Lab 3: Motor-Pump System Measurements and LabView Interface

... water level decreases rapidly and we don’t want to run the pump on air. Read the instructions carefully. 5) Start with a full tank. Run the VI. Turn on the power supply and set the voltage to 15 and enter the value in the VI’s front panel. Enter the current and press the save data button. Wait until ...

... water level decreases rapidly and we don’t want to run the pump on air. Read the instructions carefully. 5) Start with a full tank. Run the VI. Turn on the power supply and set the voltage to 15 and enter the value in the VI’s front panel. Enter the current and press the save data button. Wait until ...

Torque/Tension Control Clutches and Brakes brochure

... Electromagnetic hysteresis clutches Torque Range: 0.4~8.9in-lbs / 0.05~1Nm In hysteresis clutches, torque is independent of slip speed and can be easily controlled by varying the current. Since there is no frictional contact between the magnets, the units have an extremely wide torque range and are ...

... Electromagnetic hysteresis clutches Torque Range: 0.4~8.9in-lbs / 0.05~1Nm In hysteresis clutches, torque is independent of slip speed and can be easily controlled by varying the current. Since there is no frictional contact between the magnets, the units have an extremely wide torque range and are ...

TORQUE

... The power input to a motor is electrical. Voltage is applied to a motor’s terminals(终端)resulting in a current. The power output of a motor is mechanical. This power is transmitted by the rotor shaft as a torque. This torque tends to rotate a load, such as a fan or pump. To drive a load at a particul ...

... The power input to a motor is electrical. Voltage is applied to a motor’s terminals(终端)resulting in a current. The power output of a motor is mechanical. This power is transmitted by the rotor shaft as a torque. This torque tends to rotate a load, such as a fan or pump. To drive a load at a particul ...

Manual - Focus Applied Technologies

... calculation of actual Air Fuel Ration (AFR) when combined with an air flow sensor. ...

... calculation of actual Air Fuel Ration (AFR) when combined with an air flow sensor. ...

How Things Work - University of Illinois at Urbana–Champaign

... For the second kind of force the exact path does not matter. An example is pretty much anything but friction. Think of weight. For the second kind of force, we are going to call each work term a change in Potential Energy ...

... For the second kind of force the exact path does not matter. An example is pretty much anything but friction. Think of weight. For the second kind of force, we are going to call each work term a change in Potential Energy ...

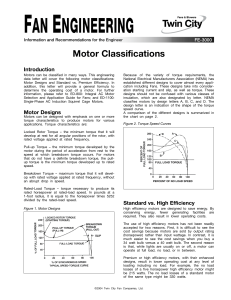

Motor Classifications - FE-3000

... ner laminations and insulated them more effectively from each other ...

... ner laminations and insulated them more effectively from each other ...

TDI 3.0 - Firmans Marine

... High Output (HO): Intended for infrequent use in variable load applications, where full power is limited to one hour out of every eight hours of operation. Also, reduced power operation must be at or below cruise speed (rpm). Cruise speed (rpm) is dependent on the engine rated speed (rpm), Refer to ...

... High Output (HO): Intended for infrequent use in variable load applications, where full power is limited to one hour out of every eight hours of operation. Also, reduced power operation must be at or below cruise speed (rpm). Cruise speed (rpm) is dependent on the engine rated speed (rpm), Refer to ...

PowerPoint-præsentation - Dansk Magnetisk Forening

... wires attract or repulse each other, and was able to show that : ...

... wires attract or repulse each other, and was able to show that : ...

25471_energy_conversion_17

... load. In this range rotor resistance is much larger than its reactance so rotor current, rotor magnetic field & induced torque increase linearly with increasing slip 3- there is a maximum possible torque that cannot be exceeded (pullout torque) is 2 to 3 times rated full-load torque of motor (calcul ...

... load. In this range rotor resistance is much larger than its reactance so rotor current, rotor magnetic field & induced torque increase linearly with increasing slip 3- there is a maximum possible torque that cannot be exceeded (pullout torque) is 2 to 3 times rated full-load torque of motor (calcul ...

Motor Drive Lecture 1#C

... • The gears are used to amplify the torque on load side at lower speed compared to the motor speed • The motors are designed to run at high speeds because it has been found that the higher the speed, the lower is the volume and size of the motor ...

