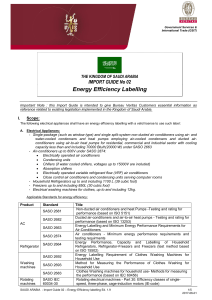

Energy Efficiency Labelling - Verigates

... Tariff code no. (850153000001): electric motors with alternating current, with power exceeding 75 Kilowatt but does not exceed 375 Kilowatt Excluding the following types: Motors made solely for converter operation in accordance with IEC 60034-25 Motors completely integrated into a machine (for e ...

... Tariff code no. (850153000001): electric motors with alternating current, with power exceeding 75 Kilowatt but does not exceed 375 Kilowatt Excluding the following types: Motors made solely for converter operation in accordance with IEC 60034-25 Motors completely integrated into a machine (for e ...

datasheet

... holes at the bottom of the case. The units may be vertically wall mounted or horizontally bench mounted using the three keyholes on the back of the case. 1. For access to the keyholes and the terminal strip, remove the two screws from the front of the case by turning them counterclockwise. Grasp the ...

... holes at the bottom of the case. The units may be vertically wall mounted or horizontally bench mounted using the three keyholes on the back of the case. 1. For access to the keyholes and the terminal strip, remove the two screws from the front of the case by turning them counterclockwise. Grasp the ...

Basic Motor Theory

... Figure 12 - How three-phase power produces a rotating magnetic field. Up to this point not much has been said about the rotor. In the previous examples, it has been assumed the rotor poles were wound with coils, just as the stator poles, and supplied with DC to create fixed polarity poles. This, by ...

... Figure 12 - How three-phase power produces a rotating magnetic field. Up to this point not much has been said about the rotor. In the previous examples, it has been assumed the rotor poles were wound with coils, just as the stator poles, and supplied with DC to create fixed polarity poles. This, by ...

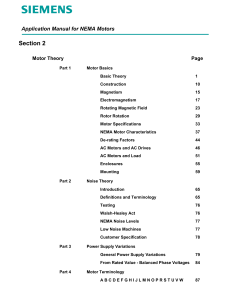

Section 2

... Indication of how fast the output shaft will turn the connected equipment when fully loaded with proper voltage and frequency applied. The base speed of this motor is 1780 RPM (60Hz) and 1475 RPM (50Hz). It is known that the synchronous speed of a 4-pole motor is 1800 RPM. When fully loaded there wi ...

... Indication of how fast the output shaft will turn the connected equipment when fully loaded with proper voltage and frequency applied. The base speed of this motor is 1780 RPM (60Hz) and 1475 RPM (50Hz). It is known that the synchronous speed of a 4-pole motor is 1800 RPM. When fully loaded there wi ...

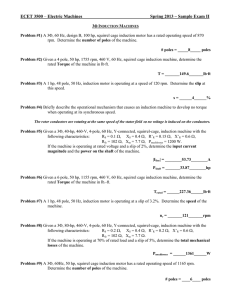

ECET 3500

... can have the number of its turns increased or decreased in order to control the speed of the motor may be connected in series with an external, variable resistor to provide a method of speed control will have the same current flowing through it that is flowing through the machine’s rotor windings al ...

... can have the number of its turns increased or decreased in order to control the speed of the motor may be connected in series with an external, variable resistor to provide a method of speed control will have the same current flowing through it that is flowing through the machine’s rotor windings al ...

Supplementary #2

... DC motors are dc machine used as motors. DC generator are dc machines used as generators. DC machine is most often used for a motor. The major advantages of dc machines are the (i) easy speed and (ii) torque regulation. However, their application is limited to mills, mines and trains. As examples, ...

... DC motors are dc machine used as motors. DC generator are dc machines used as generators. DC machine is most often used for a motor. The major advantages of dc machines are the (i) easy speed and (ii) torque regulation. However, their application is limited to mills, mines and trains. As examples, ...

AB2 Driver User Manual D/N: AB02458000-00 REV: C

... Nanomotion Ltd. (hereinafter NM) warrants the product (other than software) manufactured by it to be free from defects in material and workmanship for a period of time of one year (except those parts normally considered as consumable/expendable components such as motor conditioning brushes). The war ...

... Nanomotion Ltd. (hereinafter NM) warrants the product (other than software) manufactured by it to be free from defects in material and workmanship for a period of time of one year (except those parts normally considered as consumable/expendable components such as motor conditioning brushes). The war ...

Troubleshooting Induction Motors

... Abstract: The keys to successful motor operation include a total understanding of the application, then choosing the proper type of motor for the application. This must then be followed by the proper installation – mounting, coupling, and a total understanding of the motor surroundings or environmen ...

... Abstract: The keys to successful motor operation include a total understanding of the application, then choosing the proper type of motor for the application. This must then be followed by the proper installation – mounting, coupling, and a total understanding of the motor surroundings or environmen ...

NEMA 4X, PWM DC Control

... To start the drive: 1. Turn the speed adjust potentiometer full counter-clockwise (CCW) or set the voltage signal to zero. 2. Open the brake, enable and direction switches. 3. Apply DC power to (BAT +) and (BAT -) then close the enable switch. 4. Slowly advance the speed adjust potentiometer clockwi ...

