* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Required Output per Foot (Meter)

Ground loop (electricity) wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Solar micro-inverter wikipedia , lookup

History of electric power transmission wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Voltage optimisation wikipedia , lookup

Buck converter wikipedia , lookup

Electrical substation wikipedia , lookup

Mains electricity wikipedia , lookup

Fault tolerance wikipedia , lookup

Telecommunications engineering wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Control system wikipedia , lookup

Power over Ethernet wikipedia , lookup

Rectiverter wikipedia , lookup

Loading coil wikipedia , lookup

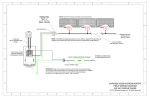

Tr o ub le sh o o t in g Gu id el in es ® PRECISION HEAT AND CONTROL Chromalox email: [email protected] www.chromalox.com Phone: (412) 967-3800 Fax: (412) 967-5148 Toll-Free: 800-443-2640 103 Gamma Drive Pittsburgh, PA 15238 USA PRECISION HEAT AND CONTROL Chromalox PJ134 Copyright © 2002-2005, 2010, Chromalox, Inc. All rights reserved. Frost Heave Prevention Design Guide Heating cable is drawing proper current but the floor is heaving. Possible Causes: Improper voltage, wrong cable, wrong design specs, improper control placement. Problem: Heating cable is energized but not drawing full current. Possible Causes: Wrong voltage, damaged cable (cold zones). Problem: Subfloor temperatures are above normal. Possible Causes: Thermostat contacts stuck closed, thermostat out of calibration, improper bulb mounting, mixed control placement. Problem: When the circuit breaker is turned ON, the breaker trips instantaneously. Possible Causes: There is a dead short in the system. To diagnose where the problem is, disconnect the power supply wires from the heating cable at the power connection box. Attach one lead of a megaohm device to one bus wire and the other lead to the ground braid. Problem: Heating cable does not operate. Possible Causes: Defective circuit breaker, open circuit, undersized distribution wiring, short circuit. A Application Guidelines _________ _________ _________ _________ 6.0 (1.8) Conduit Spacing, ft (m) 4.0 (1.2) 8.0 (2.4) Required Output per Foot (Meter) R 20 Insulation 2.0 (0.6) 6.0 (1.8) 8.0 (2.4) Required Output per Foot (Meter) R 30 Insulation 4.0 (1.2) -20ºF (-29ºC) -10ºF (-23ºC) -0ºF (-17ºC) 10ºF (-12ºC) 10.0 (3.0) -20ºF (-29ºC) -10ºF (-23ºC) -0ºF (-17ºC) 10.0 (3.0) 10ºF (-12ºC) CWM8-1CT CWM4-2CT CWM4-1CT 8 (2.4) 8 (2.4) 4 (1.2) 4 (1.2) 240 120 240 120 0.033 (0.010) 0.067 (0.020) 0.017 (0.005) 0.033 (0.010) 480 (146.3) 240 (73.2) 700 (213.4) 350 (106.7) Concrete Insulation Sand Soil Contact a Chromalox applications engineer for assistance with heat trace panel specifications. For larger loads, both of the above can serve as pilot duty to drive a remote device. For example, the THR thermostat can be used to energize the main contactor coil in the WeatherTrace FPAS panel. 2. Electronic control with RTD sensor (CMS). Provides a 20 Amp relay to 240 Vac. Optional alarm output for low-temperature condition. Straightforward, easy setup and operation. Switch-selectable output includes on/off or PI control. Sensor should be placed in conduit centered between heat tracing conduits. See Freezer Floor Frost Heave Prevention Circuit Layout Options under C, Installation Details. 