Top Ten Reasons Building HVAC Systems Do Not

... at the fan is 15% over design and the exhaust flow at the register or hood location is 20% under design. This discrepancy is due to the fact that air is leaking into the duct systems along the duct route and not at the specified exhaust point. This can lead to stuffy, stagnant rooms or laboratory ex ...

... at the fan is 15% over design and the exhaust flow at the register or hood location is 20% under design. This discrepancy is due to the fact that air is leaking into the duct systems along the duct route and not at the specified exhaust point. This can lead to stuffy, stagnant rooms or laboratory ex ...

Module 6: Pneumatic Systems Lecture 1 Pneumatic system

... form a mist of oil and air to provide lubrication to the mating components. Figure 6.3.6 shows the schematic of a typical lubricator. The principle of working of venturimeter is followed in the operation of lubricator. The compressed air from the dryer enters in the lubricator. Its velocity increase ...

... form a mist of oil and air to provide lubrication to the mating components. Figure 6.3.6 shows the schematic of a typical lubricator. The principle of working of venturimeter is followed in the operation of lubricator. The compressed air from the dryer enters in the lubricator. Its velocity increase ...

fan engineering - Twin City Fan and Blower

... Typically the flat bladed design has efficiencies of about 82%, while the curved blade and airfoil designs approach 86% and 90%, respectively. The backward inclined “family” of fans has the highest operating speeds of all the centrifugal fans (Figure 4). While this is a desirable feature for dir ...

... Typically the flat bladed design has efficiencies of about 82%, while the curved blade and airfoil designs approach 86% and 90%, respectively. The backward inclined “family” of fans has the highest operating speeds of all the centrifugal fans (Figure 4). While this is a desirable feature for dir ...

Contractor Service Tips 2 Single Phase Burns

... experience has proven that single phase motor burns are caused by the malfunction or misapplication of the system contactor(s). Contactors play a role in any compressor overload protection scheme, but are particularly important when they are part of a pilot-operated protection system. Contactors hav ...

... experience has proven that single phase motor burns are caused by the malfunction or misapplication of the system contactor(s). Contactors play a role in any compressor overload protection scheme, but are particularly important when they are part of a pilot-operated protection system. Contactors hav ...

SIKO The Safety Design Concept

... performance required today calls for design solutions which lie much closer to the physical limits of the turbochargers. The load factor for the rotating components in particular has ...

... performance required today calls for design solutions which lie much closer to the physical limits of the turbochargers. The load factor for the rotating components in particular has ...

Service Manual

... When used within a 60Hz circuit the APD70-C and APD72-C models are designed for operation in larger systems with up to 1700 feet of 6-inch diameter transmission line. The dehydrator is rated at 0.7 SCFM (0.32 liter/sec) and -40°F (-40°C) dry air dew point output at 95°F (35°C) 95% relative humidity ...

... When used within a 60Hz circuit the APD70-C and APD72-C models are designed for operation in larger systems with up to 1700 feet of 6-inch diameter transmission line. The dehydrator is rated at 0.7 SCFM (0.32 liter/sec) and -40°F (-40°C) dry air dew point output at 95°F (35°C) 95% relative humidity ...

Noise Reduction in a Reciprocating Compressor by Optimizing the Suction Muffler

... out in view of noise reduction as well as flow performance. The pressure drop characteristics of the muffler are analyzed using “ANSYS”. The noise coming out of the hermetic compressor is related to the suction side. Discharge side and other electromagnetic components. Generally, the suction side no ...

... out in view of noise reduction as well as flow performance. The pressure drop characteristics of the muffler are analyzed using “ANSYS”. The noise coming out of the hermetic compressor is related to the suction side. Discharge side and other electromagnetic components. Generally, the suction side no ...

causes of premature compressor failure

... Refrigerant that is cross contaminated with another refrigerant or contaminated with air can cause excessive high side pressure and increase loads on the compressor, especially when operating at low speed conditions under high ambient temperatures. Air contamination can also cause compressors to be ...

... Refrigerant that is cross contaminated with another refrigerant or contaminated with air can cause excessive high side pressure and increase loads on the compressor, especially when operating at low speed conditions under high ambient temperatures. Air contamination can also cause compressors to be ...

