* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download English - Det

Fault tolerance wikipedia , lookup

Flexible electronics wikipedia , lookup

Opto-isolator wikipedia , lookup

Two-port network wikipedia , lookup

Regenerative circuit wikipedia , lookup

Surface-mount technology wikipedia , lookup

Integrated circuit wikipedia , lookup

Crossbar switch wikipedia , lookup

Earthing system wikipedia , lookup

Network analysis (electrical circuits) wikipedia , lookup

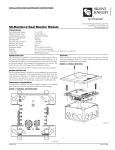

ORDERING INFORMATION SPECIFICATION DATA When ordering, please specify: Eagle Quantum™ Premier EQ2200IDC Initiating Device Circuit Initiating Device Circuit Specify: Enclosure material — Aluminum or stainless steel Number of ports — 5 or 6 Port size — 3/4 inch NPT or 25 mm Certification — FM/CSA/CENELEC/CE. EQ2200IDC For additional information or for assistance in designing a system to meet the needs of a specific application, please contact: Detector Electronics Corporation 6901 West 110th Street Minneapolis, Minnesota 55438 USA Operator: (952) 941-5665 or (800) 765-FIRE Customer Service: (952) 946-6491 Fax: (952) 829-8750 Web site: www.detronics.com E-mail: [email protected] DESCRIPTION Functioning as part of the fire detection portion of the safety system, the EQ2200IDC Initiating Device Circuit (IDC) provides two supervised digital inputs for use with dry contact inputs from devices such as relays, pushbuttons, key switches, etc. The IDC supports ANSI/NFPA 72 Class B Style B supervised input circuits. Each circuit uses its own end of line (EOL) resistor for monitoring circuit continuity. The specifications contained within this document subject to change without notice. The output of the IDC is a status message that is sent along the communication loop to the controller. System response to the message is determined at the time of configuration. The IDC supports ANSI/NFPA 72 Class A, Style 7 communication with the controller. The IDC logs time, date, and circuit number each time one of its input circuits is activated. Data for the last eight events is stored in non-volatile memory. The amber LED is provided for factory diagnostic purposes and is not used by the customer. Illumination of the amber LED normally indicates a failure in the communication chip. Replacement of the communication module circuit board is required. STATUS LEDS ADDRESSABILITY Three LEDs are located at the center of the communication module circuit board and are visible through the window on the cover. Device identification is accomplished by setting switches on an eight position DIP switch (valid address range is 5 to 250). The green LED serves as a power-on indicator and is the only LED illuminated during normal operation (no faults or alarms occurring). ENCLOSURE RED BY UL AN D STE B GI SI RE ALARM LOG S 230 RM TERMINAL WIRING BOARD FI E RE D F T E ED R 82 6 .A I I R EG ST O REG N IR M ISO 9001 The red LED is used to indicate an alarm or fault condition. The flashing rate of the red LED indicates the following conditions: The explosion-proof, water-tight NEMA/Type 4X enclosure is designed for use in a variety of hazardous locations. 5 • N O. 25 On steady = Blinking = one of the inputs is active fault condition such as an open input circuit or not configured. All external wiring is connected to screw terminal connectors on the terminal wiring board located inside the junction box. Detector Electronics Corporation 6901 West 110th Street • Minneapolis, Minnesota 55438 • Operator (952) 941-5665 or (800) 765-FIRE Customer Service (952) 946-6491 • Fax (952) 829-8750 • www.det-tronics.com • E-mail: [email protected] 2.2 ©Detector Electronics Corporation 2003 8/06 90-1121 INSTALLATION NOTE For complete instructions regarding wiring and installation, refer to manual number 95-8533 for Eagle Quantum Premier systems or manual number 95-8470 for Eagle Quantum systems. 