* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download PULSA PV - joule.ie

Index of electronics articles wikipedia , lookup

Power electronics wikipedia , lookup

Power MOSFET wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Opto-isolator wikipedia , lookup

Telecommunications engineering wikipedia , lookup

Gender of connectors and fasteners wikipedia , lookup

Surge protector wikipedia , lookup

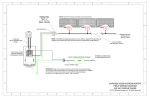

PULSA PV joule pulsa pv solar high performance ac solar module installation guide Please complete this warranty card and return it to Joule to activate the warranty. Installer Name ................................................................................................................. Company Name ................................................................................................................. Address ................................................................................................................. ................................................................................................................. ................................................................................................................. Contact Tel. no. ......................................... Contact Email.......................................... Client Name ................................................................................................................. Site Address ................................................................................................................. ................................................................................................................. ................................................................................................................. Contact Tel. no. ......................................... Unit purchased from ......................................... Installation date Contact Email.......................................... Date purchased .............................. ......................................... Inverter Serial No’s. .............................. Inverter Serial No’s. .............................. Inverter Serial No’s. .............................. Inverter Serial No’s. .............................. Inverter Serial No’s. .............................. Inverter Serial No’s. .............................. Inverter Serial No’s. .............................. Inverter Serial No’s. .............................. Inverter Serial No’s. .............................. Inverter Serial No’s. .............................. Inverter Serial No’s. .............................. Inverter Serial No’s. .............................. Scan the page or alternatively take a photo with smart phone of complete sheet with all information filled in. This must be completed by the installer and a copy sent to Joule [email protected] Table of Contents 6 7 8 9 10 11 12 13 14 16 17 19 20 21 22 23 24 26 29 31 32 34 35 36 38 39 40 41 Why Install Photovoltaic Solar Panels? Contribution to Running Costs Advantages Features Maximising Performance Transportation and Installation Notes Safety Instructions General Safety Handling Safety Installation Safety Fire Safety Technical Specification Mechanical Installation Select suitable locations for installation Components supplied Installation Locating the Inverter Installing Branch Connectors Electrical Installation Lightning Surge Protection Selecting Engage Cable Type Installation Procedure Step 1 - Measure AC at the Electricity Network connection Step 2 - Install the AC Branch Circuit Junction Box Step 3 - Position the Enphase Engage Cable Step 4 - Attach the Microinverters to the Mounting Rail Step 5 - Dress the Engage Cable Step 6 - Terminate the Unused End of the Engage Cable Step 7 - Connect the Engage Cable to AC Junction Box(es) Electrical Installation - Microinverter Technical Specification Electrical Installation Engage and Wire Sizing Overview What Contributes to Voltage Rise Sample Calculation Voltage Rise for M215s with the 230V Engage Cable Step 8 - Verification and Commissioning Maintenance Replacing a Microinverter Locating the Unit Why Install Photovoltaic Solar Panels? Since the revisions to Part L of the Building Regulations in March 2014 there has been a need for a greater contribution from renewable sources of energy for domestic and commercial constructions. One way to comply with the updated regulations is by installing Photovoltaic (PV) Solar Panels. There are numerous benefits to installing PV Solar Panels • PV panels provide clean, green energy. During electricity generation with PV panels there is no harmful greenhouse gas emissions thus solar PV is environmentally friendly. • Solar energy is energy supplied by nature – it is thus free and abundant! • Solar energy can be made available almost anywhere there is sunlight • Photovoltaic panels, through photoelectric phenomenon, produce electricity in a direct electricity generation way. • Operating and maintenance costs for PV panels are considered to be low, almost negligible, compared to costs of other renewable energy systems. • PV panels have no mechanically moving parts, except in cases of sun-tracking mechanical bases; consequently they have far less breakages or require less maintenance than other renewable energy systems (e.g. wind turbines). • PV panels are totally silent, producing no noise at all; consequently, they are a perfect solution for urban areas and for residential applications. 