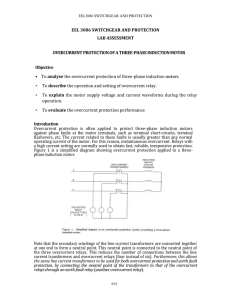

EET 3092 SWITCHGEAR AND PROTECTION

... Current Transformers, AC Ammeter, and AC Voltmeter in the EMS Workstation. Mechanically couple the Four-Pole Squirrel-Cage Induction Motor to the Prime Mover / Dynamometer using the timing belt. Make sure the Power Supply is turned off and its voltage control knob is set to the ‘0’ position. Connect ...

... Current Transformers, AC Ammeter, and AC Voltmeter in the EMS Workstation. Mechanically couple the Four-Pole Squirrel-Cage Induction Motor to the Prime Mover / Dynamometer using the timing belt. Make sure the Power Supply is turned off and its voltage control knob is set to the ‘0’ position. Connect ...

26 29 13 Motor Controls

... In Finished Areas: Square D, Class 2510, or Allen Bradley, flush mounted, sized to fit standard outlet boxes. Include plates to match general device plate types. Include manufacturer's direction plate for resetting overloads. Plates shall be engraved as noted. ...

... In Finished Areas: Square D, Class 2510, or Allen Bradley, flush mounted, sized to fit standard outlet boxes. Include plates to match general device plate types. Include manufacturer's direction plate for resetting overloads. Plates shall be engraved as noted. ...

Manual Motor Controllers (MMPs)

... 489, and therefore they cannot be listed as a circuit breaker. MMPs cannot provide motor branch circuit short-circuit and ground fault protection. They need a branch circuit overcurrent device and a motor disconnecting means on the line side for both single motor and group motor applications. Some I ...

... 489, and therefore they cannot be listed as a circuit breaker. MMPs cannot provide motor branch circuit short-circuit and ground fault protection. They need a branch circuit overcurrent device and a motor disconnecting means on the line side for both single motor and group motor applications. Some I ...

ICM326HM2 - ICM Controls

... • Multiple voltage ranges: see specifications for details • Hard start: adjustable from 1-5 seconds; provides full torque to the motor during startup to help ensure proper fan rotation and lubrication of bearings • Low speed cutoff field adjustable; user may set the minimum RPM level at which the ...

... • Multiple voltage ranges: see specifications for details • Hard start: adjustable from 1-5 seconds; provides full torque to the motor during startup to help ensure proper fan rotation and lubrication of bearings • Low speed cutoff field adjustable; user may set the minimum RPM level at which the ...

Basic Controls, 4-1 Friction Brakes

... motor in lifting appliances. They are also used to reduce motor stopping time and execute precise control. Friction brakes operate in a manner similar to automobile brakes. Braking is accomplished by friction surfaces (shoes or pads), which come in contact with a disk mounted on the motor shaft. A s ...

... motor in lifting appliances. They are also used to reduce motor stopping time and execute precise control. Friction brakes operate in a manner similar to automobile brakes. Braking is accomplished by friction surfaces (shoes or pads), which come in contact with a disk mounted on the motor shaft. A s ...

IOSR Journal of Electrical and Electronics Engineering (IOSR-JEEE)

... has a relatively simple and wide range of control structure at least as good as the FOC technique . It is also known that DTC drive is less sensitive to parameter changing. DTC method is based mainly on space vector theory by selecting proper space vector voltage across the sampling period the requi ...

... has a relatively simple and wide range of control structure at least as good as the FOC technique . It is also known that DTC drive is less sensitive to parameter changing. DTC method is based mainly on space vector theory by selecting proper space vector voltage across the sampling period the requi ...

Low Voltage and Medium Voltage Variable Frequency Drives

... significantly in the last decade due to improvements in switching devices, cooling system, harmonic mitigation, design of converters/inverters and control systems. VFD technology has matured and the cost of adopting it has become more economical as is evident by the increased number of drives put in ...

... significantly in the last decade due to improvements in switching devices, cooling system, harmonic mitigation, design of converters/inverters and control systems. VFD technology has matured and the cost of adopting it has become more economical as is evident by the increased number of drives put in ...

gTB 2 track guide trouble-shooting guide error/LED codes

... Free-running your brushless motor in a no-load condition can cause rotor failure & ESC transistor damage that will not be covered by the product’s warranty. ...

... Free-running your brushless motor in a no-load condition can cause rotor failure & ESC transistor damage that will not be covered by the product’s warranty. ...

