Intelligent Sensorless Antilock Braking System for Brushless In

... that includes a separate electric motor as its propulsion system, as well as other important components such as a frictional brake and a suspension spring, is called an in-wheel hub. Electric motors of the in-wheel hubs are desired to have high efficiency, small size, and low maintenance requirement ...

... that includes a separate electric motor as its propulsion system, as well as other important components such as a frictional brake and a suspension spring, is called an in-wheel hub. Electric motors of the in-wheel hubs are desired to have high efficiency, small size, and low maintenance requirement ...

Coupled electromagnetic and structural analysis of support

... interest in the rotorcraft market that is expected to grow significantly in the next decades. Although the technology for all-electric flight is not yet mature, hybrid solutions for aircraft and rotorcraft are suggested. A hybrid helicopter concept has been suggested by Airbus Group Innovations, whi ...

... interest in the rotorcraft market that is expected to grow significantly in the next decades. Although the technology for all-electric flight is not yet mature, hybrid solutions for aircraft and rotorcraft are suggested. A hybrid helicopter concept has been suggested by Airbus Group Innovations, whi ...

analysis of extended constant power speed range of - UTK-EECS

... advantages and their drawbacks and states the necessity of a scheme that truly can drive PMSM in wide constant power speed range. Chapter II presents PMSM models. Initially. it gives the three-phase model of the PMSM in the stationary frame, which is used in chapter III to describe how DMIC works. T ...

... advantages and their drawbacks and states the necessity of a scheme that truly can drive PMSM in wide constant power speed range. Chapter II presents PMSM models. Initially. it gives the three-phase model of the PMSM in the stationary frame, which is used in chapter III to describe how DMIC works. T ...

micromaster 430

... This equipment is capable of providing internal motor overload protection in accordance with UL508C section 42. Refer to P0610 and P0335, i2t is ON by default. Motor overload protection can also be provided using an external PTC (disabled by default P0601). This equipment is suitable for use in a ci ...

... This equipment is capable of providing internal motor overload protection in accordance with UL508C section 42. Refer to P0610 and P0335, i2t is ON by default. Motor overload protection can also be provided using an external PTC (disabled by default P0601). This equipment is suitable for use in a ci ...

MotoCalc Manual

... Deleting an Unwanted Item.......................................................................................................................79 Printing a Database Table..........................................................................................................................79 Exp ...

... Deleting an Unwanted Item.......................................................................................................................79 Printing a Database Table..........................................................................................................................79 Exp ...

M-23A, M-23B, M-3 and Low-Profile M-3 Electric

... are available, each with a single operating voltage, gear ratio and wire control scheme. The M-23A uses a different hand-throw pinion than the M23B, which affects hand-throw locking. Power operation is the same with both machines. In the M-23A, the hand throw lever gives the same mechanism stroke an ...

... are available, each with a single operating voltage, gear ratio and wire control scheme. The M-23A uses a different hand-throw pinion than the M23B, which affects hand-throw locking. Power operation is the same with both machines. In the M-23A, the hand throw lever gives the same mechanism stroke an ...

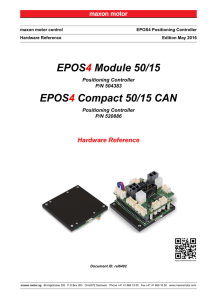

EPOS4 50/15 Hardware Reference

... • you must follow the instructions given therein. EPOS4 Module 50/15 and EPOS4 Compact 50/15 positioning controllers are considered as partly completed machinery according to EU Directive 2006/42/EC, Article 2, Clause (g) and are intended to be incorporated into or assembled with other machinery or ...

... • you must follow the instructions given therein. EPOS4 Module 50/15 and EPOS4 Compact 50/15 positioning controllers are considered as partly completed machinery according to EU Directive 2006/42/EC, Article 2, Clause (g) and are intended to be incorporated into or assembled with other machinery or ...

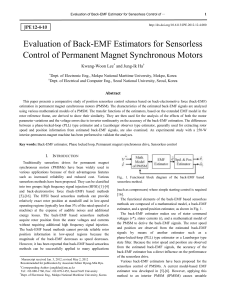

Evaluation of Back-EMF Estimators for Sensorless Control of

... machine) at the expense of audible noises and additional energy losses. The back-EMF based sensorless methods acquire rotor position from the stator voltages and currents without requiring additional high frequency signal injection. The back-EMF based methods cannot provide reliable rotor position i ...

... machine) at the expense of audible noises and additional energy losses. The back-EMF based sensorless methods acquire rotor position from the stator voltages and currents without requiring additional high frequency signal injection. The back-EMF based methods cannot provide reliable rotor position i ...

Thermal Management of Electric Machines - MacSphere

... The Inter-Laminate Cooling concept is developed with application to an iron core inductor which serves as a proxy for the electric machine. The experimental results confirmed the capability of the method, expressed by the effectiveness, which defines the performance measure of the applied cooling me ...

... The Inter-Laminate Cooling concept is developed with application to an iron core inductor which serves as a proxy for the electric machine. The experimental results confirmed the capability of the method, expressed by the effectiveness, which defines the performance measure of the applied cooling me ...

AT LEAST THE 10 FOLLOWING STEPS OF THE START

... commissioning and operation of Vacon NXL Frequency Converter. We recommend that you carefully study these instructions before powering up the frequency converter for the first time. In the Multi-Control Application Manual you will find information about the application used in the Vacon NXL Drive. T ...