6 PULSA PV installation manual Contribution to Running Costs The table below gives typical consumptions of standard electrical devices. Even when electrical devices are turned off they may still be consuming power. Photovoltaic Solar Panels can contribute towards the operation of these products with the contribution given being determined by the amount of panels installed. Customers may start with as little as one PS260AC Module and then increase their system wattage as budget, time, and space permit. As each Photovoltaic AC module produces grid compliant AC current, the modules serve as building blocks with no matching or string sizing required. The integrated Enphase Microinverter instantly converts DC electricity into ready to use AC power. If an Enphase Envoy is installed, the intelligent Microinverter also sends vital health and performance information to the Enphase communications gateway. 7 Locating the Unit Advantages This next generation design eliminates the need for expensive DC wiring components and centralized power inverters. Also, the Photovoltaic AC Module dramatically reduces the complex design and installation process associated with a traditional DC solar power system. AC Advantages • High efficiency solar module integrated with an Enphase Microinverter, the world’s most efficient AC system solution • Higher Efficiencies than String Inverter systems • Optimized for higher outputs in low light conditions • Modules are individually optimized • Eliminates module mismatch losses • Any shading will affect only the shaded panel, not the entire system • Easier to Design and Install • Installation labour reduced, no DC switches, GFCI, etc. required • Fast, inexpensive mounting - delivered ready for connection • Pre manufactured cables • Greater Productivity with more reliability • AC wiring systems are more efficient at transporting electricity as they do not suffer typical electrical losses that are common in all DC wiring circuits. • More uptime means more kW-h generated • Installers need not match PV output characteristics before installation • Better Performance • Individual PV breakages (e.g. hail) do not stop system power output • No system mismatch losses • Any shading will affect only the shaded panel, not the entire system • Optional communication hub monitors every module independently • Peak efficiency 96.3%, CEC efficiency 96% • No single point of failure will disable the system • AC Modules are sealed. No cooling vents mean that the units always stay clean and dry inside • Convection cooled with no moving parts • Safer – no DC-side wiring (eliminates dangerous high voltage DC and all DC wiring loss) • Reduced inspection code issues 8 PULSA PV installation manual Features Advantages Durability assured Up to 17% module efficiency Salt mist corrosion certification Outstanding performance in weaklight conditions Excellent temperature coefficient giving higher yields in the long term Ammonia corrosion certification Fire test certification Positive current sorting A+ class in PI Berlin test IP68 connectors enhance the reliability of the PV system Certified to withstand increased loads of up to 5400Pa 10-year product warranty 25-year performance warranty 9 Locating the Unit Maximising Performance 10 PULSA PV installation manual Transportation and Installation Notes 11 Locating the Unit Safety Instructions General Safety • The installation of a photovoltaic system requires specialized skills and knowledge and must only be carried out by licensed/qualified persons. • Installers should assume all risks of injury and do everything to avoid potential damages and risks that might occur during installation, including but not limited to, the risks of electric shock. • Joule Pulsa modules do not need special cables for connection. All of the modules have permanent junction boxes, cables and connectors. • Do not use mirrors or magnifiers to concentrate sunlight onto the modules. • The modules generate DC electrical energy from sunlight. They are designed for outdoor use and can be mounted onto frames on rooftops or in the ground etc. • Do not paint the module or attach anything on to the back of the module. • Do not attempt to disassemble the modules, and do not remove any attached nameplates or components from the modules. Handling safety • • • • • • • • When handling the module insulated gloves must be worn. Inappropriate transportation and installation may break the module. Do not lift or move the module by holding the junction box or cable. Do not place anything on the module or press on the module surface. Do not drop the module or allow objects to fall on the module. Do not expose the back of the module to direct sunlight. Do not wear metal ornaments while handling the module. Do not install or handle modules in wet or strong windy conditions. Installation safety • Local, regional and state laws and regulations must be adhered to while installing a photovoltaic system. For example, any necessary licenses must be obtained prior to the installation commencing. Regulations around vehicles and ships must also be observed during the installation. • Observe all safety rules for the other system components, including the cables, connectors, charging controllers, inverter and storage battery etc. • Do not place the modules near a location where flammable gases are either generated or collected. • Insulated gloves must be worn during the installation. • Do not wear metal ornaments during the installation. • Do not drill holes in the frame. 