Brushless DC Motor Unit - User`s Guide

... for any purpose other than its intended use. Use a direct current power supply with reinforced insulation between the primary and secondary circuits. The manufacturer shall not be held liable for the compensation of any damage caused as a result of neglecting this warning. The performance, specifica ...

... for any purpose other than its intended use. Use a direct current power supply with reinforced insulation between the primary and secondary circuits. The manufacturer shall not be held liable for the compensation of any damage caused as a result of neglecting this warning. The performance, specifica ...

AN-828 Increasing the High Speed Torque of

... Chopper drives increase the slew rates of the winding currents by applying VCC >> Vrated. Feedback-driven switching of the H-bridges holds the winding currents to the rated limit. Figure 11 shows the chopping states of a single H-bridge of a chopper drive. A low value resistor in the ground lead of ...

... Chopper drives increase the slew rates of the winding currents by applying VCC >> Vrated. Feedback-driven switching of the H-bridges holds the winding currents to the rated limit. Figure 11 shows the chopping states of a single H-bridge of a chopper drive. A low value resistor in the ground lead of ...

AG#37EM _Imp Features of Stator Slot Insul Systems_

... bombarding the windings. Quality/reputable manufacturers use heat shrink type lashing material which optimally tightened when it is heated before the varnishing process. This is also a Toshiba standard lashing material. • Varnish provides additional insulating properties plus mechanical strength. On ...

... bombarding the windings. Quality/reputable manufacturers use heat shrink type lashing material which optimally tightened when it is heated before the varnishing process. This is also a Toshiba standard lashing material. • Varnish provides additional insulating properties plus mechanical strength. On ...

Variable Frequency Drives for conveyor starting

... ncreasingly, the advantages of using variable frequency drives (VFDs) are expanding their use as the starter of choice, not only in applications that require speed control but also in applications that require torque control and mechanical ‘soft starting’. Conveyor belt application is one such examp ...

... ncreasingly, the advantages of using variable frequency drives (VFDs) are expanding their use as the starter of choice, not only in applications that require speed control but also in applications that require torque control and mechanical ‘soft starting’. Conveyor belt application is one such examp ...

IMPULSE ® •VG+ Series 3 Theory of Operation IMPULSE ® Drive

... tells the motor what to do, then checks to see if it did it, then changes its command to correct for any error.” ...

... tells the motor what to do, then checks to see if it did it, then changes its command to correct for any error.” ...

Can-Stack Stepper Motor Linear

... Unique features impart ruggedness and reliability that assure long life and consistent performance. Rare earth magnets are available for even higher thrust. All basic frame sizes are built with dual ball bearings for greater motion control, precise step accuracy and long life. For finer steps, the H ...

... Unique features impart ruggedness and reliability that assure long life and consistent performance. Rare earth magnets are available for even higher thrust. All basic frame sizes are built with dual ball bearings for greater motion control, precise step accuracy and long life. For finer steps, the H ...

instructions for knopp phase sequence

... and enhances service efficiency. By determining which terminals of a newly installed polyphase power circuit are to be connected to the sequence identified motor terminals, one eliminates the trial-and-error method and thus prevents damage and saves time. Obviously the trial-and-error method is not ...

... and enhances service efficiency. By determining which terminals of a newly installed polyphase power circuit are to be connected to the sequence identified motor terminals, one eliminates the trial-and-error method and thus prevents damage and saves time. Obviously the trial-and-error method is not ...

SLO-SYN Bipolar Model SD200 Step Motor Drive

... twisted pair type cable with appropriate cross-section for each motor phase. This will help minimize DC losses and RFI problems. As a guideline, the wires should be twisted about six times per foot. ...

... twisted pair type cable with appropriate cross-section for each motor phase. This will help minimize DC losses and RFI problems. As a guideline, the wires should be twisted about six times per foot. ...

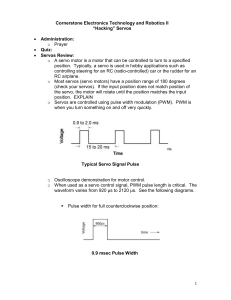

erii18_servos - Cornerstone Robotics

... o Now, use servo1.pbp to experiment with the 16F84A chip on your breadboard. Test values between 100 and 200. Find the setting around B0 = 150 that stops the servo from rotating. ...

... o Now, use servo1.pbp to experiment with the 16F84A chip on your breadboard. Test values between 100 and 200. Find the setting around B0 = 150 that stops the servo from rotating. ...