... commissioning and operation of Vacon NXL Frequency Converter. We recommend that you carefully study these instructions before powering up the frequency converter for the first time. In the Multi-Control Application Manual you will find information about the application used in the Vacon NXL Drive. T ...

Classic Analog Drives HW Manual

... consequential damages resulting from the inappropriate use of this product. High-performance motion control equipment can move rapidly with very high forces. Unexpected motion may occur especially during product commissioning. Keep clear of any operational machinery and never touch them while they a ...

... consequential damages resulting from the inappropriate use of this product. High-performance motion control equipment can move rapidly with very high forces. Unexpected motion may occur especially during product commissioning. Keep clear of any operational machinery and never touch them while they a ...

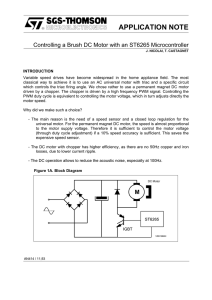

Controlling a brush DC motor with an ST6265

... otherwise fully software. Our application features a 300 watts maximum power, but this value can be easily adjusted by modifying a data table in the program, therefore allowing a very short design modification time if the drive must be used with various motors. 2 WHY USE a MICROCONTROLLER? The class ...

... otherwise fully software. Our application features a 300 watts maximum power, but this value can be easily adjusted by modifying a data table in the program, therefore allowing a very short design modification time if the drive must be used with various motors. 2 WHY USE a MICROCONTROLLER? The class ...

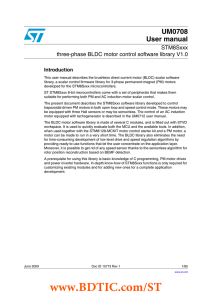

UM0708

... workspace. It is used to quickly evaluate both the MCU and the available tools. In addition, when used together with the STM8/128-MCKIT motor control starter kit and a PM motor, a motor can be made to run in a very short time. The BLDC library also eliminates the need for time-consuming development ...

... workspace. It is used to quickly evaluate both the MCU and the available tools. In addition, when used together with the STM8/128-MCKIT motor control starter kit and a PM motor, a motor can be made to run in a very short time. The BLDC library also eliminates the need for time-consuming development ...

Distributed I/O SIMATIC ET 200

... providing an alternative to the cable harness to connect particularly economical sensors and actuators in the field area via a single 2-wire cable. The power supply to the individual stations also runs via this 2-wire cable. This means that AS-Interface is the ideal partner for the PROFIBUS DP field ...

... providing an alternative to the cable harness to connect particularly economical sensors and actuators in the field area via a single 2-wire cable. The power supply to the individual stations also runs via this 2-wire cable. This means that AS-Interface is the ideal partner for the PROFIBUS DP field ...

SERIES 15V Inverter Control

... Opto-Isolated Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

... Opto-Isolated Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

- Dynamic Controls

... This manual has been designed to help you install and configure a Dynamic Controls (DYNAMIC) SHARK powerchair control system for a ‘generic’ brand powerchair. It describes the general principles, but it gives no guidelines for specific applications. If there is a specific requirement for your applic ...

... This manual has been designed to help you install and configure a Dynamic Controls (DYNAMIC) SHARK powerchair control system for a ‘generic’ brand powerchair. It describes the general principles, but it gives no guidelines for specific applications. If there is a specific requirement for your applic ...

MagnaMaxDVR® Installation, Operation, and

... from shavings when drilling or sawing. An approved connector must be used in conjunction with the conduit. To minimize the transmission of vibration, it is essential that flexible conduit be used for all electrical entrance to the generator. Refer to the connection diagram supplied with the generato ...

... from shavings when drilling or sawing. An approved connector must be used in conjunction with the conduit. To minimize the transmission of vibration, it is essential that flexible conduit be used for all electrical entrance to the generator. Refer to the connection diagram supplied with the generato ...

63-7062 - Variable Frequency Drive (VFD)

... Many of these can be replaced with a standard induction motor and a general purpose PWM VFD to provide a more reliable and cost effective solution to the VFD requirement. Using a VFD often provides energy conservation benefits and improvements in the accuracy of control as a bonus. Many opportunitie ...

... Many of these can be replaced with a standard induction motor and a general purpose PWM VFD to provide a more reliable and cost effective solution to the VFD requirement. Using a VFD often provides energy conservation benefits and improvements in the accuracy of control as a bonus. Many opportunitie ...

Electric motor

An electric motor is an electrical machine that converts electrical energy into mechanical energy. The reverse of this would be the conversion of mechanical energy into electrical energy and is done by an electric generator.In normal motoring mode, most electric motors operate through the interaction between an electric motor's magnetic field and winding currents to generate force within the motor. In certain applications, such as in the transportation industry with traction motors, electric motors can operate in both motoring and generating or braking modes to also produce electrical energy from mechanical energy.Found in applications as diverse as industrial fans, blowers and pumps, machine tools, household appliances, power tools, and disk drives, electric motors can be powered by direct current (DC) sources, such as from batteries, motor vehicles or rectifiers, or by alternating current (AC) sources, such as from the power grid, inverters or generators. Small motors may be found in electric watches. General-purpose motors with highly standardized dimensions and characteristics provide convenient mechanical power for industrial use. The largest of electric motors are used for ship propulsion, pipeline compression and pumped-storage applications with ratings reaching 100 megawatts. Electric motors may be classified by electric power source type, internal construction, application, type of motion output, and so on.Electric motors are used to produce linear or rotary force (torque), and should be distinguished from devices such as magnetic solenoids and loudspeakers that convert electricity into motion but do not generate usable mechanical powers, which are respectively referred to as actuators and transducers.