* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download INTELLIGENT BLINKER

Audio power wikipedia , lookup

Grid energy storage wikipedia , lookup

Wireless power transfer wikipedia , lookup

History of electric power transmission wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Spectral density wikipedia , lookup

Power over Ethernet wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Rechargeable battery wikipedia , lookup

Buck converter wikipedia , lookup

Voltage optimisation wikipedia , lookup

Power engineering wikipedia , lookup

Alternating current wikipedia , lookup

Mains electricity wikipedia , lookup

Distribution management system wikipedia , lookup

Distributed generation wikipedia , lookup

Life-cycle greenhouse-gas emissions of energy sources wikipedia , lookup

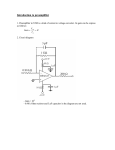

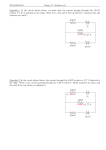

Analog Design Contest 2013 Project Report INTELLIGENT BLINKER Team Leader: Team Members: Advising Professor: University: Date: Pietro Buccella ([email protected]) Camillo Stefanucci ([email protected]) Denis Sallin ( [email protected]) Naser Khosro Pour ([email protected]) Theodoros Kyriakidis ([email protected]) Maher Kayal ([email protected]) École Polytechnique Fédérale de Lausanne (Switzerland) 25.07.2013 Qty. TI Part Number Qty. TI Part Number 1 1 2 BQ25504 TPS73001 TPD4E004 1 1 1 BQ24090 TCA6507 MSP430F5510 Project abstract: The rapid evolution of integrated technologies through last decade has enabled the realization of many portable devices. They are characterized by long lifetime operation, very low power consumption and light weight. The world of bike is lately moving toward electronic world. Bike shops have entire sections full of electronics accessories for bike, from cyclocomputers to LED lights. With the exception of bicycle lights, intended to illuminate the rider path and especially to improve his visibility at night, a small number of electronic gadgets are made for improving cyclists safety. For this reason we developed a bracelet-shaped wearable intelligent blinker. The cyclist, with a simple arm gesture can give warning to the other vehicles about his intentions to turn. An accelerometer and a magnetometer are used to detect the cyclist motion. Sensors data are processed by a microcontroller to switch on LEDs turn signal at the right time. The bracelet is powered by a button Li-ion battery that is charged by a solar panel. Furthermore, a USB charger is added to extend battery life in the most effective way. TI’s ultra-low power microcontroller in combination with TI’s nano-power energy harvester used in this work show an efficient design of portable circuits powered by a small capacity battery. TI Analog Design Contest 2013 Project Report 1 Introduction and Motivation In many countries, the basic bike traffic code rules are already taught in primary school. Such rules consist of simple arm gestures to indicate a left or right turn and even a stop. Are they sufficient to indicate intentions to car drivers? Are such gestures still visible when driving at night? The answers of these questions is the motivation of our project. Actually, these hand signals remain often unnoticed by car drivers which are used to the classical car turn signals and brake lights. To face this problem, car manufactures are adding more and more electronics to cars for safety purpose. Volvo Car Group announced the first cyclist detection system that stops the car when a forthcoming collision is predicted 1 . As for cars, electronics can be used to improve safety on bike. To increase the effectiveness of arm gestures traffic code for bikes we propose a wearable intelligent blinker (Fig. 1)2 . Right Turn Left Turn The blinker will act as a directional indicator that blinks according to the cyclist arm-motion. It will Figure 1: Intelligent blinker concept be easier for the cyclist to inform the intent to turn! This report is organized in 7 parts. The first part gives an overview of the proposed architecture for the realization of the intelligent blinker. The resulting two main challenges consist of the motion detection of the arm gestures and the power management of the LEDs blinking for a portable device. The proposed solutions are detailed respectively in the second and third part. As a proof of the concept, the realized prototype is described in the fifth part followed by experimental results. Finally, conclusion and outlook are drawn in the last sections. 