1. Mechanical thermostatic control (ON/OFF, THR). Heating cable system turns on and off based on sub-floor temperature. Switches up to 22 Amps. Sensor should be placed in conduit centered between heat tracing conduits. See Freezer Floor Frost Heave Prevention Circuit Layout Options under C, Installation Details. C o n t r o l Op t i o n s There are two basic ways to control the frost heave prevention system: L ay o u t C o n s i d er a t i o n s • Only one run of heating cable is permitted per conduit • Layout should be arranged to uniformly cover the area to be heated • Do not cross expansion joints, crack control joints, etc. • Do not place conduit closer than 4 inches (10 centimeters) to the edge of the sub-floor, drains, or other obstructions • When the total length of two or more circuits is less than the maximum circuit length of the circuit breaker size used, the circuits may be wired in parallel En d a n d C o m p o n en t A l l o w a n c es End allowance is typically 4 feet (1.2 meters) per end (length of cable in conduit between floor and junction box). Component allowance should be 2 feet (0.6 meters) per end and is the length of the cable inside the junction box. Optionally, the heating cable may be run between junction boxes. In this case, the end and component allowance would be the center-tocenter distance between conduits. M a x i m u m C i r c u i t Len g t h Typically, heating cable layout is a straight-run design. Cable is run the length of the longest side of the freezer unless this exceeds the maximum circuit length for that cable wattage and voltage. See the CWM Cable Specifications table for maximum footage lengths. Area of floor to be heated (ft/m) Conduit spacing (ft/m) + End Allowances (ft/m) + Component allowances (ft/m) 4. Estimate the length of cable required for your layout: Circuit Length and Control Scheme When water in soil underneath freezers and cold rooms freezes an icy mass can develop that can cause the floor to heave. Installing Chromalox CWM cable in the sub-floor under the freezer floor insulation (see the accompanying illustration) can prevent frost heave by maintaining the temperature of the ground above freezing. The sub-floor may be concrete or compacted sand. Typically, the cable is installed in conduit for ease of repair or retrofit. The conduit is spaced 2 to 8 feet (0.6 to 2.4 meters) apart, depending on the ambient temperature of the freezer and the R-value of the insulation. However, 6-foot (1.8-meter) spacing can be used for freezer temperatures of 0°F (-18°C) and above. B Minimum freezer temperature Insulation R value Conduit spacing Voltage supply -10°F (-23ºC) _________ R-20 _________ 4 ft (1.2 m) _________ 240V _________ 1. To begin designing your frost heave prevention system, determine the following information: Example: Minimum freezer temperature Insulation R value Conduit spacing Voltage supply 25.0 (7.5) 20.0 (6.0) 15.0 (4.5) 10.0 (3.0) 5.0 (1.5) 25.0 (7.5) 20.0 (6.0) 15.0 (4.5) 10.0 (3.0) 5.0 (1.5) 2.0 (0.6) Conduit Spacing, ft (m) Consult the CWM Cable Specifications table for the CWM cable available and the typical power output for this application. Example: CWM8-2CT with a power output of 8 W/ft (2.4 W/m) at 240V should be used. CWM8-2CT CWM Cable Specifications Model Output Output Voltage Circuit Load Max Circuit W/ft (W/m) (Vac) Amp/ft (Amp/m) Length, ft (m) 3. Example: Based on the above design information, the required cable output is 5.1 W/ft (1.6 W/m). 2. Determine the required power output per foot of cable using the graphs below. The graphs show required power output for R values of 20 and 30. Cable Power Required, W/ft (W/m) Cable Power Required, W/ft (W/m) ® Problem: FROST HEAVE PREVENTION A Application Guidelines B Minimum freezer temperature Insulation R value Conduit spacing Voltage supply _________ _________ _________ _________ Sand Soil Example: Minimum freezer temperature Insulation R value Conduit spacing Voltage supply -10°F (-23ºC) _________ R-20 _________ 4 ft (1.2 m) _________ 240V _________ 4. Estimate the length of cable required for your layout: M a x i m u m C i r c u i t Len g t h Typically, heating cable layout is a straight-run design. Cable is