12 PULSA PV installation manual • Under normal conditions, a module is likely to produce more current and/or voltage than reported under Standard Test Conditions (STC). Accordingly, the values of ISC and VOC marked on the module nameplate should be multiplied by a factor when determining the component voltage ratings, conductor current ratings, fuse sizes, and the size of controllers connected to the photovoltaic system. The exact factor value should be suggested by a licensed/qualified person. • The connecting ends with electricity may cause fire, spark or lethal shocks even when the modules are not connected. • Electricity can be generated when the modules are exposed to sunlight, even if they are not connected. It is dangerous to touch 30V DC or higher, so never open the electrical connectors or unplug the electrical connectors while the circuit is under load, and do not touch the end with electricity during installations, when the modules are exposed to sunlight. • Children should be kept away from the photovoltaic system. • In order to prevent current and voltage generation during installation an opaque board can be used to cover the modules. • Only use licensed/qualified insulated tools. • The frame of the modules must be grounded according to local, regional and state safety and electrical standards. A recommended connector or equivalent must be used for the grounding cable. The grounding cable must be appropriately fastened to the module frame. • Only Balance of System (BOS) in conformity to local, regional, state safety electricity standards and photovoltaic system such as connectors, cables and frames can be used, avoiding affect on the module performance and/or damage it. Fire Safety • Consult your local authority for guidelines and requirements for building or structural fire safety. • Roof constructions and installations may affect the fire safety of a building; an improper installation may create a hazard in the event of a fire. • Use components such as ground fault circuit breakers and fuses as required by the local authorities. • Do not use the modules near a location where flammable gases are either generated or collected. • The modules have been rated Fire Class C, and are suitable for mounting onto a Class A roof. 13 Locating the Unit Technical Specification Mechanical characteristics Solar cells Dimensions (mm) Polycrystalline 156mm x 156mm square, 6 x 10 pieces in series 75mm / 2.95 inch Collector width 992mm / 39.06 inch Collector lenght 1640mm / 64.57 inch Weight (kg) 21.6kg / 47.6lbs Front glass 3.2mm toughened glass H 1640 992 75 1360 860 8-9x14 Frame Anodized aluminium alloy Cable 0.90m wire (Ø4mm2) Diodes 6 pieces Schottky by-pass diodes Junction Box W IP65 rated @208 VAC @240 VAC 215W 215W Nominal output current 1.0A (arms at nominal duration) 0.9A (arms at nominal duration) Nominal voltage/range 208V / 183-229V 240V/211-264V Extended voltage/range 208V/179-232V 240V/206-269V Nominal frequency/range 60.0/59.3-60.5Hz 60.0/59.3-60.5Hz Extended frequency/range 60.0/59.2-60.6Hz 60.0/59.2-60.6Hz >0.95 >0.95 25 (3 phase) 17 (single phase) Maximum Output Power Power Factor Maximum units per 20A branch circuit Maximum output fault current 942 Frame (black) 992 1640 1.05 Arms, over 3 cycles; 25.2 Apeak, 1.74ms duration Ambient temperature range -40°C to +65°C Weak light performance (DC module) Intensity (W/m2) Impp Absolute maximum rating Vmpp Intensity (W/m2) Impp 1000 1 1 Operating Temperature 800 0.8 0.996 Hail Diameter @ 80km/h Up to 25mm 600 0.6 0.99 Surface Maximum Load Capacity Up to 5400Pa From -40 to +85°C 400 0.4 0.983 Maximum Series Fuse Rating 200 0.2 0.952 IEC Application Class (IEC 61215) A 100 0.1 0.921 Fire Rating (UL 1703) C Note This publication summarizes product warranty and specifications, which are subjected to change without notice. Additional information can be found on www. phonosolar.com 1. Defined as standard deviation of thousands measurements. Absolute power values depend on the measuring system. They can differ by +/-5% from one measuring system to another. 2. Measurement conditions under irradiance level of Standard Test Conditions (STC): 1000W/m2, Air mass 1.5 Spectrum, cell temperature of 25°C. 14 110 9 H AC Electrical typical values Output Data (AC) 2-Ø4 Back sheet (black) Collector height L 15A Temperature characteristics (DC module) NOCT (Nominal Operation Cell Temperature) 45°C ± 2°C Voltage Temperature Coefficient -0.31%/K Current Temperature Coefficient +0.07%/K Power Temperature Coefficient -0.40%/K PULSA PV installation manual 15 Locating the Unit Mechanical Installation (Note: All instructions hereafter are for reference only. A licensed/qualified person or installer must be responsible for the design, installation, mechanical load calculation and security of the photovoltaic system.) Select suitable locations for installation Select a suitable location for installing the modules. Joule recommends that to achieve the best performance the modules should face south. The exact tilt angle and orientation of mounted modules should be recommended by a licensed/qualified installer. Clamp fitting: Use the provided module clamps on the long side of the module frame to mount the modules in portrait orientation or on the short side of the module frame for landscape orientation. Components Supplied • Module Frame • Mounting Rail M8 Screw Split Washer • M8 Bolt • M8 Nut • Flat Washer • Mounting Rail • Roof Fixing Bolts • End Clamps • Middle Clamps • Drop Connectors • Microinverters • AC Lockable Isolator • AC Junction Box 16 PULSA PV installation manual Installation Select the appropriate installation method as per the installation diagram. The module clamps should not come into contact with