fusion 14.9 kJ mol-1 : Enthalpy of Vaporisation : 340.2 kJ mol-1 Heat Capacity : 25.10 J mol-1 K-1 Thermal Conductivity : 80.4 W m-1 K-1 Thermal Expansion : 11.8 µm m-1 K-1 Electrical properties Electrical resistivity : 9.7 x 10-8 Ω m Electrical conductivity : 0.0993 106/cm Ω Chemical properties Electrochemical Equivalent : 0.69455 g Ah-1 Electron Work Function : 4.7 eV Valence Electron Potential : 67 (-eV) 98 3.1.4 3.1.5 3.1.6 Ionization potential First : 7.87 Second : 16.18 Third : 30.651 Main : Fe+2, Fe+3 Other : Fe-2, Fe-1, Fe0, Fe+1, Fe+4, Fe+5, Fe+6 : Body centered cubic Oxidation States Crystal Structure Structure a = 286.65 pm b = 286.65 pm c = 286.65 pm α = 90° β = 90° γ = 90° 3.2 Iron Compounds 3.2.1 Haemoglobin C2952H4664N812O832S8Fe4 The iron-containing oxygen-transport metalloprotein in the red cells of the blood in mammals and other animals, Hemoglobin in vertebrates transports oxygen from the lungs to the rest of the body, such as to the muscles, where it releases the oxygen load. Hemoglobin also has a variety of other gas-transport and effect-modulation duties, which vary from species to species, and which in invertebrates may be quite diverse. 3.2.2 Iron(II) sulfate FeSO4.H2O In horticulture it is used as a lawn conditioner and moss killer, traditionally referred to as sulphate of iron. Ferrous sulfate is also used to treat iron-deficiency anemia. Side effects of therapy may include nausea and epigastric abdominal discomfort after taking iron. These side effects can be minimized by taking ferrous sulfate at bedtime. 99 Ferrous sulfate can also be used to color concrete. It is best used for newly cured concrete. Mix with water until saturated and spray onto concrete. The color will range from yellow to rust. 3.2.3 Iron(III) chloride - FeCl3 Highly Corrosive : Toxic Most widely used for etching copper in the production of printed circuit boards. Iron(III) chloride is also used as a catalyst for the reaction of ethylene with chlorine, forming ethylene dichloride (1,2 (1,2-Dichloroethane), an important ant commodity chemical, which is mainly used for the industrial production of vinyl chloride,, the monomer for making PVC. It is also commonly used by knife craftsmen and swordsmiths to stain blades, as to give a contrasting effect to the metal, and also tto o view metal layering or imperfections. Iron(III) oxide 3.2.4 Iron(III) oxide - Fe2O3 Used: in magnetic storage, for example in the magnetic layer of floppy disks. A very fine powder of ferric oxide is known as jeweller's rouge, red rouge, or simply rouge. It is used to put the final polish on metallic jewellery and lenses, and historically as a cosmetic. 3.3 Reactions 3.3.1 Reaction with air On heating with oxygen th the result is formation of the iron oxides Fe2O3 and Fe3O4. 4Fe(s) + 3O2(g) 2Fe2O3(s) ……………(1) 3Fe(s) + 2O2(g) 2Fe3O4(s) …………....(2) Iron reacts with excess of fluorine, chlorine and bromine to form Fe (III) halides. 2Fe(s) + 3F2(g) 2FeF3(s) …………….(3) 2Fe(s) + 3Cl2(g) 2FeCl3(s) …………..(4) 2Fe(s) + 3Br2(g) 2FeBr3(s) ………….(5) Fe(s) + I2(s) FeI2(s) …………………(6) 100 3.3.2 Reactions with acids Iron metal dissolves readily in dilute sulphuric acid in the absence of oxygen to form solutions containing the aquated Fe(II) ion together with hydrogen gas. Fe(s) + H2SO4(aq) Fe2+(aq) + SO42-(aq) + H2(g) …………….(7) If oxygen is present, some of the Fe(II) oxidizes to Fe(III). The strongly oxidizing concentrated nitric acid, HNO3, reacts on the surface of iron and passivates the surface. 3.4 Chemiresistive sensor material material- Iron Oxide In Fe-O O system, three different polymorphic forms , FeO, Fe3O4 and Fe2O3 exist. Also Fe2O3 has typical two modifications: α Fe2O3 (hematite, corundum-type corundum hexagonal lattice, a=5.035Ǻ and c=13.750 c=13.750Ǻ) and γFe2O3 (meghaemite). Fig. 3.1: Unit cell of α-Fe2O3 rhombohedral hedral crystal structure. structure Fig. 3.2: Corundum crystal structure. 101 α- Fe2O3 has a complex defect structure in which three types of defect species, namely, oxygen vacancies, fe3+ interstitials and Fe2+ interstitials are present. The presence of these defects gives rise to semiconducting properties. Loss of oxygen leaves behind extra electrons and produce an n-type semiconductor, while extra oxygen (entering the lattice as O2) creates a deficit of electron (i.e. introduces electronic holes) which produces p-type behavior. Thus in α- Fe2O3 a transition from n- to p- type response or vice versa can be introduce by the change in the gas concentration, by appropriate dopant and/ or by the operating temperature. Fe2O3 is known to show high sensitivity towards organic gases. [5,6.]