... To start the drive: 1. Turn the speed adjust potentiometer full counter-clockwise (CCW) or set the voltage signal to zero. 2. Open the brake, enable and direction switches. 3. Apply DC power to (BAT +) and (BAT -) then close the enable switch. 4. Slowly advance the speed adjust potentiometer clockwi ...

Making of Micromouse - India Electronics and Robotics Components

... kp is proportional controller constant kd is derivative controller constant The value of adj is used to either speed up or speed down one of the wheel . www.raghu.co.nr ...

... kp is proportional controller constant kd is derivative controller constant The value of adj is used to either speed up or speed down one of the wheel . www.raghu.co.nr ...

Chapter 9 – DC Motors and Generators

... Poles are made of permanent magnets instead of field coils. Advantages: - No copper losses of field circuit - Smaller motor due to elimination of field winding Common in smaller fractional and subfractional-horsepower sizes. Disadvantages: - Permanent-magnet cannot produce as high a flux density as ...

... Poles are made of permanent magnets instead of field coils. Advantages: - No copper losses of field circuit - Smaller motor due to elimination of field winding Common in smaller fractional and subfractional-horsepower sizes. Disadvantages: - Permanent-magnet cannot produce as high a flux density as ...

Electrical Wiring #675 - Hytrol Conveyor Co., Inc.

... switch, but has the added advantage of being able to reverse the motor. It is standard equipment on most HYTROL portable model conveyors, and is normally mounted near the conveyor drive. The reversing drum switch is considered as a single point control, but may be extended through the use of a remot ...

... switch, but has the added advantage of being able to reverse the motor. It is standard equipment on most HYTROL portable model conveyors, and is normally mounted near the conveyor drive. The reversing drum switch is considered as a single point control, but may be extended through the use of a remot ...

LK3420692075

... improve the performance of the system compare to two-level inverter. Three-level inversion is realized by connecting two two-level inverters in cascade, in the proposed configuration [8] .An isolated DC power supply is used to supply each inverter in this power circuit. Each DC-link voltage is equal ...

... improve the performance of the system compare to two-level inverter. Three-level inversion is realized by connecting two two-level inverters in cascade, in the proposed configuration [8] .An isolated DC power supply is used to supply each inverter in this power circuit. Each DC-link voltage is equal ...

... corresponding to a pre-determined speed of rotation, followed by one or more periods of operation at other constant loads corresponding to different speeds of rotation (carried out, for example, by means of a change of the number of poles in the case of induction motors) NOTE There is no rest or de- ...

IOSR Journal of Electrical and Electronics Engineering (IOSRJEEE)

... Stator voltage. (b) Torque*. (c) Stator and rotor fluxes*. (d) Rotor currents*. (e) Stator currents*. (f) DC bus voltage**. (g) Torque**. (h) Stator and rotor fluxes**. (i) Rotor currents**. (j) Stator currents**. Order to handle with voltage dips. When the wind turbine is affected by a voltage dip, ...

... Stator voltage. (b) Torque*. (c) Stator and rotor fluxes*. (d) Rotor currents*. (e) Stator currents*. (f) DC bus voltage**. (g) Torque**. (h) Stator and rotor fluxes**. (i) Rotor currents**. (j) Stator currents**. Order to handle with voltage dips. When the wind turbine is affected by a voltage dip, ...

1S120 Manual

... Well-performed throttle and brake control function could control the punch/brake rate by point and the point can be set by user. The precision of the punch/brake rate is 1. And the user could also custom the throttle/brake curve. Punch control is reasonable and precise and can meet different custome ...

... Well-performed throttle and brake control function could control the punch/brake rate by point and the point can be set by user. The precision of the punch/brake rate is 1. And the user could also custom the throttle/brake curve. Punch control is reasonable and precise and can meet different custome ...

Layne Bowler Submersible Pumps Operating Manual

... These Instructions must always be kept close to the product’s operating location or directly with the product. The unit is produced with great care and commitment to continuous quality control, utilizing sophisticated quality techniques, and safety requirements. Layne Bowler as were designed pumps d ...

... These Instructions must always be kept close to the product’s operating location or directly with the product. The unit is produced with great care and commitment to continuous quality control, utilizing sophisticated quality techniques, and safety requirements. Layne Bowler as were designed pumps d ...

Brushless DC electric motor

Brushless DC electric motor (BLDC motors, BL motors) also known as electronically commutated motors (ECMs, EC motors) are synchronous motors that are powered by a DC electric source via an integrated inverter/switching power supply, which produces an AC electric signal to drive the motor. In this context, AC, alternating current, does not imply a sinusoidal waveform, but rather a bi-directional current with no restriction on waveform. Additional sensors and electronics control the inverter output amplitude and waveform (and therefore percent of DC bus usage/efficiency) and frequency (i.e. rotor speed).The rotor part of a brushless motor is often a permanent magnet synchronous motor, but can also be a switched reluctance motor, or induction motor.Brushless motors may be described as stepper motors; however, the term stepper motor tends to be used for motors that are designed specifically to be operated in a mode where they are frequently stopped with the rotor in a defined angular position. This page describes more general brushless motor principles, though there is overlap.Two key performance parameters of brushless DC motors are the motor constants Kv and Km.