Simultaneous Chromatography and Electrophoresis: Apparatus Design and Development

... separations. This model has removed several variables which were likely causing non-uniformity in magnitude of pressureand is cri pressure application solvent flow. These variables included plate bowing, pressure gaps around the O-ring and electrode channels, and the manually tightened bolt/C-clamp ...

... separations. This model has removed several variables which were likely causing non-uniformity in magnitude of pressureand is cri pressure application solvent flow. These variables included plate bowing, pressure gaps around the O-ring and electrode channels, and the manually tightened bolt/C-clamp ...

Module -1 Basic Principles of Turbomachines` Lecture

... Eqs. (1.2) and (1.4) is applicable regardless of changes in density or components of velocity in other directions. Moreover, the shape of the path taken by the fluid in moving from inlet to outlet is of no consequence. The expression involves only the inlet and outlet conditions. A rotor, the moving ...

... Eqs. (1.2) and (1.4) is applicable regardless of changes in density or components of velocity in other directions. Moreover, the shape of the path taken by the fluid in moving from inlet to outlet is of no consequence. The expression involves only the inlet and outlet conditions. A rotor, the moving ...

BITZER Output data

... For more information concerning the application range use the "Limits" button. Operation modes 4VES-7 (4VCS-6.2) to 6FE-44 (6F-40.2) and 44JE-30 (44J-26.2) to 66FE-88 (66F-80.2) with R407F/R407A/R22: CIC = liquid injection with low temperature application, suction gas cooled motor ASERCOM certified ...

... For more information concerning the application range use the "Limits" button. Operation modes 4VES-7 (4VCS-6.2) to 6FE-44 (6F-40.2) and 44JE-30 (44J-26.2) to 66FE-88 (66F-80.2) with R407F/R407A/R22: CIC = liquid injection with low temperature application, suction gas cooled motor ASERCOM certified ...

Fluid Dynamics

... kg/m3 at a rate of 1.2 10-2 m3/s. The input to the pump is from a pipe with a cross-sectional area A1 of 4 10-3 m2 at a suction pressure P1 of 1 104 Pa. The discharge of the pump is at a gauge pressure P2 of 2.8 105 Pa into a pipe with a cross-sectional area A2 of 8 10-4 m2. The pipes at t ...

... kg/m3 at a rate of 1.2 10-2 m3/s. The input to the pump is from a pipe with a cross-sectional area A1 of 4 10-3 m2 at a suction pressure P1 of 1 104 Pa. The discharge of the pump is at a gauge pressure P2 of 2.8 105 Pa into a pipe with a cross-sectional area A2 of 8 10-4 m2. The pipes at t ...

BITZER Output data

... For more information concerning the application range use the "Limits" button. Operation modes 4VES-7 (4VCS-6.2) to 6FE-44 (6F-40.2) and 44JE-30 (44J-26.2) to 66FE-88 (66F-80.2) with R407F/R407A/R22: CIC = liquid injection with low temperature application, suction gas cooled motor ASERCOM certified ...

... For more information concerning the application range use the "Limits" button. Operation modes 4VES-7 (4VCS-6.2) to 6FE-44 (6F-40.2) and 44JE-30 (44J-26.2) to 66FE-88 (66F-80.2) with R407F/R407A/R22: CIC = liquid injection with low temperature application, suction gas cooled motor ASERCOM certified ...

Experiment 2-3

... that resistance will cause energy loss in a fluid power system. It is therefore necessary to discuss frictional loses in order to appreciate system designs that minimize pressure drop. A pressure drop is simply the difference in pressure between any two points in a fluid power system. ...

... that resistance will cause energy loss in a fluid power system. It is therefore necessary to discuss frictional loses in order to appreciate system designs that minimize pressure drop. A pressure drop is simply the difference in pressure between any two points in a fluid power system. ...

VP Leg June 2012

... Obstruction meters: venturi nozzles, orifice plates, flow nozzles and variable area use reduction in status pressure to convert to flow velocity. Pressure is lost through these measurements and has limited in range. The velocity measurement is achieved by Static pressure, direction sensing, pitot st ...

... Obstruction meters: venturi nozzles, orifice plates, flow nozzles and variable area use reduction in status pressure to convert to flow velocity. Pressure is lost through these measurements and has limited in range. The velocity measurement is achieved by Static pressure, direction sensing, pitot st ...