. Various metal oxides have been doped into Fe2O3 to make it selective for particular gas. It has been demonstrated that ZnO doped Fe2O3 works as a selective NH3 sensor working at room temperature. When doped with Pt, Pd or RuO2, Fe2O3 sensor detects acetone, which finds utility in medical diagnostics [6]. Au or Zn doped Fe2O3 is reported to sense CO and NO2[7]. γ-Fe2O3 is known to be a good sensing element for H. 3.5 Gas-sensing metal oxides It is observed that almost any metal oxide could be a basis for solid-state gas sensor. For this purpose we need only to prepare this metal oxide as a sufficiently fine dispersed porous substance with properties controlled by surface states. While selecting the metal oxide we must understand their electronic structure [8]. In ref [8] the following information along with the issue of choice of the material for gas sensing application is thoroughly explained. Metal oxides exhibit a very wide range of electro-physical properties [9-13]. Their electrical behavior ranges from the best insulators (e.g., Al2O3 and MgO) through wideband gap and narrow-band gap semiconductors (TiO2, SnO2 and Ti2O3, respectively) to metals (V2O3, Nax WO3, and ReO3), and superconductors (including reduced SrTiO3). The range of electronic structures of oxides is so wide that metal oxides were divided into two following categories: • Transition-metal oxides (Fe2O3, NiO, Cr2O3, etc.) and • Non-transition-metal oxides, which include i) pre-transition-metal oxides (Al2O3, etc.) and ii) post-transition- metal oxides (ZnO, SnO2, etc.) 102 The fact that valence orbitals of the metal atoms are of s- and p-symmetry is the common feature of the non-transition-metal oxides. With transitional metal oxides, however, the d atomic orbitals assume crucial importance. Many of the complications with transition-metal oxides stem from this difference, because of the different bonding properties, associated with d orbitals. These complexities include the existence of variable oxidation states, the frequent failure of the band model, and the crystal field splitting of the d orbitals [9]. In Ref. [9] the following explanation of the difference in behavior of nontransition and transition-metal oxides was given. The non-transition-metal oxides contain elements that with some exceptions have only one preferred oxidation state. Other states are inaccessible, because too much energy is needed to add or remove an electron from the cations when they are coordinated with O2− ligands. Transition-metal oxides behave differently because the energy difference between a cation dn configuration and either a dn+1 or dn−1 configurations is often rather small. The most obvious consequence is that many transition elements have several stable oxides with different compositions. It is also much easier than with nontransient-metal oxides to make defects, having different electron configurations. A as result of high defect concentration the bulk and surface chemistry of transition-metal oxides is very complicated. Trends in the stability of different oxidation states are very important in surface chemistry, as they control both the types of defect that may be formed easily, and the type of chemisorptions that may take place [9, 10, 12]. The d0 configuration represents the highest oxidation state that can ever be attained: thus pure TiO2, V2O5, etc., cannot gain any more oxygen, although they can lose oxygen to form defects or other bulk phases. On the other hand, dn oxides with n≥1 are potentially susceptible to oxidation, as well as reduction. The stability of high oxidation states declines with atomic number increase across a given series. In contrast to transition-metal oxides, pre-transition-metal oxides (MgO, etc.) are expected to be quite inert, since they can neither be reduced nor oxidized easily. In terms of electronic structure, this is related to the large band gap, which means that neither electrons nor holes can easily be formed. It means that these oxides are good isolators. However oxides, characterized by exceedingly high resistance, are not promising material 103 for resistive gas sensors, because of the difficulties, encountered in electrical conductivity measurements. Such big difference in pre-transition, and transition-metal oxides’ behavior means that transition-metal oxides are more sensitive to the change of outside ambient. Therefore it seems that this type of oxides could be more preferable for the use in gas sensors. However, in practice the transition-metal oxides are not being used for