11 14 10 13 8 7 2 3 4 5 6 WARNING The hazardous area must be de-classified prior to removing a junction box cover with power applied. Special Conditions for Safe Use (X): The device has an ambient temperature rating for performance of –40°C to +75°C. 1. Remove the cover from the junction box. SHIPPING WEIGHT— Aluminum: 6 pounds (2.7 kilograms). Stainless Steel: 10 pounds (4.5 kilograms). 2. Remove the communication module from the junction box. Connect external system wiring to the appropriate terminals on the terminal block inside the junction box. See Figure 2 for terminal block location and Figure 3 for terminal identification. The input to the IDC consists of one or more normally open switches (momentary pushbuttons are not recommended), with a 10K ohm, 1/4 watt EOL resistor in parallel across the last switch. An EOL resistor must be installed on both IDC inputs (including unused inputs). Wiring impedance must not exceed 500 ohms. SPECIFICATIONS INPUT VOLTAGE— 24 vdc nominal, 18 to 30 vdc. Overvoltage of 10% (33 vdc) will not cause damage to the equipment. 0.28 (0.71) POWER REQUIREMENTS— 4.0 watts maximum. 4.7 (11.8) 3.4 (8.6) INPUTS— Two supervised digital inputs (switch or relay contacts). A 10 kohm EOL resistor is required for each input. A1870 Figure 2—IDC Terminal Wiring Board Mounted in Six-Port Junction Box IDC 5.2 (13.2) TEMPERATURE RANGE— Operating: –40°F to +167°F (–40°C to +75°C) Storage: –67°F to +185°F (–55°C to +85°C). 2.7 (6.8) 2 + 3 – 4 A 5 B 6 EOL (10K) EOL (10K) COM 2 DIMENSIONS— See Figure 1. B2045 Figure 1—Dimensions of IDC in Inches (Centimeters) (Six Port Model Shown) 90-1121 – 8 13 – A 9 12 + B 10 11 + 24 VDC COM 1 A1871 Figure 3—Terminal Configuration for Initiating Device Circuit 6. Inspect the junction box O-ring to be sure that it is in good condition and properly installed. Lubricate the O-ring and the threads of the junction box cover with a thin coat of an appropriate grease to ease installation and ensure a watertight enclosure. The recommended lubricant is a silicone free grease, available from Det-Tronics. Place the cover on the junction box. Tighten only until snug. Do not over tighten. 2.2 14 1 2 3 4 5 6 7 8 OPEN BINARY VALUE 1 2 4 8 16 32 64 128 1 2 3 4 OPEN } 1.28 (3.25) 7 COM SHIELDS 5. Install the communication module inside the junction box. Be sure that the keyed ribbon cable is properly connected. 6.6 (16.8) 2 – CIRCUIT 2 4. Set the node address for the device. Each device on the LON/SLC must be assigned a unique address. This is accomplished by setting DIP switches on the module’s circuit board. See Figure 4. Each rocker switch has a specific binary value. The node address is equal to the added value of all closed rocker switches. All open switches are ignored. The valid address range is from 5 to 250. Refer to the Eagle Quantum system manual (form 95-8470) for additional information. HUMIDITY RANGE— 5 to 95% RH, non-condensing. CERTIFICATION — FM / CSA: Class I, Div. 1, Groups B, C, D. Class I, Zone 1, Group IIC. Class II/III, Div. 1, Groups E, F, G. Class I, Div. 2, Groups A, B, C, D (T4A). Class I, Zone 2, Group IIC (T4). Class II/III, Div. 2, Groups F & G (T4A). NEMA/Type 4X. 1 3. Check the wiring to ensure proper connections. 0.32 (0.81) OVAL SLOT MOUNTING (TYPICAL FOUR PLACES) VIBRATION— Meets MIL SPEC 810C, method 514.2, curve AW. + MANUAL PULL STATION OR OTHER CONTACT DEVICE CIRCUIT 1 IMPORTANT Insulate the shields to prevent shorting to the device housing or to any other conductor. OUTPUTS— Digital communication, transformer isolated (78.5 kbps). 2.2 GND 12 • Two Class B Style B supervised digital inputs. • Field addressable. • Unique patented fault isolation. • Non-volatile memory for configuration and alarm logs. • Utilizes state-of-the-art communication technology. • Pass through communication circuitry on power loss. • EMI hardened. • FMR, CSA, CENELEC and CE Mark Certifications. • FMR performance verified per ANSI/NFPA 72-1996. • Compatible with Eagle Quantum Premier and Eagle Quantum systems. 9 CENELEC/CE: ATEX/EMC Directive Compliant. 