* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download PNIMNiPE_nr56

Survey

Document related concepts

Transcript

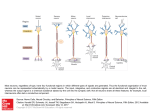

Nr 62 Prace Naukowe Instytutu Maszyn, Napędów i Pomiarów Elektrycznych Politechniki Wrocławskiej Nr 62 Studia i Materiały Nr 28 2008 synchronous machine, faulty states detection, neural network, spectral analysis. Zygfryd GŁOWACZ*, Jarosław KOZIK* FAULTY STATES DETECTION OF SYNCHRONOUS MOTOR USING NEURAL NETWORK Electrical machines, similarly to the other electrical and mechanical devices are constantly exposed to both external and internal influences which cause the changes to their physical state and functionality [1]. These gradually developing irreversible changes worsen the efficiency of the machine and thus the industrial process it is the part of and finally can lead to complete damage to the machine and very expensive breaks. To minimize these adverse effects the state of the machine should be periodically checked allowing the maintenance works to be done before the fault develops. Rapid development of a digital measurement techniques in the last decades created new possibilities of machines condition diagnostics, which do not require any disintegration to the machine, and can be undertaken even without stopping the process. These new methods include: spectral analysis of currents, axis flux, vibration and sound analysis, thermal pattern recognition. The conclusions are usually done by experts, but recently the growing importance acquire the automatic methods of detection employing an artificial intelligence [2]. This paper describes an automatic recognition of synchronous motor faults based on spectral analysis of stator and field currents with the aid of neural network. 1. DIAGNOSTIC OBJECT AND APPLIED MEASUREMENT METHODS As the diagnostic object a specially designed and constructed 2-pair pole synchronous machine was used. The stator of the machine consists of 48 slots with double layer windings inside (80 turns per phase). Winding pitch is 10. The rotor is of salient pole type with 4 poles and 145 turns per pole. The nominal voltage is 220 V but for the purpose of the diagnostics was lowered to 100–130 V. The field circuit was supplied from Graetz converter. The connection diagram of stator windings is presented in the figure 1. All the ends of every group of windings are accesible allowing simulation of many fault conditions to be done. For the purpose of this paper a nineteen different fault conditions were investigated. That included alone breaks of one group of __________ *AGH Univerity of Science and Technology, Krakow, al. Mickiewicza 30, e-mail: [email protected], [email protected] 467 windings for each stator phase, simultaneous breaks of one group of windings for each pair of phases and for all three phases, alone shorts of one group of windings for each stator phase and combined short and break faults. All the shorts were done with the resistor of resistance 2,5 Ω. The all eight measurement sessions were undertaken in different days. For all the simulated fault conditions phase currents and field current training sets for neural networks were produced (80 sets of data for each: training and verification, including 19 different combinations of faults and 1 healthy state recorded in 8 measurement sessions). Fig. 1. Connection diagram of a stator windings Fig. 2. The sequence of generating the training sets for the neural network The procedure that produces the training sets is as follows. The motor stator and field currents filtered with analong antialiasing filters (3 pole Butterworth filters, cutoff frequency 5 kHz) were recorded using data acquisiton card installed in a PC computer (4 channels, sampling frequency 25 kHz).The stored measurement samples were then transformed to the frequency domain using FFT function in Matlab environment. Having all the samples transformed the spectral analysis was undertaken, as a result of which the frequencies typical of particular fault were extracted. On that basis the training sets were created, consisting of amplitudes of typical frequencies for that 468 particular state and information about machine condition. The diagram of the sequence of producing the training sets is presented in the figure. 2. 2. SPECTRAL ANALYSIS OF STATOR AND FIELD CURRENTS Spectral analysis of a stator currents revealed that only frequencies of values which are a multiple of 25 Hz should be taken into account. Further analysis embraced multiples of 25 Hz ranging from 25 Hz to 1250 Hz. Because the attempts of recognition of faulty states using all of the frequencies from that extent were ineffective and led to wrong results, only these frequencies, that give a similar changes in their amplitude for every measuring sample, were further investigated. As a result of this the authors came to the conclusion that frequencies of 25 Hz and 75 Hz are increasing significantly in the case of a break in a group of windings, whereas for the other states (healthy, short-circuit fault) stay at the approximately same level. In the case of a short-circuit of a group of windings the amplitude for the frequency of 50 Hz increases, while the equivalent amplitudes in a healthy and a break fault states are at the approximately same level. The results of spectral analysis of a stator phase current with clearly visible changes in the amplitudes for three mentioned frequencies (25, 50, 75 Hz) for three different states (healthy, break fault, short-circuit