* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Lab 3: Motor-Pump System Measurements and LabView Interface

Survey

Document related concepts

Transcript

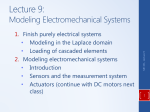

Lab 3: Motor-Pump System Measurements and LabView Interface In this lab experience you will create a Virtual Instrument (VI) using LabView. The VI will be used to capture data for later analysis. A separate instruction sheet explains the procedure to be followed to create the VI. This document contains the procedure to be followed after the VI has been created and tested for successful operation. Safety Precautions: Always remember that water and electricity do not mix. Use extreme caution when transferring the hose from one position to another. Transfer the hose with the system powered down. Use the rags to dry any water that might have splashed or that might be leaking from the pump seals or hose connections. Do not operate any knobs with wet hands. Hose in Recirculation Mode Use this configuration when testing the system and setting up the VI. Avoid kinks on the hose To eliminate a kink, turn the coupling as necessary. Hose in Flow Mode I) Torque Sensor Calibration The torque sensor will be calibrated without the use of the VI. This is because the scale used to measure the force does not have output connectivity (bummer!). 0)With the power supply OFF, decrease the motor supply voltage to zero using the large black wheel. 1)Attach the lever arm to the torque sensor’s pump side brass coupling as shown in the picture. Place the scale underneath the nut at the end of the lever arm. Do not change the location of the nut. The moment arm has been carefully measured to be 5.885 inches. Mount the arm at right angles to the shaft! 2) Turn on the scale, and have the nut barely touch the plate of the scale, with a zero gram reading. Connect the multimeter terminals to the brown and white wires coming from the sensor. You can also use the terminal connections at channel ACH0 on the Elvis board. Turn on the power supply used to provide 12V to the sensor (the Agilent supply, not the motor supply). 3) Open a blank spreadsheet and prepare it to calculate the force in N from the mass in grams (this is what the scale will indicate) and the torque in N-mm corresponding to each sensor voltage reading. 4) Gradually increase the motor voltage to generate force on the scale. You will notice that the force keeps increasing even without increasing the voltage. For this reason, you will have to take simultaneous readings of the scale and the sensor voltage quite fast. Take 10 to15 data pairs with ascending voltage and another 10 to15 with descending voltage. Do not exceed 5 amps of current. 5) Return the voltage wheel to zero and turn off the motor supply. Remove the arm. 6) Plot the sensor voltage against the true torque and extract the sensitivity in V/N-mm. This number will be entered in the VI next. II) Data collection 1) Enter the correct value for the torque sensor sensitivity in the VI. 2) Place the hose in flow mode and twist the coupling to eliminate the kink. 3) Zero out the velocity and torque values using the slider controls of your VI. 4) You have a limited time to perform the tasks described in step 5, since water level decreases rapidly and we don’t want to run the pump on air. Read the instructions carefully. 5) Start with a full tank. Run the VI. Turn on the power supply and set the voltage to 15 and enter the value in the VI’s front panel. Enter the current and press the save data button. Wait until the water level sensor is halfway thru the stroke or so, and press the save data button again. Stop the VI. Then turn off the motor power. Verify that a file has been created. 6) Repeat step 3 for the following motor voltages: 14, 13, 12, 11, 10, 9. Keep track of filenames!! 7) Return the hose to the recirculation position and clean up any water leaks. III) Data Analysis and Report 1) Write a very short report summarizing what has been done. Concentrate on the following steps. 2) Summarize and present the data used to find the torque sensor sensitivity. Plot the torque-voltage data for the ascending and descending ranges in a single chart. 3) For the data corresponding to the flow mode, prepare the following plots: Pump flow rate in liters/min vs. speed in rpm. Pump torque in N-mm vs. flow rate in liters/min. Motor electrical power vs. time and motor mechanical power vs. time (assume the torque to be equal throughout the shaft) in one plot. Motor electromechanical conversion efficiency vs. time. Motor torque in N-mm vs. motor current in A. Motor speed in rpm vs. motor voltage. Motor speed vs. motor torque. Wiring Color Codes DC Motor: Red: Black: Red (shielded): Black (shielded): Armature +V Armature –V Tachometer + Tachometer – Level Sensor: Brown: Green: White: +5V Sensor output 0-5V Common ground Torque Sensor: Purple: Yellow: Brown: White: Excitation (+12V) Excitation ground Sensor + output (0-10V) Sensor – output Motor Power Supply: A pair of B/W wires is connected to a parallel bank of capacitors to reduce voltage ripple.