Transient Peak Currents in Permanent Magnet Synchronous Motors

... vehicles are a high starting torque, a good torque per volume and power per volume ratio as well as a high efficiency. This is why permanent magnet synchronous motors (PMSM) became more and more popular for these applications. The performance of PMSM drives increased significantly in recent years du ...

... vehicles are a high starting torque, a good torque per volume and power per volume ratio as well as a high efficiency. This is why permanent magnet synchronous motors (PMSM) became more and more popular for these applications. The performance of PMSM drives increased significantly in recent years du ...

Research Setup for Special Purpose Permanent Magnet

... are mainly used as small traction machines or as supplementary machines in the automotive, transportation or energy production industry. From the historical perspective, we can see first the application of brushed DC machines. They were used in all kinds of drives. They have the advantage of simple ...

... are mainly used as small traction machines or as supplementary machines in the automotive, transportation or energy production industry. From the historical perspective, we can see first the application of brushed DC machines. They were used in all kinds of drives. They have the advantage of simple ...

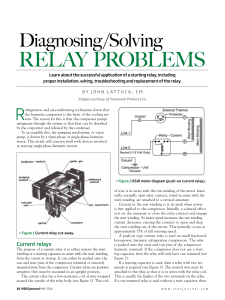

relay problems

... of wire is in series with the run winding of the motor. Internally, normally open relay contacts, wired in series with the start winding, are attached to a vertical armature. Current in the run winding is at its peak when power is first applied to the compressor. Initially, a solenoid effect acts on ...

... of wire is in series with the run winding of the motor. Internally, normally open relay contacts, wired in series with the start winding, are attached to a vertical armature. Current in the run winding is at its peak when power is first applied to the compressor. Initially, a solenoid effect acts on ...

Fundamentals of Motors

... a load to full speed. The lowest point may be the locked rotor point for some motors. Also called pull in torque. Breakdown Torque the maximum amount of torque that is available from the motor shaft. When a motor operates at full voltage and maximum speed, the load is increased until the maximum tor ...

... a load to full speed. The lowest point may be the locked rotor point for some motors. Also called pull in torque. Breakdown Torque the maximum amount of torque that is available from the motor shaft. When a motor operates at full voltage and maximum speed, the load is increased until the maximum tor ...

An Improved Direct Decoupled Power Control of Doubly Fed

... N recent years, using renewable energy sources instead of the fossil fuel is constantly increasing. Most of the renewable energy sources come from natural events, which mostly have random characteristics. Wind energy as one of the natural renewable energy sources is used to generate power through wi ...

... N recent years, using renewable energy sources instead of the fossil fuel is constantly increasing. Most of the renewable energy sources come from natural events, which mostly have random characteristics. Wind energy as one of the natural renewable energy sources is used to generate power through wi ...

Basic training for industrial-duty and commercial-duty

... of the power supply line produces a rotating field around the rotor surface. The rotor tends to follow this rotating field with a rotational speed that varies inversely with the number of poles wound into the stator. Singlephase motors do not produce a rotating field at a standstill, so a starter wi ...

... of the power supply line produces a rotating field around the rotor surface. The rotor tends to follow this rotating field with a rotational speed that varies inversely with the number of poles wound into the stator. Singlephase motors do not produce a rotating field at a standstill, so a starter wi ...

SIMOTICS Low-voltage motors - Siemens

... to be designed and built, therefore creating the basis for their widespread use in industry today. Since then, motor development has been a core business of the company, and with far more than 100 years of experience, Siemens sets the pace when it comes to innovative motor technology. Today, million ...

... to be designed and built, therefore creating the basis for their widespread use in industry today. Since then, motor development has been a core business of the company, and with far more than 100 years of experience, Siemens sets the pace when it comes to innovative motor technology. Today, million ...

ABB drives - Technical guide No. 7

... Chapter 4 - Induction (AC) motor.............................................................11 4.1 Fundamentals .............................................................................11 4.2 Motor current .............................................................................13 ...

... Chapter 4 - Induction (AC) motor.............................................................11 4.1 Fundamentals .............................................................................11 4.2 Motor current .............................................................................13 ...

Disturbance Torque Observers for the Induction Motor Drives Mihai

... speed or on the position (feedforward control). For example, this kind of control is used by the directdrive systems that function in low speed range [4-6]. Also, the values of the estimated disturbance torque are necessary if an instantaneous speed observer is used [7-10]. Because in the direct-dri ...

... speed or on the position (feedforward control). For example, this kind of control is used by the directdrive systems that function in low speed range [4-6]. Also, the values of the estimated disturbance torque are necessary if an instantaneous speed observer is used [7-10]. Because in the direct-dri ...

SB800 - Marathon Motors Basic Training Manual

... in conjunction with the phase sequence of the power supply line produces a rotating field around the rotor surface. The rotor tends to follow this rotating field with a rotational speed that varies inversely with the number of poles wound into the stator. Singlephase motors do not produce a rotating ...

... in conjunction with the phase sequence of the power supply line produces a rotating field around the rotor surface. The rotor tends to follow this rotating field with a rotational speed that varies inversely with the number of poles wound into the stator. Singlephase motors do not produce a rotating ...

Commutator (electric)

A commutator is the moving part of a rotary electrical switch in certain types of electric motors and electrical generators that periodically reverses the current direction between the rotor and the external circuit. It consists of a cylinder composed of multiple metal contact segments on the rotating armature of the machine. The commutator is one component of a motor; there are also two or more stationary electrical contacts called ""brushes"" made of a soft conductor like carbon press against the commutator, making sliding contact with successive segments of the commutator as it rotates. The windings (coils of wire) on the armature are connected to the commutator segments. Commutators are used in direct current (DC) machines: dynamos (DC generators) and many DC motors as well as universal motors. In a motor the commutator applies electric current to the windings. By reversing the current direction in the rotating windings each half turn, a steady rotating force (torque) is produced. In a generator the commutator picks off the current generated in the windings, reversing the direction of the current with each half turn, serving as a mechanical rectifier to convert the alternating current from the windings to unidirectional direct current in the external load circuit. The first direct current commutator-type machine, the dynamo, was built by Hippolyte Pixii in 1832, based on a suggestion by André-Marie Ampère. Commutators are relatively inefficient, and also require periodic maintenance such as brush replacement. Therefore, commutated machines are declining in use, being replaced by alternating current (AC) machines, and in recent years by brushless DC motors which use semiconductor switches.