An alternator is an electrical generator that converts mechanical

... alternators are designed to be explosion proof so that brush sparking will not ignite explosive gas mixtures in an engine room environment. Alternator mounted on an automobile They may be 12 or 24 volt depending on the type of system installed. engine with a serpentine belt pulley Larger marine dies ...

... alternators are designed to be explosion proof so that brush sparking will not ignite explosive gas mixtures in an engine room environment. Alternator mounted on an automobile They may be 12 or 24 volt depending on the type of system installed. engine with a serpentine belt pulley Larger marine dies ...

Viesturs Bražis. Asynchronous electric drive with frontal part winding

... the full supply voltage does not provide the quality starting process because motor torque and current are not restricted at all. The induction motor parametric control includes the stator voltage control during start. In the second half of 20th century this method were researched by L. Petrov [10] ...

... the full supply voltage does not provide the quality starting process because motor torque and current are not restricted at all. The induction motor parametric control includes the stator voltage control during start. In the second half of 20th century this method were researched by L. Petrov [10] ...

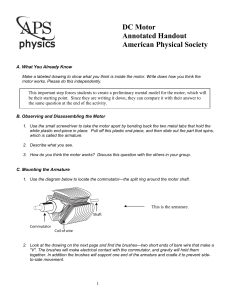

DC Motor Workshop

... In the diagram, one turn of each coil is shown, and these coils have been rotated 90° towards your line of sight. Follow the direction of the positive current, which enters the commutator on the right and then splits, with part going into the lower coil and the rest into the upper right coil (the br ...

... In the diagram, one turn of each coil is shown, and these coils have been rotated 90° towards your line of sight. Follow the direction of the positive current, which enters the commutator on the right and then splits, with part going into the lower coil and the rest into the upper right coil (the br ...

EE – 3410 Electric Power Electromechanical Energy Conversion

... The secondary part can be in a form of permanent magnet as shown in Fig.2. In this case the magnetic force acting on the “rotor” is an effect of interaction of two magnetic fields: one produced by the “stator” and another one by the “rotor”. The “rotor” moves here synchronously with the magnetic fie ...

... The secondary part can be in a form of permanent magnet as shown in Fig.2. In this case the magnetic force acting on the “rotor” is an effect of interaction of two magnetic fields: one produced by the “stator” and another one by the “rotor”. The “rotor” moves here synchronously with the magnetic fie ...

Demagnetization Diagnosis of Permanent Magnet Synchronous

... Recently, electric vehicles have got significant attention because it is more eco-friendly and efficient than internal combustion engine vehicles. Instead of an internal combustion engine, the electric vehicle has a motor for propulsion. The permanent magnet synchronous motor which has permanent mag ...

... Recently, electric vehicles have got significant attention because it is more eco-friendly and efficient than internal combustion engine vehicles. Instead of an internal combustion engine, the electric vehicle has a motor for propulsion. The permanent magnet synchronous motor which has permanent mag ...

Jim Hendershot - Coil Winding Expo

... combining Jim’s practical hands-on motor design skills with TIM’S theoretical knowledge and research For the past few years Jim has also been associated with Infolytica Corp, Prof. Dave Lowther (of McGill University), Prof. Ernie Freeman retired from Imperial College, London and their staff for cont ...

... combining Jim’s practical hands-on motor design skills with TIM’S theoretical knowledge and research For the past few years Jim has also been associated with Infolytica Corp, Prof. Dave Lowther (of McGill University), Prof. Ernie Freeman retired from Imperial College, London and their staff for cont ...

Brushless DC electric motor

Brushless DC electric motor (BLDC motors, BL motors) also known as electronically commutated motors (ECMs, EC motors) are synchronous motors that are powered by a DC electric source via an integrated inverter/switching power supply, which produces an AC electric signal to drive the motor. In this context, AC, alternating current, does not imply a sinusoidal waveform, but rather a bi-directional current with no restriction on waveform. Additional sensors and electronics control the inverter output amplitude and waveform (and therefore percent of DC bus usage/efficiency) and frequency (i.e. rotor speed).The rotor part of a brushless motor is often a permanent magnet synchronous motor, but can also be a switched reluctance motor, or induction motor.Brushless motors may be described as stepper motors; however, the term stepper motor tends to be used for motors that are designed specifically to be operated in a mode where they are frequently stopped with the rotor in a defined angular position. This page describes more general brushless motor principles, though there is overlap.Two key performance parameters of brushless DC motors are the motor constants Kv and Km.