run the length of the longest side of the freezer unless this exceeds the maximum circuit length for that cable wattage and voltage. See the CWM Cable Specifications table for maximum footage lengths. En d a n d C o m p o n en t A l l o w a n c es End allowance is typically 4 feet (1.2 meters) per end (length of cable in conduit between floor and junction box). Component allowance should be 2 feet (0.6 meters) per end and is the length of the cable inside the junction box. Optionally, the heating cable may be run between junction boxes. In this case, the end and component allowance would be the center-tocenter distance between conduits. Example: Based on the above design information, the required cable output is 5.1 W/ft (1.6 W/m). Required Output per Foot (Meter) R 20 Insulation Cable Power Required, W/ft (W/m) Insulation Area of floor to be heated (ft/m) Conduit spacing (ft/m) + End Allowances (ft/m) + Component allowances (ft/m) 2. Determine the required power output per foot of cable using the graphs below. The graphs show required power output for R values of 20 and 30. 25.0 (7.5) 20.0 (6.0) -20ºF (-29ºC) -10ºF (-23ºC) 15.0 (4.5) -0ºF (-17ºC) 10ºF (-12ºC) 10.0 (3.0) L ay o u t C o n s i d er a t i o n s • Only one run of heating cable is permitted per conduit • Layout should be arranged to uniformly cover the area to be heated • Do not cross expansion joints, crack control joints, etc. • Do not place conduit closer than 4 inches (10 centimeters) to the edge of the sub-floor, drains, or other obstructions • When the total length of two or more circuits is less than the maximum circuit length of the circuit breaker size used, the circuits may be wired in parallel C o n t r o l Op t i o n s There are two basic ways to control the frost heave prevention system: 5.0 (1.5) 2.0 (0.6) 4.0 (1.2) 6.0 (1.8) 8.0 (2.4) 10.0 (3.0) Conduit Spacing, ft (m) Required Output per Foot (Meter) R 30 Insulation 25.0 (7.5) 20.0 (6.0) -20ºF (-29ºC) -10ºF (-23ºC) 15.0 (4.5) -0ºF (-17ºC) 10ºF (-12ºC) 10.0 (3.0) 5.0 (1.5) 2.0 (0.6) 4.0 (1.2) 6.0 (1.8) 8.0 (2.4) 10.0 (3.0) Conduit Spacing, ft (m) 3. Concrete Circuit Length and Control Scheme 1. To begin designing your frost heave prevention system, determine the following information: Cable Power Required, W/ft (W/m) FROST HEAVE PREVENTION Copyright © 2002-2005, 2010, Chromalox, Inc. All rights reserved. email: [email protected] www.chromalox.com 103 Gamma Drive Pittsburgh, PA 15238 USA PRECISION HEAT AND CONTROL Chromalox Possible Causes: Problem: Possible Causes: Problem: Possible Causes: Problem: Possible Causes: Problem: Possible Causes: ® Phone: (412) 967-3800 Fax: (412) 967-5148 Toll-Free: 800-443-2640 Defective circuit breaker, open circuit, undersized distribution wiring, short circuit. Heating cable does not operate. There is a dead short in the system. To diagnose where the problem is, disconnect the power supply wires from the heating cable at the power connection box. Attach one lead of a megaohm device to one bus wire and the other lead to the ground braid. When the circuit breaker is turned ON, the breaker trips instantaneously. Thermostat contacts stuck closed, thermostat out of calibration, improper bulb mounting, mixed control placement. Subfloor temperatures are above normal. Wrong voltage, damaged cable (cold zones). Heating cable is energized but not drawing full current. Improper voltage, wrong cable, wrong design specs, improper control placement. Heating cable is drawing proper current but the floor is heaving. Problem: Tr o ub le sh o o t in g Gu id el in es PJ134 Frost Heave Prevention Design Guide PRECISION HEAT AND CONTROL Chromalox ® When water in soil underneath freezers and cold rooms freezes an icy mass can develop that can cause the floor to heave. Installing Chromalox CWM