2 System Architecture Overview There is an increasing demand for battery-powered portable devices, especially for sensing and monitoring applications. These devices face the increasingly difficult challenge of realizing multifunctional systems that offer at the same time extremely long lifetime and energy autonomy. These are the main aspects that were taken into account during the development of our project. The system architecture of our project is presented in Fig. 2. The system has been divided into three main blocks: power management, motion detection and debug interface. Power management incorporates energy harvesting source, energy storage device and electronic circuits for power management. A rechargeable battery has been selected 1 2 www.media.volvocars.com Original background image from: http://www.nhtsa.gov/Bicycles 1 TI Analog Design Contest 2013 Project Report as the main power source. The bracelet-shaped blinker is for outdoor usage and here’s why a solar panel has been added as the main energy source to recharge the battery. In addition, the battery can be easily charged using a USB charger. For prototype version, a low dropout regulator (LDO) has been used to power the circuit with a constant and accurate voltage. In future prototypes, such LDO will be replaced by a step-down DC-DC converter to improve energy efficiency. The microcontroller (MCU) is the core component for signal processing part. It collects and processes sensors data via I2 C interface to turn-on the LEDs by means of a LED driver. A motion detection algorithm is implemented to detect the cyclist arm gestures that is converted into a flashing light turn signal. An external data memory has been used for the debug purpose in the initial prototype. During the initial design phase, sensor data were stored in the external memory during a bike tour to record arm gestures. Afterwards, memory data were downloaded to a PC via the USB interface and processed with MatlabTM to test the motion detection algorithm. POWER MANAGEMENT MOTION DETECTION Sensors USB Battery Charger OR VCC I2C Energy VBAT Storage LDO VCC Microcontroller Energy Harvesting I2C Data Memory Solar Energy Source I2C LED Driver LED USB DEBUG INTERFACE USB PC - Matlab TM Figure 2: System level block diagram 3 Motion Detection For motion detection an inertial measurement unit (IMU) is usually required. This electronic module contains several sensors used to measure the position and the velocity of an object in the space. Different analog signals are generated from the sensors depending on the number of degrees-of-freedom (DoF). These signals are amplified, converted in digital form with an ADC and outputted to the microcontroller for further signal processing. In this work we are interested in the determination of the three attitude angles with respect to the coordinates system axes: the pitch, the roll and the yaw. In the following we describe the choice of sensors, the proposed algorithm for arm-motion detection and the MCU specifications. 2 TI Analog Design Contest 2013 Project Report 3.1 Proposed Algorithm For the targeted application we have to detect the arm movement when the cyclist get acc and mag interrupt measurements wants to turn. This threshold detection strongly relaxes the requirement for sensors since the exact dynamical characterization of Low-Pass filter the wrist (for a bracelet implementation) is not required. The turn gesture forces the wrist to move from a position parallel to the bike course, to Use acc to retrieve Use acc to retrieve a position almost perpendicular to that. The Pitch angle Roll angle basic sensor needed to measure an angular position with respect to an absolute refstore erence is the magnetometer. However, this store Yaw angle Use mag to retrieve is not sufficient since the wrist can be tilted values Yaw angle with respect to the sensor reference. This implies also the knowledge of the relative angular attitude of the wrist that can be easily measured by means of an accelerometer. As π/2 diff in Yaw angle a result we have chosen for our application a 6-DoF IMU with a 3-axes magnetometer and detected a 3-axes accelerometer. To implement the tilt compensation a single frame attitude estitrigger LED blink interrupt mation is proposed based on the Factored Quaternion Algorithm (FQA3 ). An overview Figure 3: Algorithm overview of the algorithm is shown in Fig. 3. First we estimate from the accelerometer the pitch and roll angles