the front glass and must not deform the module frame. Avoid any shadowing effects from the module clamps. The module frame cannot be modified under any circumstances. Regardless of the orientation chosen, at least 4 clamps must be used on each module. For portrait orientation, 2 clamps should be attached to the long sides of the module and for landscape orientation 2 clamps should be attached to the short sides of the module. Depending on the local wind and snow loads, additional clamps may be required. The applied torque should be about 8Nm. The modules should be completely free of shade at all times. Do not place the modules near a location where flammable gases are either generated or collected. Mounting System The system for the fixation of modules onto the cross beam rails allows for optimum security and short mounting times giving the following benefits: • Quick and convenient mounting • Secure fixation with qualitity steel thread • Application of standard components 17 Locating the Unit Mechanical Installation Roof fixing bolts are drilled down through the slate or tile covering the roof. The rubber gasket on the bolt keeps the penetration point in the roof weather proofed. A UVresistant EPDM gasket with sealing cone and support collar is counter screwed with a third mounting nut and safely seals the roof. The roof fixing bolt bolt is connected to the profile by use of a stainless steel clamp of which one side which slides into the square side of the horizontal profile. The bolt head slides through the profile to the desired location where the second side of the clamp locks the profile into position. 18 PULSA PV installation manual Locating the Inverter • With the rail in position the Microinverters are then fitted. • Each Joule Pulsa panel requires its own Microinverter and the Microinverters should be fitted to the right hand side of the connection cables that are fixed to the Pulsa panel. • The supplied M8 square nut is positioned in the profile using the plastic positioner supplied. • The Microinverter is fixed to the rail using the M8 bolt. • Use one inverter per module, one bolt per iverter Installing Branch Connectors In addition to the Enphase Microinverters, PV modules, mounting rail, and associated hardware, you will need the following items. Enphase equipment: • Enphase Engage Cable. See “Selecting Engage Cable Type” on page 5 for options. • Sealing caps, as needed (for any unused drops on the Engage Cable) • Terminators, as needed (one needed at the end of each AC branch circuit) • Enphase disconnect tool Other items: • Outdoor-rated, weather-proof AC junction box(es) • Gland or strain relief fitting (one per AC junction box) • Earthing (bonding) conductor • Torque wrench, sockets, spanners for mounting hardware • Adjustable spanner or open ended spanner (for terminators) 19 Locating the Unit Electrical Installation Lightning Surge Protection Lightning protection and resulting voltage surge are protected in accordance with BS 7671 and EN 62305-1. It is assumed that the PV modules are installed in accordance with related standards and that the Microinverter is a part of a broader lightning protection system in accordance with BS 7617 and EN 62305-1, -3. In some areas, the statistical frequency of lightning strikes near a PV installation is high enough that lightning protection must be installed as part of an Enphase system. In some areas, a surge protection device might be mandatory following a risk analysis, according to local regulation, BS 7671, or NF C 15-100 (art. 443) & NF C 15-443L. The first step to install the Engage Cable is to simply roll out the desired length and cut it to size. One end is wired directly into the junction box at the head of the branch circuit, eliminating the need for a separate AC interconnect cable. The other end is sealed from the environment using an Enphase Branch Terminator. The Microinverter AC cable connectors are then plugged into the regularly-spaced connectors as shown. 20 PULSA PV installation manual Installation Procedure Installing the Enphase Engage Cable and Accessories involves several key steps: 1. Measure AC at the Electricity Network Connection 2. Install the AC Branch Circuit Junction Box 3. Position the Enphase Engage Cable 4. Attach the Microinverters to the Mounting Rail 5. Dress the Enphase Engage Cable 6. Terminate the Unused End 7. Connect the Engage Cable to AC Junction Box(es) 8. Verification and Commissioning Risk of Electrical Shock Due to presence of exposed conductors, DO NOT connect the Enphase Microinverters to the electricity network or energize the main AC circuit(s) until you complete all of the installation procedures as described in the following sections. Step 1 – Measure AC at the Electricity Network Connection Measure AC line voltage at the electricity network connection to confirm that it is within range. Acceptable ranges are shown in the following table. Single-Phase Service Three-Phase Service L1 to neutral L1 to L2 to L3 207 to 253 Vac 360 to 440 Vac Be sure the Engage Cable you are using matches the electricity network connection at the site. Use 5G2.5 Engage Cable at sites with three-phase (and neutral) service, or use 3G2.5 Engage Cable at sites with single-phase service. Check the labelling on the drop connectors to verify the voltage type. Enphase Microinverters are designed to operate phase-to-neutral. When multiple phases are present at sites with single-phase service, connect only one phase to each Microinverter branch. Connecting multiple phases to a Microinverter branch circuit will damage or destroy the Microinverters. 