FUNDAMENTALS OF GAS TURBINE ENGINES

... The efficiency of a compressor is primarily determined by the smoothness of the airflow. During design, every effort is made to keep the air flowing smoothly through the compressor to minimize airflow losses due to friction and turbulence. This task is a difficult one, since the air is forced to fl ...

... The efficiency of a compressor is primarily determined by the smoothness of the airflow. During design, every effort is made to keep the air flowing smoothly through the compressor to minimize airflow losses due to friction and turbulence. This task is a difficult one, since the air is forced to fl ...

Fluids AP

... fluid dynamics (hydrodynamics if water) If flow is smooth- streamline or Laminar if flow is erratic, currents present – turbulent Viscosity- internal resistance within fluid ...

... fluid dynamics (hydrodynamics if water) If flow is smooth- streamline or Laminar if flow is erratic, currents present – turbulent Viscosity- internal resistance within fluid ...

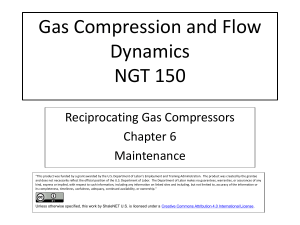

Gas Processing I NGT 140

... not be overloaded. 7. If spilled, oil should be wiped up from the floor immediately to prevent slipping. (control and contain all fluid spills or leaks) 8. Vapor proof extension lights should be used. 9. Compressor suction and discharge valves should be sealed off by a blind vent valve left open bef ...

... not be overloaded. 7. If spilled, oil should be wiped up from the floor immediately to prevent slipping. (control and contain all fluid spills or leaks) 8. Vapor proof extension lights should be used. 9. Compressor suction and discharge valves should be sealed off by a blind vent valve left open bef ...

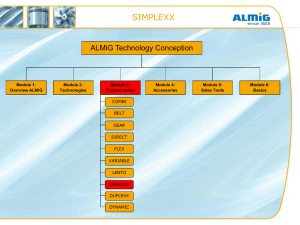

PowerPoint-Präsentation

... TOP 2: High-efficiency airends The central element of all compressors are the airends. In the course of time they undergo heavy wear and therefore the quality of their manufacture is especially high. •The special “FPS-coat” surface coating (Fluorine-Polymere-System) is a chemical / physical coatin ...

... TOP 2: High-efficiency airends The central element of all compressors are the airends. In the course of time they undergo heavy wear and therefore the quality of their manufacture is especially high. •The special “FPS-coat” surface coating (Fluorine-Polymere-System) is a chemical / physical coatin ...

What are pneumatics

... It consists of two helical screws which are mesh with each other. An electrical motor drives a male rotor and female are driven by male rotor. ...

... It consists of two helical screws which are mesh with each other. An electrical motor drives a male rotor and female are driven by male rotor. ...

izmir institute of technology

... Click the “Go” button on the software to take a sample. Using the discharge as a guide, select incremental values for discharge that will give 10-15 individual steps between minimum and maximum velocity. Reduce the compressor setting gradually to reduce the discharge by approximately the incre ...

... Click the “Go” button on the software to take a sample. Using the discharge as a guide, select incremental values for discharge that will give 10-15 individual steps between minimum and maximum velocity. Reduce the compressor setting gradually to reduce the discharge by approximately the incre ...

Axial compressor

An axial compressor is a machine that can continuously pressurise gases. It is a rotating, airfoil-based compressor in which the gas or working fluid principally flows parallel to the axis of rotation. This differs from other rotating compressors such as centrifugal compressors, axi-centrifugal compressors and mixed-flow compressors where the fluid flow will include a ""radial component"" through the compressor. The energy level of the fluid increases as it flows through the compressor due to the action of the rotor blades which exert a torque on the fluid. The stationary blades slow the fluid, converting the circumferential component of flow into pressure. Compressors are typically driven by an electric motor or a steam or a gas turbine.Axial flow compressors produce a continuous flow of compressed gas, and have the benefits of high efficiency and large mass flow rate, particularly in relation to their size and cross-section. They do, however, require several rows of airfoils to achieve a large pressure rise, making them complex and expensive relative to other designs (e.g. centrifugal compressors).Axial compressors are integral to the design of large gas turbines such as jet engines, high speed ship engines, and small scale power stations. They are also used in industrial applications such as large volume air separation plants, blast furnace air, fluid catalytic cracking air, and propane dehydrogenation. Due to high performance, high reliability and flexible operation during the flight envelope, they are also used in aerospace engines.