cable in the sub-floor under the freezer floor insulation (see the accompanying illustration) can prevent frost heave by maintaining the temperature of the ground above freezing. The sub-floor may be concrete or compacted sand. Typically, the cable is installed in conduit for ease of repair or retrofit. The conduit is spaced 2 to 8 feet (0.6 to 2.4 meters) apart, depending on the ambient temperature of the freezer and the R-value of the insulation. However, 6-foot (1.8-meter) spacing can be used for freezer temperatures of 0°F (-18°C) and above. Consult the CWM Cable Specifications table for the CWM cable available and the typical power output for this application. Example: CWM8-2CT with a power output of 8 W/ft (2.4 W/m) at 240V should be used. CWM Cable Specifications Model Output Output Voltage Circuit Load Max Circuit W/ft (W/m) (Vac) Amp/ft (Amp/m) Length, ft (m) CWM4-1CT 4 (1.2) 120 0.033 (0.010) 350 (106.7) CWM4-2CT 4 (1.2) 240 0.017 (0.005) 700 (213.4) CWM8-1CT 8 (2.4) 120 0.067 (0.020) 240 (73.2) CWM8-2CT 8 (2.4) 240 0.033 (0.010) 480 (146.3) 1. Mechanical thermostatic control (ON/OFF, THR). Heating cable system turns on and off based on sub-floor temperature. Switches up to 22 Amps. Sensor should be placed in conduit centered between heat tracing conduits. See Freezer Floor Frost Heave Prevention Circuit Layout Options under C, Installation Details. 2. Electronic control with RTD sensor (CMS). Provides a 20 Amp relay to 240 Vac. Optional alarm output for low-temperature condition. Straightforward, easy setup and operation. Switch-selectable output includes on/off or PI control. Sensor should be placed in conduit centered between heat tracing conduits. See Freezer Floor Frost Heave Prevention Circuit Layout Options under C, Installation Details. For larger loads, both of the above can serve as pilot duty to drive a remote device. For example, the THR thermostat can be used to energize the main contactor coil in the WeatherTrace FPAS panel. Contact a Chromalox applications engineer for assistance with heat trace panel specifications. Controls & Accessories FPAS Freeze Protection Heat Trace Panel PJB Rain-Tight Junction Box FPAS freeze protection heat trace panels offer power-distribution, ground-fault protection, individual circuit-alarming, and ambient-sensing control for groups of heat trace circuits with an external controller/thermostat. The panels are standard NEMA 4 enclosures for indoor or outdoor applications. NEMA 4X 304 stainless steel enclosures are available for harsh environments. Watertight polycarbonate enclosure for use with the SSK junction box connection kit. SSK Junction Box Connection Kit A complete kit with everything necessary to connect CWM cable to customer-supplied wiring, including: • Compression fitting (1) • Tube of RTV sealant (1) • 1-inch (25-millimeter) locknut (1) • Silicone boot (1) • O-ring (1) • Pipe standoff (1) • Uninsulated barrel connectors (2) • Self-regulating cable grommet (1) • Constant-wattage cable grommet (1) • Insulated barrel connectors (2) The 3⁄4-inch (19-millimeter) conduit connection fitting will connect the conduit containing the heating cable to a customersupplied junction box or Chromalox PJB rain-tight junction box. Line-Sensing Thermostat THR The THR remote-mount thermostat employs a stainless steel bulb and capillary design to accurately sense temperature at key points along the heating cable. The NEMA 4X enclosure is epoxy coated to seal from moisture and contaminants. Switch output is one SPDT with a 22-amp electrical rating. The bulb is 115⁄8 inches (29.5 centimeters) long with a 1⁄8-inch (0.3-centimeter) outside diameter. F r ee z e r Fl o o r F r o s t H ea v e P r ev e n t i o n Cr o s s S e c t i o n Floor Insulation Subfloor Floor Insulation Soil Subfloor Fr e ez