and the corresponding vector rotation quaternions are computed. Then, these two angles are used to tilt-compensate the yaw angle measured by the magnetometer. This is done interpreting the quaternion as a rotation matrix. Notice that the main advantage of FQA is that it always tries to avoid trigonometric functions. All inter√ mediate results are obtained using only +, −, ·, / and operations saving computational power and time. About signal processing, new measurements are taken by the sensors using a timed interrupt triggered every ts = 0.01s. Before feeding the raw measurements into the algorithm, a preprocessing step is done. The sensors raw data can be written as: a = atr − g + ab + av + an m = mearth + mb + mv + mn (1) where a is the accelerometer reading, m the magnetometer reading, atr the translational acceleration, g the gravitational acceleration, mearth the geomagnetic field, ab , mb the measurement drift and an , mn the measurement noise. For the algorithm it should ideally hold a = −g and m = mearth , thus a preprocessing 3 X. Yun, E. R. Bachmann, and R. B. McGhee, IEEE Trans. Instr. Meas., 57, 3, 638-650, (2008) 3 TI Analog Design Contest 2013 Project Report step aims to reduce the influence of the other components. For this, the signal is low-pass (LP) filtered, using a Butteworth IIR filter with a normalized cutoff frequency of ωc = 0.2. Empirical studies showed that this LP-filtering greatly improves the quality of the signals to be fed into the algorithm. In the above ab and av are considered to be negligible after the LP filtering. However, the translational acceleration is still present in the final signal. This reduces the effectiveness of the algorithm when the target experiences heavy motion. For this study, it is considered atr = 0, for simplicity purposes. A possible solution to this could be the spectral characterization of atr , and the design of a bandpass (BP) filter, for high-frequency noise components an , and low-frequency atr components. Finally, calibration is always required to adjust offsets and conversion-gain differences on the three axes. Partial self-calibration is already available in commercial sensors. Additional compensation (e.g. hard-iron) procedures are available, and have been easily implemented 4 . 3.2 Signal Processing Hardware Since the sensors are always on, the ultra-low power compact solution LSM303DLHC from STMicroelectronics has been selected that allows power consumptions as low as 110µA and integrates both accelerometer and magnetometer. An important parameter for the power optimization is the sampling frequency. Since the movement to be detected is in the order of hundreds of milliseconds, 30 Hz data rate for sensors operation has been selected. The chosen data rate allows to reduce measurements errors with average values and to decrease noise. After preliminary estimation, 12 bits resolution with typical ranges of ±2g for acceleration and ±1.3G for magnetic field are sufficient to accurately detect the arm movement. Regarding the MCU for the implementation of the algorithm of section 3.1, this work uses the MSP430F5510. Also for the choice of the MCU, the most important requirement is the low power consumption. This is a big advantage for the MSP430, since it is a very low-power MCU with lots of different configurable low-power modes. Moreover, the MCU must be able to perform effectively the calculations that are needed in the signal processing algorithm. The fact that a hardware multiplier is present in MSP430F5510 is an advantage. Finally, the availability of the MCU in relatively small packages is useful since the final design should be compact in order to be wearable. 4 Power Management Our bracelet-shaped intelligent blinker has been designed to be an autonomous portable device; therefore a rechargeable battery has been used as the main power source that is charged by solar energy harvesting. In this chapter the power management has been analyzed at system level to select an appropriate rechargeable battery together with an energy harvesting solution to guarantee autonomous operation of the intelligent blinker. A detailed analysis of the power consumption of each part is presented. 