Heating Water: Rate Correction Due to Newtonian Cooling

... Fig. 1). The deviation from linearity can be quantitatively explained by an application of Newton’s law of cooling. Students can find Newton’s cooling constant by measuring the cooling curve of temperature versus time after boiling when the heat source is removed. The constant is used in a correctio ...

... Fig. 1). The deviation from linearity can be quantitatively explained by an application of Newton’s law of cooling. Students can find Newton’s cooling constant by measuring the cooling curve of temperature versus time after boiling when the heat source is removed. The constant is used in a correctio ...

Für den stetig an Bedeutung gewinnenden Markt an der

... Hot water recirculation pump without external cooling Early in June 2014, KSB Aktiengesellschaft, Frankenthal, Germany, will launch a new generation of hot water recirculation pumps for large industrial heating systems as well as forced circulation boilers and district heating systems. The horizonta ...

... Hot water recirculation pump without external cooling Early in June 2014, KSB Aktiengesellschaft, Frankenthal, Germany, will launch a new generation of hot water recirculation pumps for large industrial heating systems as well as forced circulation boilers and district heating systems. The horizonta ...

Document

... very important for reliable operation. Each device must be symmetric for thermal dilatation point of view. It can not be like a „bimetal“. Unfortunately, the most often used material Si + Cu are quite a problem. Therefore, Mo or W disk are inserted between Si and Cu parts. (W is today very expensive ...

... very important for reliable operation. Each device must be symmetric for thermal dilatation point of view. It can not be like a „bimetal“. Unfortunately, the most often used material Si + Cu are quite a problem. Therefore, Mo or W disk are inserted between Si and Cu parts. (W is today very expensive ...

Cooling, thermal resistance, modeling of heat transfer as an electric

... very important for reliable operation. Each device must be symmetric for thermal dilatation point of view. It can not be like a „bimetal“. Unfortunately, the most often used material Si + Cu are quite a problem. Therefore, Mo or W disk are inserted between Si and Cu parts (W is today very expensive) ...

... very important for reliable operation. Each device must be symmetric for thermal dilatation point of view. It can not be like a „bimetal“. Unfortunately, the most often used material Si + Cu are quite a problem. Therefore, Mo or W disk are inserted between Si and Cu parts (W is today very expensive) ...

Modern role for historic water tower

... and art historians alike. Typical examples were combined water and observation towers, which were usually built in the centre of towns. ...

... and art historians alike. Typical examples were combined water and observation towers, which were usually built in the centre of towns. ...

Our design for the heating and cooling system is centered upon two

... because of the energy released by the equipment used inside these spaces and the larger number of people using them. The dining facility also requires better ventilation because of the smells associated with cooking. As a result its air should not be reused but rather taken out of the building. The ...

... because of the energy released by the equipment used inside these spaces and the larger number of people using them. The dining facility also requires better ventilation because of the smells associated with cooking. As a result its air should not be reused but rather taken out of the building. The ...

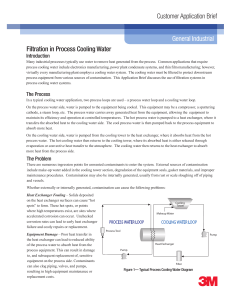

Customer Application Brief General Industrial Filtration in Process

... maintain its efficiency and operation at controlled temperatures. The hot process water is pumped to a heat exchanger, where it transfers the absorbed heat to the cooling water side. The cool process water is then pumped back to the process equipment to absorb more heat. On the cooling water side, w ...

... maintain its efficiency and operation at controlled temperatures. The hot process water is pumped to a heat exchanger, where it transfers the absorbed heat to the cooling water side. The cool process water is then pumped back to the process equipment to absorb more heat. On the cooling water side, w ...

module 6 humidification and air conditioning

... Thus, cooling is accomplished by sensible heat transfer from water to air and evaporation of a small portion of water. A generalized cooling tower system is shown in Figure 6.4. The hot water which is coming from heat exchanger is sprayed at the top of the cooling tower. Air enters through the louve ...

... Thus, cooling is accomplished by sensible heat transfer from water to air and evaporation of a small portion of water. A generalized cooling tower system is shown in Figure 6.4. The hot water which is coming from heat exchanger is sprayed at the top of the cooling tower. Air enters through the louve ...

Analysis of cooling and heating of water with flat-plate solar

... Extensive analysis of flat-plate radiative panels operation using average hourly weather data for a maritime climate region was performed. The panels are integrated in the space-ventilation system with air-cooling by means of a cold-water coil. Their primary function is to prepare sufficient quantit ...

... Extensive analysis of flat-plate radiative panels operation using average hourly weather data for a maritime climate region was performed. The panels are integrated in the space-ventilation system with air-cooling by means of a cold-water coil. Their primary function is to prepare sufficient quantit ...

14_Water Cooling System

... Large slow speed, two stroke engines have 2 separate closed cooling circuits. A header or expansion tank allows venting of the system. The header has connections from engine discharge & pump suction line. A heater is fitted with by pass to warm the engine when necessary. ...

... Large slow speed, two stroke engines have 2 separate closed cooling circuits. A header or expansion tank allows venting of the system. The header has connections from engine discharge & pump suction line. A heater is fitted with by pass to warm the engine when necessary. ...

Cooling tower

A cooling tower is a heat rejection device which rejects waste heat to the atmosphere through the cooling of a water stream to a lower temperature. Cooling towers may either use the evaporation of water to remove process heat and cool the working fluid to near the wet-bulb air temperature or, in the case of closed circuit dry cooling towers, rely solely on air to cool the working fluid to near the dry-bulb air temperature.Common applications include cooling the circulating water used in oil refineries, petrochemical and other chemical plants, thermal power stations and HVAC systems for cooling buildings. The classification is based on the type of air induction into the tower: the main types of cooling towers are natural draft and induced draft cooling towers.Cooling towers vary in size from small roof-top units to very large hyperboloid structures (as in the adjacent image) that can be up to 200 metres (660 ft) tall and 100 metres (330 ft) in diameter, or rectangular structures that can be over 40 metres (130 ft) tall and 80 metres (260 ft) long. The hyperboloid cooling towers are often associated with nuclear power plants, although they are also used to some extent in some large chemical and other industrial plants. Although these large towers are very prominent, the vast majority of cooling towers are much smaller, including many units installed on or near buildings to discharge heat from air conditioning.