Corrosion of Aluminium and Zinc-Aluminium Alloys Based Metal

... General thinning takes place until failure. Uniform corrosion is relatively easily measured and predicted. In many cases it is objectionable only from an appearance standpoint. Zinc-aluminium alloys corrode in a uniform manner, unlike aluminium alloys which are prone to pitting corrosion. Pitting co ...

... General thinning takes place until failure. Uniform corrosion is relatively easily measured and predicted. In many cases it is objectionable only from an appearance standpoint. Zinc-aluminium alloys corrode in a uniform manner, unlike aluminium alloys which are prone to pitting corrosion. Pitting co ...

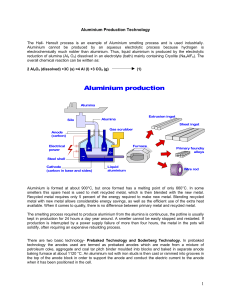

For detailed information on Aluminium Production

... of the electrolyte. It is added in the form of lithium carbonate (Li2Co3), which reacts with aluminium fluoride dissolved in the electrolyte to form dissolved lithium fluoride. Its consumption varies 2-3 Kgs of Li2CO3 per ton of aluminium to maintain a concentration of 1.5 – 3.0 mass% LiF. IX Magnes ...

... of the electrolyte. It is added in the form of lithium carbonate (Li2Co3), which reacts with aluminium fluoride dissolved in the electrolyte to form dissolved lithium fluoride. Its consumption varies 2-3 Kgs of Li2CO3 per ton of aluminium to maintain a concentration of 1.5 – 3.0 mass% LiF. IX Magnes ...

The production and use of metals

... down and steel production has decreased however, also because of pollution, economic prosperity has declined in the area and people have started to move away. The uses and properties of aluminium, copper and titanium. A property of a metal is how it behaves, for example it might be very strong, a go ...

... down and steel production has decreased however, also because of pollution, economic prosperity has declined in the area and people have started to move away. The uses and properties of aluminium, copper and titanium. A property of a metal is how it behaves, for example it might be very strong, a go ...

[edit]Occurrence in solution

... radiation. The yield strength of pure aluminium is 7–11 MPa, whilealuminium alloys have yield strengths ranging from 200 MPa to 600 MPa.[6] Aluminium has about one-third thedensity and stiffness of steel. It is easily machined, cast, drawn and extruded. Corrosion resistance can be excellent due to a ...

... radiation. The yield strength of pure aluminium is 7–11 MPa, whilealuminium alloys have yield strengths ranging from 200 MPa to 600 MPa.[6] Aluminium has about one-third thedensity and stiffness of steel. It is easily machined, cast, drawn and extruded. Corrosion resistance can be excellent due to a ...

Aluminum Alloy Designation

... treated condition mechanical properties are similar to, and sometimes exceed, those of mild steel. In some instances artificial aging in employed to further increase the mechanical properties. This treatment materially increases yield strength, with attendant loss in elongation; its effort on the te ...

... treated condition mechanical properties are similar to, and sometimes exceed, those of mild steel. In some instances artificial aging in employed to further increase the mechanical properties. This treatment materially increases yield strength, with attendant loss in elongation; its effort on the te ...

prediction of room temperature mechanical properties in aluminium

... Sente Software Ltd., Surrey Technology Centre, Guildford GU2 7YG, U.K. ...

... Sente Software Ltd., Surrey Technology Centre, Guildford GU2 7YG, U.K. ...

Aluminium alloy

Aluminium alloys (or aluminum alloys; see spelling differences) are alloys in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable. About 85% of aluminium is used for wrought products, for example rolled plate, foils and extrusions. Cast aluminium alloys yield cost-effective products due to the low melting point, although they generally have lower tensile strengths than wrought alloys. The most important cast aluminium alloy system is Al–Si, where the high levels of silicon (4.0–13%) contribute to give good casting characteristics. Aluminium alloys are widely used in engineering structures and components where light weight or corrosion resistance is required.Alloys composed mostly of aluminium have been very important in aerospace manufacturing since the introduction of metal-skinned aircraft. Aluminium-magnesium alloys are both lighter than other aluminium alloys and much less flammable than alloys that contain a very high percentage of magnesium.Aluminium alloy surfaces will develop a white, protective layer of aluminium oxide if left unprotected by anodizing and/or correct painting procedures. In a wet environment, galvanic corrosion can occur when an aluminium alloy is placed in electrical contact with other metals with more negative corrosion potentials than aluminium, and an electrolyte is present that allows ion exchange. Referred to as dissimilar-metal corrosion, this process can occur as exfoliation or as intergranular corrosion. Aluminium alloys can be improperly heat treated. This causes internal element separation, and the metal then corrodes from the inside out. Aircraft mechanics deal daily with aluminium alloy corrosion. Aluminium alloy compositions are registered with The Aluminum Association. Many organizations publish more specific standards for the manufacture of aluminium alloy, including the Society of Automotive Engineers standards organization, specifically its aerospace standards subgroups, and ASTM International.

![[edit]Occurrence in solution](http://s1.studyres.com/store/data/009755146_1-58e56f0cc08d3d020872dbc6c3acbb66-300x300.png)