conductometric gas sensor design. As it will be shown in the next sections, structure instability and nonoptimality of other parameters important for conductometric gas sensors, such as Eg and electroconductivity, considerably limit their field of use. As it is known many transition-metal oxides have small band gap. Moreover, the band model predicts that majority of oxides, having a partially filled d band – that is for dn with 0 < n < 10 – should be metallic. These expectations are frequently not fulfilled because of intervention of various types of electron–electron and electron–lattice interactions. Nevertheless, “simple” metallic behavior is found with a number of oxides of elements in the 4d and 5d series (ReO3, RuO2). Some oxides of the 3d series (Ti2O3, VO2, Fe2O3) also have high conductivity in the metallic range. Only transition-metal oxides with d0 and d10 electronic configurations find their real gas sensor application. As we know, the post-transition-metal oxides, such as ZnO and SnO2 have cations with the filled d10 configuration. The d0 configuration is found in binary transition-metal oxides such as TiO2, V2O5, WO3, and also in perovoskites such as ScTiO3, LiNbO3, etc. These compounds share many features with the non-transition metal oxides. They have a filled valence band of predominantly O 2p character, and gap between valence band and an empty conduction band. Typical band gaps are 3–4 eV. Unlike transition-metal oxides with 0 < n < 10, stoichiometric, post-transition-metal oxides ZnO, SnO2, and d0 transition-metal oxides may be reduced, but not oxidized. The post-transition oxides ZnO, In2O3, SnO2, as well as majority of transition-metal oxides are active in “redox” reactions since the electron configuration of the solid may be altered. However, the reaction with oxidizing species such as O2 is expected only with samples that have been bulk reduced or where the surfaces have been made oxygen deficient [14] At that the reduction of post-transition oxides as a rule leads to the formation of free carriers, which greatly increase the metal oxide conductivity, a fact that is crucial for 104 sensor applications. However, limited use of pure transition-metal oxides (1 < n < 10) for conductometric gas sensor fabrication does not mean that transition-metal oxides are not of interest of gas sensor designers. On the contrary, unique surface properties, plus high catalytic activity make them very attractive for various sensor applications, such as properties’ modification of more stable and wide band gap oxides, and forming of more complicated nanocomposite materials [15]. For example, for optical waveguide gas sensors, where the change of optical refraction index is more important than the change of electroconductivity, transition-metals oxides such as WO3 (H2 and alcohol detection), Mn2O3, Co3O4, and NiO (CO detection) [16] are the most attractive. *** 105 References 1] R. Zboril, M. Mashlan, D. Petridis, Chemistry of Materials 14 (2002) 969. 2] R. Zboril, M. Mashlan, D. Krausova, P. Pikal, Hyperfine Interact. 120/121 (1999) 497. 3] J. L. Dormann, N. Viart., J. L. Rehspringer, A. Ezzir, D. Niznansky, Hyperfine Interact. 112 (1998) 89. 4] G. Annas, A. Musinu, G. Piccaluga, D. Zedda, D. Gatteschi, C. Sangreorio, J. L.Stanger, G. Concas, G. Spano, Chem. Mater. 10 (1998) 495. 5] P. Althanzi, L. Schuy, J. Goschnic, H. J. Ache, Sens. Actuators B 24 (1995) 448. 6] S. V. Ryabtsev, A. V. Shaposhnick, A. N. Lukin, E. P. Domashevskaya, Sens. Actuators B 59 (1999) 26. 7] G. Neri, A. Bonavita, S. Galvano, P. Siciliano, S. Capone, Sens. Actuators B 82 (2002) 40. 8] G. Korotcenkov, Materials Science and Engineering B 139 (2007) 1. 9] V. E. Henrich, P. A. Cox, The Surface Science of Metal Oxides, Cambridge University Press, Cambridge, 1994. 10] P. A. Cox, Transition Metal Oxides: An Introduction to their Electronic Structure and Properties, Clarendon Press, Oxford, 1992, pp. 66–68. 11] A. Hamnett, J. B. Goodenough, in: O. Madelung, Landolt-Bornstein (Eds.), New Series III, vol. 17, Springer, Berlin, 1984. 12] O. V. Krilov, V. F. Kisilev, Adsorption and Catalysis on the Transition Metals and their Oxides. Chemistry, Moscow, 1981. 13] G. V. Samsonov, The Oxide Handbook, IFI/Plenum, New York, 1973. 14] M. Calatayud, A. Markovits, M. Menetrey, B. Mguig, C. Minot, Catal. Today 85 (2003) 125. 15] E. Kanazawa, G. Sakai, K. Shimanoe, Y. Kanmura, Y. Teraoka, N. Miura, N. Yamazoe, Sens. Actuators B 77 (2001) 72. 16] J. Dakin, B. Culshaw (Eds.), Optical Fiber Sensors: Principles and Components, vol. 1, Artech House, Boston, 1988. *** 106