fault) are presented in the figure 3. a) healthy state, Us=100 [V] a ) h e a o n e l t h y s t a t e , U s = 1 0 0 [ V ] 60 Amplitude [A] Amplitude [A] 80 40 20 0 0 10 20 b ) 30 b r e a k 40 50 60 frequency [Hz] o f o n e g r o u p o f w i n d i n g 70 80 90 , U s = 1 0 0 [ V 20 b Amplitude [A] Amplitude [A] 10 ] ) 30 b r e a k 40 o f r 50 e g q r u o e u n p c o 60 y f [ w i H z n 70 80 90 100 90 100 90 100 ] d i n g s , U s = 1 0 0 [ V ] 0.3 40 20 0 10 20 30 40 f c ) s h o r t o f o n e r g 50 e r q o u u e p n c y o f w 60 [ i H n z d 70 80 90 0.2 0.1 0 100 0 10 20 30 40 ] i n f g s , U s = 1 0 0 [ V ] c 80 ) s h o r t o f o n e r g 50 e r q o u u e p n o c f 60 y w [ i H n z d 70 80 ] i n g s , U s = 1 0 0 [ V ] 0.3 60 Amplitude [A] Amplitude [A] 0 f s 60 40 20 0 0.1 0 100 80 0 0.2 0 10 20 30 40 f r e 50 q u e n c y 60 [ H z ] 70 80 90 100 0.2 0.1 0 0 10 20 30 40 f r e 50 q u e n c y 60 [ H z 70 80 ] Fig. 3. Spectral analysis of stator phase current in healthy state (a) compared to that same phase current with break in one group of coils (b), and with short of one group of coils (c) 469 Spectral analysis of a field current shown that the amplitudes for the frequencies of 75 Hz, 125 Hz, 200 Hz and 225 Hz give the clearest distinction between the motor states. The amplitudes corresponding to 25 Hz and 75 Hz are suitable for discrimination between break fault and healthy or short-circuit states, while the amplitudes correspoding to 200 Hz and 225 Hz allow to discriminate between the healthy state and the fault condition. As a later experiments revealed, such information is sufficient to enable the network to do the correct recognitions of the motor state. 3. AUTOMATIC RECOGNITION USING NEURAL NETWORK BASED ON STATOR AND FIELD CURRENTS ANALYSIS As it was previously mentioned the recognition of all frequencies from the investigated range is ineffective and leads to inaccurate diagnoses, as the arbitrariness in the values of amplitudes for some frequencies worsen the effectiveness of the network. Thus only the frequencies which give clear and steady change for particular fault and for all the measuring samples were taken into account. These frequencies were respectively 25 Hz and 75 Hz for the break fault, and 50 Hz for the short-circuit fault. This information determines the number of inputs of the network. As the network is expected to recognize in which stator phase the fault exists, the number of input neurons is 9 (three frequencies for each of three phases). The number of outputs is based on the information that network is claimed to return. First neuron in the output layer gives the information if the short-circuit fault exists (value close to 1 – exists, value close to 0 – does not exist), without discerning in which phase, as the information contained within the investigated frequencies does not allow to clearly discriminate the shorted phase for all the measurement samples. The second, third and fourth neurons in that layer are responsible for returning the information about the break-fault in the respectively R, S and T phase. If there is a value close to 0 on particular neuron it means that this phase is free of a break fault, if there is a value close to 1 – in this particular phase one group of windings has a break fault. Thus the output layer consists of four neurons. The number of hidden layers, and the number of neurons they consist of were determined experimentally, based on results of network simulation. The structure of a neural network that was used in a break and short-circuit faults detection is presented in the figure 4. In the case of the network for faults recognition based on the field current analysis the input layer consists of 4 neurons as four frequencies of the field current are taken into account. The network is expected to return the information about the motor state using 3 neurons of its output layer in the following way: if there is a value close to 1 in the first output neuron and values close to 0 on the other two neurons, the motor is in 470 Fig. 4. The structure of a neural network used in faults detection based on stator phase currents analysis Fig. 5. The structure of a neural network used in faults detection based on field current analysis a healthy state, combinations 0 1 0 and 0 0 1 (or close values) denote respectively break or short-circuit in one group of windings. If the break and short circuit fault are simultaneously present the network should to reply with 0 1 1 (or close values). From obvious reasons analysis of the field current does not allow to obtain the information which of the phases is affected by the fault. The number of hidden layers, and the number of neurons they consist of were determined experimentally, based on results of network simulation. The structure of a neural network that was used in a motor state detection using field current spectrum is presented in the figure 5. 