4 T. Ozyagcilar, Freescale Application Note 4246, (2013) 4 TI Analog Design Contest 2013 Project Report 4.1 System Level Power Management Many energy harvesting methods exist to convert the collected energy into electrical energy from different sources, including piezoelectric, electrostatic, thermoelectric, photovoltaic and electromagnetic sources. Among the different solution we examined piezoelectric and photovoltaic to be the most appropriate energy harvesting solutions for our project. The piezoelectric energy source was finally discarded, because it was difficult to find a trade-off between piezoelectric sensor size and resonance bandwidth along with bike vibration spectrum 5 . The photovoltaic energy solution instead has been retained. However, as energy harvested from solar cells is intermittent and the maximum power that it can provide may be much less than the required peak power during circuit operation, a rechargeable battery is used to store the harvested energy. In this project yellow power LEDs are used as turn signal with a on/off blinking rate of ∼1 Hz. As for cars, such LEDs should not dazzle other people and should have high visibility even in direct sunlight. VCC The LEDs parameters taken into consideration include light intensity versus the viewing angle and current/voltage specifications. To increase visibilRP ity and reduce the number of LEDs (max 6) on the bracelet, we selected a SMD power LED with a viewing angle of 120 ◦ and a luminous intensity VF varying from 360 to 720 mcd at IF = 20mA. TI’s TCA6507 TCA6507 LED driver has been used to turn on and off the LEDs, controlling at the same time their intenVOL sity. The low voltage operating condition along with the pulse-width modulation (PWM) driving feature makes TCA6507 device ideal for our project to further reduce the overall power consumption. A 25Ω Figure 4: TCA6507 output driver resistor RP (Fig. 4) has been used to limit the LED maximum intensity current to 20mA (VCC=2.5V). Regarding the supply voltage, all circuits can operate at 2.5V. Energy storage device should be selected according to the required voltage level and power throughput. The battery should provide enough voltage and peak discharge current even when it is close to fully discharged state. Meanwhile it should have enough capacity to guarantee continuous operation of the device, even when it is not charged for a long time. LIR2450 of Multicomp has been used as the target battery. This battery has a nominal voltage of 3.6V, a typical capacity of 120mAh and a peak discharge current of 240mA that is more than the peak current consumption of the system. The battery voltage reaches an end-of-charge voltage (VEOC) of 4.2V when it is fully charged and drops to 2.75V when it is fully discharged. Finally, TPS73001 LDO with adjustable output voltage has been used to provide the 2.5V supply voltage. 5 E. Minazara, D. Vasic, F. Costa, Proceedings of ICREPQ, (2008) 5 TI Analog Design Contest 2013 Project Report 4.2 Energy Harvester Circuit After selecting the right battery, the next step is finding an appropriate energy harvesting solution (Fig. 5). The BQ25504 has been used for harvesting solar energy. This integrated circuit is a state-of-the-art intelligent nano-power management solution from TI that is well suited for our project. Solar Panel BAT +5V Solar Battery 2 1 Vbat Header 2 VSS D12 pwr 2 1 +5V 2 1 Header 2 VSS LDO VBUS D Schottky Header 2 VSS U5 Vbat_LDO VCC 1 BOOST charger 2 VSS L1 Solar_cell 3 Inductor 22uH Chvr Cap Semi 4.7uF VRDIV VRDIV Rov2 Res3 6.8M D15 D Schottky VRDIV Rov3 Res3 DNP Ruv2 Res3 6.8M 7 8 LBST VIN_DC VSTOR VOC_SAMP VBAT VREF_SAMP VSS OT_PROG AVSS VBAT_OV VBAT_OK VRDIV OK_PROG VBAT_UV OK_HYST BQ25504 VSS Rov1 Res3 4.7M VSS Ruv1 Res3 5.6M 4 C4 Cap Semi 10nF ON/OFF SWITCH C5 Cap Semi 15pF switch 3 R14 Res3 30.1k Vbat_LDO 2 Vbat 1 SW-SPDT VSS 16 15 14 VSS Vbat_boost 13 12 Cfltr Cap Semi 100nF USB Charger Cstor Cap Semi 4.7uF VSS VSS 11 R30 Vbat_OK_boost 10 Res3 0 VSS 9 VBUS U3 D16 1 C3 Cap Semi 1uF D Schottky D17 VBUS_boost Rok1 Res3 3.3M D Schottky VSS /PG R3 Res3 1K R4 Res3 2k Rok2 Res3 5.6M 2 3 4 5 IN OUT ISET TS VSS /CHG PRETERM ISET2 /PG BQ24090 EP 6 VBUS VSS NR R13 Res3 51k NC 10 Vbat_usb 9 TS 8 /CHG 7 ISET2 6 R9 Res3 1K TS R7 Res3 1K ISET2 R10 Res3 1K R8 Res3 1K R6 Res3 1.5k R5 Res3 1.5k D1 LED2 /PG D2 LED2 /CHG 11 5 VSS EP 4 Cref Cap Semi 10nF EN 6 5 TPS73001 17 3 VSS FB VSS 2 Roc1 Res3 10M OUT GND U1 1 VSS Roc2 Res3 2.2M IN VSS Rok3 Res3 560K VRDIV VSS VSS Figure 5: Power management circuit The BQ25504 has an ultra-low quiescent current and nominally transfers up to an average of 100 mA of input current. According to the datasheet, this circuit has the highest efficiency, when the input voltage is not