0539 II 2 G EEx d IIC T4-T6 DEMKO 02 ATEX 131321X T6 (Tamb = –55°C to +50°C). T5 (Tamb = –55°C to +65°C). T4 (Tamb = –55°C to +75°C). IP66. 1 FEATURES LEAVE IN OPEN POSITION NODE ADDRESS EQUALS THE ADDED VALUE OF ALL CLOSED ROCKER SWITCHES OPEN = OFF CLOSED = ON A1557 Figure 4—Field Device Address Switches 3 90-1121 INSTALLATION NOTE For complete instructions regarding wiring and installation, refer to manual number 95-8533 for Eagle Quantum Premier systems or manual number 95-8470 for Eagle Quantum systems. 11 14 10 13 8 7 2 3 4 5 6 WARNING The hazardous area must be de-classified prior to removing a junction box cover with power applied. Special Conditions for Safe Use (X): The device has an ambient temperature rating for performance of –40°C to +75°C. 1. Remove the cover from the junction box. SHIPPING WEIGHT— Aluminum: 6 pounds (2.7 kilograms). Stainless Steel: 10 pounds (4.5 kilograms). 2. Remove the communication module from the junction box. Connect external system wiring to the appropriate terminals on the terminal block inside the junction box. See Figure 2 for terminal block location and Figure 3 for terminal identification. The input to the IDC consists of one or more normally open switches (momentary pushbuttons are not recommended), with a 10K ohm, 1/4 watt EOL resistor in parallel across the last switch. An EOL resistor must be installed on both IDC inputs (including unused inputs). Wiring impedance must not exceed 500 ohms. SPECIFICATIONS INPUT VOLTAGE— 24 vdc nominal, 18 to 30 vdc. Overvoltage of 10% (33 vdc) will not cause damage to the equipment. 0.28 (0.71) POWER REQUIREMENTS— 4.0 watts maximum. 4.7 (11.8) 3.4 (8.6) INPUTS— Two supervised digital inputs (switch or relay contacts). A 10 kohm EOL resistor is required for each input. A1870 Figure 2—IDC Terminal Wiring Board Mounted in Six-Port Junction Box IDC 5.2 (13.2) TEMPERATURE RANGE— Operating: –40°F to +167°F (–40°C to +75°C) Storage: –67°F to +185°F (–55°C to +85°C). 2.7 (6.8) 2 + 3 – 4 A 5 B 6 EOL (10K) EOL (10K) COM 2 DIMENSIONS— See Figure 1. B2045 Figure 1—Dimensions of IDC in Inches (Centimeters) (Six Port Model Shown) 90-1121 – 8 13 – A 9 12 + B 10 11 + 24 VDC COM 1 A1871 Figure 3—Terminal Configuration for Initiating Device Circuit 6. Inspect the junction box O-ring to be sure that it is in good condition and properly installed. Lubricate the O-ring and the threads of the junction box cover with a thin coat of an appropriate grease to ease installation and ensure a watertight enclosure. The recommended lubricant is a silicone free grease, available from Det-Tronics. Place the cover on the junction box. Tighten only until snug. Do not over tighten. 2.2 14 1 2 3 4 5 6 7 8 OPEN BINARY VALUE 1 2 4 8 16 32 64 128 1 2 3 4 OPEN } 1.28 (3.25) 7 COM SHIELDS 5. Install the communication module inside the junction box. Be sure that the keyed ribbon cable is properly connected. 6.6 (16.8) 2 – CIRCUIT 2 4. Set the node address for the device. Each device on the LON/SLC must be assigned a unique address. This is accomplished by setting DIP switches on the module’s circuit board. See Figure 4. Each rocker switch has a specific binary value. The node address is equal to the added value of all closed rocker switches. All open switches are ignored. The valid address range is from 5 to 250. Refer to the Eagle Quantum system manual (form 95-8470) for additional information. HUMIDITY RANGE— 5 to 95% RH, non-condensing. CERTIFICATION — FM / CSA: Class I, Div. 1, Groups B, C, D. Class I, Zone 1, Group IIC. Class II/III, Div. 1, Groups E, F, G. Class I, Div. 2, Groups A, B, C, D (T4A). Class I, Zone 2, Group IIC (T4). Class II/III, Div. 2, Groups F & G (T4A). NEMA/Type 4X. 1 3. Check the wiring to ensure proper connections. 0.32 (0.81) OVAL SLOT MOUNTING (TYPICAL FOUR PLACES) VIBRATION— Meets MIL SPEC 810C, method 514.2, curve AW. + MANUAL PULL STATION OR OTHER CONTACT DEVICE CIRCUIT 1 IMPORTANT Insulate the shields to prevent shorting to the device housing or to any other conductor. OUTPUTS— Digital communication, transformer isolated (78.5 kbps). 