471 4. RESULTS OF RECOGNITION The final structure of the network, the training algorithm and the number of epochs of a training process were choosen taking into account the number of incorrect motor state recognitions done by the trained network. Consecutive simulations revealed, that a Levenberg-Marquardt [3] training algorithm is optimum for this task. As the result of a network training process is depandable on the initial neurons weights (which are generated randomly) the training processes were undertaken for 20 times with the same values of parameters and for each case the lowest number of network mistaken responses for the verification data was noted. Many experiments done by the authors emerged the optimum network architectures. The exemplary sets of network structure and number of training epochs (number of presentations the training sets to the network) together with the corresponding number of mistaken responses of both networks: based on the stator currents analysis and based on field current analysis are presented respectively in the table 1 and the table 2. The number of wrong diagnoses in the tables relates to the number of incorrect network responses for the total of 80 verification data sets. It should be noted that all the mistaken responses were concerned about the the number of phases with a break fault for these cases, where a break fault was applied to more than one phase at a time. There was no errors in discerning if the machine was in a healthy or faulty state, and for faulty state if it was a break or a short-circuit fault. Table 1. Results of faults recognitions based on stator currents analysis done by the networks of different structures neurons number of number of neurons in number of number of neurons in number of number of in hidden epochs wrong hidden epochs wrong hidden epochs wrong layer diagnoses layer(s) diagnoses layers diagnoses 10 100 13 30 300 9 15 + 10 300 8 10 200 10 30 400 11 20 + 10 300 9 10 300 9 10 + 20 300 10 40 300 8 20 100 14 40 400 10 20 + 20 300 9 20 200 10 50 400 10 20 + 20 400 10 20 300 9 10 + 10 200 13 30 + 20 300 10 20 400 11 10 +10 300 10 30 + 20 400 11 Results presented in the table 1 show that the lowest number of mistaken responses is generated by the network with 1 hidden layer consisting of 40 neurons trained in 300 epochs or the by network containing 15 and 10 neurons in each ot the two hidden layers trained in 300 epochs. As can be seen the greater number of epochs does not always lead to improvement in network behaviour (overtraining phenomenon). 472 Table 2. Results of faults recognitions based on field current analysis done by the networks of different structures neurons number of number of neurons in number of number of neurons in number of number of in hidden epochs wrong hidden epochs wrong hidden epochs wrong layer diagnoses layer(s) diagnoses layers diagnoses 10 100 6 20 200 6 10 + 10 200 4 10 200 6 20 300 5 10 +10 300 5 10 300 5 20 400 5 15 + 10 200 5 15 100 5 30 300 5 15 + 10 300 6 15 200 5 30 400 6 10 + 20 300 6 15 300 5 40 300 5 20 + 10 300 6 20 100 6 40 400 6 20 + 20 400 5 As it can be seen in the table 2 the optimum structure of the network for the sake of the lowest number of mistaken responses is generated by the network with 2 hidden layers consisting of 10 neurons in each layer trained in 200 epochs. As the case, that machine is affected by one than more fault at a time is rather unlikely to occur the correct distinction of the number of faults simultaneously applied to the machine is non-compulsory. Thus the results of experiments can be considered as satisfactory. 5. CONCLUSIONS The accomplished studies show that spectral analysis of the motor currents followed by the automatic recognition with the application of the neural networks can be successfully used in diagnostics of the motor state. The stator and field currents contain the information about machine condition which can be extracted using spectral analysis. Conclusions based on this anylasis can be done by the expert having relevant knowledge or automatically using one of the artificial intelligence methods. As the undertaken experiments shown, the neural networks give good results of such detection. The approach to the problem presented in the paper has indisputable advantages, including non-invasive propensity, continuous state diagnostics and instant detection of the faults. It is also cost-effective, as does not require an expert diagnoses. REFERENCES [1] KORBICZ J., KOŚCIELNY J.M., KOWALCZUK Z., CHOLEWA W., Diagnostyka procesów. Modele. Metody sztucznej inteligencji. Zastosowania. WNT, Warszawa, 2002. [2] KOWALSKI C.T., Zastosowanie sztucznej inteligencji w diagnostyce silników indukcyjnych, Przegląd Elektrotechniczny, R. 82, Nr 11/2006, pp. 53–58. [3] OSOWSKI S., Sieci neuronowe do przetwarzania informacji, OWPW, Warszawa, 2006. 473 WYKRYWANIE STANÓW AWARYJNYCH MASZYNY SYNCHRONICZNEJ Z WYKORZYSTANIEM SIECI NEURONOWYCH W referacie poruszony został problem wykrywania uszkodzeń silnika synchronicznego metodą nieinwazyjną bazującą na analizie spektralnej prądów stojana. Badanym obiektem była maszyna synchroniczna o specjalnym wykonaniu posiadająca w każdej z faz dwie gałęzie równoległe, z których każda podzielona jest na dwie grupy zezwojów. Końce każdej z grup zezwojów wyprowadzone są na zewnątrz maszyny umożliwiając ich różne połączenia. Brano pod uwagę uszkodzenia takie jak: przerwa w jednej grupie zezwojów w jednej, dwóch oraz trzech fazach, zwarcie w jednej grupie zezwojów w jednej fazie, a także różne kombinacje zwarć i przerw (w sumie 19 rożnych stanów awaryjnych). Na podstawie dokonanej analizy spektralnej prądów stojana oraz prądu wirnika wytypowano częstotliwości, których amplitudy najsilniej reagują na dany stan awaryjny, a następnie użyto tych częstotliwości w automatycznym procesie wykrywania rodzaju uszkodzenia. Rozpoznawanie stanu maszyny dokonywane było z użyciem sieci neuronowych typu feed-forward. Zbadano wpływ struktury sieci na poprawność dokonywanej detekcji uszkodzeń. Wykonane badania potwierdzają duża skuteczność tego rodzaju wykrywania.