e r F l o o r Fr o s t H e a v e P r e v en t i o n C i r c u i t L a y o u t O p t i o n s Power Connection End of Circuit Power Connection End of Circuit Sensor in Conduit Sensor in Conduit Heating Cable Conduits – 1 inch (25.4 millimeters) Hairpin Layout Heating Cable Conduits – 1 inch (25.4 millimeters) Hairpin Layout I m p o r t a n t S a fe g u a r d s • Inspect all junction box, connection box, and sensor connections • Verify all circuits have been properly grounded • Verify all circuits are connected to proper panel locations • Verify proper circuit breakers are in place (always use 30mA trip GFI type breakers) • Verify all proper safety warnings are in place • Always use ground fault circuit breakers (30mA trip level) El ec t r ic a l Tes t s • Insulation resistance (Megger) Before pulling cable After pulling cable After installing terminations Before energizing system • Circuit voltage • Initial current I n s t a ll a t i o n Tip s To o ls Need ed • Wire cutters • Megger • Phillips head screwdriver • Standard screwdriver • Voltmeter • Do not twist buss wires together at end of circuit • Insulate all conductive parts • Seal all electrical connections against moisture • Seal ends of exposed cable during installation Tr o ub le sh o o t in g Gu id el in es ® PRECISION HEAT AND CONTROL Chromalox email: [email protected] www.chromalox.com Phone: (412) 967-3800 Fax: (412) 967-5148 Toll-Free: 800-443-2640 103 Gamma Drive Pittsburgh, PA 15238 USA PRECISION HEAT AND CONTROL Chromalox PJ134 Copyright © 2002-2005, 2010, Chromalox, Inc. All rights reserved. Frost Heave Prevention Design Guide Heating cable is drawing proper current but the floor is heaving. Possible Causes: Improper voltage, wrong cable, wrong design specs, improper control placement. Problem: Heating cable is energized but not drawing full current. Possible Causes: Wrong voltage, damaged cable (cold zones). Problem: Subfloor temperatures are above normal. Possible Causes: Thermostat contacts stuck closed, thermostat out of calibration, improper bulb mounting, mixed control placement. Problem: When the circuit breaker is turned ON, the breaker trips instantaneously. Possible Causes: There is a dead short in the system. To diagnose where the problem is, disconnect the power supply wires from the heating cable at the power connection box. Attach one lead of a megaohm device to one bus wire and the other lead to the ground braid. Problem: Heating cable does not operate. Possible Causes: Defective circuit breaker, open circuit, undersized distribution wiring, short circuit. A Application Guidelines _________ _________ _________ _________ 6.0 (1.8) Conduit Spacing, ft (m) 4.0 (1.2) 8.0 (2.4) Required Output per Foot (Meter) R 20 Insulation 2.0 (0.6) 6.0 (1.8) 8.0 (2.4) Required Output per Foot (Meter) R 30 Insulation 4.0 (1.2) -20ºF (-29ºC) -10ºF (-23ºC) -0ºF (-17ºC) 10ºF (-12ºC) 10.0 (3.0) -20ºF (-29ºC) -10ºF (-23ºC) -0ºF (-17ºC) 10.0 (3.0) 10ºF (-12ºC) CWM8-1CT CWM4-2CT CWM4-1CT 8 (2.4) 8 (2.4) 4 (1.2) 4 (1.2) 240 120 240 120 0.033 (0.010) 0.067 (0.020) 0.017 (0.005) 0.033 (0.010) 480 (146.3) 240 (73.2) 700 (213.4) 350 (106.7) Concrete Insulation Sand Soil Contact a Chromalox applications engineer for assistance with heat trace panel specifications. For larger loads, both of the above can serve as pilot duty to drive a remote device. For example, the THR thermostat can be used to energize the main contactor coil in the WeatherTrace FPAS panel. 2. Electronic control with RTD sensor (CMS). Provides a 20 Amp relay to 240 Vac. Optional alarm output for low-temperature condition. Straightforward, easy setup and operation. Switch-selectable output includes on/off or PI control. Sensor should be placed in conduit centered between heat tracing conduits. See Freezer Floor Frost Heave Prevention Circuit Layout Options under C, Installation Details. 