21 Locating the Unit Electrical Installation Step 2 – Install the AC Branch Circuit Junction Box Risk of Electrical Shock. • Be aware that installation of this equipment includes risk of electric shock. Do not install the AC junction box without first removing AC power from the Enphase System. • Use electrical system components approved for wet locations only. • When stripping off the Engage Cable sheath, make sure that the conductors are not damaged. • Loose cables might become a tripping hazard. Dress the Engage Cable to minimize this potential. • Do NOT exceed the 17 Microinverters in an single phase AC branch circuit, and protect each Microinverter AC branch circuit with a 20 A maximum breaker (or in accordance with local installation code). • Size the AC cable/wire size to account for voltage drop. Select conductor diameter based on the distance from the beginning of the Microinverter AC branch circuit to the breaker in the AC mains. • All components of system wiring must be considered, including internal voltage drop within the length of Engage Cable. Typically, three wire sections and several wire terminations must be quantified. There is also some resistance associated with each circuit breaker. As all of these resistances are in series, they add together. Since the same current is flowing through each resistance, the total voltage drop is total current times the total resistance. • For a single-phase system, the total resistance is equal to two times the one-way resistance. For a three-phase system, each of the three line currents and resistances must be calculated. Standard guidelines for voltage drop on feeder and AC branch circuit conductors might not be sufficient for Microinverter AC branch circuits that contain the maximum allowable Microinverters. This is due to high inherent voltage rise on the AC branch circuit. • Install an outdoor rated, weather-proof AC junction box at a suitable location on the mounting rail (typically at the end of a row of PV modules). • Provide an AC connection from the AC junction box back to the electrical utility connection, using equipment and practice as required by local standards. • Enphase Microinverters are designed to operate phase-to-neutral. When multiple phases are present at sites with single phase 230V service, connect only one phase to each Microinverter branch. Connecting multiple phases to a Microinverter branch circuit will damage or destroy the Microinverters. Step 3 – Position the Enphase Engage Cable 22 PULSA PV installation manual • Position the Engage Cable to the right hand side of the centre of the panel so that connectors that are attached to the panels are not obstructed when fitting the Joule Pulsa panel to the mounting rail. • Lay the Engage Cable along the route it will travel, positioning the connectors so that they align with the PV modules. Step 4 – Attach the Microinverters to the Mounting Rail Mount the Microinverters as per the diagram below. Ensure both that the Microinverter does not interfere with the PV module frames and that the AC connector from the Microinverter can easily reach the AC connector on the Engage Cable. 23 Locating the Unit Electrical Installation Step 5 – Dress the Engage Cable Adhere to the following requirements: • Do not expose the connection to directed, pressurized liquid (water jets, etc.). • Do not expose the connection to continuous immersion. • Do not expose the AC connector to continuous tension (e.g., avoid pulling or bending the Engage Cable near the connectors) • Do not allow contamination or debris in the connectors. • Use the Engage Cable and Accessories only when all parts are present and intact. • Fit the connection using only the prescribed tools. • There are two release holes in the connector. These holes are to be used only for disconnecting. Keep these release holes clear and accessible. • Dress any excess in loops so that Engage Cable does not contact the roof. Tripping Hazard. Loose cables might become a tripping hazard. Dress the Engage Cable to minimize this potential. 24 PULSA PV installation manual • Place tie wraps on either side of the drop connector. Use one or two tie wraps, or other support scheme to secure the Engage Cable between connectors. • Remove and discard the temporary shipping caps from the Engage Cable. • Connect the Microinverter and listen for two clicks as the two prongs engage. Ensure that both latching mechanisms engage. • The connector is not designed for repeated plugging and unplugging. • Cover any unused connector with a sealing cap. Listen for two clicks as the connectors engage. Ensure that both latching mechanisms engage. • Ensure the gasket seal is intact and fitted correctly to the drop connector before connecting to the Microinverter. If the gasket is not correctly in situ the system will not have an IP67 rated connection. AC Drop Connector Gasket gives IP67 seal 25 Locating the Unit Electrical Installation • Install sealing caps on all unused AC connectors. Unused AC connectors are live when the system is energized. • Do not use the shipping cap to cover unused connectors. The shipping cap does not provide an adequate environmental seal. Enphase sealing caps are required for protection against moisture ingress. • Enphase sealing caps are IP67 rated. Within the term “IP67”, “IP” indicates an Ingress Protection (IP) rating against dust and liquids. This specific rating of IP67 indicates that this connector protects against all dust particles and immersion in liquid. • If you need to remove a sealing cap, you must use a disconnect tool. Step 6 – Terminate the Unused End of the Engage Cable Attaching the Terminator The terminator is intended for one-time use only. If you open the terminator following installation, the latching mechanism is destroyed and the terminator cannot be used again. If the latching mechanism is defective, the terminator must not be used. The latching mechanism must not be circumvented or manipulated. Adhere to the following requirements: • Use the terminator assembly to seal the conductor end of the Engage Cable. No other method is allowed. • Do not expose the terminator to directed, pressurized liquid (water jets, etc.). • Do not expose the terminator to continuous immersion. • Do not expose the terminator to continuous tension (e.g., avoid pulling or bending the Engage Cable near the terminator) • Use the terminator only when all parts are present and intact. • Fit the terminator using only the prescribed tools. To attach the terminator: Check the terminator for completeness. It is made up of the individual parts shown. 26 PULSA PV installation manual To guarantee the safety of the wire organizer and to ensure that it remains sealed, please make sure that all parts are present and that all seals are seated correctly in the wire organizer. The wire organizer must be complete, as shown. Risk of Electrical Shock. The terminator must not be installed while power is connected. At the end of the Engage Cable, strip at least 60 mm (2.5 inches) of the cable sheath from the conductors. If the exposed wires are damaged, system function can no longer be guaranteed. Slide the hex nut onto the Engage Cable. • Insert the Engage Cable end all the way into the wire organizer (up to the stop). • Bend the individual wires into the slots (spaces) on the wire organizer. • Using a diagonal cutter, trim wires to the correct length so that they fit cleanly into the slots (spaces) in the wire organizer. • Press the cap onto the wire organizer, bending the wires into the slots of the wire organizer. If the wires resist being pressed into the cap, you may need to trim the wires a little further. • Screw the hex nut onto the cap. Never unscrew the hex nut as this can twist and damage the cable. • Insert a #2 Philips screwdriver into the slot on the cap to hold it in place. (Alternatively you can hold the cap firmly in place using the disconnect tool). • Use a 22mm (7/8 inch) spanner and tighten the nut until the latching mechanism has been screwed all the way to the base. • Use a tie wrap to attach the cable to the mounting rail, so that the Engage Cable and terminator do not touch the roof. 27 Locating the Unit Electrical Installation Replacing or Removing the Terminator • If the terminator must be replaced or removed, observe the following. • Risk of Electrical Shock. Be aware that installation of this equipment includes risk of electric shock. Do not install the AC junction box without first removing AC power from the Enphase System. Never open, remove or replace the terminator while it is connected to the power supply. • Damage to the latching mechanism cannot be seen with the naked eye. Label the opened terminator and dispose of it immediately to ensure that it cannot be reused accidentally. • The terminator is intended for one-time use only. If you open the terminator again following the installation, this will destroy the latching mechanism, meaning that the unit then cannot be used again. • Remove the terminator by cutting it off using a diagonal cutter set flush against the end of the Engage Cable. • Replace the terminator as described in the previous steps. Step 7 – Connect the Engage Cable to AC Junction Box(es) Perform the following steps in accordance with local standards. • Connect the Engage Cable into the AC branch circuit junction box using an appropriate gland or strain relief fitting. It requires a strain relief fitting with an opening of 1.3 cm (0.5 inches) in diameter. • Connect the Engage Cable into additional AC junction boxes as needed to transition to conduit between smaller sub-arrays. Remember to adhere to AC branch circuit limits for the Microinverters being used. 28 Fitting Branch Termination Endcap PULSA PV installation manual 29 Locating the Unit Electrical Installation Fixing the Pulsa Solar Module to the rails 1.Push click components into the upper groove of the cross beam profile, insert square nuts into the click components and distribute at approximate distances along the length of the profile. 2.Loosely attach the first two end clamps with serrated M8 screws (or screws with locking nuts) at the end of the cross beam rail. 3.Then position the first module and loosely secure with end clamps (the end clamps should be placed at least 5mm from the outer edge of the cross beam). Now adjust the first module in line with the cross beam. 4.When mounting with clamps, click these into the required position, arrange flush with the modules and tighten screws. After aligning the first module in each row, a middle clamp is loosely fastened to the corresponding cross beam. 5.The next module is then connected, shifted beneath the module clamp and secured. 6.The first middle clamp is then tightened. 7.Repeat steps 5 and 6 until all panels are in position. 