Lecture03-motors

... motor’s spin; transistors absorb the energy generated by the motor and cause it to stop. If, on the other hand, none of the transistors is active, then the motor is allowed to spin freely; i.e., to coast ...

... motor’s spin; transistors absorb the energy generated by the motor and cause it to stop. If, on the other hand, none of the transistors is active, then the motor is allowed to spin freely; i.e., to coast ...

SUMMARY OF TOPICS

... document and ANSI/NEMA MG-1, Standard for Motors and Generators and CSA C22.2 No. 100, Standard for Motors and Generators. b) Provision for a methodology to perform the ratings and temperature tests on air-over motors - Some thermally protected motors intended for air-over are unique in that they re ...

... document and ANSI/NEMA MG-1, Standard for Motors and Generators and CSA C22.2 No. 100, Standard for Motors and Generators. b) Provision for a methodology to perform the ratings and temperature tests on air-over motors - Some thermally protected motors intended for air-over are unique in that they re ...

2012S

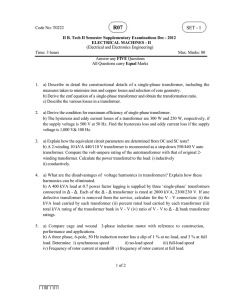

... 6. a) What is the purpose of using deep-bar cage rotors? Explain the construction and working of a deep-bar cage motor. b) The power input to a 3 phase, 6-pole, 440V, 50 Hz induction motor is 80 kW. The rotor e.m.f is observed to make 100 complete revolutions per minute. Calculate i) slip ii) rotor ...

... 6. a) What is the purpose of using deep-bar cage rotors? Explain the construction and working of a deep-bar cage motor. b) The power input to a 3 phase, 6-pole, 440V, 50 Hz induction motor is 80 kW. The rotor e.m.f is observed to make 100 complete revolutions per minute. Calculate i) slip ii) rotor ...

Electrical Safety - HCC Learning Web

... Another type of overload is the internal overload used in hermetic compressors. This type of overload is actually embedded in the windings of the hermetic compressor motor, which gives it a faster response to overloads. The type of internal overload currently used is hard to check because it has no ...

... Another type of overload is the internal overload used in hermetic compressors. This type of overload is actually embedded in the windings of the hermetic compressor motor, which gives it a faster response to overloads. The type of internal overload currently used is hard to check because it has no ...

Drawing the Maze

... The same algorithmic idea on GUNDAM is applied to path to predict next stretch of maze pathways to draw out as the GUNDAM’s next move Packets may be lost or resent, causing software to not be reliable ...

... The same algorithmic idea on GUNDAM is applied to path to predict next stretch of maze pathways to draw out as the GUNDAM’s next move Packets may be lost or resent, causing software to not be reliable ...

5-PH Stepping Motor Driver RD-053A ((22CCKK IInnppuutt

... Stepping motor drive current turns OFF at Low level (connects to GND potential) and the motor shaft can be rotated by hand. When turning FREE input to High level (open) again, the motor is excited at the phase home. CLOCK OUT (Output) Outputs clock pulses input to Clock input terminal CW(CLOCK), CCW ...

... Stepping motor drive current turns OFF at Low level (connects to GND potential) and the motor shaft can be rotated by hand. When turning FREE input to High level (open) again, the motor is excited at the phase home. CLOCK OUT (Output) Outputs clock pulses input to Clock input terminal CW(CLOCK), CCW ...

Motor Single-Phasing Voltage Unbalance

... From the above data, it can be seen that 44% of motor failure problems are related to HEAT. Allowing a motor to reach and operate at a temperature 10°C above its maximum temperature rating will reduce the motor’s expected life by 50%. Operating at 10°C above this, the motor’s life will be reduced ag ...

... From the above data, it can be seen that 44% of motor failure problems are related to HEAT. Allowing a motor to reach and operate at a temperature 10°C above its maximum temperature rating will reduce the motor’s expected life by 50%. Operating at 10°C above this, the motor’s life will be reduced ag ...

Online Off-Site Condition Monitoring Of Three Phase

... The MCSA (Motor Current Signal Analysis) is a noninvasive, on-line monitoring technique for diagnosing problems in induction motors. This method is based on the spectral decomposition of the steady state stator current which can be acquired with simple measurement equipment and under normal operatio ...

... The MCSA (Motor Current Signal Analysis) is a noninvasive, on-line monitoring technique for diagnosing problems in induction motors. This method is based on the spectral decomposition of the steady state stator current which can be acquired with simple measurement equipment and under normal operatio ...

III Sem

... hysteresis, series and parallel magnetic circuits, practical magnetic circuits, permanent magnet and their applications. hysteresis, series and parallel magnetic circuits, practical magnetic circuits, permanent magnet and their applications. hysteresis, series and parallel magnetic circuits, practic ...

... hysteresis, series and parallel magnetic circuits, practical magnetic circuits, permanent magnet and their applications. hysteresis, series and parallel magnetic circuits, practical magnetic circuits, permanent magnet and their applications. hysteresis, series and parallel magnetic circuits, practic ...

Ahmad Shtaiyat

... a. while ( distance >= 20 ) : move forward , So our path will be forward . b. while ( distance < 20 ) : change the angle to left , Then recalculate the distance . change the angle to right , Then recalculate the distance . move in the direction of the larger distance . still doing this unt ...