1. Mechanical thermostatic control (ON/OFF, THR). Heating cable system turns on and off based on sub-floor temperature. Switches up to 22 Amps. Sensor should be placed in conduit centered between heat tracing conduits. See Freezer Floor Frost Heave Prevention Circuit Layout Options under C, Installation Details. C o n t r o l Op t i o n s There are two basic ways to control the frost heave prevention system: L ay o u t C o n s i d er a t i o n s • Only one run of heating cable is permitted per conduit • Layout should be arranged to uniformly cover the area to be heated • Do not cross expansion joints, crack control joints, etc. • Do not place conduit closer than 4 inches (10 centimeters) to the edge of the sub-floor, drains, or other obstructions • When the total length of two or more circuits is less than the maximum circuit length of the circuit breaker size used, the circuits may be wired in parallel En d a n d C o m p o n en t A l l o w a n c es End allowance is typically 4 feet (1.2 meters) per end (length of cable in conduit between floor and junction box). Component allowance should be 2 feet (0.6 meters) per end and is the length of the cable inside the junction box. Optionally, the heating cable may be run between junction boxes. In this case, the end and component allowance would be the center-tocenter distance between conduits. M a x i m u m C i r c u i t Len g t h Typically, heating cable layout is a straight-run design. Cable is run the length of the longest side of the freezer unless this exceeds the maximum circuit length for that cable wattage and voltage. See the CWM Cable Specifications table for maximum footage lengths. Area of floor to be heated (ft/m) Conduit spacing (ft/m) + End Allowances (ft/m) + Component allowances (ft/m) 4. Estimate the length of cable required for your layout: Circuit Length and Control Scheme When water in soil underneath freezers and cold rooms freezes an icy mass can develop that can cause the floor to heave. Installing Chromalox CWM cable in the sub-floor under the freezer floor insulation (see the accompanying illustration) can prevent frost heave by maintaining the temperature of the ground above freezing. The sub-floor may be concrete or compacted sand. Typically, the cable is installed in conduit for ease of repair or retrofit. The conduit is spaced 2 to 8 feet (0.6 to 2.4 meters) apart, depending on the ambient temperature of the freezer and the R-value of the insulation. However, 6-foot (1.8-meter) spacing can be used for freezer temperatures of 0°F (-18°C) and above. B Minimum freezer temperature Insulation R value Conduit spacing Voltage supply -10°F (-23ºC) _________ R-20 _________ 4 ft (1.2 m) _________ 240V _________ 1. To begin designing your frost heave prevention system, determine the following information: Example: Minimum freezer temperature Insulation R value Conduit spacing Voltage supply 25.0 (7.5) 20.0 (6.0) 15.0 (4.5) 10.0 (3.0) 5.0 (1.5) 25.0 (7.5) 20.0 (6.0) 15.0 (4.5) 10.0 (3.0) 5.0 (1.5) 2.0 (0.6) Conduit Spacing, ft (m) Consult the CWM Cable Specifications table for the CWM cable available and the typical power output for this application. Example: CWM8-2CT with a power output of 8 W/ft (2.4 W/m) at 240V should be used. CWM8-2CT CWM Cable Specifications Model Output Output Voltage Circuit Load Max Circuit W/ft (W/m) (Vac) Amp/ft (Amp/m) Length, ft (m) 3. Example: Based on the above design information, the required cable output is 5.1 W/ft (1.6 W/m). 2. Determine the required power output per foot of cable using the graphs below. The graphs show required power output for R values of 20 and 30. Cable Power Required, W/ft (W/m) Cable Power Required, W/ft (W/m) ® Problem: FROST HEAVE PREVENTION