8.Repeat steps 2 and 3 for the edge last panel 30 PULSA PV installation manual Electrical Installation - Microinverter The Microinverter with integrated ground delivers increased energy harvest and reduces design and installation complexity with its all-AC approach. With the advanced M215, the DC circuit is isolated and insulated from ground, so no Ground Electrode Conductor (GEC) is required for the Microinverter. This further simplifies installation, enhances safety, and saves on labor and materials costs. Productive, Simple, Reliable • Maximizes energy production • Minimizes impact of shading, dust, and debris • No single point of system failure • No GEC needed for Microinverter • No DC design or string calculation required • Easy installation with Engage Cable • More than 1 million hours of testing and millions of units shipped • Industry-leading warranty, up to 25 Years 31 Locating the Unit Electrical Installation - Microinverter Technical Specification 32 PULSA PV installation manual 33 Locating the Unit Electrical Installation - Microinverter Electrical Installation Legend 1. Joule Pulsa Photovoltaic Panel 2.Microinverter 3. Drop Connector 4. Branch Terminator 5. Junction Box 6. 20A Lockable 2-pole AC Isolator 7. PV Generation Meter (not supplied) 8 Consumer Board 9. Utility Meter 10.Cut Out Fuse Notes 1.IMPORTANT: Check the L to N voltage at the point of connection. This must be in the range 207 to 253V. 2.All wiring and equipment designed must be installed in accordance with the most recent edition of BS 7671 and must by a qualified Competant Person 3.All calculations assume Ze = 0.35Ω at the point of connection (ie consumer unit). 4.AC Cable between junction box and the consumer board to be sized based on a total voltage drop not exceeding 1%. 5.Typically a single phase engage cable branch is terminated into a 1-pole 20A Type B MCB 6.The Microinverter uses a HF transformer which provides simple separation. A Type B RCD is NOT required. A Type AC RCD may be required as a result of the AC circuit design. 34 PULSA PV installation manual Engage and Wire Sizing Overview The Engage Cable is a continuous length of 2.5mm2 stranded copper, outdoor rated cable, with integrated connectors for the Microinverters. The Engage Cable is available either with 1.025 meters between connectors for PV modules in portrait orientation or with 1.7 meters between connectors for PV modules in landscape orientation. Voltage type / conductor count Connector Spacing PV module orientation 230/240 Vac, 4 conductor 1.025 m Portrait 230/240 Vac, 4 conductor 1.7 m Landscape In this document, calculations are provided for both Engage Cable options. Regardless of the application, Joule recommends that the total percentage of voltage rise in the AC wiring be less than 2%, with (an inclusive) less than 1% voltage rise. All components within the system wiring can add resistance and must be considered when calculating the total VRise. Typically, the resistance of three distinct wire sections and several wire terminations must be quantified. There is also some resistance associated with each OCPD (Over Current Protective Device), typically a circuit breaker. As all of these resistances are in series, they are cumulative. Since the same current is flowing through each resistance, the total VRise is simply the total current times the total resistance. For a single-phase system, the total resistance is equal to two times the one-way resistance. Wire sizing is very important because improper wire size can result in nuisance tripping of the Microinverter’s utility protective functions. This results in loss of energy harvest. What Contributes to Voltage Rise Enphase Microinverter systems are installed as dedicated branch circuits. Each dedicated branch circuit of the Microinverters is protected by a 20A OCPD. Wire size, circuit current, circuit, length, voltage margin, and utility voltage must all be considered. Wire size: Of course, there is a tradeoff to be made between increased wire size and increased cost. The wire size can often be increased by one trade size with minimal cost impact. At some point, however, increasing the wire size necessitates increases in wiring and conduit costs can be offset by the increase in energy production over the lifetime of the system. Circuit current: The circuit current will vary depending on which ‘wire section’ is being considered in the installation. See ‘VRise Calculations by Wire Section’. A typical installation will contain three wiresections. In the Engage Cable (wire section 1), the current increases with each inverter added to the circuit. 35 Locating the Unit Electrical Installation - Microinverter Circuit length: There is often little choice in circuit length, but center-feeding the dedicated branch circuit will significantly reduce voltage rise within the branch, See ‘Advantages of Center-Feeding the AC branch Circuits’ in the following section. Voltage margin: If the service voltage is chronically high, the utility will sometimes perform a tap change on the distribution transformer. This can provide a percent or two of additional voltage margin Utility voltage: The utility strives to maintain voltage at the main service meter within a certain percentage of nominal. The protective functions of the Microinverters are set to +10%/-12% by default, but your local utility may have alternate requirements. The high voltage end of the tolerance is of most concern because inverters are a source and not a load. If the utility is consistently 5% high, this leaves less than 5% for all wiring and interconnection losses and inverter measurement accuracy. If you are concerned about the utility’s voltage, you may request that your utility place a data logger at the main service meter and make a record of the voltages available to you at the site. Sample Calculation The following example is for a fully populated branch circuit of 17 Microinverters. • • • • • Microinverter full load AC current = 0.93 amps