2.2 GND 12 • Two Class B Style B supervised digital inputs. • Field addressable. • Unique patented fault isolation. • Non-volatile memory for configuration and alarm logs. • Utilizes state-of-the-art communication technology. • Pass through communication circuitry on power loss. • EMI hardened. • FMR, CSA, CENELEC and CE Mark Certifications. • FMR performance verified per ANSI/NFPA 72-1996. • Compatible with Eagle Quantum Premier and Eagle Quantum systems. 9 CENELEC/CE: ATEX/EMC Directive Compliant. 0539 II 2 G EEx d IIC T4-T6 DEMKO 02 ATEX 131321X T6 (Tamb = –55°C to +50°C). T5 (Tamb = –55°C to +65°C). T4 (Tamb = –55°C to +75°C). IP66. 1 FEATURES LEAVE IN OPEN POSITION NODE ADDRESS EQUALS THE ADDED VALUE OF ALL CLOSED ROCKER SWITCHES OPEN = OFF CLOSED = ON A1557 Figure 4—Field Device Address Switches 3 90-1121 ORDERING INFORMATION SPECIFICATION DATA When ordering, please specify: Eagle Quantum™ Premier EQ2200IDC Initiating Device Circuit Initiating Device Circuit Specify: Enclosure material — Aluminum or stainless steel Number of ports — 5 or 6 Port size — 3/4 inch NPT or 25 mm Certification — FM/CSA/CENELEC/CE. EQ2200IDC For additional information or for assistance in designing a system to meet the needs of a specific application, please contact: Detector Electronics Corporation 6901 West 110th Street Minneapolis, Minnesota 55438 USA Operator: (952) 941-5665 or (800) 765-FIRE Customer Service: (952) 946-6491 Fax: (952) 829-8750 Web site: www.detronics.com E-mail: [email protected] DESCRIPTION Functioning as part of the fire detection portion of the safety system, the EQ2200IDC Initiating Device Circuit (IDC) provides two supervised digital inputs for use with dry contact inputs from devices such as relays, pushbuttons, key switches, etc. The IDC supports ANSI/NFPA 72 Class B Style B supervised input circuits. Each circuit uses its own end of line (EOL) resistor for monitoring circuit continuity. The specifications contained within this document subject to change without notice. The output of the IDC is a status message that is sent along the communication loop to the controller. System response to the message is determined at the time of configuration. The IDC supports ANSI/NFPA 72 Class A, Style 7 communication with the controller. The IDC logs time, date, and circuit number each time one of its input circuits is activated. Data for the last eight events is stored in non-volatile memory. The amber LED is provided for factory diagnostic purposes and is not used by the customer. Illumination of the amber LED normally indicates a failure in the communication chip. Replacement of the communication module circuit board is required. STATUS LEDS ADDRESSABILITY Three LEDs are located at the center of the communication module circuit board and are visible through the window on the cover. Device identification is accomplished by setting switches on an eight position DIP switch (valid address range is 5 to 250). The green LED serves as a power-on indicator and is the only LED illuminated during normal operation (no faults or alarms occurring). ENCLOSURE RED BY UL AN D STE B GI SI RE ALARM LOG S 230 RM TERMINAL WIRING BOARD FI E RE D F T E ED R 82 6 .A I I R EG ST O REG N IR M ISO 9001 The red LED is used to indicate an alarm or fault condition. The flashing rate of the red LED indicates the following conditions: The explosion-proof, water-tight NEMA/Type 4X enclosure is designed for use in a variety of hazardous locations. 5 • N O. 25 On steady = Blinking = one of the inputs is active fault condition such as an open input circuit or not configured. All external wiring is connected to screw terminal connectors on the terminal wiring board located inside the junction box. Detector Electronics Corporation 6901 West 110th Street • Minneapolis, Minnesota 55438 • Operator (952) 941-5665 or (800) 765-FIRE Customer Service (952) 946-6491 • Fax (952) 829-8750 • www.det-tronics.com • E-mail: [email protected] 2.2 ©Detector Electronics Corporation 2003 8/06 90-1121