Question Bank - Saraswathi Velu College of Engineering

... 3. i) Explain double revolving field theory as applied to a single phase induction motor? ii) Describe Kramar system of speed control for 3phase induction motor? 4. Draw the torque versus speed characteristics curve and explain the relation between torque and slip before and after max.torque? 5. A 3 ...

... 3. i) Explain double revolving field theory as applied to a single phase induction motor? ii) Describe Kramar system of speed control for 3phase induction motor? 4. Draw the torque versus speed characteristics curve and explain the relation between torque and slip before and after max.torque? 5. A 3 ...

Super ECO Mode - CSF ELEKTRO sro

... SitePro has an output power factor (PF) higher than industry standard This prevents the need for over sizing the UPS ...

... SitePro has an output power factor (PF) higher than industry standard This prevents the need for over sizing the UPS ...

Electric Efficient Motor

... constant cool environment for stored films and video tapes. A detailed study was undertaken on four motors so that the performance of high-efficiency motors could be compared directly. Table 23 gives details of the motors selected & table 2-4 shows the comparison between Standard and HEM in these 4 ...

... constant cool environment for stored films and video tapes. A detailed study was undertaken on four motors so that the performance of high-efficiency motors could be compared directly. Table 23 gives details of the motors selected & table 2-4 shows the comparison between Standard and HEM in these 4 ...

14PE1 Maximum power transfer tracking for Ultralow

... conditions, responding to changes in both excitation and the load conditions. At 2 Vdc output, the total current consumption of the combined ancillary and control circuits is just 22μA. The power conditioning system is capable of transferring up to 70% of the potentially extractable power to the ene ...

... conditions, responding to changes in both excitation and the load conditions. At 2 Vdc output, the total current consumption of the combined ancillary and control circuits is just 22μA. The power conditioning system is capable of transferring up to 70% of the potentially extractable power to the ene ...

RV SYSDrive AC Inverters

... for installation and maintenance. Screw terminals are used throughout to provide reliable connection. The cooling fan automatically switches off when not required, prolonging fan life. When the fan does require changing, the process is simplified through a detachable fan design. The face cover is a ...

... for installation and maintenance. Screw terminals are used throughout to provide reliable connection. The cooling fan automatically switches off when not required, prolonging fan life. When the fan does require changing, the process is simplified through a detachable fan design. The face cover is a ...

... LINEST with a set of known x-values (in this case, the speed values) and a set of known y-values (in this case, the voltages). LINEST will return the slope of the line that best fits the data. In terms of the DC machine model, what is this value? f) In part b, you measured the resistance of the moto ...

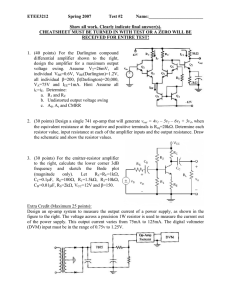

ETEE3212 Spring 2007 Test

... 1. (40 points) For the Darlington compound differential amplifier shown to the right, design the amplifier for a maximum output voltage swing. Assume VT=26mV, all individual VBE=0.6V, VBE(Darlington)=1.2V, all individual β=200, β(Darlington)=20,000, VA=75V and IEE=1mA. Hint: Assume all ...

... 1. (40 points) For the Darlington compound differential amplifier shown to the right, design the amplifier for a maximum output voltage swing. Assume VT=26mV, all individual VBE=0.6V, VBE(Darlington)=1.2V, all individual β=200, β(Darlington)=20,000, VA=75V and IEE=1mA. Hint: Assume all ...

How to Create Square Waves in MATLAB

... to reduce the motor speed. This type of control is referred to as Pulse Width Modulation (PWM). Our DAQs don’t source enough current to drive a motor so we will use PWM to control the light level of a Light Emitting Diode (LED). ...

... to reduce the motor speed. This type of control is referred to as Pulse Width Modulation (PWM). Our DAQs don’t source enough current to drive a motor so we will use PWM to control the light level of a Light Emitting Diode (LED). ...

Snap-Trol 183 Nema 1 Instruction Manual

... voltage level is controlled by controlling the phase angle firing of the SCR’s. A commutating (free wheeling) diode provides a path for current, during phase back operation as well as helping to minimize DC output ripple. The SCR firing circuit controls the phase angle firing of the SCR’s response t ...

... voltage level is controlled by controlling the phase angle firing of the SCR’s. A commutating (free wheeling) diode provides a path for current, during phase back operation as well as helping to minimize DC output ripple. The SCR firing circuit controls the phase angle firing of the SCR’s response t ...

Slip power recovery systems When are Wound rotor motors

... converter is switched at a higher frequency (usually 1500Hz or higher). The harmonic currents from this type of converter are centered around the switching frequency and multiples of it. These currents are greatly reduced by the impedance (15-20 per cent on the drive rating base) in the source react ...

... converter is switched at a higher frequency (usually 1500Hz or higher). The harmonic currents from this type of converter are centered around the switching frequency and multiples of it. These currents are greatly reduced by the impedance (15-20 per cent on the drive rating base) in the source react ...

Is Your Factory Power Source Corrupting Your Product Testing?

... currents associated with the tested products must be accounted for. Products that incorporate pumps, compressors or other motor-driven loads present issues that can cause test failures due to the high starting currents required. Products with non-linear input currents can cause distortion of the AC ...

... currents associated with the tested products must be accounted for. Products that incorporate pumps, compressors or other motor-driven loads present issues that can cause test failures due to the high starting currents required. Products with non-linear input currents can cause distortion of the AC ...

Series MH60 - hitek power supplies

... Range of outputs available Positive or negative polarity Short circuit & flashover protection Remotely controllable V & I control V & I monitor LED status indication Low ripple EU RoHS Compliant to 2002/95/EC marked for EU LV Directive 73/23/EEC DESCRIPTION The Series MH60 is a range of versatile hi ...

... Range of outputs available Positive or negative polarity Short circuit & flashover protection Remotely controllable V & I control V & I monitor LED status indication Low ripple EU RoHS Compliant to 2002/95/EC marked for EU LV Directive 73/23/EEC DESCRIPTION The Series MH60 is a range of versatile hi ...

Motors use electromagnets.

... Page 541 shows how a simple motor works. The photograph at the top of the page shows a motor that turns the blades of a fan. The illustration in the middle of the page shows the main parts of a simple motor. Although they may look different from each other, all motors have similar parts and work in ...

... Page 541 shows how a simple motor works. The photograph at the top of the page shows a motor that turns the blades of a fan. The illustration in the middle of the page shows the main parts of a simple motor. Although they may look different from each other, all motors have similar parts and work in ...

Variable-frequency drive

A variable-frequency drive (VFD) (also termed adjustable-frequency drive, variable-speed drive, AC drive, micro drive or inverter drive) is a type of adjustable-speed drive used in electro-mechanical drive systems to control AC motor speed and torque by varying motor input frequency and voltage.VFDs are used in applications ranging from small appliances to the largest of mine mill drives and compressors. However, around 25% of the world's electrical energy is consumed by electric motors in industrial applications, which are especially conducive for energy savings using VFDs in centrifugal load service, and VFDs' global market penetration for all applications is still relatively small. That lack of penetration highlights significant energy efficiency improvement opportunities for retrofitted and new VFD installations.Over the last four decades, power electronics technology has reduced VFD cost and size and has improved performance through advances in semiconductor switching devices, drive topologies, simulation and control techniques, and control hardware and software.VFDs are available in a number of different low- and medium-voltage AC-AC and DC-AC topologies.