Wire gauge for individual branch circuit = 4mm2 CU 4mm2 CU resistance = .00461Ω/m (4.61ohms/km) Length of individual branch circuit = 15m Two way wire length= 30m Vrise = (0.93 * 17) * (0.00461Ω/m) * (15m * 2) = 15.81 * 0.00461 * 30m =2.19 volts =2.19 volts / 230 volts = 0.95% Vrise *The voltage rise from the junction box to the Microinverter subpanel is 0.95% Voltage Rise from the Microinverter Subpanel to the Main service meter Vrise = (Amps/inverter * #inverters) * (resistance Ω/m) * (2 way wire length) 36 PULSA PV installation manual Example: • • • • • • 3 branches of 17 = 51 M215s current of 3 branches = 47.43A wire gauge for sub-panel feed = 25mm2 CU 35 mm2 CU resistance = .000524Ω/m Length of Microinverter sub-panel feed = 30m Two way wire length = 60m VRise = (51 * 0.93A) * (0.000524Ω/m) * (30m * 2) = 47.43A * 0.000524Ω/m * 60m = 1.49 volts = 1.49 volts / 230 volts = .6% Vrise * The voltage rise from the Microinverter sub panel to the main service meter is 0.6% 37 Locating the Unit Electrical Installation - Microinverter Voltage Rise for M215s with the 230V Engage Cable 230V Engage Internal VRise 38 PULSA PV installation manual Step 8 – Verification and Commissioning Prior to final connection to the electricity network, ensure that all AC and DC wiring is correct. • • • • • Ensure that none of the AC and DC wires are pinched or damaged. Ensure that all AC junction boxes are properly closed. Ensure that all unused connectors are capped. Ensure that all connectors are properly seated. Install the Microinverters and commission the system as instructed by the Enphase Microinverter installation and operation manual and in accordance with all local and national requirements. Start Up Sequence 1. Ensure the PV system MCB and the AC isolator are set to ON 2. Wait 3 minutes for the Microinverter system to start up. 3. A flashing green LED light on each Microinverter indicates that the system is operating correctly Shut Down Sequence 1.Turn OFF the AC isolater between the consumer unit and the PV panels 39 Locating the Unit Maintenance The Microinverter system requires virtually no maintenance and provides you with trouble-free energy production. Visually inspect the modules (panels), especially after storms, hail and high winds An inspection from the ground, with binoculars if needed, is usually sufficient. Check the array for dust, debris, leaves, and other soiling. Clean solar modules generate maximum energy harvest. Some geographic regions do not have much dust, debris, and pollution, so solar modules remain relatively clean and maintain optimum energy performance. In other areas, rain and snow naturally clean modules and help maintain performance. Perform an annual check In order to ensure optimum module performance, Joule recommends the following: • If necessary, the glass front of the module can be cleaned with water and a soft sponge or cloth. A mild, non-abrasive detergent can be used to remove more stubborn stains. • Check the electrical and mechanical connections periodically and make sure they are clean, safe, complete and secure. • In the event of a problem, consult with a licensed/qualified person Talk to your solar professional about performing a yearly check. Your solar professional can inspect your array and verify that the electrical and mechanical connections are intact and working efficiently. Monitor system performance An add on Photovoltaic Envoy can be purchased to check energy production from your Enphase Microinverters on MyEnlighten to compare the month-to-month, or the year-to-year performance of your system. For example, use the MyEnlighten energy grid or generate a report and compare the energy production for one month to the same month in the previous year. Is it the same or lower? If lower, did cloud cover reduce energy production? If not, you may want to perform a visual inspection of your array and check for debris. 40 PULSA PV installation manual Replacing a Microinverter To ensure the Microinverter is not disconnected from the PV modules under load, adhere to the following disconnection steps in the order shown: 1. Using a clamp-on meter, verify there is no current flowing in the DC wires between the PV module and the Microinverter. Take care when measuring DC currents due to the fact that most clamp-on meters must be zeroed first and tend to drift with time. 2. Disconnect the PV module DC wire connectors from the Microinverter. 3. Disconnect the Microinverter AC connector from the Engage Cable. 4. The Microinverter connectors are tool-removable only. To disconnect a Microinverter from the Engage Cable, insert these two prongs into the two holes in the AC connector. Squeeze the sides of the disconnect tool to engage with the AC connector. Rock the connector back and forth while pulling gently to disengage. 5. Remove the Microinverter from the mounting rail. Risk of Electrical Shock. Do not leave the drop connector uncovered for an extended period. If you do not plan to replace the Microinverter immediately, you must cover any unused connector with a sealing cap. Listen for two clicks as the cap engages. Sealing caps may not be reused 41 JOULE IE JOULE UK JOULE PL mail tel fax eml web Kylemore Park West, Ballyfermot, Dublin 10 +353 (1) 623 7080 +353 (1) 626 9337 [email protected] www.joule.ie mail Unit 17C&D Power Road, Plantation Bus. Pk. Bromborough, Wirral, CH62 3RN +44 (0) 1513 551 094 +44 (0) 1513 568 336 [email protected] www.jouleuk.co.uk mail tel fax eml web 23-200 Kraśnik, ul. Towarowa 34. +48 (0) 128811171 +48 (0) 814709046 [email protected] www.joule-pl.pl tel fax eml web