(full text)

... price tag is not a substantial constraint. These tools are designed to pattern periodic structures over large areas 共 ⬎ 1 mm2兲 for applications such as spectroscopy, magnetic storage, and nanofabrication process development.1 However, some of these applications, such as nanofabrication process devel ...

... price tag is not a substantial constraint. These tools are designed to pattern periodic structures over large areas 共 ⬎ 1 mm2兲 for applications such as spectroscopy, magnetic storage, and nanofabrication process development.1 However, some of these applications, such as nanofabrication process devel ...

Semiconductor Manufacturing Process

... This process has the exposed wafers sprayed with a mixture of organic solvents that dissolves portions of the photoresist . Conventional methods of ashing require an oxygen-plasma ash, often in combination with halogen gases, to penetrate the crust and remove the photoresist. Usually, the plasma ash ...

... This process has the exposed wafers sprayed with a mixture of organic solvents that dissolves portions of the photoresist . Conventional methods of ashing require an oxygen-plasma ash, often in combination with halogen gases, to penetrate the crust and remove the photoresist. Usually, the plasma ash ...

Prezentacja programu PowerPoint

... developer solution, it will etch away one of the two regions (exposed or unexposed). If the exposed material is etched away by the developer and the unexposed region is resilient, the material is considered to be a positive resist. The exact opposite process happens in negative resists. Transfer of ...

... developer solution, it will etch away one of the two regions (exposed or unexposed). If the exposed material is etched away by the developer and the unexposed region is resilient, the material is considered to be a positive resist. The exact opposite process happens in negative resists. Transfer of ...

Paper 6a.3_publicati..

... metal hard mask, a standard bi-layer, (lift-off layer, LOL and photoresist) photolithography process was used to create the pattern. The cross section of the hard mask fabrication is shown in Figure 1. Here, LOL is not photoactive, and any LOL not protected by the PR will be developed. This creates ...

... metal hard mask, a standard bi-layer, (lift-off layer, LOL and photoresist) photolithography process was used to create the pattern. The cross section of the hard mask fabrication is shown in Figure 1. Here, LOL is not photoactive, and any LOL not protected by the PR will be developed. This creates ...

Nanopatterning With Interferometric Lithography = 46:9-nm Laser Using a Compact

... wavelength provides a direct path to decreasing feature size. Obtaining a good quality interference pattern also requires the illumination source to have a high degree of coherence and high average power to allow for short exposure times. The high spatial and temporal coherence are also essential fo ...

... wavelength provides a direct path to decreasing feature size. Obtaining a good quality interference pattern also requires the illumination source to have a high degree of coherence and high average power to allow for short exposure times. The high spatial and temporal coherence are also essential fo ...

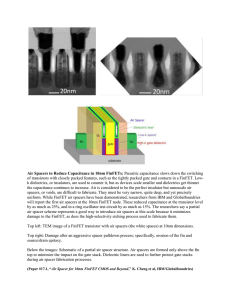

17-1 Air Spacers to Reduce Capacitance in 10nm FinFETs

... uniform. While FinFET air spacers have been demonstrated, researchers from IBM and Globalfoundries will report the first air spacers at the 10nm FinFET node. These reduced capacitance at the transistor level by as much as 25%, and in a ring oscillator test circuit by as much as 15%. The researchers ...

... uniform. While FinFET air spacers have been demonstrated, researchers from IBM and Globalfoundries will report the first air spacers at the 10nm FinFET node. These reduced capacitance at the transistor level by as much as 25%, and in a ring oscillator test circuit by as much as 15%. The researchers ...

Multiple patterning

Multiple patterning (or multi-patterning) is a class of technologies for manufacturing integrated circuits (ICs), developed for photolithography to enhance the feature density. The simplest case of multiple patterning is double patterning, where a conventional lithography process is enhanced to produce double the expected number of features. The resolution of a photoresist pattern begins to blur at around 45 nm half-pitch. For the semiconductor industry, therefore, double patterning was introduced for the 32 nm half-pitch node and below, mainly using state-of-the-art 193 nm immersion lithography tools.There are several types of double patterning. In combination, these may be used for multiple patterning.