... a. while ( distance >= 20 ) : move forward , So our path will be forward . b. while ( distance < 20 ) : change the angle to left , Then recalculate the distance . change the angle to right , Then recalculate the distance . move in the direction of the larger distance . still doing this unt ...

Microelectromechanical Devices

... Control of BLDM Drives (cont’d) The switches Q1-Q6 are switched on so that the input dc current Id is symmetrically located at the center of each phase voltage wave. At any instant in time, one switch from the upper group (Q1,Q3,Q5) and one switch from the lower group (Q2,Q4,Q6) are on together. Th ...

... Control of BLDM Drives (cont’d) The switches Q1-Q6 are switched on so that the input dc current Id is symmetrically located at the center of each phase voltage wave. At any instant in time, one switch from the upper group (Q1,Q3,Q5) and one switch from the lower group (Q2,Q4,Q6) are on together. Th ...

TEMP EFFECTS full paper Jan3.indd

... Motor winding resistance (Rmt) is the main cause of heat generation within the motor. In order for any electric motor to generate torque, current needs to be forced through the motor windings. Copper is an excellent conductor, however, it’s not perfect; material physics and impurities will cause the ...

... Motor winding resistance (Rmt) is the main cause of heat generation within the motor. In order for any electric motor to generate torque, current needs to be forced through the motor windings. Copper is an excellent conductor, however, it’s not perfect; material physics and impurities will cause the ...

Using the MP6530 Family of Pre

... which is acted upon by three sets of coils. To make the motor move, the magnetic field generated by the coils is rotated, or commutated, by an electronic driver. The simplest form of 3-phase BLDC motor, which has a 2-pole rotor (one north pole and one south pole) is shown in Figure 1. BLDC motors ca ...

... which is acted upon by three sets of coils. To make the motor move, the magnetic field generated by the coils is rotated, or commutated, by an electronic driver. The simplest form of 3-phase BLDC motor, which has a 2-pole rotor (one north pole and one south pole) is shown in Figure 1. BLDC motors ca ...

Intro_to_Motors Workshop

... Some motors have an internal circuit breaker, which will stop the motor, or PTC thermistor*, which will stop or slow the motor by increasing its electrical resistance, if the motor gets too hot. After the motor cools, it runs normally again. ...

... Some motors have an internal circuit breaker, which will stop the motor, or PTC thermistor*, which will stop or slow the motor by increasing its electrical resistance, if the motor gets too hot. After the motor cools, it runs normally again. ...

Arduino, PWM, MOSFETs and Motors

... wires. Use the alligator clips to connect the motor leads to the breadboard. Ensure that the kickback diode is in place and the cathode points to the high voltage power rail. Do all circuit construction without the power supply connected. Generate a PWM signal with the function generator. Use the os ...

... wires. Use the alligator clips to connect the motor leads to the breadboard. Ensure that the kickback diode is in place and the cathode points to the high voltage power rail. Do all circuit construction without the power supply connected. Generate a PWM signal with the function generator. Use the os ...

Starting Time Calculation for Induction Motor

... the heavy applications requirement. Some are considered large even in comparison to the total capacity of large industrial power systems. Starting of such large motors can cause adverse effects to any locally connected load, other motors and also to buses, which are electrically remote from the poin ...

... the heavy applications requirement. Some are considered large even in comparison to the total capacity of large industrial power systems. Starting of such large motors can cause adverse effects to any locally connected load, other motors and also to buses, which are electrically remote from the poin ...

THE FUNDAMENTALS OF AC ELECTRIC INDUCTION MOTOR

... three-phase system. The rotor also consists of laminations of slotted ferromagnetic material, but the rotor winding may be either the squirrel-cage type or the wound-rotor type. The latter is of a form similar to that of the stator winding. The winding terminals are brought out to three slip rings. ...

... three-phase system. The rotor also consists of laminations of slotted ferromagnetic material, but the rotor winding may be either the squirrel-cage type or the wound-rotor type. The latter is of a form similar to that of the stator winding. The winding terminals are brought out to three slip rings. ...

60ml “TL-CL

... ring circuit. Thus in the particular embodiment shown, trol stage to the next and therefore that there is a step there is a closed cycle of operations in the sequency ping-on of the direct current ?ow from one phase wind power transistors 5-6—~7—5-6. Also, each control stage is 10 ing to the next-in ...

... ring circuit. Thus in the particular embodiment shown, trol stage to the next and therefore that there is a step there is a closed cycle of operations in the sequency ping-on of the direct current ?ow from one phase wind power transistors 5-6—~7—5-6. Also, each control stage is 10 ing to the next-in ...

Brushless DC electric motor

Brushless DC electric motor (BLDC motors, BL motors) also known as electronically commutated motors (ECMs, EC motors) are synchronous motors that are powered by a DC electric source via an integrated inverter/switching power supply, which produces an AC electric signal to drive the motor. In this context, AC, alternating current, does not imply a sinusoidal waveform, but rather a bi-directional current with no restriction on waveform. Additional sensors and electronics control the inverter output amplitude and waveform (and therefore percent of DC bus usage/efficiency) and frequency (i.e. rotor speed).The rotor part of a brushless motor is often a permanent magnet synchronous motor, but can also be a switched reluctance motor, or induction motor.Brushless motors may be described as stepper motors; however, the term stepper motor tends to be used for motors that are designed specifically to be operated in a mode where they are frequently stopped with the rotor in a defined angular position. This page describes more general brushless motor principles, though there is overlap.Two key performance parameters of brushless DC motors are the motor constants Kv and Km.