less than 1V. By applying 1V-2V as Vin, more than 80% efficiency is achievable for 10mA-100mA input current. The BQ25504 implements a programmable maximum power point tracking (MPPT) sampling network. Since the ratio between the open-circuit voltage (Voc) and the maximum power point voltage (Vmpp) of the solar cell is almost fixed for different illumination conditions (see next section), the MPPT sampling ratio was set between 0.7-0.8 by programming the external resistive divider. For successfully extracting energy from the source, three different threshold voltages were programmed using external resistors, namely the under voltage (UV) threshold, battery good threshold (VBAT OK) and over voltage (OV) threshold. As the solar energy harvesting source is intermittent, USB Li-ion charger BQ24090 from TI has been used as a backup solution to charge the battery through a USB port. 4.3 Solar Energy Harvesting SMLD121H04L from IXOLAR has been used as the photovoltaic (PV) module in our project. This monocrystalline cell has 22% efficiency and can be used in both indoor and outdoor applications. The main electrical specifications can be seen in Fig. 6. 6 TI Analog Design Contest 2013 Project Report In order to evaluate the deliverable power, the PV module has been modeled using the well-known PV cell equivalent circuit and it was finally simulated with TINA tool in combination with BQ25504 battery charger to check the overall system functionality. 90 80 PV Module Power [mW] 70 89.2 mW Direct sun (100klx−120klx) Bright (50klx−100klx) Cloudy (10klx−50klx) Rainy (1klx−10klx) IPH D1 RP RS 60 50 41.9 mW 40 30 16.0 mW 20 7.7 mW 10 0 0 0.5 1 1.5 PV Module Voltage [V] 2 2.5 3 Figure 6: Deliverable power of our PV module under different illumination levels When illumination level is only 10% of direct sun condition, the PV module can still provide 7.7 mW. In this situation, BQ25504 has more than 80% efficiency and the output power is approximately 6.1mW that is used to charge the battery. In order to evaluate autonomous operation of the system in this situation, we have analyzed the power consumption of the whole system and the results have been presented in Table 1. The nominal voltage of the battery (3.6V) has been considered to calculate the average power consumption. Components Power (Active) Power (Idle) Power (Avg.) MCU (8 MHz) 7.2 mW 0.3 mW 1.0 mW Sensors 1.6 mW 4 µW 1.6 mW Energy Harvester + LDO 0.6mW 6 µW 0.6 mW LEDs driver + 6 LEDs 54 mW 10 µW 1.8 mW Total Power (10s turn time each 5 min.) 5.0 mW Table 1: Power consumption of different components As a result, the total power consumption of the system reaches to 5 mW and the system can continue its autonomous operation even at 10% of direct sun illumination. 7 TI Analog Design Contest 2013 Project Report 5 Prototype Implementation The realized prototype PCB (Fig. 7) is a two-layer board designed using Altium Designer. Its dimensions are 70mm x 75mm and it has power planes for GND and 2.5V regulated VCC that supplies MCU, sensor, LED driver, and debug EEPROM memory. In order to limit PCB size and component cost, emphasis was put on the use of SMD components whenever possible. The PCB contains all the required debug features in addition to the necessary components (including TPD4E004 for ESD protection) and can be easily connected to a PC through the MSP-FET430UIF debugging interface. A generic connector is used for the battery, such that different types can be used. The same concept is applied to the solar cell connection. 6 Figure 7: Prototype PCB Experimental results Yaw before [degree] The functionality of the BQ25504 with 4 PV cells in series (84 mW measured at full sunlight), the USB charger and the LIR2450 was successfully checked. MSP430F5510 was programmed by Code Composer Studio in order to be able to communicate via I2 C with sensors, LED driver and EEPROM memory. In Fig. 8 the results after the signal processing of raw sensors data for different arm movements are reported. When the arm is moving left or right, the threshold for the yaw angle is reached turning on the LEDs. The up (and down) movement is indeed filtered out by the tilt-compensation algorithm. However, this allows to successfully retain lateral movements with wrist rotation. Arm up Arm left 100 Blinking Threshold 0 −100 Arm right 0 10 20 30 40 Yaw after [degree] time [s] LED on 100 Arm right 50 (rotated wrist) LED on LED off 60 70 LED on Blinking Threshold 0 −100 0 10 20 30 40 50 60 70 time [s] Figure 8: Measured yaw angle before (up) and after (down) processing 8 TI Analog Design Contest 2013 Project Report 7 Conclusion This project shows how a solar energy source in combination with TI power management circuits, sensors and TI microprocessor can be used to power a bracelet-shaped wearable intelligent blinker for bike safety application. The system benefits from the fractional open circuit MPPT approach implemented in BQ25504 circuit to track the maximum power point voltage of the PV module and to extract the maximum power for a 5 mW portable device. We showed also that MSP430F5510 with its low-power modes is an optimal choice to process sensors data and to implement FQA algorithm for motion detection. Moreover this project gave us the possibility to work together as a team. We got more familiar with TI product and development tools and we will continue promoting TI product for developing student bachelor and master projects. 8 Future plans As future developments we have identified two main targets. The first target is developing a compact prototype. In this case the PCB should be reduced to the minimal elements including the power management circuitry, the microprocessor and the sensors. Solar panels and the rechargeable battery can be easily assembled as shown in Fig. 9. Thin films Li-ion batteries and flexible amorphous PV modules can be eventually used. The second goal is indeed to use additional sensors for non-invasive health monitoring applications. One of the most common applications is measuring oxygen level and heart rate by pulsoximetry that is also known as photoplethysmography (PPG). We plan to integrate an existing reflective PPG prototype we developed based on SLAA274B TI application note in the intellingent blinker and to take advantage of the accelerometer for motion tolerant operation using active noise cancellation approach. Finally, USB port for battery charging allows the connection of the MCU to the computer. This will be used for a user-configurable programming of the LED patterns and/or the access to sensor data and eventual add-on memory storage. Figure 9: Bracelet-shaped wearable intelligent blinker compact prototype 9 TI Analog Design Contest 2013 Project Report Bill of materials Description Designator LibRef Quantity Value Crystal Oscillator LDO Boost Converter (backup) ESD protection LED Driver SPDT Subminiature Toggle Switch, Right Angle Mounting, Vertical Actuation Switch Y3 U5 U2 U6a, U6b U10 XTAL TPS73001 TPS61070 TPD4E004 TCA6507 1 1 1 2 1 switch SW-SPDT 1 S1, S2, S3, S4, S5 SW-PB 5 Resistor R11, R12, R20, R28, R29, R37, R39, R40, R41, R42, Roc1 Res3 11 10K Resistor Resistor Resistor Resistor Resistor Resistor Resistor R13 R14 R21, R22, R23 R24, R25 R26 R27 R2a, R30, R31, R32, R33, R35 Res3 Res3 Res3 Res3 Res3 Res3 Res3 1 1 3 2 1 1 6 51k 30.1k 50 27 1.4K 100 0 Resistor R3, R7, R8, R9, R10, R15, R16, R17, R18, R19, R43, R44, R45, R46, Rshield1, Rshield2 Res3 16 1K Resistor Resistor Resistor Resistor Resistor Resistor Resistor Resistor Resistor MCU Accelerometer + Magnetometer Typical RED, GREEN, YELLOW, AMBER GaAs LED Typical RED, GREEN, YELLOW, AMBER GaAs LED Inductor Header, 12-Pin, Dual row Header, 7-Pin, Dual row Header, 2-Pin R4 R5, R6 R73 Roc2 Rok1 Rok2, Ruv1 Rok3 Rov1 Rov2, Ruv2 U7 U8 Res3 Res3 Res3 Res3 Res3 Res3 Res3 Res3 Res3 MSP430F5540IRGZ LSM303DLHC 1 2 1 1 1 2 1 1 2 1 1 2k 1.5k 1M 2.2K 3.3K 5.6K 560 4.7K 6.8K D1, D2, D6, D7, D8, D9 LED2 6 D3, D4, D5 LED2 3 Inductor Header 12X2 Header 7X2 Header 2 FT232RL D Schottky 1 1 1 3 1 6 22uH Schottky Diode L1 P2 P1 Battery, pwr, Solar FTDI1 D10, D11, D12, D15, D16, D17 Capacitor (Semiconductor SIM Model) C11, C19 Cap Semi 2 10uF Capacitor (Semiconductor SIM Model) C14a, C14b, Cdec1, Cdec2 Cap Semi 4 100pF Capacitor (Semiconductor SIM Model) C17, C18 Cap Semi 2 10pF Capacitor (Semiconductor SIM Model) C20 Cap Semi 1 470nF Capacitor (Semiconductor SIM Model) C3 Cap Semi 1 1uF Capacitor (Semiconductor SIM Model) C4, Cref Cap Semi 2 10nF Capacitor (Semiconductor SIM Model) C5 Cap Semi 1 15pF Capacitor (Semiconductor SIM Model) C6, C7, C10, C12, C13, C21, C22, C23, C24, Cfltr Cap Semi 10 100nF Capacitor (Semiconductor SIM Model) C8, C15, C16 Cap Semi 3 220nF Capacitor (Semiconductor SIM Model) C9, Chvr, Cstor Cap Semi 3 4.7uF Capacitor Boost Converter USB Charger dual-SPDT Switch 1024K I2C Serial EEPROM Mini USB Type B C108, C109 U1 U3 U4 U9 J1, J2 Cap BQ25504 BQ24090 ADG884 24FC1025 1-353576-1 2 1 1 1 1 2 10pF 10