Introduction to DC Electric Motors

... The movement of the motor comes from the interaction of magnetic fields. A magnetic force that is perpendicular to the magnetic field and the current in the coils delivers a rotational force - torque - that turns the axle of the motor. Intuitively, the higher the torque the greater the force o ...

... The movement of the motor comes from the interaction of magnetic fields. A magnetic force that is perpendicular to the magnetic field and the current in the coils delivers a rotational force - torque - that turns the axle of the motor. Intuitively, the higher the torque the greater the force o ...

electric rotational

... A motor generates rotational motion. Conventional motors use chemical or electromagnetic and electric PE. ie: Car engines (motors) burn gasoline to turn wheels. ...

... A motor generates rotational motion. Conventional motors use chemical or electromagnetic and electric PE. ie: Car engines (motors) burn gasoline to turn wheels. ...

DC Motors 2

... Instead of permanent magnet, we could raise the field strength B with an electromagnet. The wires wrapped around a ferromagnetic core are known as field windings. The field windings are stationary and are part of the stator. ...

... Instead of permanent magnet, we could raise the field strength B with an electromagnet. The wires wrapped around a ferromagnetic core are known as field windings. The field windings are stationary and are part of the stator. ...

FAKULTI KEJURUTERAAN ELEKTRIK, UNIVERSITI TEKNOLOGI

... applications of power electronic converters can be found in almost all aspects of our daily lives. One of the many applications of power electronic converters is electrical drive. In this experiment we will look on how power electronic converters are used to control the speed of small permanent magn ...

... applications of power electronic converters can be found in almost all aspects of our daily lives. One of the many applications of power electronic converters is electrical drive. In this experiment we will look on how power electronic converters are used to control the speed of small permanent magn ...

Abstract - theelectromech.in

... The project is designed to provide low voltage start to induction motors. This is achieved by using star to delta conversion. Star/Delta starters are probably the most common reduced voltage starters in the 50Hz industrial motor world. Star delta is used in an attempt to reduce the start current app ...

... The project is designed to provide low voltage start to induction motors. This is achieved by using star to delta conversion. Star/Delta starters are probably the most common reduced voltage starters in the 50Hz industrial motor world. Star delta is used in an attempt to reduce the start current app ...

EC FANS EN

... Electronically commutated motors also allow the advantages of “soft start” which means lower inrush currents compared to nominal values. The voltage range is much wider than that which is available for traditional motors and due to a 0-10V input these fans can be regulated continuously. This means t ...

... Electronically commutated motors also allow the advantages of “soft start” which means lower inrush currents compared to nominal values. The voltage range is much wider than that which is available for traditional motors and due to a 0-10V input these fans can be regulated continuously. This means t ...

Lab 3

... Hold the motor carefully so you will not be hit by the fan blades. Start with Vin = 1 V and gradually increase Vin until the motor begins to turn. You might need to give the fan blades a small push to get it going. Be careful not to increase the voltage more than you need; the small resistors will d ...

... Hold the motor carefully so you will not be hit by the fan blades. Start with Vin = 1 V and gradually increase Vin until the motor begins to turn. You might need to give the fan blades a small push to get it going. Be careful not to increase the voltage more than you need; the small resistors will d ...

Structures of the Energy flow system

... • Smaller and smoother rotor – lower inertia and inductance – Shorter torque rise time – Faster acceleration ...

... • Smaller and smoother rotor – lower inertia and inductance – Shorter torque rise time – Faster acceleration ...

Project Name“Bicycle”

... Can be added second DC motor Other motor can be added the other wheel and by using special components. the direction of motion of bike can be controlled. Can go with the help of two-way switch The switch which will be added causes changing direction of motion. ...

... Can be added second DC motor Other motor can be added the other wheel and by using special components. the direction of motion of bike can be controlled. Can go with the help of two-way switch The switch which will be added causes changing direction of motion. ...

Speed Control With Low Armature Loss for Very Small Sensorless

... Low-cost and mechanically small brushed motors do not have a dedicated shaft sensor; therefore,backelectromotive-force (EMF) sensing is the established way to sense speed. With pulsewidth modulation (PWM), speed sensing is achieved by running the motor in discontinuousconduction mode and directly ...

... Low-cost and mechanically small brushed motors do not have a dedicated shaft sensor; therefore,backelectromotive-force (EMF) sensing is the established way to sense speed. With pulsewidth modulation (PWM), speed sensing is achieved by running the motor in discontinuousconduction mode and directly ...

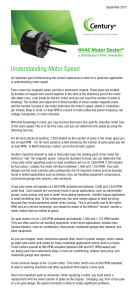

Understanding Motor Speed

... the no load RPM. For 50 hertz systems: 6,000 divided by the number of poles gives you the no load RPM. In North American, motors run on the 60 hertz system. Another important element to note is that under load, the rotating parts of the motor fall behind or “slip” the magnetic speed. Using the stand ...

... the no load RPM. For 50 hertz systems: 6,000 divided by the number of poles gives you the no load RPM. In North American, motors run on the 60 hertz system. Another important element to note is that under load, the rotating parts of the motor fall behind or “slip” the magnetic speed. Using the stand ...

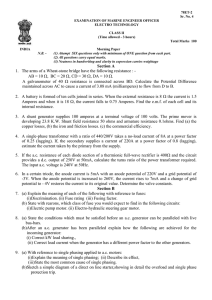

6 Lead, Single Voltage, Wye Start / Delta Run

... connected in wye, then reconnected in delta for running condition." This is accomplished by a special Wye-Delta starter configuration using six leads from the motor and is intended to limit the inrush current required to start the motor. Motors designed by US Motors for Wye start, Delta Run may also ...

... connected in wye, then reconnected in delta for running condition." This is accomplished by a special Wye-Delta starter configuration using six leads from the motor and is intended to limit the inrush current required to start the motor. Motors designed by US Motors for Wye start, Delta Run may also ...

Brushed DC electric motor

A brushed DC motor is an internally commutated electric motor designed to be run from a direct current power source. Brushed motors were the first commercially important application of electric power to driving mechanical energy,and DC distribution systems were used for more than 100 years to operate motors in commercial and industrial buildings. Brushed DC motors can be varied in speed by changing the operating voltage or the strength of the magnetic field. Depending on the connections of the field to the power supply, the speed and torque characteristics of a brushed motor can be altered to provide steady speed or speed inversely proportional to the mechanical load. Brushed motors continue to be used for electrical propulsion, cranes, paper machines and steel rolling mills. Since the brushes wear down and require replacement, brushless DC motors using power electronic devices have displaced brushed motors from many applications