... • The gears are used to amplify the torque on load side at lower speed compared to the motor speed • The motors are designed to run at high speeds because it has been found that the higher the speed, the lower is the volume and size of the motor ...

Exercise 1 - Portal UniMAP

... 7. A 480 V 60 Hz, four-pole synchronous motor draws 50 A from the line at unity power factor and full load. Assuming that the motor is lossless: (a) What is the output torque of this motor? ...

... 7. A 480 V 60 Hz, four-pole synchronous motor draws 50 A from the line at unity power factor and full load. Assuming that the motor is lossless: (a) What is the output torque of this motor? ...

Electric Motor Comparison

... DC generators operate by applying moving a conductor through a magnetic field. In a dynamometer, the magnetic field can be varied, resulting in a variable load. By adjusting the socalled excitation current, one can apply a varying load to the AC-motor being tested. The torque is measured by measurin ...

... DC generators operate by applying moving a conductor through a magnetic field. In a dynamometer, the magnetic field can be varied, resulting in a variable load. By adjusting the socalled excitation current, one can apply a varying load to the AC-motor being tested. The torque is measured by measurin ...

How Electric Motors are made Three phase AC induction motor

... An induction motor operates on the basis of interaction of induced rotor Currents and the airgap field. If the rotor is allowed to run under the torque developed by this interaction, the machine will operate as a motor. On the other hand, the motor may be driven by an external agency beyond a speed ...

... An induction motor operates on the basis of interaction of induced rotor Currents and the airgap field. If the rotor is allowed to run under the torque developed by this interaction, the machine will operate as a motor. On the other hand, the motor may be driven by an external agency beyond a speed ...

EX-503put - Corporate Group of Institutes

... Q.7. The stator of a three phase ,16-pole alternator has 144 slots and there are 4 conductors per slot connected in two layers and the conductors of each phase are connected in series. If the speed of the alternator is 375 rpm. Calculate: EMF induced per phase . The resultant flux in the air gap is ...

... Q.7. The stator of a three phase ,16-pole alternator has 144 slots and there are 4 conductors per slot connected in two layers and the conductors of each phase are connected in series. If the speed of the alternator is 375 rpm. Calculate: EMF induced per phase . The resultant flux in the air gap is ...

ENHANCED AUTOMOTIVE TECHNOLOGY

... original engine management program in the ECU to the Emulator and then allows the user to manipulate this program while the engine is running. This Real-time use allows tuning changes to be evaluated immediately, either out on the road or track or using a Dynamometer. Once the desired performance ch ...

... original engine management program in the ECU to the Emulator and then allows the user to manipulate this program while the engine is running. This Real-time use allows tuning changes to be evaluated immediately, either out on the road or track or using a Dynamometer. Once the desired performance ch ...

TA310 LINEAR DRIVE

... The Trust Automation TA310 Linear Drive is a linear three phase servo motor amplifier designed to drive a brushless motor with up to 340W of power. The TA310 is an excellent solution for small rotary or linear brushless motors in high precision positioning applications and systems requiring ultra qu ...

... The Trust Automation TA310 Linear Drive is a linear three phase servo motor amplifier designed to drive a brushless motor with up to 340W of power. The TA310 is an excellent solution for small rotary or linear brushless motors in high precision positioning applications and systems requiring ultra qu ...

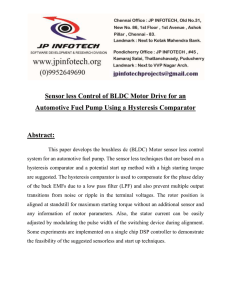

Sensor less Control of BLDC Motor Drive for an

... This paper develops the brushless dc (BLDC) Motor sensor less control system for an automotive fuel pump. The sensor less techniques that are based on a hysteresis comparator and a potential start up method with a high starting torque are suggested. The hysteresis comparator is used to compensate fo ...

... This paper develops the brushless dc (BLDC) Motor sensor less control system for an automotive fuel pump. The sensor less techniques that are based on a hysteresis comparator and a potential start up method with a high starting torque are suggested. The hysteresis comparator is used to compensate fo ...

The AAA Challenge

... From best fit line calculate Power=torque x angular velocity. Maximum power is target for best performance of motor/gear train. ...

... From best fit line calculate Power=torque x angular velocity. Maximum power is target for best performance of motor/gear train. ...

Slide 1

... Due to the absence of rotor windings, SRM is very simple to construct, has a low inertia and allows an extremely high-speed operation. SRM operates in constant torque from zero speed up to the rated speed. Above rated speed up to a certain speed, the operation is in constant power. The range of this ...

... Due to the absence of rotor windings, SRM is very simple to construct, has a low inertia and allows an extremely high-speed operation. SRM operates in constant torque from zero speed up to the rated speed. Above rated speed up to a certain speed, the operation is in constant power. The range of this ...

Multiphase Brushless DC Motor

... STATOR= Stator windings of a BLDC motor are connected to a control circuit (an integrated switching circuit).It is wound with a specific number of poles. ...

... STATOR= Stator windings of a BLDC motor are connected to a control circuit (an integrated switching circuit).It is wound with a specific number of poles. ...

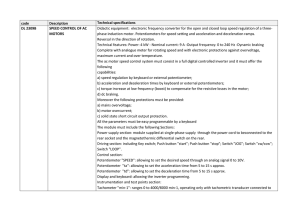

code Description Technical specifications DL 2309B SPEED

... Didactic equipment: electronic frequency converter for the open and closed loop speed regulation of a threephase induction motor. Potentiometers for speed setting and acceleration and deceleration ramps. Reversal in the direction of rotation. Technical features: Power: 4 kW - Nominal current: 9 A -O ...

... Didactic equipment: electronic frequency converter for the open and closed loop speed regulation of a threephase induction motor. Potentiometers for speed setting and acceleration and deceleration ramps. Reversal in the direction of rotation. Technical features: Power: 4 kW - Nominal current: 9 A -O ...

Measurement of brake power

... inoperative by cutting off the supply of fuel. It is assumed that pumping and friction are the same when the cylinder is inoperative as well as during firing. In this test, the engine is first run at the required speed and the brake power is measured. Next, one cylinder is cut off by short cir ...

... inoperative by cutting off the supply of fuel. It is assumed that pumping and friction are the same when the cylinder is inoperative as well as during firing. In this test, the engine is first run at the required speed and the brake power is measured. Next, one cylinder is cut off by short cir ...

Word

... Note that the amount of frequency drop and the amount of mechanical power increase are the values that occur at the end of the control action. This point is clarified by Fig. 3 where we observe the response in bus voltage frequency deviation for several buses in the western US grid for loss of a la ...

... Note that the amount of frequency drop and the amount of mechanical power increase are the values that occur at the end of the control action. This point is clarified by Fig. 3 where we observe the response in bus voltage frequency deviation for several buses in the western US grid for loss of a la ...

Dynamometer

.jpg?width=300)

A dynamometer or ""dyno"" for short, is a device for measuring force, torque, or power. For example, the power produced by an engine, motor or other rotating prime mover can be calculated by simultaneously measuring torque and rotational speed (RPM).A dynamometer can also be used to determine the torque and power required to operate a driven machine such as a pump. In that case, a motoring or driving dynamometer is used. A dynamometer that is designed to be driven is called an absorption or passive dynamometer. A dynamometer that can either drive or absorb is called a universal or active dynamometer.In addition to being used to determine the torque or power characteristics of a machine under test (MUT), dynamometers are employed in a number of other roles. In standard emissions testing cycles such as those defined by the United States Environmental Protection Agency (US EPA), dynamometers are used to provide simulated road loading of either the engine (using an engine dynamometer) or full powertrain (using a chassis dynamometer). In fact, beyond simple power and torque measurements, dynamometers can be used as part of a testbed for a variety of engine development activities, such as the calibration of engine management controllers, detailed investigations into combustion behavior, and tribology.In the medical terminology, hand-held dynamometers are used for routine screening of grip and hand strength, and the initial and ongoing evaluation of patients with hand trauma or dysfunction. They are also used to measure grip strength in patients where compromise of the cervical nerve roots or peripheral nerves is suspected.In the rehabilitation, kinesiology, and ergonomics realms, force dynamometers are used for measuring the back, grip, arm, and/or leg strength of athletes, patients, and workers to evaluate physical status, performance, and task demands. Typically the force applied to a lever or through a cable is measured and then converted to a moment of force by multiplying by the perpendicular distance from the force to the axis of the level.